ICGOO在线商城 > 射频/IF 和 RFID > RF 屏蔽 > BMI-S-103

- 型号: BMI-S-103

- 制造商: Laird Technologies

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

BMI-S-103产品简介:

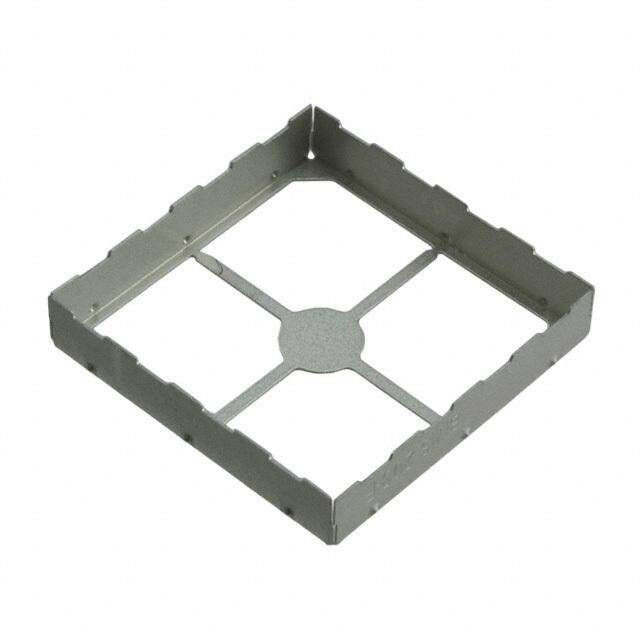

ICGOO电子元器件商城为您提供BMI-S-103由Laird Technologies设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 BMI-S-103价格参考¥8.11-¥17.64。Laird TechnologiesBMI-S-103封装/规格:RF 屏蔽, RF Shield Shield, 1-Piece 1.032" (26.21mm) X 1.032" (26.21mm) Vent Holes in Pattern Solder。您可以下载BMI-S-103参考资料、Datasheet数据手册功能说明书,资料中有BMI-S-103 详细功能的应用电路图电压和使用方法及教程。

Laird Technologies EMI 的 BMI-S-103 属于 RF(射频)屏蔽产品系列,主要用于电子设备中的电磁干扰 (EMI) 和射频干扰 (RFI) 屏蔽。以下是该型号的主要应用场景: 1. 移动通信设备 - BMI-S-103 可用于手机、平板电脑和其他无线通信设备中,提供高效的射频屏蔽,减少内部组件之间的干扰,确保信号传输的稳定性和设备性能。 2. 物联网 (IoT) 设备 - 在智能家居、可穿戴设备和工业物联网设备中,BMI-S-103 能够保护敏感电路免受外部电磁干扰的影响,同时防止设备自身的射频信号泄漏。 3. 汽车电子系统 - 适用于车载信息娱乐系统、导航模块和通信模块等场景,确保汽车电子系统的正常运行,避免因电磁干扰导致的功能异常。 4. 医疗设备 - 在医疗领域,BMI-S-103 可用于心率监测仪、超声波设备和 MRI 系统等精密仪器中,提供可靠的射频屏蔽,保障设备的准确性和安全性。 5. 航空航天与国防 - 此型号适用于卫星通信、雷达系统和军用通信设备,能够有效隔离高频信号,防止信号泄露或受到外界干扰。 6. 消费电子产品 - 包括无线耳机、蓝牙音箱和智能手表等小型电子设备,BMI-S-103 提供紧凑型设计的屏蔽解决方案,满足高密度集成的需求。 核心优势 - 高性能屏蔽:对高频射频信号具有优异的屏蔽效果。 - 灵活安装:适合多种尺寸和形状的应用环境。 - 可靠性强:能够在恶劣环境下保持稳定的屏蔽性能。 - 轻量化设计:适合便携式和小型化设备。 综上所述,BMI-S-103 广泛应用于需要高效射频屏蔽的各种电子设备中,帮助提升产品的可靠性和抗干扰能力。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | BOARD SHIELD 1.032X1.032" 1PIECE |

| 产品分类 | |

| 品牌 | Laird Technologies EMI |

| 数据手册 | http://www.lairdtech.com/WorkArea/linkit.aspx?LinkIdentifier=id&ItemID=2924http://www.lairdtech.com/WorkArea/linkit.aspx?LinkIdentifier=id&ItemID=5765http://www.lairdtech.com/WorkArea/linkit.aspx?LinkIdentifier=id&ItemID=3282 |

