- 型号: PLED6US

- 制造商: Littelfuse

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

PLED6US产品简介:

ICGOO电子元器件商城为您提供PLED6US由Littelfuse设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 PLED6US价格参考。LittelfusePLED6US封装/规格:照明保护, 。您可以下载PLED6US参考资料、Datasheet数据手册功能说明书,资料中有PLED6US 详细功能的应用电路图电压和使用方法及教程。

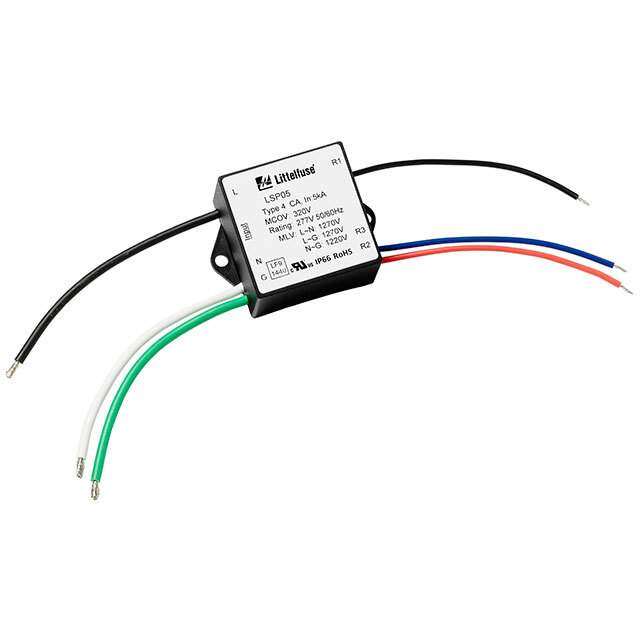

Littelfuse Inc. 是一家知名的电路保护和传感器解决方案供应商。型号为 PLED6US 的产品属于其 照明保护(Lighting Protection)系列,主要用于保护LED照明系统免受过电压、浪涌等电气干扰的损害。 PLED6US的应用场景包括: 1. 户外LED照明系统 适用于街道照明、景观照明、广告牌照明等易受雷击或电网波动影响的户外环境,提供可靠的过电压和浪涌保护。 2. 工业与商业照明 在工厂、仓库、商场等大型场所使用的LED灯具中,用于防止因开关操作或电力设备启停引起的电压浪涌损坏照明装置。 3. 智能照明系统 在集成控制系统的LED照明中(如调光系统或物联网照明),PLED6US可保护敏感电子元件不受静电放电(ESD)和瞬态电压的影响。 4. 路灯与隧道灯 广泛应用于市政工程中的LED路灯和隧道灯系统,提升灯具使用寿命和运行稳定性。 5. 电源驱动模块保护 直接用于LED驱动电源输入端,吸收瞬时高压脉冲,保护后级电路安全。 该器件通常采用PPTC(聚合物正温度系数)技术,具备自动恢复功能,可在故障排除后恢复正常工作,无需更换,提高系统可靠性。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | LED PROTECTOR UNI 6V DO214 2LLED保护设备 Uni 6V 2L UNI DO214 |

| 产品分类 | |

| 品牌 | Littelfuse |

| 产品手册 | |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | LED照明电子器件,LED保护设备,Littelfuse PLED6USPLED® |

| 数据手册 | |

| 产品型号 | PLED6US |

| 产品 | LED Protector |

| 产品培训模块 | http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=19478 |

| 产品种类 | LED保护设备 |

| 供应商器件封装 | DO-214AA |

| 保持电流Ih最大值 | 30 mA |

| 其它名称 | F6294DKR |

| 击穿电压 | 16 V |

| 功率(W) | - |

| 包装 | Digi-Reel® |

| 商标 | Littelfuse |

| 安装风格 | SMD/SMT |

| 封装 | Reel |

| 封装/外壳 | * |

| 封装/箱体 | DO-214AA |

| 工厂包装数量 | 2500 |

| 应用 | LED 保护 |

| 开启状态RMS电流-ItRMS | 1 mA |

| 开启状态电压 | 1.2 V |

| 技术 | 混合技术 |

| 最大工作温度 | + 150 C |

| 最小工作温度 | - 40 C |

| 标准包装 | 1 |

| 特色产品 | http://www.digikey.cn/product-highlights/zh/pledxux-unidirectional-series-open-led-protectors/52460 |

