ICGOO在线商城 > Labels, Signs, Barriers, Identification > Accessories > GLZ301

- 型号: GLZ301

- 制造商: Honeywell Solid State Electronics

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

GLZ301产品简介:

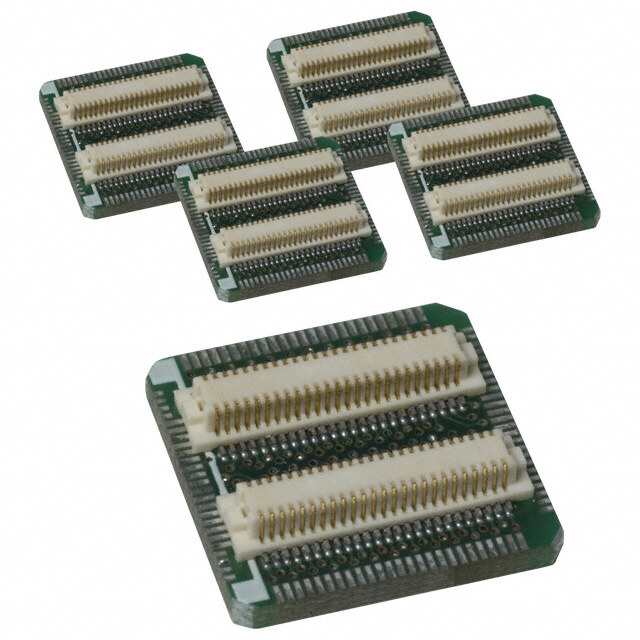

ICGOO电子元器件商城为您提供GLZ301由Honeywell Solid State Electronics设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 GLZ301价格参考。Honeywell Solid State ElectronicsGLZ301封装/规格:Accessories, Contact Block。您可以下载GLZ301参考资料、Datasheet数据手册功能说明书,资料中有GLZ301 详细功能的应用电路图电压和使用方法及教程。

Honeywell Sensing and Productivity Solutions 旗下的型号为 GLZ301 的配件(分类:Accessories),主要应用于工业自动化和传感系统中。GLZ301 是一种用于气体探测系统的适配器或连接组件,常与 Honeywell 的气体传感器或变送器配套使用,确保传感器在严苛工业环境下的稳定安装与可靠密封。其典型应用场景包括石油、天然气、化工、制药及污水处理等行业,用于支持可燃气体或有毒气体检测系统的构建与维护。该配件具备良好的耐腐蚀性和密封性能,适用于需要高安全等级的防爆环境(如Class I, Division 1场所),帮助提升气体监测系统的整体可靠性与安全性。此外,GLZ301 也便于现场安装与后期维护,减少系统停机时间,提高生产效率。总之,GLZ301 作为关键辅助组件,广泛服务于对气体安全监控要求严格的工业领域。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | SWITCH CONTACT BLOCK SNAP SPDT开关触点块/开关套件 Snap Action SPDT LIMIT SWITCH |

| 产品分类 | |

| 品牌 | Honeywell |

| 产品手册 | http://sensing.honeywell.com/index.php?ci_id=49957&la_id=1 |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 开关配件,开关触点块/开关套件,Honeywell GLZ301- |

| mouser_ship_limit | 该产品可能需要其他文件才能进口到中国。 |

| 数据手册 | 点击此处下载产品Datasheethttp://sensing.honeywell.com/index.php/ci_id/49957/la_id/1/document/1/re_id/0 |