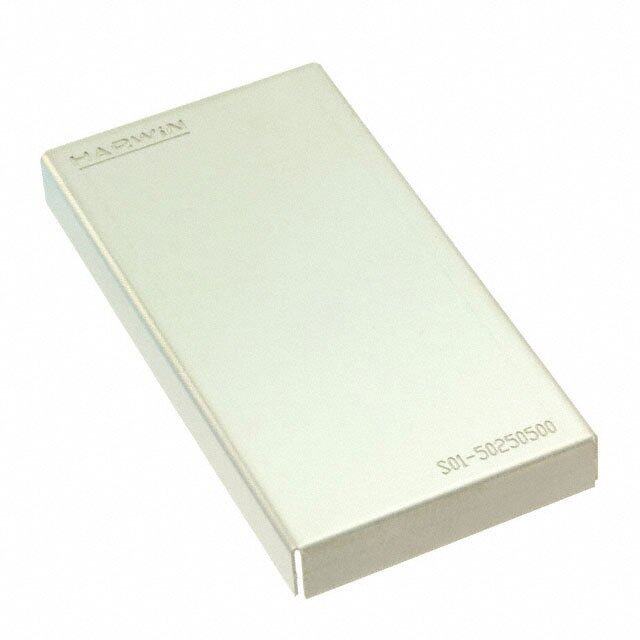

| 产品图片 |

|

| 产品型号 | BMI-S-103 |

| rohs | 无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | - |

| 产品培训模块 | http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=25191 |

| 产品目录绘图 |

|

| 产品目录页面 | |

| 其它名称 | 903-1008-1 |

| 包装 | 剪切带 (CT) |

| 安装类型 | |

| 宽度-总 | 1.032"(26.21mm) |

| 标准包装 | 1 |

| 类型 | 1 件 |

| 通风 | 通风孔,按样式排列 |

| 长度-总 | 1.032"(26.21mm) |

| 高度-总 | 0.200" (5.08 mm) |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

EMI C A T A L O G w w w . l a i r d t e c h . c o m

ABOUT LAIRD Laird is a global technology business focused on enabling wireless communication and smart systems, and providing components and systems that protect electronics. Laird operates through two divisions, Wireless Systems and Performance Materials. Wireless Systems solutions include antenna systems, embedded wireless modules, telematics products and wireless automation and control solutions. Performance Materials solutions include electromagnetic interference shielding, thermal management and signal integrity products. As a leader in the design, supply and support of innovative technology, our products allow people, organisations, machines and applications to connect effectively, helping to build a world where smart technology transforms the way of life. Custom products are supplied to major sectors of the electronics industry including the handset, telecommunications, IT, automotive, public safety, consumer, medical, rail, mining and industrial markets. Providing value and differentiation to our customers though innovation, reliable fulfilment and speed, Laird PLC is listed and headquartered in London, and employs over 9,000 people in more than 58 facilities located in 18 countries. .

TABLE OF CONTENTS EMI INTRODUCTION 2 Fiber Optic Shield 40 GBIC Fiber Optic Shield 40 EMI SUMMARY 3 "D" Connector Shielding / Slotted "D" 41 Precision Stamped Metals 42 BOARD LEVEL SHIELDS 6 Contacts 42 Product Selection Guide 6 Custom Design 44 Introduction 8 Metals Galvanic Compatibility Chart 46 Standard Design Shields 9 EZ Peel™ 11 VENT PANELS 48 Rigid Corner 11 MaxAir™ 49 ReCovr™ 12 Elecro-Air™ 50 ReMovl 12 Electrovent™ 51 Overview 13 FABRIC-OVER FOAM 52 FINGERSTOCK 14 Product Selection Guide 52 Product Selection Guide 14 Introduction 54 Introduction 15 EcoGreen™ 56 Mounting Methods 16 I/O / Gasket Selection Guide 57 Ordering Information 17 Profile Selection Guide 58 UltraSoft® Series 18 I/O Selection Guide 62 Recyclable Clean Copper 18 Knitted Conductive Gaskets 65 Slot Mount Series 19 Visual Part Reference Guide 66 Dual Slot Series 21 Part Number Cross Reference 67 Teardrop Series 21 Ultraflex® 68 Compact PCI Symmetrical Mount 22 All Mesh 69 Alternate Slot Series 22 Elastomer Core 70 Variable Slot Mount 23 Electroground® EMI Washers 72 Symmetrical (S3) Slotted Shielding 24 Electromesh® Tape 75 Solid Top (S3) Symmetrical Slotted Shielding 25 Conductive Fabric 76 Clip-On Symmetrical Shielding 26 MRI "A" Fabric 77 No Snag Gasket 27 Conductive Tape 78 All-Purpose Series 28 Clip-On Series 29 ELECTRICALLY CONDUCTIVE ELASTOMERS 79 Low Profile Hook-On Gasket 31 Introduction 79 Low Profile Gasket 31 Product Selection Guide 80 Large Enclosure Series 32 Case Study 81 Double-Sided Contact Series 32 Visual Part Reference Guide 85 Foldover Series 33 Electroseal™ Conductive Elastomer 86 Stainless Steel I/O Shielding 33 Extrusions Guide 87 Flexible Low Compression Series 34 Gemini™ Coextrusions 93 Clip-On Twist Series 34 Fabricated Components Guide 95 Twist Series 35 Metal Impregnated Materials 99 Divider Edge Shielding 35 Specialty Products 102 Card Guide Clip-On 36 Automated Form-In-Place Gaskets 103 Clip-On Perpendicular Shielding 36 MICROWAVE ABSORBERS 105 Clip-On Perpendicular Grounding Strip 37 Product Selection Guide 105 Clip-On Longitudinal Grounding Strip 37 Design Guide 106 Mini-Longitudinal Grounding Gasket 38 Q-Zorb® 2000 HF 109 Longitudinal Grounding Series 38 Q-Zorb® 3000 HP 110 Custom Stamping 39 RFRET 4000 111 Contact Strips / Contact Rings 39 RFLS 5000 112 IEEE 1394 Horizontal Connector Gasket 39 Analysis, Test and Prototype Development 113 DIN Connector Series 39 USB Connector 40 www.lairdtech.com

