ICGOO在线商城 > 分立半导体产品 > 晶体管 - 双极 (BJT) - 单 > 2SC6011

- 型号: 2SC6011

- 制造商: Sanken

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

2SC6011产品简介:

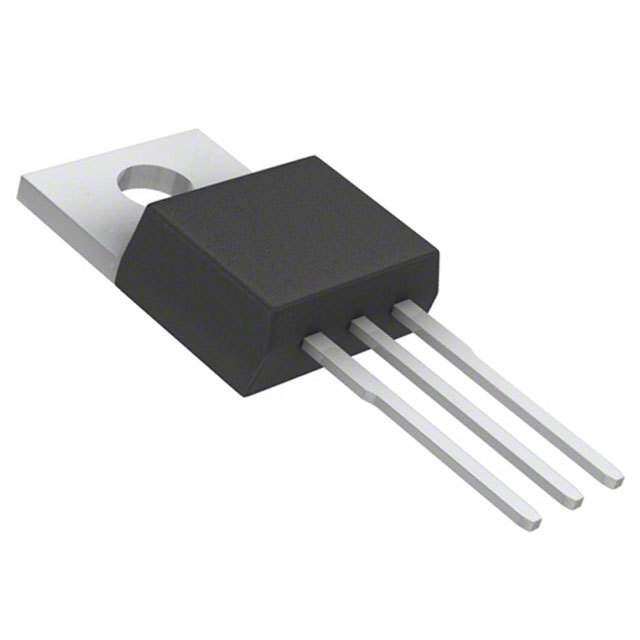

ICGOO电子元器件商城为您提供2SC6011由Sanken设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 2SC6011价格参考¥79.02-¥89.80。Sanken2SC6011封装/规格:晶体管 - 双极 (BJT) - 单, 双极 (BJT) 晶体管 NPN 200V 15A 20MHz 160W 通孔 TO-3P。您可以下载2SC6011参考资料、Datasheet数据手册功能说明书,资料中有2SC6011 详细功能的应用电路图电压和使用方法及教程。

Sanken 2SC6011 是一款双极型晶体管(BJT),属于 NPN 型结构,广泛应用于高频、大功率的放大和开关电路中。以下是其主要应用场景: 1. 射频(RF)功率放大器 - 2SC6011 适用于高频信号的功率放大,特别是在业余无线电、通信设备以及广播系统中。 - 它能够处理较高的频率范围,适合用于 VHF 和 UHF 频段的功率放大。 2. 音频功率放大器 - 在音频设备中,2SC6011 可用作功率输出级晶体管,实现高保真音频信号的放大。 - 其高增益和低失真特性使其成为音频功放设计中的理想选择。 3. 驱动电路 - 该晶体管可用于驱动继电器、电机或其他负载,尤其是在需要较大电流或较高电压的应用中。 - 其高集电极电流能力和耐压特性使其能够胜任多种驱动任务。 4. 开关电源(SMPS) - 在开关电源的设计中,2SC6011 可作为开关元件使用,适用于某些特定拓扑结构中的功率转换。 - 它能够在高频条件下高效工作,满足开关电源对快速开关特性的要求。 5. 脉冲电路 - 2SC6011 能够在脉冲电路中提供快速响应和高电流输出,适合用于触发器、振荡器等应用。 - 其良好的动态特性使其能够准确地传递和放大脉冲信号。 6. 工业控制 - 在工业自动化领域,2SC6011 可用于控制各种电气设备,例如电磁阀、步进电机等。 - 它的耐用性和稳定性使其能够在严苛的工作环境下长期运行。 总结 2SC6011 凭借其高频率特性、大功率处理能力和稳定的性能表现,广泛应用于射频、音频、驱动、开关电源等领域。在设计具体电路时,需根据其电气参数(如最大集电极电流、最大集电极-发射极电压等)合理选择偏置条件和散热措施,以确保其稳定可靠地工作。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | TRANS NPN 200V 15A TO3P |