| 产品型号 | GLZ301 |

| 产品种类 | 开关触点块/开关套件 |

| 其它名称 | 480-3532 |

| 商标 | Honeywell |

| 标准包装 | 1 |

| 用于 | GLS Series |

| 类型 | Base |

| 系列 | GLS |

| 设计目的 | Limit and Enclosed Switches |

型号:HL-G1CCJ10

品牌:Panasonic Industrial Automation Sales

产品名称:Labels, Signs, Barriers, Identification

获取报价

PDF Datasheet 数据手册内容提取

(cid:1)(cid:2)(cid:3)(cid:4)(cid:5)(cid:6)(cid:7)(cid:3)(cid:8)(cid:9)(cid:4)(cid:10)(cid:11)(cid:6)(cid:3)(cid:6)(cid:12)(cid:13)(cid:14)(cid:10)(cid:15)(cid:16)(cid:17)(cid:17)(cid:12)(cid:4)(cid:18)(cid:4)(cid:2)(cid:3)(cid:19)(cid:10)(cid:11)(cid:6)(cid:3)(cid:6)(cid:12)(cid:13)(cid:14)(cid:10)(cid:20)(cid:21)(cid:22)(cid:19) (cid:1)(cid:2)(cid:3)(cid:4)(cid:5)(cid:6)(cid:3)(cid:7)(cid:8)(cid:8)(cid:9)(cid:3)(cid:9)(cid:8)(cid:10)(cid:11)(cid:12)(cid:13)(cid:8)(cid:9)(cid:3)(cid:14)(cid:15)(cid:5)(cid:9)(cid:6)(cid:16)(cid:10)(cid:3)(cid:12)(cid:7)(cid:2)(cid:5)(cid:15)(cid:17)(cid:11)(cid:10)(cid:12)(cid:5)(cid:7)(cid:18)(cid:3)(cid:5)(cid:15)(cid:3)(cid:19)(cid:8)(cid:13)(cid:14)(cid:3)(cid:16)(cid:19)(cid:5)(cid:5)(cid:20)(cid:12)(cid:7)(cid:21)(cid:3)(cid:10)(cid:19)(cid:8)(cid:3)(cid:15)(cid:12)(cid:21)(cid:19)(cid:10) (cid:14)(cid:15)(cid:5)(cid:9)(cid:6)(cid:16)(cid:10)(cid:3)(cid:2)(cid:5)(cid:15)(cid:3)(cid:4)(cid:5)(cid:6)(cid:15)(cid:3)(cid:11)(cid:14)(cid:14)(cid:13)(cid:12)(cid:16)(cid:11)(cid:10)(cid:12)(cid:5)(cid:7)(cid:18)(cid:3)(cid:20)(cid:8)(cid:8)(cid:3)(cid:5)(cid:6)(cid:15)(cid:3)(cid:1)(cid:7)(cid:10)(cid:8)(cid:15)(cid:11)(cid:16)(cid:10)(cid:12)(cid:22)(cid:8)(cid:3)(cid:23)(cid:11)(cid:10)(cid:11)(cid:13)(cid:5)(cid:21)(cid:24)(cid:3)(cid:25)(cid:20)(cid:8)(cid:3)(cid:10)(cid:19)(cid:8) Sensing and Control (cid:1)(cid:7)(cid:10)(cid:8)(cid:15)(cid:11)(cid:16)(cid:10)(cid:12)(cid:22)(cid:8)(cid:3)(cid:23)(cid:11)(cid:10)(cid:11)(cid:13)(cid:5)(cid:21)(cid:3)(cid:10)(cid:5)(cid:3)(cid:11)(cid:16)(cid:16)(cid:8)(cid:20)(cid:20)(cid:3)(cid:10)(cid:19)(cid:8)(cid:3)(cid:17)(cid:5)(cid:20)(cid:10)(cid:3)(cid:16)(cid:5)(cid:17)(cid:14)(cid:13)(cid:8)(cid:10)(cid:8)(cid:3)(cid:11)(cid:7)(cid:9)(cid:3)(cid:6)(cid:14)(cid:26)(cid:10)(cid:5)(cid:26)(cid:9)(cid:11)(cid:10)(cid:8) Interactive (cid:12)(cid:7)(cid:2)(cid:5)(cid:15)(cid:17)(cid:11)(cid:10)(cid:12)(cid:5)(cid:7)(cid:3)(cid:11)(cid:22)(cid:11)(cid:12)(cid:13)(cid:11)(cid:27)(cid:13)(cid:8)(cid:24) Catalog... (cid:28)(cid:19)(cid:8)(cid:3)(cid:1)(cid:7)(cid:10)(cid:8)(cid:15)(cid:11)(cid:16)(cid:10)(cid:12)(cid:22)(cid:8)(cid:3)(cid:23)(cid:11)(cid:10)(cid:11)(cid:13)(cid:5)(cid:21)(cid:3)(cid:14)(cid:15)(cid:5)(cid:22)(cid:12)(cid:9)(cid:8)(cid:20)(cid:3)(cid:11)(cid:7)(cid:3)(cid:8)(cid:29)(cid:10)(cid:8)(cid:7)(cid:20)(cid:12)(cid:22)(cid:8)(cid:3)(cid:16)(cid:5)(cid:13)(cid:13)(cid:8)(cid:16)(cid:10)(cid:12)(cid:5)(cid:7)(cid:3)(cid:5)(cid:2)(cid:3)(cid:14)(cid:15)(cid:5)(cid:9)(cid:6)(cid:16)(cid:10) (cid:1)(cid:2)(cid:3)(cid:4)(cid:5)(cid:6)(cid:7)(cid:8)(cid:3)(cid:9)(cid:6)(cid:3)(cid:4)(cid:10)(cid:11)(cid:6)(cid:7)(cid:10)(cid:6)(cid:7)(cid:12)(cid:13) (cid:20)(cid:14)(cid:8)(cid:16)(cid:12)(cid:2)(cid:12)(cid:16)(cid:11)(cid:10)(cid:12)(cid:5)(cid:7)(cid:20)(cid:18)(cid:3)(cid:11)(cid:14)(cid:14)(cid:13)(cid:12)(cid:16)(cid:11)(cid:10)(cid:12)(cid:5)(cid:7)(cid:3)(cid:9)(cid:11)(cid:10)(cid:11)(cid:18)(cid:3)(cid:11)(cid:7)(cid:9)(cid:3)(cid:10)(cid:8)(cid:16)(cid:19)(cid:7)(cid:12)(cid:16)(cid:11)(cid:13)(cid:3)(cid:13)(cid:12)(cid:10)(cid:8)(cid:15)(cid:11)(cid:10)(cid:6)(cid:15)(cid:8)(cid:3)(cid:10)(cid:19)(cid:11)(cid:10)(cid:3)(cid:16)(cid:11)(cid:7)(cid:3)(cid:27)(cid:8) (cid:7)(cid:8)(cid:14)(cid:6)(cid:15)(cid:11)(cid:7)(cid:14)(cid:12)(cid:16)(cid:4)(cid:7)(cid:3)(cid:17)(cid:14)(cid:6)(cid:1)(cid:16)(cid:7)(cid:16)(cid:2)(cid:10)(cid:18)(cid:19) (cid:20)(cid:8)(cid:11)(cid:15)(cid:16)(cid:19)(cid:8)(cid:9)(cid:3)(cid:27)(cid:11)(cid:20)(cid:8)(cid:9)(cid:3)(cid:5)(cid:7)(cid:3)(cid:16)(cid:15)(cid:12)(cid:10)(cid:8)(cid:15)(cid:12)(cid:11)(cid:3)(cid:4)(cid:5)(cid:6)(cid:3)(cid:20)(cid:8)(cid:13)(cid:8)(cid:16)(cid:10)(cid:24) (cid:28)(cid:19)(cid:12)(cid:20)(cid:3)(cid:30)(cid:31) (cid:3)(cid:16)(cid:11)(cid:10)(cid:11)(cid:13)(cid:5)(cid:21)(cid:3)(cid:12)(cid:7)(cid:2)(cid:5)(cid:15)(cid:17)(cid:11)(cid:10)(cid:12)(cid:5)(cid:7)(cid:3)!(cid:11)(cid:20)(cid:3)(cid:14)(cid:6)(cid:27)(cid:13)(cid:12)(cid:20)(cid:19)(cid:8)(cid:9)(cid:3)(cid:12)(cid:7)(cid:3)"(cid:5)(cid:22)(cid:8)(cid:17)(cid:27)(cid:8)(cid:15)(cid:3)#$$$(cid:24) (cid:1)(cid:2)(cid:3)(cid:4)(cid:5)(cid:3)(cid:6)(cid:7)(cid:8)(cid:3)(cid:9)(cid:7)(cid:10)(cid:11)(cid:3)(cid:12)(cid:13)(cid:11)(cid:14) (cid:1)(cid:2)(cid:3)(cid:4)(cid:5)(cid:6)(cid:4)(cid:7)(cid:7)(cid:8)(cid:9)(cid:3)(cid:10)(cid:11) (cid:12)(cid:12)(cid:8)(cid:13)(cid:4)(cid:14)(cid:15)(cid:8)(cid:16)(cid:17)(cid:18)(cid:19)(cid:3)(cid:20)(cid:8)(cid:16)(cid:15)(cid:18)(cid:4)(cid:4)(cid:15) (cid:21)(cid:18)(cid:4)(cid:4)(cid:17)(cid:2)(cid:18)(cid:15)(cid:22)(cid:8)(cid:9)(cid:23)(cid:8)(cid:24)(cid:12)(cid:25)(cid:26)(cid:27) www.honeywell.com/sensing