TABLE OF CONTENTS EMI INTRODUCTION 2 Fiber Optic Shield 40 GBIC Fiber Optic Shield 40 EMI SUMMARY 3 "D" Connector Shielding / Slotted "D" 41 Precision Stamped Metals 42 BOARD LEVEL SHIELDS 6 Contacts 42 Product Selection Guide 6 Custom Design 44 Introduction 8 Metals Galvanic Compatibility Chart 46 Standard Design Shields 9 EZ Peel™ 11 VENT PANELS 48 Rigid Corner 11 MaxAir™ 49 ReCovr™ 12 Elecro-Air™ 50 ReMovl 12 Electrovent™ 51 Overview 13 FABRIC-OVER FOAM 52 FINGERSTOCK 14 Product Selection Guide 52 Product Selection Guide 14 Introduction 54 Introduction 15 EcoGreen™ 56 Mounting Methods 16 I/O / Gasket Selection Guide 57 Ordering Information 17 Profile Selection Guide 58 UltraSoft® Series 18 I/O Selection Guide 62 Recyclable Clean Copper 18 Knitted Conductive Gaskets 65 Slot Mount Series 19 Visual Part Reference Guide 66 Dual Slot Series 21 Part Number Cross Reference 67 Teardrop Series 21 Ultraflex® 68 Compact PCI Symmetrical Mount 22 All Mesh 69 Alternate Slot Series 22 Elastomer Core 70 Variable Slot Mount 23 Electroground® EMI Washers 72 Symmetrical (S3) Slotted Shielding 24 Electromesh® Tape 75 Solid Top (S3) Symmetrical Slotted Shielding 25 Conductive Fabric 76 Clip-On Symmetrical Shielding 26 MRI "A" Fabric 77 No Snag Gasket 27 Conductive Tape 78 All-Purpose Series 28 Clip-On Series 29 ELECTRICALLY CONDUCTIVE ELASTOMERS 79 Low Profile Hook-On Gasket 31 Introduction 79 Low Profile Gasket 31 Product Selection Guide 80 Large Enclosure Series 32 Case Study 81 Double-Sided Contact Series 32 Visual Part Reference Guide 85 Foldover Series 33 Electroseal™ Conductive Elastomer 86 Stainless Steel I/O Shielding 33 Extrusions Guide 87 Flexible Low Compression Series 34 Gemini™ Coextrusions 93 Clip-On Twist Series 34 Fabricated Components Guide 95 Twist Series 35 Metal Impregnated Materials 99 Divider Edge Shielding 35 Specialty Products 102 Card Guide Clip-On 36 Automated Form-In-Place Gaskets 103 Clip-On Perpendicular Shielding 36 MICROWAVE ABSORBERS 105 Clip-On Perpendicular Grounding Strip 37 Product Selection Guide 105 Clip-On Longitudinal Grounding Strip 37 Design Guide 106 Mini-Longitudinal Grounding Gasket 38 Q-Zorb® 2000 HF 109 Longitudinal Grounding Series 38 Q-Zorb® 3000 HP 110 Custom Stamping 39 RFRET 4000 111 Contact Strips / Contact Rings 39 RFLS 5000 112 IEEE 1394 Horizontal Connector Gasket 39 Analysis, Test and Prototype Development 113 DIN Connector Series 39 USB Connector 40 www.lairdtech.com