| 产品分类 | 晶体管(BJT) - 单路 |

| 品牌 | Sanken |

| 数据手册 | |

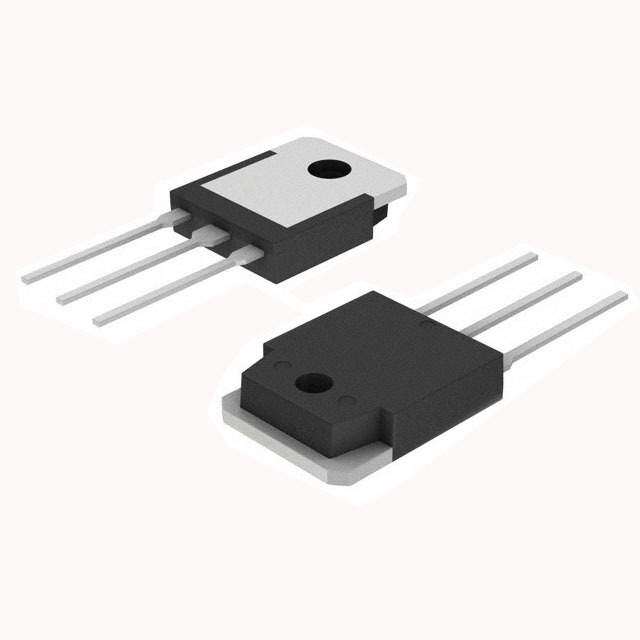

| 产品图片 |

|

| 产品型号 | 2SC6011 |

| rohs | 无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | - |

| 不同 Ib、Ic时的 Vce饱和值(最大值) | 500mV @ 500mA,5A |

| 不同 Ic、Vce 时的DC电流增益(hFE)(最小值) | 50 @ 3A,4V |

| 供应商器件封装 | TO-3P |

| 功率-最大值 | 160W |

| 包装 | 散装 |

| 安装类型 | 通孔 |

| 封装/外壳 | TO-3P-3,SC-65-3 |

| 晶体管类型 | NPN |

| 标准包装 | 30 |

| 电压-集射极击穿(最大值) | 200V |

| 电流-集电极(Ic)(最大值) | 15A |

| 电流-集电极截止(最大值) | 10µA(ICBO) |

| 频率-跃迁 | 20MHz |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

2SC6011 Audio Amplification Transistor Features and Benefits Description ▪ Small package (TO-3P) By adapting the Sanken unique wafer-thinner technique, these ▪ High power handling capacity, 160 W NPN power transistors achieve power-up by decreasing thermal ▪ Improved sound output by reduced on-chip impedance resistance, and provide higher voltage avalanche breakdown ▪ For professional audio (PA) applications, V = 200 V rating. The high power-handling capacity of the TO-3P package CEO versions available allows a smaller footprint on the circuit board design. This ▪ Complementary to 2SA2151 series of transistors is very well suited to not only multichannel ▪ Recommended output driver: 2SC4832 applications for AV (audio-visual) amplifiers and receivers, but also parallel connection applications for PA (professional audio system) amplifiers. Applications include the following: Package: 3-Lead TO-3P ▪ Single transistors for audio amplifiers ▪ Home audio amplifiers ▪ Professional audio amplifiers ▪ Automobile audio amplifiers ▪ Audio market ▪ Single transistors for general purpose Not to scale Equivalent Circuit E 3 B 1 2 C 38102, Rev. 1 SANKEN ELECTRIC CO., LTD. http://www.sanken-ele.co.jp/en/

2SC6011 Audio Amplification Transistor SELECTION GUIDE Part Number Type h Rating Packing FE Range O: 50 to 100 2SC6011* NPN Range P: 70 tp 140 30 pieces per tube Range Y: 90 to 180 *Specify h range when ordering. If no h range is specified, order will be fulfilled with either or both range O and range Y, FE FE depending upon availability. ABSOLUTE MAXIMUM RATINGS at T = 25°C A Characteristic Symbol Rating Unit Collector-Base Voltage V 200 V CBO Collector-Emitter Voltage V 200 V CEO Emitter-Base Voltage V 6 V EBO Collector Current I 15 A C Base Current I 4 A B Collector Power Dissipation P 160 W C Junction Temperature T 150 °C J Storage Temperature T –55 to150 °C stg ELECTRICAL CHARACTERISTICS at T = 25°C A Characteristic Symbol Test Conditions Min. Typ. Max. Unit Collector-Cutoff Current I V = 200 V – – 10 μA CBO CB Emitter Cutoff Current I V = 6 V – – 10 μA EBO EB Collector-Emitter Voltage V I = 50 mA 200 – – V (BR)CEO C DC Current Transfer Ratio* h V = 4 V, I = 3 A 50 – 180 – FE CE C Collector-Emitter Saturation Voltage V I = 5 A, I = 0.5 A – – 0.5 V CE(sat) C B Cutoff Frequency f V = 12 V, I = –0.5 A – 20 – MHz T CE E Output Capacitance C V = 10 V, I = 0 A, f = 1 MHz – 270 – pF OB CB E *h rating: 50 to 100 (O brand on package), 70 to 140 (P), 90 to 180 (Y). FE 38102, Rev. 1 2 SANKEN ELECTRIC CO., LTD.