Limit and Enclosed Switches GLS Series Global Limit Switches L im it / E n c lo s e d GENERAL INFORMATION Customers will benefit from Honeywell’s FEATURES The GLS series is specifically designed for vast experience in serving world industries (cid:49) Designed to the new IEC standard for world-wide applications and is supported over many years. To minimize plant down- world-wide applications by Honeywell global resources for sales and time and reduced maintenance costs, the (cid:49) EN50041metal standard and plug-in after sales service. GLS series includes plug-in and indicator versions switches with single or twin LEDs. (cid:49) EN50047 metal and double insulated Over 300 versions designed to the newest versions IEC standard are available and include a All EN50041products feature modular con- (cid:49) EN50047 mounting compatible, 3-cable wide range of EN50041and EN50047 type structions. Head, body or basic switch com- entry metal versions switches. Miniature EN50047 limit switches ponents are available separately as replace- (cid:49) UL, CSA, and CE are available in metal and double insulated ment parts. GLS allows end user mainten- (cid:49) Sealing up to IP 67/NEMA 4 enclosures and a metal enclosed 3-cable ance inventories and costs to be contained. (cid:49) International conduit sizes entry version (EN50047 mounting compat- Most GLS versions are interchangeable with (cid:49) Snap action and slow action mechanism ible) is also offered. The larger EN50041 almost all other makes of EN50041/47 with forced disconnect switches include metal enclosed standard switches. (cid:49) Direct PLC interface compatible (two and plug-in versions. circuit) TYPICAL APPLICATIONS (cid:49) Galvanically isolated contacts (two Standard GLS switch circuit variations in- (cid:49) Machine tools: metal fabrication circuit) clude 2 and 4-circuit snap action versions equipment, presses, transfer lines and (cid:49) Modular construction reduces with forced disconnect mechanism and two special machinery maintenance parts costs 2-circuit slow make and break versions. (cid:49) Material handling equipment: (cid:49) Design for ease of installation Two-circuit bifurcated contact versions al- conveyors, elevators, cranes and hoists (cid:49) Five basic switch versions low direct PLC interface. Plug-in GLS switch (cid:49) Packaging machinery and process (cid:49) Wide choice of actuators types feature a 2-circuit snap action switch equipment with forced disconnect. (cid:49) Textile machinery (cid:49) Construction machinery and equipment, GLS includes features to make quick in- vehicles and lift trucks stallation easier and safer. Screwdriver guides, wire guides and finger guard pro- tection are provided. Honeywell(cid:49) Sensing and Control(cid:49)1-800-537-6945 USA(cid:49)(cid:70)1-815-235-6847 International(cid:49)1-800-737-3360 CanadaA11

Limit and Enclosed Switches Standards/How to read and understand the bar chart information Standards How to read and understand the bar chart IEC 947-1 explains the general rules relating to Low-voltage information switchgear and controlgear. The purpose of this standard is to The following example relates to a unit which has a snap action harmonize as much as possible the product performance and test basic and which has a roller pin plunger actuator i.e. GLCB01C. requirements for equipment where the rated voltage does not ex- ceed 1,000 VAC or 1,500 VDC. When reading these bar charts follow these rules: 1. Check what type of actuator was used to test the product, this IEC 947-5-1is part 5 of the general rules which relates to Control- is on the drawings which show the head style available. It will circuit devices and switching elements. Also within this part there be one of two types: is a section which considers Special Requirements For Control a) Vertical travel plunger Switches With Positive Opening Operation. Any control switch b) Linear cam travel which has this positive opening operation and conforms to these special requirements will be marked on the outside of the product 2. Start reading from top left of figure B, at the arrow labeled with this symbol: ‘‘A’’. 3. Follow the black arrows and the black strip on the chart. The black strip indicates that there is a circuit between the termi- nals whose numbers are shown on the left and when white there is no circuit. The Contact Element Form defines the configuration of the contacts and the number of contacts within the switch. e.g. Form Za – both contact elements have the same polarity. All dimensions are in mm/(inches). Form Zb – the two contact elements are electrically separated. The Utilization Categorydefines the type of current carried (AC) Alternating current, (DC) Direct current and the typical application in which the switch is used e.g. AC15 – Control of Electromagnetic Loads (less than 72VA) DC13 – Control of electromagnets. The contact rating Designationrelates to the utilization categories and defines the conventional thermal current lth (A), rated oper- ational current le (A) at rated operational voltages Ue and the VA rating e.g. A600 – The ‘‘A’’ denotes the maximum VA rating (AC) and the Figure A ‘‘600’’ denotes the maximum rated (AC) voltage. Q300 – The ‘‘Q’’ denotes the maximum VA rating (DC) and the ‘‘300’’ denotes the maximum rated (DC) voltage. These IEC standards have been adopted by CENELEC (The Eu- ropean Commitee for Electrotechnical Standardization) and have been identified by replacing IEC with EN 60 e.g. IEC 947-5-1then becomes EN 60947-5-1. CENELEC has defined the dimensions and characteristics of two types of limit switch in the standards EN 50041and EN 50047. These standards relate to Low voltage switchgear and control- gear for industrial useand define the enclosure dimensions, the operating point for various head actuators, the earth terminal re- Figure B quirement, the terminal marking and the minimum degree of IP protection. Look at Figures A and B as examples. Actuator type used for test is the linear Cam travel type (b) shown left. The start point is at the ELECTRICAL RATINGS arrow marked ‘‘A’’ (See fig. B). This shows the free position to be 5.3 IEC947-5-1/ EN60947-5-1 mm from the vertical center line of the unit. At this stage there is a circuit between the terminals 21-22 but no circuit between terminals Designation & Rated operational current le (A) VA Utilization Category at rated operational voltage Ue rating 13-14. The unit can be actuated until it reaches the operating posi- tion which is 10.5 mm from the center line – a travel distance of 10.5 – 120V240V380V480V500V600V Make Break 5.3 =5.2 mm from the free position. At this point the circuit arrange- AC15 A600 6 3 1.9 1.5 1.4 1.2 7200 720 ment changes – no circuit between 21-22 but making a circuit AC15 A300 6 3 — — — — 7200 720 between 13-14. If, however, the contacts of terminals 21-22 weld together and will not separate, a mechanical safety feature will take AC15 B300 3 1.5 — — — — 3600 360 effect if the switch is travelled past the point from which positive AC14 D300 0.6 0.3 — — — — 432 72 opening is assured, 13.9 mm. As the switch returns it reaches the 125V 250V release position at 8.9 mm from the center line. The circuit will change back to the original state and the difference between the DC13 Q300 0.55 0.27 69 69 operating position and the release position gives what is known as DC13 R300 0.22 0.1 28 28 the differential travel i.e. 10.5 – 8.9 = 1.6 mm. The asterisk (*) indicates the point from which the positive opening is assured. A12 Honeywell(cid:49) Sensing and Control(cid:49)1-800-537-6945 USA(cid:49)(cid:70)1-815-235-6847 International(cid:49)1-800-737-3360 Canada