EMI ESSENTIALS EMI INTRODUCTION Overview of EMC/RFI Issues The phenomenon of electromagnetic interference (EMI) is familiar to virtually everyone, even if they do not understand the underlying principles. Most people have witnessed firsthand the effects of interference. To control EMI, government organizations, such as the FCC, CSA, and EEC, mandate that manufacturers may not design, produce or sell electronic equipment that jams the public broadcast services. In other instances, however, EMI can constitute more than a mere nuisance. The military and medical communities, for example, require trouble-free operation of their electronic equipment in adverse electromagnetic environments since malfunctions could jeopardize missions and personnel. The European Union’s EMC directive also mandates that “the apparatus has an adequate level of intrinsic immunity to electromagnetic disturbance to enable it to operate as intended”. EMC Design of High Speed Systems The interference and susceptibility (immunity) effects of electronic apparatus are created by time-variant electromagnetic fields which may be propagated along a conducting medium or by radiation through space. Because the source of the conducted and radiated interference energy levels may be related, a coordinated systems design effort is required to reduce these effects. A design program for an equipment item that must meet both an emission and an immunity requirement consists of: • Suppression: Reducing the interference at its source. • Isolation: Isolating the offending circuits by filtering, grounding and shielding. • Desensitization: Increasing the immunity of any susceptible circuits. These three steps should be carried on throughout the entire equipment design and implemented as early as possible within the design program. Effects of Logic Speed The trend in today’s electronic devices is faster, smaller, and digital rather than analog. Most equipment (95%) of today contains digital circuits. Today’s digital designer must create a circuit board that has the lowest possible EMI, combined with the highest possible operating/processing speeds. Design of the PCB is the most critical EMC influencing factor for any system, since virtually all active devices are located on the board. It is the changing current (accelerated electron movement) produced by the active devices that result in EMI. Design Approaches There are two approaches that can be used to reduce the emission from the PC board. The first approach is to operate the circuit at the slowest speeds consistent with the functionality of the system, lay out the PCB with the smallest possible loop areas (especially the high speed devices), and insert suppression components such as filters, ferrite beads, and bypass capacitors into the circuit to reduce its bandwidth. These techniques will result in a desired decrease in the high frequency harmonic amplitudes and circuit bandwidth and a corresponding undesired decrease in both the operating speed and system reliability. The use of slower speeds with reduced bandwidth will help to desensitize the circuit to external susceptibility fields. The second is to use shielding. Shielding is the only non-invasive suppression technique. Since the shielding is not inserted into the circuit, it does not affect the high frequency operating speed of the system, nor does it affect the operation of the system should changes be made to the design in the future. In addition, shielding does not create timing problems and waveform distortion; it does not decrease system reliability; and it reduces crosstalk. Plus, shielding works for both emission suppression as well as susceptibility (immunity) problems. Even with the overall advantages of shielding, the most cost-effective approach is to use a combination 2 of circuit suppression/hardening and shielding. www.lairdtech.com

Fabric-Over-Foam and Conductive Foam Wire Mesh Tape Applications • Shielding or grounding of computer and • Covers opened infrequently for servicing • Design flexibility provides grounding and telecommunication equipment seams (6-12 times per year) shielding solutions for I/O shielding panels, and apertures • Long lasting resiliency is ideal for highly disk drive insulators, ground planes or circuit sensitive components in permanent or boards, electromedical devices, keyboard semi-permanent enclosures devices • Consistent point-to-point contact for high • Mask-and-peel tape for painted electronic shielding effectiveness over the life of the enclosures gasket • Cable and wire harness wrapping Features and Benefits • UL 94VO and HB flame retardant • Most economical gasket for low-cycling • Simple installation Product Highlights • Ideal for applications requiring low applications • Ideally suited for thin or low-profile pressure force • High shielding effectiveness over broad applications • Self-terminating cut-to lengths frequency range • Conductive foil tape with release mask for • High conductivity and shielding attenuation • Available in wide variety of sizes and shapes painted enclosures • Galvanically-compatible with most mating • Knit construction for long lasting resiliency • Tin copper cloth and nickel copper cloth surfaces • Versatile mounting options versions provide easy-to-handle alternatives • High abrasion and shear resistance • Available with elastomer gasket for moisture to foils and dust sealing Electrical Shielding >85 dB 90 - 105 dB — Effectiveness Transfer Impedance (500 MHz) H-field (200 MHz) 30 - 45 dB 55 - 65 dB — Modified Mil 285 Plane Wave (2 GHz) 90 - 100 dB 80 - 115 dB 85 - 95 dB Modified Mil 285 Surface Resistivity <0.07 ohms/square N/A Low surface resistivity based on material selection Volume Resistivity N/A 0.0004 - 0.114 ohm-cm N/A Mechanical Height: 0.015 - 0.945 (0,038 - 24,0) Height: 0.062 - 0.500 (1,57 - 12,7) Width: 0.025 - 2.00 (6,4 - 50,8) Available Size Range Thickness: 0.003 - 0.007 (0,08 - 0,18) Deflection Operating Range 20 - 75% deflection 20 - 70% deflection N/A Compression Force 3 - 10 Ibs/in. ft. (4,5 - 15,0 Kg/m) From 6 - 50 Ibs/in. ft. N/A (based on shape selection) @ 20% deflection (dependent on foam (8,8 - 74 Kg/m) round selection and shape) Compression Set <4 - 20% @ 50% deflection 10% @ 20% compression N/A Joint Unevenness 0.020 - 0.050 (0,51 - 1,27) 0.010 - 0.300 (0,25 - 7,6) N/A Accommodation Compound/Material Cover: Flame retardant metallized Ni/Cu, BeCu, Monel, aluminum, tin-plated steel, Tin-plated copper, copper foil, nickel copper Availability Tin/Cu and silver woven or non-woven textile. tin-plated brass, Enviroseal version with cloth tape Core: Flame retardant urethane, TPE neoprene or silicone Temperature Range -40 - 158°F (-40 - 70°C) Enviroseal -103 - 500°F (-75 - 260°C) 50 - 500°F (10 - 260°C) based on material selection Available Profiles Round, rectangular, square “D”, “C”, “J”, “P”, Round, rectangular, square, single-round with Rolls “U”, clip-on, knife edge fin, double-round with fin Mounting Methods Groove, PSA, clip-on, dart Groove, pressure-sensitive adhesive, Pressure-sensitive adhesive, conductive or mechanical fasteners, channel mount non-conductive Custom Shapes Available Cut-to lengths, mitered and spliced corners, Cut-to lengths, mitered corners, flat tape, and Die-cut shapes kiss-cut, other profiles EMI washers Environmental N/A Enviroseal product only: moisture, rain N/A Fluid Seal Air/Dust Provides barrier against dust Enviroseal product only N/A Galvanic Compatibility Compatible with a wide variety of mating Variety of platings to ensure galvanic Wide variety of materials available to meet surfaces—zinc, aluminum, stainless steel, etc. compatibility with mating surface galvanic compatibility requirements 3 wwwwww..llaaiirrddtteecchh..ccoomm