2SC6011 Audio Amplification Transistor Performance Characteristics 15 3 1 A 500 mA 300 mA 200 mA 10 100 mA V) 2 IC vs. VCE I (A)C 50 mA VCE(sat) vs. IB V (CE(sat) 5 1 IB= 20 mA IC= 10 A I = 5 A C 0 0 0 1 2 3 4 0 0.5 1.0 1.5 2.0 VCE (V) IB (A) 15 1000 10 Typ. IVCC E v =s 4. VV CBoEn tinuous I (A) C5 125°C 25°C –30°C hVCFEE = v4s V. CICo ntinuohuFEs 11000 0 1 0 0.5 1.0 1.5 2.0 0.01 0.1 1 10 100 VBE (V) IC (A) 10.00 1000 125°C 1.00 hFE 100 25°C W) hVCFEE = v4s V. CICo ntinuous –30°C RθJA vs. t R(°C/θJA 10 0.10 1 0.01 0.01 0.1 1 10 100 1 10 100 1000 IC (A) t (ms) 38102, Rev. 1 3 SANKEN ELECTRIC CO., LTD.

2SC6011 Audio Amplification Transistor Performance Characteristics, continued Safe Operating Area TA= 25°C, single pulse, no heatsink, natural cooling 100.0 10 10.0 100 mmss DC (A)C1.0 I 0.1 0.01 1 10 100 1000 VCE (V) 40 200 30 Typ. 150 VfTC E v =s 1.2 I VE Continuousf (MHz)T 20 PC vs. TA P (W)C100 With Infin ite Heatsink 10 50 0 3.5 Without Heatsink 0.01 0.1 1 10 100 0 0 25 50 75 100 125 150 IE (A) TA (°C) 38102, Rev. 1 4 SANKEN ELECTRIC CO., LTD.

2SC6011 Audio Amplification Transistor Package Outline Drawing, TO-3P 15.8 ±0.2 15.6 ±0.3 14.0 ±0.3 3 2 2 2 0. 0. 0. 0. 5.0 MAX Exposed 139..66 ±±00..22 1.8 ± 2.0 ± 5.0 ± 6.0 ± 2.1 MAX heatsink pad Branding 1 Area 0.3 ±0. XXXXXXXXXXXXXXXXXX 9.9 ± Ø3.2 1 +0.2 5 1.7–0.1 3. 2+–00..12 2+–00..12 0.6+–00..12 +0.2 3–0.1 N MI 1.0+–00..12 20.0 View A View B 5.45 ±0.1 Terminal dimension at lead tip 1 2 3 0.7 MAX 0.7 MAX View A View B Gate burr: 0.3 mm (max.), mold flash may appear at opposite side Branding codes (exact appearance at manufacturer discretion): Terminal core material: Cu 1st line, type: C6011 Terminal treatment: Ni plating and Pb-free solder dip 2nd line left, lot: YM Leadform: 100 Where: Y is the last digit of the year of manufacture Package: TO-3P (M100) M is the month (1 to 9, O, N, D) Approximate weight: 6 g 2nd line right, subtype: H Where: H is the h rating (O, P, or Y; for values see FE Dimensions in millimeters footnote, Electrical Characteristics table) Leadframe plating Pb-free. Device composition includes high-temperature solder (Pb >85%), which is exempted from the RoHS directive. 38102, Rev. 1 5 SANKEN ELECTRIC CO., LTD.