Limit and Enclosed Switches Degree of Protection NEMA Classification (USA) IP Classification NEMA (National Electrical Manufacturer’s Association) pre- The IEC 529standard describes a system for classifying the degree pares standards which define a product, process or procedure with of protection provided by the enclosures of electrical equipment. reference to one or more of the following: nomenclature, composi- The level of protection given by the enclosure is indicated by the IP tion, construction, dimensions, tolerances, safety, operating char- code. acteristics, performance, quality, electrical rating, testing and the This code system uses the letters ‘‘IP’’ (International Protection) service for which designed. followed by up to four digits. Normally only the first two digits are This standard provides degrees of protection for Enclosures for used. Electrical Equipement (1000 Volts Maximum) similar to that of the IEC 529 standard. The reference standard herein reflects the latest IP 1st 2nd 3rd 4th data in the NEMA Standards Publication when this information went Digit Digit Digit Digit to print. The first digit is numerical and indicates the level of protection within Non-hazardous locations the enclosure against the ingress of solid foreign objects and ac- Type 1enclosures are intended for indoor use primarily to provide a cess to hazardous parts by persons. degree of protection against contact with the enclosed equipment. L The second digit is also numerical and indicates the level of protec- Type 3 enclosures are intended for outdoor use primarily to pro- im tion against the ingress of WATERinto the enclosure. vide a degree of protection against windblown dust, rain, sleet, and it / The third digit is a letter and indicates a higher level of protection for external ice formation. E n persons against access to hazardous parts. Type 4 enclosures are intended for indoor or outdoor use primarily c The fourth digit is also a letter and is used in exceptional cases for to provide a degree of protection against windblown dust and rain, los supplementary information. splashing water, and hose-directed water. e d If the first or second digit is not required to be specified, then it is Type 4X enclosures are intended for indoor or outdoor use primar- replaced by the letter ‘‘X’’ (‘‘XX’’ if both digits are not required). ily to provide a degree of protection against corrosion, windblown While the tables below serve as a guide to the level of protection, dust and rain, splashing water, and hose-directed water. Honeywell recommends that customers refer to the full official IEC Type 6 enclosures are intended for indoor or outdoor use primarily specification for the exact definitions. If in doubt about the degree of to provide a degree of protection against the entry of water during protection required for a particular application, please consult your occasional temporary submersion at a limited depth. local Honeywell office. Type 6P enclosures are intended for indoor or outdoor use primar- ily to provide a degree of protection against the entry of water during Note: prolonged submersion at a limited depth. The IEC 529 standard does not relate to protection against rust, corrosion, icing or corrosive solvents (e.g. cutting fluids) and that Type 12 enclosures are intended for indoor use primarily to provide product coded IP 67 may not necessarily meet IP 66 requirements. a degree of protection against dust, falling dirt, and dripping non- corrosive liquids. Type 13 enclosures are intended for indoor use primarily to provide First Digit Protection against ingress of solid objects a degree of protection against dust, spraying water, oil and non- IP TEST corrosive coolant. 0 no protection Note: Enclosures are based, in general, on the broad definitions 1 protected against solid objects with a diameter greater outlined in NEMA Standards. Therefore, it will be necessary to than 50 mm. ascertain that a particular enclosure will be adequate when exposed 2 protected against solid objects with a diameter greater to the specific conditions that might exist in intended applications. than 12 mm. Except as might otherwise be noted, all references to products 3 protected against solid objects with a diameter greater relative to NEMA enclosure type are based on Honeywell evaluation than 2.5 mm. and Underwriter’s Laboratory (UL) tested. 4 protected against solid objects with a diameter greater than 1 mm. This NEMA Standards Publication does test for environmental con- 5 protected against dust-limited ingress (no harmful ditions such as corrosion, rust, icing, oil, and coolants. The IEC 529 deposit) does not, and does not specify degree of protection against me- 6 totally protected against dust chanical damage of equipment. For this reason, and because the tests and evaluations for other characteristics are not identical, the IEC Enclosure Classification Designations cannot be exactly equa- Second Digit Protection against ingress of water ted with NEMA Enclosure Type Numbers. IP TEST 0 no protection 1 protected against vertically falling drops of water. 2 protected against vertically falling drops of water when the enclosure is tilted at an angle up to 15 degrees. 3 protected against water sprayed at an angle of 60 degrees from the vertical 4 protected against splashing water from all directions – limited ingress (no harmful effects) 5 protected against low pressure jets of water from all directions – limited ingress permitted 6 protected against powerful jets of water from all directions – limited ingress permitted 7 protected against the effects of temporary immersion in water 8 protected against the effects of continuous immersion in water Honeywell(cid:49) Sensing and Control(cid:49)1-800-537-6945 USA(cid:49)(cid:70)1-815-235-6847 International(cid:49)1-800-737-3360 CanadaA13

Limit and Enclosed Switches GLA – Metal Standard GLF – (w/1 LED) Snap-Action Contacts Slow-Action Contacts 12...250Vac/dc BREAK BEFORE MAKE GLH – (w/2 LED) 18...30Vdc EN 50041 Circuit closed * Positive opening to IEC 947-5-1-3 Technical Data Mechanical life up to 15 million (F.P.) 0(cid:176) operations (O.P.) 26(cid:176) (F.P.) 0(cid:176) Degree of protection IP 67 (R.P.) 14(cid:176) (O.P.) 26(cid:176) NEMA/UL (R.P.) (D.T.) 12(cid:176) type 1, 4, 12, 13 (D.T.) (*) 55(cid:176) Temperature range Operating: (O.P.2) 38(cid:176) (O.T.) 71(cid:176) to –25(cid:176) C to +85(cid:176) C 85(cid:176) (O.T.) 71(cid:176) to –13(cid:176) F to +185(cid:176) F 85(cid:176) Storage: –40(cid:176) C to +85(cid:176) C –40(cid:176) F to +185(cid:176) F Approvals IEC 947-5-1 EN60947-5-1 AC15 A300/A600 DC13 Q300 UL & CSA Vibration (Actuator 10 g conforming to not fitted) IEC 68-2-6 Shock (Actuator 50 g conforming to not fitted) IEC 68-2-27 Terminal marking to EN 50013 Conduit Thread Std = A A =1/2(cid:78)NPT (w/1LED) = F B =PG 13,5 (w/2LED) = H C =20 mm * Point from which the positive opening is assured. D =PF 1/2 01 03 Ordering: (cid:88) (cid:88) 07 (Gold contact version) (cid:88) GL X X XX Example: GLA B 01B — GLF B 01B — GLH B 01B A14 Honeywell(cid:49)Sensing and Control(cid:49)1-800-537-6945 USA(cid:49)(cid:70)1-815-235-6847 International(cid:49)1-800-737-3360 Canada

Limit and Enclosed Switches Slow-Action Contacts Snap-Action Contacts Actuator Types MAKE BEFORE BREAK DOUBLE POLE (F.P.) 0(cid:176) (F.P.) 0(cid:176) (O.P.) 26(cid:176) (O.P.) 26(cid:176) (R.P.) (R.P.) 14(cid:176) A1B (D.T.) (D.T.) 12(cid:176) Additional (O.P.2) 38(cid:176) (*) 55(cid:176) levers available L (O.T.) 71(cid:176) to (O.T.) 71(cid:176) to (see page A24) im 85(cid:176) 85(cid:176) it / E n c lo s e d B C D E7B (GLA) (GLF, GLH) 04 20 or 24 (cid:88) XXX Honeywell(cid:49) Sensing and Control(cid:49)1-800-537-6945 USA(cid:49)(cid:70)1-815-235-6847 International(cid:49)1-800-737-3360 CanadaA15