Fingerstock Board-Level Shields Vent Panels and Filters Form-In-Place Electrically Conductive Elastomers Oriented Wire Microwave Absorbers Applications • Ideal for high-cycling applications requiring • All applications that require shielding of • Provides air flow for component cooling and a barrier to • Ideal for applications with miniature • EMI and environmental sealing applications • Providing both EMI shielding and an • Antenna sidelobe reduction frequent access board- level components reduce RF leakage electrical housings, thin wall where flat or groove mounting surface re- environmental seal on cast or machined • Surface current suppression • Ideal in wiping applications when gasket needs • Low height down to 0.04 (1,0) • Sizes range from small muffin fans on desktops to large construction, and intricate multi- quires a complex molded or extruded shape surfaces • Applied directly to the top of high-speed to be engaged from either the top or side accommodating mother/daughter board room-size facilities components (i.e., cell phones, hand- • Vulcanized frame configurations can be CPUs, LSIs, and ICs • Wide variety of profiles and mounting methods configurations • Available in commercial and military grade materials held devices, medical instrumentation used with pre-cast housings, vent panels, • Crosstalk suppression accommodating applications from small hand- • Secure cover design ideal for applications and equipment) and computer terminal window frames • Improves antenna gain in RFID held devices to room-size enclosures subject to shock and vibration such as • Die-cut wall widths as low as 0.090 applications mobile military vehicles, commercial aircraft, (2,27) for circular military connectors • Radar cross-section reduction and wireless electronics and D-sub connectors Features and Benefits • Large selection of sizes and shapes • Custom shapes available • Available in a wide range of materials and platings • Automated process offers cost savings • Meets military and commercial standards • Provides both EMI and moisture seal • Higher frequency use than traditional shielding Product Highlights • Wide mechanical operating range • Provides isolation of board-level that meet a broad range of shielding effectiveness on raw material, labor and assembly time • Provides EMI and environmental shielding • Available in sponge or solid silicone with • Frequency range extended used with other • Superior performance at elevated temperatures components requirements • Small dimension which provide critical • Extruded shapes ideal for extremely narrow Monel or aluminum wire shielding • High shielding effectiveness levels • Minimizes crosstalk and susceptibility • Varied mounting configurations meeting packaging space for board level mounting surfaces • Can be die-cut in complex shapes • Variety of types for custom solutions • Ideal for high-cycle applications without impacting system speed environmental space criteria components • Custom die-cut and molding available • Monel wire bonded into the silicone • Easy installation into noisy cavities • Good design flexibility with either wiping action • Available in tape-and-reel for automated • Available protective grille for high traffic areas • Fast prototyping and turn over to mass • Wide variety of material compounds for provides multiple spring effect with each with pressure-sensitive adhesive or in compression pick-and-place applications • Provides cooling of electronic equipment while production galvanic compatibility to mounting surfaces contact point resulting in low compres- • EMI and radar cross-section reduction • For use in a wide variety of slotted and • ReCovr/ReMovl features available for maintaining EMI integrity of enclosure • Various bead size and cross section • High corrosion-resistant compounds available sion set • Internal EMI and cavity resonance reduction, grounding contact applications convenient component access. • MaxAir vent panels offer 10-20% additional airflow shape available used in conjunction with board-level shielding over frames Al vent panels • Dispense on metal or plastics Electrical Shielding 80 - 100 dB — — 85 - 120 dB 40 - 105 dB 60 - 100 dB N/A Effectiveness Transfer Impedance (500 MHz) H-field (200 MHz) 60 - 70 dB 48 dB 40 - 70 dB 50 - 70 dB 30 - 75 dB 25 - 60 dB N/A Modified Mil 285 Plane Wave (2 GHz) 75 - 120 dB 40 - 60 dB 45 - 115 dB 70 - 100 dB 40 - 120 dB 30 - 95 dB N/A Modified Mil 285 Surface Resistivity N/A N/A N/A N/A N/A N/A N/A Volume Resistivity N/A N/A N/A 0.002 - 0.03 ohm-cm 0.002 - 5 ohm-cm 0.006 ohm-cm N/A Mechanical Selection of various sizes and configurations Fence and lid: 0.130 - 1.00 (3,3 - 25,4) height Thickness: 0.25 - 0.500 (6,35 - 12,7) Height: 0.014 - 0.090 (0,36 - 2,3) Sheet: 0.020 (0,51) - 0.125 (3,17) thick Thickness: 0.032 - 0.250 (0,81 - 6,35) Offered in sheets as a die-cut or kiss-cut Available Size Range to accommodate gaps from 0.010 - 0.400 6.000 (152,4) width Width: 0.020 - 0.125 (0,5 - 3,1) O-strip: 0.040 (1,02) - 0.250 (6,35) dia. component (0,25 - 10,2) One-piece construction: 0.04 - 0.25 (1,0 - 6,4) O-tubing: 0.090 (2,28) O.D. x 0.050 (1,27) I.D. height, 0.250 - 0.375 (6,35 - 9,53) width to 0.4371 (11,10) O.D. x 0.250 (6,35) I.D. Deflection Operating Range 20 - 80% deflection, N/A N/A 15 - 20% deflection Sheet: 10% deflection 10 - 20% deflection N/A Maximum deflection is dependent on the part Solid extrusions: 10 -25% deflection profile Hollow extrusions: 20 - 50% deflection Compression Force UltraSoft® 98 Series: 1.6 Ibs/in. ft. N/A N/A 1.5 Ibs/in. ft. (0,27 Kg/cm) @ Sheet: 75 - 100 PSI (516,7 - 689 kPa) 25 - 100 PSI N/A (based on shape selection) (2,4 Kg/m) to 41 Ibs/in. ft. (61 Kg/m) 0.222 (0,56) height @ 20% deflection (125 - 689 KPa) Standard 97 Series: 3.1 Ibs/in. ft. (4.6 Kg/m) to 118 Ibs/in. ft. (176 Kg/m) Compression Set None within operating range N/A N/A <20% @ 50% deflection 15 - 50% @ 50% deflection 2 - 5% @ 50 PSI (344,5 KPa) N/A Joint Unevenness 0.003 - 0.350 (0,08 - 8,89) maximum N/A N/A 0.002 - 0.006 (0,05 - 0,15) Sheet: 0.005 - 0.010 (0,13 - 0,25) 0.005 - 0.015 (0,13 - 0,38) N/A Accommodation Tubing: 0.005 - 0.300 (0,13 - 7,6) Compound/Material Standard material is Beryllium Copper, other Tin-plated phosphor bronze, tin-coated steel, Gasket material: Monel, tin/copper/steel, BeCu, Elastomer silicone fillers: Ag/Al, Ag/ Compounds that meet MIL-G-83528: Elastomer: solid or sponge silicone Microwave absorbing elastomers (Q-Zorb) Availability beryllium free variants on request stainless steel, brass, BeCu, and nickel silver; metallized fabric-over-foam Cu, Ag/Ni, Ni/graphite Elastomers: silicone, fluorosilicone, EPDM Wire: Monel, aluminum are offered in silicone; microwave absorber other materials also available Fingerstock frame: aluminum alloy, steel, brass Fillers: Ag, Ag/Cu, Ag/Al, Ag/Ni, Ag/Gl, CAR, foam is urethene-based, open-celled foam Honeycomb material: aluminum, steel, brass, Ni/graphite. metallized polymeric Available in NASA-specified ES75 compounds for outgassing Temperature Range Continuous operation @ 250°F (121°C) Withstands reflow and solder temperature N/A -58 - 212°F (-50 - 100°C) -67 to 302°F (-55 to 150°C) 80 - 500°F (26 - 260°C) Q-Zorb: -85 - 350°F (-65 - 175°C) RF foam: -85 - 250°F (-65 - 120°C) Available Profiles Over 350 standard shapes available, as well Squares, rectangles, L-shapes, 90° inside N/A “D” shape bead Solid extrusions: rectangular, round ,“D”, and U-channel Rectangular, strip, flat sheets; die-cut Q-Zorb thickness: 0.006 - 0.375 (0,15 - 9,53) as cut-to lengths and modified standards that corners, and other custom shapes Hollow extrusions: square, round, “D”, “P”, modified shapes RF Foam thickness: 0.125 - 0.250 (3,18 - 6,35) include finger removal, notches, punch holes, etc. standards, cut-to length sheets Mounting Methods Clip-on, Sticky Fingers® (pressure-sensitive Surface mount/thru-hole, various pin styles Captive fastener thru-holes Directly applied to mounting surface Groove, pressure-sensitive adhesive, channel Groove, pressure-sensitive adhesive Pressure-sensitive adhesive adhesive tape), rivet, weld, solder, and slot mount available clip- on, mechanical fastening Custom Shapes Available Custom designs to meet specific applications Flexible fence with flat lid, photo etched Available in circular configurations and Infinite variety of patterns and larger Large variation on extruded shapes, complex Complex die-cut shapes, bonded or Infinite die-cut shapes and molded parts flat blanks for hand forming, solid can custom shapes custom bead sizes die-cuts, and molded parts vulcanized construction, supplied with dividers to provide isolation Environmental None N/A Drip-proof versions available Moisture, rain seal Moisture, rain, jet fuel, and nuclear biological Moisture and rain Moisture, rain, jet fuel, and nuclear Fluid Seal chemical (NBC) UL compounds biological chemical (NBC) UL compounds Air/Dust Limited to twist series with Poron seal N/A 95% open area for minimal pressure drop In limited applications Excellent sealing against air and dust Provides barrier against dust Available in limited applications Galvanic Compatibility Over 20 plating finishes available to ensure Compatible with all solder materials Gasket materials compatible with wide variety of Available in four compounds to provide 21 standard variations Monel and aluminum wire are compatible Moisture, rain, jet fuel, and nuclear galvanic compatibility with mating surface plated surfaces galvanic compatibility with most mating with a broad range of mating surfaces biological chemical (NBC) UL compounds 4 materials www.lairdtech.com