2SC6011 Audio Amplification Transistor Because reliability can be affected adversely by improper use a flat-head machine screw because of the stress to the storage environments and handling methods, please observe products. Self-tapping screws are not recommended. When the following cautions. using self-tapping screws, the screw may enter the hole Cautions for Storage diagonally, not vertically, depending on the conditions of hole • Ensure that storage conditions comply with the standard before threading or the work situation. That may stress the temperature (5°C to 35°C) and the standard relative products and may cause failures. humidity (around 40% to 75%); avoid storage locations • Recommended screw torque: 0.686 to 0.882 N●m (7 to 9 that experience extreme changes in temperature or kgf●cm). humidity. • Diameter of Heatsink Hole: < 4 mm. The defl ection of the press mold when making the hole may cause the case material to crack at the joint • Avoid locations where dust or harmful gases are present with the heatsink. Please pay special attention for this effect. and avoid direct sunlight. • For tightening screws, if a tightening tool (such as a driver) • Reinspect for rust on leads and solderability of the hits the products, the package may crack, and internal products that have been stored for a long time. stress fractures may occur, which shorten the lifetime of Cautions for Testing and Handling the electrical elements and can cause catastrophic failure. When tests are carried out during inspection testing and Tightening with an air driver makes a substantial impact. other standard test periods, protect the products from In addition, a screw torque higher than the set torque can power surges from the testing device, shorts between be applied and the package may be damaged. Therefore, an the product pins, and wrong connections. Ensure all test electric driver is recommended. parameters are within the ratings specified by Sanken for When the package is tightened at two or more places, first the products. pre-tighten with a lower torque at all places, then tighten Remarks About Using Silicone Grease with a Heatsink with the specified torque. When using a power driver, torque • When silicone grease is used in mounting the products on control is mandatory. a heatsink, it shall be applied evenly and thinly. If more Soldering silicone grease than required is applied, it may produce • When soldering the products, please be sure to minimize excess stress. the working time, within the following limits: • Volatile-type silicone greases may crack after long periods 260±5°C 10±1 s (Flow, 2 times) of time, resulting in reduced heat radiation effect. Silicone 350±5°C 3±0.5 s (Soldering iron, 1 time) greases with low consistency (hard grease) may cause • Soldering should be at a distance of at least 1.5 mm from cracks in the mold resin when screwing the products to a the body of the products. heatsink. Electrostatic Discharge Our recommended silicone greases for heat radiation • When handling the products, the operator must be purposes, which will not cause any adverse effect on the grounded. Grounded wrist straps worn should have at product life, are indicated below: least 1 MΩ of resistance from the operator to ground to prevent shock hazard, and it should be placed near the Type Suppliers operator. G746 Shin-Etsu Chemical Co., Ltd. • Workbenches where the products are handled should be YG6260 Momentive Performance Materials Inc. grounded and be provided with conductive table and floor SC102 Dow Corning Toray Co., Ltd. mats. • When using measuring equipment such as a curve tracer, Cautions for Mounting to a Heatsink the equipment should be grounded. • When the flatness around the screw hole is insufficient, such • When soldering the products, the head of soldering irons as when mounting the products to a heatsink that has an or the solder bath must be grounded in order to prevent extruded (burred) screw hole, the products can be damaged, leak voltages generated by them from being applied to the even with a lower than recommended screw torque. For products. mounting the products, the mounting surface flatness should • The products should always be stored and transported in be 0.05 mm or less. Sanken shipping containers or conductive containers, or • Please select suitable screws for the product shape. Do not be wrapped in aluminum foil. 38102, Rev. 1 6 SANKEN ELECTRIC CO., LTD.

2SC6011 Audio Amplification Transistor • The contents in this document are subject to changes, for improvement and other purposes, without notice. Make sure that this is the latest revision of the document before use. • Application and operation examples described in this document are quoted for the sole purpose of reference for the use of the prod- ucts herein and Sanken can assume no responsibility for any infringement of industrial property rights, intellectual property rights or any other rights of Sanken or any third party which may result from its use. • Although Sanken undertakes to enhance the quality and reliability of its products, the occurrence of failure and defect of semicon- ductor products at a certain rate is inevitable. Users of Sanken products are requested to take, at their own risk, preventative measures including safety design of the equipment or systems against any possible injury, death, fires or damages to the society due to device failure or malfunction. • Sanken products listed in this document are designed and intended for the use as components in general purpose electronic equip- ment or apparatus (home appliances, office equipment, telecommunication equipment, measuring equipment, etc.). When considering the use of Sanken products in the applications where higher reliability is required (transportation equipment and its control systems, traffic signal control systems or equipment, fire/crime alarm systems, various safety devices, etc.), and whenever long life expectancy is required even in general purpose electronic equipment or apparatus, please contact your nearest Sanken sales representative to discuss, prior to the use of the products herein. The use of Sanken products without the written consent of Sanken in the applications where extremely high reliability is required (aerospace equipment, nuclear power control systems, life support systems, etc.) is strictly prohibited. • In the case that you use Sanken products or design your products by using Sanken products, the reliability largely depends on the degree of derating to be made to the rated values. Derating may be interpreted as a case that an operation range is set by derating the load from each rated value or surge voltage or noise is considered for derating in order to assure or improve the reliability. In general, derating factors include electric stresses such as electric voltage, electric current, electric power etc., environmental stresses such as ambient temperature, humidity etc. and thermal stress caused due to self-heating of semiconductor products. For these stresses, instantaneous values, maximum values and minimum values must be taken into consideration. In addition, it should be noted that since power devices or IC's including power devices have large self-heating value, the degree of derating of junction temperature affects the reliability significantly. • When using the products specified herein by either (i) combining other products or materials therewith or (ii) physically, chemically or otherwise processing or treating the products, please duly consider all possible risks that may result from all such uses in advance and proceed therewith at your own responsibility. • Anti radioactive ray design is not considered for the products listed herein. • Sanken assumes no responsibility for any troubles, such as dropping products caused during transportation out of Sanken's distribu- tion network. • The contents in this document must not be transcribed or copied without Sanken's written consent. 38102, Rev. 1 7 SANKEN ELECTRIC CO., LTD.

Datasheet下载

Datasheet下载