Limit and Enclosed Switches GLB – Metal Plug-in GLG – (w/1LED) 12...250Vac/dc Snap-Action Contacts GLJ – (w/2LED) 18...30Vdc EN 50041 Circuit closed * Positive opening to IEC 947-5-1-3 Technical Data Mechanical life up to 15 million operations (F.P.) 0(cid:176) (O.P.) 26(cid:176) Degree of protection IP 67 NEMA/UL type 1, 4, 12, 13 (R.P.) 14(cid:176) Temperature range Operating: (D.T.) 12(cid:176) –25(cid:176) C to +85(cid:176) C (*) 55(cid:176) –13(cid:176) F to +185(cid:176) F (O.T.) 71(cid:176) to Storage: 85(cid:176) –40(cid:176) C to +85(cid:176) C –40(cid:176) F to +185(cid:176) F Approvals IEC 947-5-1 EN60947-5-1 AC15 A300/A600 DC13 Q300 UL & CSA Vibration (Actuator not fitted) 10 g conforming to IEC 68-2-6 Shock (Actuator not fitted) 50 g conforming to IEC 68-2-27 Terminal marking to EN 50013 Conduit Thread Plug-in = B A =1/2(cid:78)NPT (w/1LED) = G B =PG 13,5 (w/2LED) = J C =20 mm * Point from which the positive opening is assured. (GLB only) D =PF 1/2 02 Ordering: (cid:88) (cid:88) GL X X Example: GLB B 02 B — GLG B 12 B — GLJ B 13 B A16 Honeywell(cid:49)Sensing and Control(cid:49)1-800-537-6945 USA(cid:49)(cid:70)1-815-235-6847 International(cid:49)1-800-737-3360 Canada

Limit and Enclosed Switches Snap-Action Contacts Snap-Action Contacts Actuator Types (F.P.) 0(cid:176) (F.P.) 0(cid:176) (O.P.) 26(cid:176) (O.P.) 26(cid:176) (R.P.) 14(cid:176) (R.P.) 14(cid:176) A1B (D.T.) 12(cid:176) (D.T.) 12(cid:176) Additional (*) 55(cid:176) (*) 55(cid:176) levers available L (O.T.) 71(cid:176) to (O.T.) 71(cid:176) to (see page A24) im 85(cid:176) 85(cid:176) it / E n c lo s e d B C D E7B (GLG only) (GLJ only) 12 13 (cid:88) (cid:88) XX XXX Honeywell(cid:49)Sensing and Control(cid:49)1-800-537-6945 USA(cid:49)(cid:70)1-815-235-6847 International(cid:49)1-800-737-3360 CanadaA17

Limit and Enclosed Switches GLC EN 50047 Snap-Action Contacts Metal standard Technical Data Mechanical life up to 15 million operations Degree of protection IP 66 Circuit closed NEMA/UL type 1, 4, 12, 13 * Positive opening to IEC 947-5-1-3 Temperature range Operating: –25(cid:176) C to +85(cid:176) C (F.P.) 0(cid:176) –13(cid:176) F to +185(cid:176) F Storage: (O.P.) 26(cid:176) –40(cid:176) C to +85(cid:176) C (R.P.) 14(cid:176) –40(cid:176) F to +185(cid:176) F (D.T.) 12(cid:176) Approvals IEC 947-5-1 (*) 55(cid:176) EN60947-5-1 AC15 A300 (O.T.) 61(cid:176) to 75(cid:176) DC13 Q300 UL & CSA Vibration (Actuator not fitted) 10 g conforming to IEC 68-2-6 Shock (Actuator not fitted) 50 g conforming to IEC 68-2-27 Terminal marking to EN 50013 Conduit Thread A =1/2(cid:78)NPT adapter B =PG 13,5 C =20 mm * Point from which the positive opening is assured. D =PF 1/2 01 Ordering: (cid:88) GLC X Example: GLC B 01B A18 Honeywell(cid:49) Sensing and Control(cid:49)1-800-537-6945 USA(cid:49)(cid:70)1-815-235-6847 International(cid:49)1-800-737-3360 Canada

Limit and Enclosed Switches Slow-Action Contacts Slow-Action Contacts Actuator Types BREAK BEFORE MAKE MAKE BEFORE BREAK (F.P.) 0(cid:176) (F.P.) 0(cid:176) (O.P.) 26(cid:176) (O.P.) 26(cid:176) (R.P.) (R.P.) A1B (D.T.) (D.T.) (O.P.2) 39(cid:176) (O.P.2) 39(cid:176) Additional levers available (O.T.) 61(cid:176) to (O.T.) 61(cid:176) to (see page A24) Lim 75(cid:176) 75(cid:176) it / E n c lo s e d B C D E7B 03 04 (cid:88) (cid:88) XX XXX Honeywell(cid:49) Sensing and Control(cid:49)1-800-537-6945 USA(cid:49)(cid:70)1-815-235-6847 International(cid:49)1-800-737-3360 CanadaA19

Limit and Enclosed Switches GLD EN 50047 Snap-Action Contacts Double insulated standard Technical Data Mechanical life up to 15 million operations Degree of protection IP 66 Circuit closed NEMA/UL type 1, 12, 13 * Positive opening to IEC 947-5-1-3 Temperature range Operating: –25(cid:176) C to +85(cid:176) C (F.P.) 0(cid:176) –13(cid:176) F to +185(cid:176) F Storage: (O.P.) 26(cid:176) –40(cid:176) C to +85(cid:176) C (R.P.) 14,5(cid:176) –40(cid:176) F to +185(cid:176) F (D.T.) 11,5(cid:176) Approvals IEC 947-5-1 (*) 54(cid:176) EN60947-5-1 AC15 A600 (O.T.) 61(cid:176) to DC13 Q300 75(cid:176) UL & CSA Vibration (Actuator not fitted) 10 g conforming to IEC 68-2-6 Shock (Actuator not fitted) 50 g conforming to IEC 68-2-27 Terminal marking to EN 50013 Conduit Thread A =1/2(cid:78)NPT adapter B =PG 13,5 C =20 mm adapter * Point from which the positive opening is assured. D =PF 1/2 adapter 01 Ordering: (cid:88) GLD X Example: GLD B 01B A20 Honeywell(cid:49)Sensing and Control(cid:49)1-800-537-6945 USA(cid:49)(cid:70)1-815-235-6847 International(cid:49)1-800-737-3360 Canada

Limit and Enclosed Switches Slow-Action Contacts Slow-Action Contacts Actuator Types BREAK BEFORE MAKE MAKE BEFORE BREAK (F.P.) 0(cid:176) (F.P.) 0(cid:176) (O.P.) 26(cid:176) (O.P.) 26(cid:176) (R.P.) (R.P.) A1B (D.T.) (D.T.) (O.P.2) 39(cid:176) (O.P.2) 39(cid:176) Additional levers available (O.T.) 61(cid:176) to (O.T.) 61(cid:176) to (see page A24) Lim 75(cid:176) 75(cid:176) it / E n c lo s e d B C D E7B 03 04 (cid:88) (cid:88) XX XXX Honeywell(cid:49)Sensing and Control(cid:49)1-800-537-6945 USA(cid:49)(cid:70)1-815-235-6847 International(cid:49)1-800-737-3360 CanadaA21