| 电压-工作 | 6V |

| 电压-箝位 | 16V |

| 电路数 | 1 |

| 系列 | PLED |

| 额定重复关闭状态电压VDRM | 6 V |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

PLED Open LED Protectors PLED Unidirectional Series PLED Unidirectional Series (PLEDxUx) RoHS Description PLED Unidirectional Series (PLEDxUx Series) open LED protectors provide a switching electronic shunt path around a single LED that fails as an open circuit. This ensures the remaining string of LEDs will continue to function even though a single LED in the string has failed open. It also provides reverse battery or reverse power polarity protection. PLED Unidirectional Series devices were designed to enable higher reliability in outdoor LED lighting applications such as street lighting, outdoor signage, aircraft runway lighting, roadside warning lights and other applications. Compatible with one, two and three watt LEDs that have a nominal 3V forward characteristic, PLED Unidirectional Agency Approvals Series devices are available in two surface mount packages, the DO-214AA and the Quad Flat Pak No-lead (QFN). The Agency Agency File Number QFN’s low profile, chip scale package (CSP) is ideal for dense board applications. E133083 Schematic Symbol Features MT2 • F ast switching • IEC-61000-4-2 ESD 30kV Cathode (Air), 30kV (Contact) • R everse Battery/Power (bar marking side) Protection • ESD protection of data lines in accordance with • Automatically resets after Control IEC 61000-4-2 (IEC801-2 power cycle Circuit • C ompatible with PWM • Available in low profile, frequencies up to 10 kHz small footprint QFN MT1 and Standard DO214AA • R oHS compliant and packages halogen-free • C ompatible with industrial • R ecognized to UL 497B lighting environments as an Isolated Loop Circuit Protector Electrical Characteristics (All parameters are measured at T =25°C unless otherwise noted) A V V Critical rate of BR DRM I I I@V V I@V V I 1 Breakdown Breakdown H S T T T F F F O rise dV/dt Part Number Marking Volts Volts mAmps mAmps Amps Volts Amps Volts Amps Volts Min Max Min Max Max Max Max Max Max Min Max PLED6UQ12 PL6U 6 16 6 30 50 1.0 1.2 1.0 1.0 1.0 PLED6US PL6U 6 16 6 30 50 1.0 1.2 1.0 1.0 1.0 PLED9UQ12 PL9U 9 18 9 30 50 1.0 1.2 1.0 1.0 1.0 PLED9US PL9U 9 18 9 30 50 1.0 1.2 1.0 1.0 1.0 PLED13UQ12 PL13U 13 26 13 30 50 1.0 1.2 1.0 1.0 1.0 250V/µs PLED13US PL13U 13 26 13 30 50 1.0 1.2 1.0 1.0 1.0 PLED18UQ12 PL18U 18 33 18 30 50 1.0 1.2 1.0 1.0 1.0 PLED18US PL18U 18 33 18 30 50 1.0 1.2 1.0 1.0 1.0 PLED35US PL35U 35 50 35 30 50 1.0 1.2 1.0 1.0 1.0 Note: 1. I- Operation current tested @ aluminum boards, ambient temp 85°C O © 2020 Littelfuse, Inc. Specifications are subject to change without notice. Revised: 05/01/20

PLED Open LED Protectors PLED Unidirectional Series Thermal Considerations Package Symbol Parameter Value Unit T Operating Junction Temperature Range -40 to +150 °C J QFN 3x3 DO-214AA T Storage Temperature Range -65 to +150 °C S DO-214AA: 901 DO-214AA: 402 R Thermal Resistance: Junction to Ambient QFN: 1201 °C/W ƟJA QFN: 603 Notes: 3) Aluminum PCB 1) Standard FR-4 PCB with Copper Pads (Recommended Size) Thickness: 1.6mm 2) Aluminum PCB Grade: 1-2 W/mK Thermal Conductivity Thickness: 1.6mm Trace thickness: 2 oz Grade: 1-2 W/mK Thermal Conductivity Insulation layer thickness: 60 µm Trace thickness: 2 oz Solder Pad Dimensions: 1.27mm x 2.54mm (Recommended Size) Insulation layer thickness: 215 µm Solder Pad Dimensions: 2.0mm x 2.8mm (Recommended Size) V-I Characteristics V vs. Junction Temperature BR +I 14 % 12 VF – e 10 gn 8 a VBRVDRM VT hC 6 25 ˚C VBR 4 -V IDRM +V fo tn 02 e IH rc -4 e IS P -6 IT -8 -40 -20 0 20 40 60 80 100 120 140 160 Junction Temperature (T ) – ˚C -I J Normalized DC Holding Current vs. Case Temperature LED Interference Test Circuit Q1 2.0 LED ) 1.8 Driver C˚ 2.0 Ω, 1/4 W 5 1.6 iH 2 = 1.4 110 kΩ, 1/4 W C 25 ˚C T( 1.2 ++ Vbat H 12 Vdc Q2 i 1.0 -- 2N2222 f o o 0.8 PWM ita 0.6 MT2 R CCoirncutriotl Unidiretional 0.4 ON/OFF PLED Switch MT1 -40 -20 0 20 40 60 80 100 120 140 160 CaseTemperature (T ) – ˚C C © 2020 Littelfuse, Inc. Specifications are subject to change without notice. Revised: 05/01/20