Fingerstock Board-Level Shields Vent Panels and Filters Form-In-Place Electrically Conductive Elastomers Oriented Wire Microwave Absorbers Applications • Ideal for high-cycling applications requiring • All applications that require shielding of • Provides air flow for component cooling and a barrier to • Ideal for applications with miniature • EMI and environmental sealing applications • Providing both EMI shielding and an • Antenna sidelobe reduction frequent access board- level components reduce RF leakage electrical housings, thin wall where flat or groove mounting surface re- environmental seal on cast or machined • Surface current suppression • Ideal in wiping applications when gasket needs • Low height down to 0.04 (1,0) • Sizes range from small muffin fans on desktops to large construction, and intricate multi- quires a complex molded or extruded shape surfaces • Applied directly to the top of high-speed to be engaged from either the top or side accommodating mother/daughter board room-size facilities components (i.e., cell phones, hand- • Vulcanized frame configurations can be CPUs, LSIs, and ICs • Wide variety of profiles and mounting methods configurations • Available in commercial and military grade materials held devices, medical instrumentation used with pre-cast housings, vent panels, • Crosstalk suppression accommodating applications from small hand- • Secure cover design ideal for applications and equipment) and computer terminal window frames • Improves antenna gain in RFID held devices to room-size enclosures subject to shock and vibration such as • Die-cut wall widths as low as 0.090 applications mobile military vehicles, commercial aircraft, (2,27) for circular military connectors • Radar cross-section reduction and wireless electronics and D-sub connectors Features and Benefits • Large selection of sizes and shapes • Custom shapes available • Available in a wide range of materials and platings • Automated process offers cost savings • Meets military and commercial standards • Provides both EMI and moisture seal • Higher frequency use than traditional shielding Product Highlights • Wide mechanical operating range • Provides isolation of board-level that meet a broad range of shielding effectiveness on raw material, labor and assembly time • Provides EMI and environmental shielding • Available in sponge or solid silicone with • Frequency range extended used with other • Superior performance at elevated temperatures components requirements • Small dimension which provide critical • Extruded shapes ideal for extremely narrow Monel or aluminum wire shielding • High shielding effectiveness levels • Minimizes crosstalk and susceptibility • Varied mounting configurations meeting packaging space for board level mounting surfaces • Can be die-cut in complex shapes • Variety of types for custom solutions • Ideal for high-cycle applications without impacting system speed environmental space criteria components • Custom die-cut and molding available • Monel wire bonded into the silicone • Easy installation into noisy cavities • Good design flexibility with either wiping action • Available in tape-and-reel for automated • Available protective grille for high traffic areas • Fast prototyping and turn over to mass • Wide variety of material compounds for provides multiple spring effect with each with pressure-sensitive adhesive or in compression pick-and-place applications • Provides cooling of electronic equipment while production galvanic compatibility to mounting