Limit and Enclosed Switches GLE EN 50047 Compatible Snap-Action Contacts Slow-Action Contacts 3 Conduit Metal BREAK BEFORE MAKE standard Technical Data Mechanical life up to 15 million Circuit closed operations * Positive opening to IEC 947-5-1-3 Degree of protection IP 66 NEMA/UL (F.P.) 0(cid:176) type 1, 4, 12, 13 (F.P.) 0(cid:176) (O.P.) 26(cid:176) Temperature range Operating: (O.P.) 26(cid:176) (R.P.) 14,5(cid:176) –25(cid:176) C to +85(cid:176) C (R.P.) –13(cid:176) F to +185(cid:176) F (D.T.) 11,5(cid:176) (D.T.) Storage: (*) 54(cid:176) –40(cid:176) C to +85(cid:176) C (O.P.2) 39(cid:176) (O.T.) 61(cid:176) to –40(cid:176) F to +185(cid:176) F 75(cid:176) (O.T.) 61(cid:176) to Approvals IEC 947-5-1 75(cid:176) EN60947-5-1 AC15 A300 DC13 Q300 UL & CSA Vibration (Actuator 10 g conforming to not fitted) IEC 68-2-6 Shock (Actuator 50 g conforming to not fitted) IEC 68-2-27 Terminal marking to EN 50013 Conduit Thread A =1/2(cid:78)NPT adapter B =PG 13,5 C =20 mm * Point from which the positive opening is assured. D =PF 1/2 01 03 Ordering: (cid:88) (cid:88) GLE X XX Example: GLE B 01B A22 Honeywell(cid:49) Sensing and Control(cid:49)1-800-537-6945 USA(cid:49)(cid:70)1-815-235-6847 International(cid:49)1-800-737-3360 Canada

Limit and Enclosed Switches Slow-Action Contacts Snap-Action Contacts Actuator Types MAKE BEFORE BREAK DOUBLE POLE (F.P.) 0(cid:176) (F.P.) 0(cid:176) (O.P.) 26(cid:176) (O.P.) 26(cid:176) (R.P.) (R.P.) 18(cid:176) A1B (D.T.) (D.T.) 8(cid:176) Additional (O.P.2) 39(cid:176) (*) 54(cid:176) levers available L (O.T.) 61(cid:176) to (O.T.) 61(cid:176) to (see page A24) im 75(cid:176) 75(cid:176) it / E n c lo s e d B C D E7B 04 24 (cid:88) XXX Honeywell(cid:49) Sensing and Control(cid:49)1-800-537-6945 USA(cid:49)(cid:70)1-815-235-6847 International(cid:49)1-800-737-3360 CanadaA23

Limit and Enclosed Switches Additional Lever Types For use with all Side Rotary Head Style. Figure 1illustrates Miniature Din lever types conforming to EN 50047 while Figure 2 illustrates Standard Din lever types which conform to EN 50041. All dimensions are in mm/(inches). GLC, GLD, GLE (EN 50047) Side Rotary Roller Lever Side Rotary Adjustable Lever Side Rotary Adjustable Rod A1A Plastic Roller A2A Plastic Roller A4J Metal Rod Head A1B Metal Roller A2B Metal Roller Offset Side Rotary Roller Lever Side Rotary Conveyor Lever A5A Plastic Roller A9A Ceramic Roller A5B Metal Roller Head Figure 1 GLA, GLB, GLF, GLH, GLG, GLJ (EN 50041) Side Rotary Roller Lever Offset Side Rotary Roller Lever A1A Plastic Roller A5A – Plastic Roller A1B Metal Roller A5B – Metal Roller Side Rotary Adjustable Lever A2A Plastic Roller A2B Metal Roller Side Rotary Adjustable Rod A4J Metal Rod Head Figure 2 A24 Honeywell(cid:49) Sensing and Control(cid:49)1-800-537-6945 USA(cid:49)(cid:70)1-815-235-6847 International(cid:49)1-800-737-3360 Canada

Limit and Enclosed Switches Spare Parts for the GLS Series To order spare parts for your particular GLS simply use the GLS number on the front of the switch to identify the construction used and therefore the spare part you need. For Example: The part No: GLAB01E7B For Example: The part No: GLDC04A1B GLA B 01 E7B GLD C 04 A1B Wobble Head Fixed Side Rotary Steel Roller 01 Basic Snap Action 04 Make Before Break Slow Action B Thread PG13.5 C Thread 20 mm EN 50041 Body EN 50047 Body From the tables below it is possible to obtain replacement Basic Switches, Heads, Actuators, Levers and LED Assemblies. Note: Spare parts should only be used to replace parts on existing listings. Honeywell accepts no liability for parts used in combinations not recognized by Honeywell as valid listings. L im Basic Switches it / Body Basic Switch E n Type 01 02 03 04 12 13 20 24 c lo GLA GLZ301 GLZ303 GLZ304 GLZ320 s e GLB GLZ3021 d GLC GLZ301 GLZ303 GLZ304 GLD GLZ301 GLZ303 GLZ304 GLE GLZ301 GLZ303 GLZ304 GLZ324 GLF GLZ301 GLZ303 GLZ304 GLG GLZ3121 GLH GLZ301 GLZ303 GLZ304 GLJ GLZ3131 Note 1:For these spares you will receive the front of the body with no head. To replace the faulty switch/LED assembly remove the old body and old head. Retrofit the head onto the replacement and plug in the spare switch/LED assembly into the old base. Heads Body Head Types Type A B C D E7A E7B E7D K8A K8B K8C GLA GLZ1AA GLZ1AB GLZ1AC GLZ1AD GLZ1AE7A GLZ1AE7B GLZ1AE7D GLZ1AK8A GLZ1AK8B GLZ1AK8C GLB GLZ1AA GLZ1AB GLZ1AC GLZ1AD GLZ1AE7A GLZ1AE7B GLZ1AE7D GLZ1AK8A GLZ1AK8B GLZ1AK8C GLC N/A N/A N/A N/A N/A N/A N/A N/A N/A GLD N/A N/A N/A N/A N/A N/A N/A N/A N/A GLE N/A N/A N/A N/A N/A N/A N/A N/A N/A GLF GLZ1AA GLZ1AB GLZ1AC GLZ1AD GLZ1AE7A GLZ1AE7B GLZ1AE7D GLZ1AK8A GLZ1AK8B GLZ1AK8C GLG GLZ1AA GLZ1AB GLZ1AC GLZ1AD GLZ1AE7A GLZ1AE7B GLZ1AE7D GLZ1AK8A GLZ1AK8B GLZ1AK8C GLH GLZ1AA GLZ1AB GLZ1AC GLZ1AD GLZ1AE7A GLZ1AE7B GLZ1AE7D GLZ1AK8A GLZ1AK8B GLZ1AK8C GLJ GLZ1AA GLZ1AB GLZ1AC GLZ1AD GLZ1AE7A GLZ1AE7B GLZ1AE7D GLZ1AK8A GLZ1AK8B GLZ1AK8C Levers / Actuators (For GLZ1AA Head Type Only (side rotary)) Body Lever Actuator Type Type 1A 1B 2A 2B 4J 5B GLA GLZ51A GLZ51B GLZ52A GLZ52B GLZ54J GLZ55B GLB GLZ51A GLZ51B GLZ52A GLZ52B GLZ54J GLZ55B GLC N/A N/A N/A N/A N/A N/A GLD N/A N/A N/A N/A N/A N/A GLE N/A N/A N/A N/A N/A N/A GLF GLZ51A GLZ51B GLZ52A GLZ52B GLZ54J GLZ55B GLG GLZ51A GLZ51B GLZ52A GLZ52B GLZ54J GLZ55B GLH GLZ51A GLZ51B GLZ52A GLZ52B GLZ54J GLZ55B GLJ GLZ51A GLZ51B GLZ52A GLZ52B GLZ54J GLZ55B Honeywell(cid:49) Sensing and Control(cid:49)1-800-537-6945 USA(cid:49)(cid:70)1-815-235-6847 International(cid:49)1-800-737-3360 CanadaA25