PLED Open LED Protectors PLED Unidirectional Series 6 LEDs in Series 50% Duty Cycle 10kHz 5 LEDs and 1 PLED in Series 50% Duty Cycle 10kHz Note: These two graphs show the current magnitude through the LED string with and without the PLED included. There is no noticeable effect on the LED current magnitude when the PLED is included in the circuit as compared to the LED current magnitude when the PLED is not in the circuit. (The conversion factor for the test measurement in the graphs above is 10mA/mV for the Pearson coil measurement, therefore, the current magnitude in the first figure is 10mA*8.9 = 89mA, while the second figure is 91mA.) PLED in the Off-State 10kHz PLED device zeners and then turns fully on 10kHz Channel 1: current through LEDs (318 mA) Channel 1: current through LEDs (346 mA) and PLED device once it is fully turned on 2.5 μsec later Channel 2: voltage across PLED device (4.5 V) Channel 2: voltage across PLED device (21.3 V before PLED crowbars with 2 V drop) © 2020 Littelfuse, Inc. Specifications are subject to change without notice. Revised: 05/01/20

PLED Open LED Protectors PLED Unidirectional Series Soldering Parameters Reflow Condition Pb – Free assembly - Temperature Min (T ) 150°C tP s(min) T P Critical Zone Pre Heat - Temperature Max (Ts(max)) 200°C RRaammpp--uupp tL to tP - Time (min to max) (ts) 60 – 180 secs TL t Average ramp up rate (Liquidus Temp (T) to peak 3°C/second max T L L S(max) TS(max) to TL - Ramp-up Rate 3°C/second max eru RRaammpp--ddoown - Temperature (T) (Liquidus) 217°C ta PPrreehheeaatt Reflow L re TS(min) - Temperature (tL) 60 – 150 seconds pm tS Peak Temperature (T) 260+0/-5 °C e P T Time within 5°C of actual peak Temperature (t) 30 seconds 25 p time to peak temperature Time Ramp-down Rate 6°C/second max Time 25°C to peak Temperature (T) 8 minutes max P Do not exceed 260°C Physical Specifications Environmental Specifications Terminal Material Copper Alloy MIL-STD-750: Method 1040, Condition A High Temperature Terminal Finish 100% Matte Tin Plated Voltage Blocking 80% min VDRM (VAC-peak), 150°C, 504 hours UL recognized compound meeting flammability Body Material classification V-0 MIL-STD-750: Method 1051 Temperature Cycling -65°C to 150°C, 15-minute dwell, 100 cycles Biased Temperature & EIA/JEDEC: JESD22-A101 Humidity 52VDC, 85°C, 85%RH, 1008 hours High Temperature MIL-STD-750: Method 1031 Storage 150°C, 1008 hours Low Temperature Storage -65°C, 1008 hours MIL-STD-750: Method 1056 Thermal Shock 0°C to 100°C, 5-minute dwell, 10-second transfer, 10 cycles Resistance to MIL-STD-750: Method 2031 Solder Heat 260°C, 10 seconds Moisture Sensitivity 85%RH, +85ºC, 168 hrs, 3 Reflow Cycles Level (+260ºC Peak). JEDEC-JSTD-020, Level 1 Part Numbering System Part Marking System DO-214AA PLED x U x PLxU Package Type XXXXX Type Q12: 3.0x3.0mm QFN PLED: LED Protector S: DO-214AA Cathode Bar Indication V Unidirectional DRM 6 Volts 9 Volts QFN 13 Volts PLxU 18 Volts XXXXX 35 Volts Cathode Bar Indication © 2020 Littelfuse, Inc. Specifications are subject to change without notice. Revised: 05/01/20