Limit and Enclosed Switches LED Assemblies Body LED-Assembly TYPE Type 1-LED 2-LED GLA GLB GLC GLD GLE GLF GLZ6F GLG GLH GLZ6H GLJ Parts Description Heads GLZ1AA Side Rotary Head GLZ1AB Top Pin Plunger Head GLZ1AC Top Roller Plunger Head GLZ1AD Roller Arm Head GLZ1AE7A Plastic Wobble Stick Head Assembly GLZ1AE7B Coil Wobble Stick Head Assembly GLZ1AE7D Coil Whisker Head Assembly GLZ1AK8A 140mm Cat’s Whisker Head Assembly GLZ1AK8B 190mm Cat’s Whisker Head Assembly GLZ1AK8C Cat’s Whisker Head Assembly Basics GLZ301 Snap Action SPDT (01) GLZ302 Snap Action SPDT Plug-In (02) see Note 1 on page A25 GLZ303 SPDT Break Before Make (03) GLZ304 SPDT Make Before Break (04) GLZ312 Snap Action SPDT 1 LED Plug-In (12) see Note 1 on page A25 GLZ313 Snap Action SPDT 2 LED Plug-In (13) see Note 1 on page A25 GLZ320 Snap Action DPDT (20) GLZ324 Snap Action DPDT for 3 Conduit (24) Actuators GLZ51A Side Rotary Fixed Lever Nylon Roller Actuator GLZ51B Side Rotary Fixed Lever Steel Roller Actuator GLZ52A Side Rotary Adjustable Lever Nylon Roller Actuator GLZ52B Side Rotary Adjustable Lever Steel Roller Actuator GLZ54J Side Rotary Adjustable Rod Actuator GLZ55B Side Rotary Fixed Offset Lever Steel Roller LED Assemblies GLZ6F Spare 1 LED Assembly for GLF... GLZ6H Spare 2 LED Assembly for GLH... A26 Honeywell(cid:49)Sensing and Control(cid:49)1-800-537-6945 USA(cid:49)(cid:70)1-815-235-6847 International(cid:49)1-800-737-3360 Canada

Limit and Enclosed Switches Proper Application of Limit Switches The following are guidelines for the correct application of Limit Tools Switches. The following tools will be needed – depending on the task. Never use the Limit Switch as a physical end stop. Mechanical Posidrive screwdriver n(cid:176) 1& n(cid:176) 2 damage or incorrect operation may occur if this is done. Always Allen key 3 mm ensure that the mechanical actuator is protected from excessive When tightening a screw down the maximum force which should be mechanical shock. Never release the actuator suddenly – gradual applied should not exceed 80N.cm (7in.LB) on any screw on the actuation and release will ensure that stress on the mechanics of the complete assembly or basic switch terminal. switch is kept to a minimum. This has the added benefit that the switch life will be improved. Mounting Instructions The following diagrams illustrate how to actuate your limit switch for Mounting, Installation and Wiring of the Limit Switch plays a critical optimum performance. role in the performance of the switch in service. Care should be taken in the position and orientation of the switch for optimum performance. All of the guidelines given below apply equally when replacing parts on the switch. Wiring L The GLS series has been designed to accept 14AWG wire maxi- im mum. Care should be taken to ensure that the wires are carefully it arranged in the switch so that they do not overlap or otherwise / E interfere with the operation of the switch when the switch cover is n replaced. If the wires are trapped between the basic and the cover clo then the switch may fail to operate correctly – ensure that an s adequate gap exists between the fitted wires and the cover when ed fitted. It is not good practice to have very different diameter wires share the same terminal in the switch – uneven pressure on the wires will result. For limit switches with pushrod actuators, the actuating force should be applied as nearly as possible in line with the pushrod axis. Mounting The GLS series has been designed to be extremely flexible in mounting. Elongated mounting holes mean that the switch can be adjusted substantially prior to fixing in position. We recommend M4 maximum screws be used for mounting the switch in its application. Fix and test the switch for intended switch point in the application. When mounting the switch ensure that it is positioned to allow natural drainage of any moisture which may enter the enclosure during service. Natural drainage can be achieved by mounting the switch upright with the conduit entry at the bottom of the switch. Mounting the switch in the upright position will enable maintenance and replacement procedures to be carried out easily. Adjustment and Set-up Cam or dog arrangements should be such that the actuator is notsuddenly In general no adjustment of the GLS should be necessary beyond released to snap back freely. correct mounting of the switch body as required. It is possible to change the switch actuator orientation. The example below shows a top roller plunger head rotated through 90(cid:176) . The other head styles can also be rotated. Operating mechanisms for limit switches should be so designed that, under any operating or emergency conditions, the limit switch is not operated beyond its overtravel limit position. A limit switch should not be used as a mechanical stop. The head can be rotated by carefully removing the four combination head screws holding the head in position. Carefully remove the head assembly and rotate to the desired position. Replace the head assembly and tighten the mounting screws. Ensure that the head is properly located. Hand test the actuator to ensure that the switch functions and the actuator moves freely (sticking can occur if materi- For limit switches with lever actuators, the actuating force should be applied as nearly perpendicular to the lever as practical and perpendicular to the shaft axis al has been deposited inside the drive train whilst the head assem- about which the lever rotates. bly was removed). Honeywell(cid:49) Sensing and Control(cid:49)1-800-537-6945 USA(cid:49)(cid:70)1-815-235-6847 International(cid:49)1-800-737-3360 CanadaA27

Limit and Enclosed Switches Side Rotaries EN 50041Side Rotary Actuator Direction Adjustment The side rotary assemblies incorporate a feature for adjusting the As furnished, GLS rotary switches will operate when the lever is free position of the side rotary lever. The EN 50041body style allows rotated from either the left or right. They can be field modified to infinite adjustment and reclamp. The EN 50047 style allows clamp- operate in one direction only (Clockwise CW; Counter clockwise ing in 10(cid:176) increments. See the following diagrams for details of the CCW) by following these steps: (1) Carefully remove the complete mechanism in each case. head assembly; (2) Turn the head assembly upside down as shown in the drawing below. Standard EN 50041body style (3) Pull the plunger mechanism out and rotate it through 90(cid:176) degree increments until the alignment tab points to the desired function (CW, CCW, or CW and CCW). (4) Push plunger mechanism in. (5) Reassemble the head assembly and re-test the switch in your There are two lever mounting options: (1) By fully seating the lever in application. one of the four 90(cid:176) detent positions on the shaft hub which provides positive lever retention; (2) By mounting the lever on the serrated portion of the shaft (which enables the lever to be mounted in any Replacement Instructions position). All levers for side rotaries are available as replacment parts. All To change the rotary lever’s free position: (1) Use a 3 mm hex Allen basics, except the plug-in, can be replaced. All EN 50041heads can wrench to loosen the Allen screw, as shown in the drawing above; be replaced. The replacement procedures for these components (2) Back off the lever 2 mm and move it to the desired free position; are straightforward in nature. (3) retighten the Allen screw; (4) Check to see if the free position is satisfactory for the application; (5) Repeat the adjustment proce- Side Rotary Levers dure if necessary. Remove the old lever from the product being replaced. On EN 50041 product this is achieved by loosening the Allen screw holding the A teller tab located at the bottom of the lever (see diagram below) lever on the shaft. On EN 50047 product this is achieved by un- helps prevent lever slippage. It enables the installer to detect the screwing the combination screw holding the lever on the shaft. correct tightening torque. When this tab cannot be moved, the Allen screw has been tightened properly. Replace the lever and tighten the Allen screw or combination screw. Retest the switch in its application. Heads All EN 50041style switch heads can be removed and replaced. Remove the old head by unscrewing the four retaining screws on the head assembly. Ensure replacement part is identical to one being removed. Re-test the assembly and ensure correct operation. Miniature EN 50047 body style Basics Non plug-in EN 50041and three conduit EN 50047 body styles. Basic switches can be removed and replaced by following this procedure: (1) Remove the cover from the body; (2) Before dis- connecting the switch wiring, carefully note the wiring arrangement for your application, particularly the safety ground connection; (3) Remove the basic switch retaining screw; (4) Remove the old basic and replace it with the same thing; (5) Use the retaining screw to install the new basic – ensure that it is correctly seated in the switch body; (6) Wire the switch terminals as before; (7) Before replacing the cover – ensure that the switch wires are not twisted or otherwise lifted from the basic (to prevent them from becoming trapped when A serrated coupling is used to set the lever free position in 10(cid:176) the cover is replaced); then (8) Test the switch in the application. increments. This adjustment is achieved by: (1) Unscrewing the combination head screw which holds the lever in place, taking care not to lose any parts; (2) Readjust the assembly and rotate to the desired free position; (3) Re-assemble and tighten the combination screw. (4) Check that the free position is correct for the application and repeat the adjustment procedure if necessary. NOTE: The lever can be set in 90(cid:176) increments by removing the lever and rotating it to the desired 90(cid:176) position. A28 Honeywell(cid:49)Sensing and Control(cid:49)1-800-537-6945 USA(cid:49)(cid:70)1-815-235-6847 International(cid:49)1-800-737-3360 Canada

Limit and Enclosed Switches Miniature EN 50047 body style Use same replacement procedure as above except that no retaining screw is involved. The basic switch is secured in the miniature housings by a press fit. To remove an inoperative switch, merely grasp the basic firmly and pull it out of the housing. Insert the new switch in its place. Then wire the new basic as before and test it in the application. Plug-in EN 50041body style The switch enclosure portion of this two-piece body style plugs into a pre-wired terminal block mounted in the application. Replacement is accomplished by unplugging the old switch enclosure and plug- ging-in a new switch enclosure (basics are permanently staked in the switch enclosure). In ‘‘Wiring Arrangement 3’’ you can see that regardless of the LED Wiring position of the main switch the current for the LED can flow through L The GLF, GLG, GLH and GLJ versions of GLS (EN 50041) come the LED and the LED will illuminate indicating power available. im complete with LED indicators. These indicators can be wired in a it/ E variety of ways. The standard adopted in the GLG (1LED Plug-in n body) and in the GLJ (2 LED Plug-in body) versions is to use green to c lo indicate power available and yellow to indicate operation. Operation s can indicate actuator free or actuator operated depending on the e d wireing arrangement employed. The table below indicates the body styles and indicators offered. Body Function Spec. GLF... 1 LED 12 →250V AC and DC Less than 1,5mA draw GLG... 1 LED plug-in 12 →250V AC and DC Less than 1,5mA draw In ‘‘Wiring Arrangement 4’’ you can see that when the load is GLH... 2 LED 18 →30V DC 7mA typ. current draw energised the LED will illuminate. The above circuit ideas give a flavour for what is possible with these GLJ... 2 LED plug-in 18 →30V DC 7mA typ. current draw versions of GLS. The LED’s should be treated as ’’for indication only’’ devices. The following wiring arrangements show possible configurations Note: that can be used for the LED’s. Combinations of these arrange- While every effort is made to ensure that the above guidelines are ments can be used where the dual LED versions of GLS are accurate, no responsibility can be accepted for failure to apply good employed. engineering practice to machinery design and use of Honeywell products. Never apply any of the procedures outlined above on live circuits. Ensure that testing of changes is carried out with no risk of injury during tests. These guidelines are produced to help our customers make the right choices in applying our Limit Switches to general applications. Contact your local Honeywell representative if you have any difficulties. In ‘‘Wiring Arrangement 1’’ you can see that while the main basic is open the current for the LED can flow through the LED (via the load) and the LED illuminates. In ‘‘Wiring Arrangement 2’’ you can see that while the main switch is closed the current for the LED cannot flow through the LED and the LED will not illuminate. Honeywell(cid:49) Sensing and Control(cid:49)1-800-537-6945 USA(cid:49)(cid:70)1-815-235-6847 International(cid:49)1-800-737-3360 CanadaA29

Mouser Electronics Authorized Distributor Click to View Pricing, Inventory, Delivery & Lifecycle Information: H oneywell: GLJA13D GLZ1AA GLZ1AB GLZ1AC GLZ1AD GLZ1AE7A GLZ1AE7B GLZ1AE7D GLZ1AK8A GLZ1AK8B GLZ1AK8C GLZ301 GLZ303 GLZ304 GLZ51B GLZ52A GLZ52B GLZ54J GLZ55B GLZ6F

Datasheet下载

Datasheet下载