PLED Open LED Protectors PLED Unidirectional Series Packaging Package Description Packaging Quantity Industry Standard Q12 QFN 3x3 5000 EIA-481-1 S DO-214AA 2500 EIA-481-1 Dimensions - QFN (3x3) Package TOP VIEW BOTTOM VIEW Inches Millimeters A C J Dimensions Min Typ Max Min Typ Max E A 0.114 0.118 0.122 2.900 3.000 3.100 B 0.114 0.118 0.122 2.900 3.000 3.100 B F C 0.075 0.079 0.083 1.900 2.000 2.100 E 0.011 0.015 0.019 0.285 0.385 0.485 F 0.076 0.080 0.084 1.930 2.030 2.130 H 0.035 0.039 0.043 0.900 1.000 1.100 J 0.000 0.004 0.008 0.000 0.100 0.200 END VIEW SIDE VIEW K1 0.004 0.008 0.012 0.100 0.200 0.300 H K2 K2 0.004 0.008 0.012 0.100 0.200 0.300 M1 0.056 0.060 0.064 1.143 1.530 1.630 N2 M2 M2 N1 K1 M1 M1 M2 0.038 0.042 0.046 0.970 1.070 1.170 N1 0.096 0.100 0.104 2.440 2.540 2.640 N2 0.082 0.086 0.090 2.080 2.180 2.280 0.585mm 0.023” 1.93mm 0.076” 2.15mm 0.085” Recommended solder pad layout (Reference Only) Dimensions - DO-214 AA Package B CASE TEMPERATURE Inches Millimeters D MEASURING POINT Dimensions Min Max Min Max A 0.130 0.156 3.30 3.95 B 0.201 0.220 5.10 5.60 C A C 0.077 0.087 1.95 2.20 D 0.159 0.181 4.05 4.60 E 0.030 0.063 0.75 1.60 F 0.075 0.096 1.90 2.45 K H F G 0.002 0.008 0.05 0.20 H 0.077 0.104 1.95 2.65 K 0.006 0.016 0.15 0.41 E G 0.079" (2.0mm) 0.110" (2.8mm) 0.079" (2.0mm) Recommended solder pad layout (Reference Only) © 2020 Littelfuse, Inc. Specifications are subject to change without notice. Revised: 05/01/20

PLED Open LED Protectors PLED Unidirectional Series Tape and Reel Specification - QFN (3x3) Inches Millimeters Symbols Description Min Max Min Max C A Reel Diameter N/A 12.992 N/A 330.0 A D N B Drive Spoke Width 0.059 N/A 1.50 N/A W1 C Arbor Hole Diameter 0.504 0.531 12.80 13.50 B D Drive Spoke Diameter 0.795 N/A 20.20 N/A N Hub Diameter 1.969 N/A 50.00 N/A W1 Reel Inner Width at Hub 0.488 0.567 12.40 14.40 Reel Dimension A0 Pocket Width at bottom 0.126 0.134 3.20 3.40 B0 Pocket Length at bottom 0.126 0.134 3.20 3.40 T D0 PP02 D1 CARRIER TAPE E1 DD01 FPeoeckde Ht oHloel eD iDamiameteetrer 00..005599 0N.0/6A3 11..5500 1N.6/A0 E1 Feed hole Position 1 0.065 0.073 1.65 1.85 B0 F W E2 Feed hole Position 2 0.400 0.408 10.15 10.35 W0 E2 F Feed hole center-Pocket hole 0.215 0.219 5.45 5.55 K0 K0 Pocket Depth 0.039 0.051 1.00 1.30 P1 A1 P0 Feed hole Pitch 0.153 0.161 3.90 4.10 COVER TAPE P1 Component Spacing 0.311 0.319 7.90 8.10 P2 Feed hole center-Pocket hole 0.077 0.081 1.90 2.06 Tape Dimension Items T Carrier Tape Thickness 0.010 0.014 0.25 0.35 W Embossed Carrier Tape Width 0.453 0.484 11.50 12.30 COANT THHOIDS ES BIDAER CARRIER TAPE COVER TAPE W0 Cover Tape Width 0.358 0.366 9.10 9.30 END START TRAILER LEADER 160mm MIN 400mm MIN Leader and Trailer Dimension of the Ttape DO-214AA Embossed Carrier Reel Pack (RP) Meets all EIA-481-1 Standards 0.157 Cathode bar on this side (4.0) 0.472 (12.0) 0.36 (9.2) 0.315 (8.0) 0.059 DIA Cover tape (1.5) 12.99 0.512 (13.0) Arbor (330.0) Hole Dia. Dimensions are in inches (and millimeters). 0.49 (12.4) Direction of Feed Disclaimer Notice - Information furnished is believed to be accurate and reliable. However, users should independently evaluate the suitability of and test each product selected for their own applications. Littelfuse products are not designed for, and may not be used in, all applications. Read complete Disclaimer Notice at: www.littelfuse.com/disclaimer-electronics. © 2020 Littelfuse, Inc. Specifications are subject to change without notice. Revised: 05/01/20

Datasheet下载

Datasheet下载