surfaces contact point resulting in low compres- • EMI and radar cross-section reduction • For use in a wide variety of slotted and • ReCovr/ReMovl features available for maintaining EMI integrity of enclosure • Various bead size and cross section • High corrosion-resistant compounds available sion set • Internal EMI and cavity resonance reduction, grounding contact applications convenient component access. • MaxAir vent panels offer 10-20% additional airflow shape available used in conjunction with board-level shielding over frames Al vent panels • Dispense on metal or plastics Electrical Shielding 80 - 100 dB — — 85 - 120 dB 40 - 105 dB 60 - 100 dB N/A Effectiveness Transfer Impedance (500 MHz) H-field (200 MHz) 60 - 70 dB 48 dB 40 - 70 dB 50 - 70 dB 30 - 75 dB 25 - 60 dB N/A Modified Mil 285 Plane Wave (2 GHz) 75 - 120 dB 40 - 60 dB 45 - 115 dB 70 - 100 dB 40 - 120 dB 30 - 95 dB N/A Modified Mil 285 Surface Resistivity N/A N/A N/A N/A N/A N/A N/A Volume Resistivity N/A N/A N/A 0.002 - 0.03 ohm-cm 0.002 - 5 ohm-cm 0.006 ohm-cm N/A Mechanical Selection of various sizes and configurations Fence and lid: 0.130 - 1.00 (3,3 - 25,4) height Thickness: 0.25 - 0.500 (6,35 - 12,7) Height: 0.014 - 0.090 (0,36 - 2,3) Sheet: 0.020 (0,51) - 0.125 (3,17) thick Thickness: 0.032 - 0.250 (0,81 - 6,35) Offered in sheets as a die-cut or kiss-cut Available Size Range to accommodate gaps from 0.010 - 0.400 6.000 (152,4) width Width: 0.020 - 0.125 (0,5 - 3,1) O-strip: 0.040 (1,02) - 0.250 (6,35) dia. component (0,25 - 10,2) One-piece construction: 0.04 - 0.25 (1,0 - 6,4) O-tubing: 0.090 (2,28) O.D. x 0.050 (1,27) I.D. height, 0.250 - 0.375 (6,35 - 9,53) width to 0.4371 (11,10) O.D. x 0.250 (6,35) I.D. Deflection Operating Range 20 - 80% deflection, N/A N/A 15 - 20% deflection Sheet: 10% deflection 10 - 20% deflection N/A Maximum deflection is dependent on the part Solid extrusions: 10 -25% deflection profile Hollow extrusions: 20 - 50% deflection Compression Force UltraSoft® 98 Series: 1.6 Ibs/in. ft. N/A N/A 1.5 Ibs/in. ft. (0,27 Kg/cm) @ Sheet: 75 - 100 PSI (516,7 - 689 kPa) 25 - 100 PSI N/A (based on shape selection) (2,4 Kg/m) to 41 Ibs/in. ft. (61 Kg/m) 0.222 (0,56) height @ 20% deflection (125 - 689 KPa) Standard 97 Series: 3.1 Ibs/in. ft. (4.6 Kg/m) to 118 Ibs/in. ft. (176 Kg/m) Compression Set None within operating range N/A N/A <20% @ 50% deflection 15 - 50% @ 50% deflection 2 - 5% @ 50 PSI (344,5 KPa) N/A Joint Unevenness 0.003 - 0.350 (0,08 - 8,89) maximum N/A N/A 0.002 - 0.006 (0,05 - 0,15) Sheet: 0.005 - 0.010 (0,13 - 0,25) 0.005 - 0.015 (0,13 - 0,38) N/A Accommodation Tubing: 0.005 - 0.300 (0,13 - 7,6) Compound/Material Standard material is Beryllium Copper, other Tin-plated phosphor bronze, tin-coated steel, Gasket material: Monel, tin/copper/steel, BeCu, Elastomer silicone fillers: Ag/Al, Ag/ Compounds that meet MIL-G-83528: Elastomer: solid or sponge silicone Microwave absorbing elastomers (Q-Zorb) Availability beryllium free variants on request stainless steel, brass, BeCu, and nickel silver; metallized fabric-over-foam Cu, Ag/Ni, Ni/graphite Elastomers: silicone, fluorosilicone, EPDM Wire: Monel, aluminum are offered in silicone; microwave absorber other materials also available Fingerstock frame: aluminum alloy, steel, brass Fillers: Ag, Ag/Cu, Ag/Al, Ag/Ni, Ag/Gl, CAR, foam is urethene-based, open-celled foam Honeycomb material: aluminum, steel, brass, Ni/graphite. metallized polymeric Available in NASA-specified ES75 compounds for outgassing Temperature Range Continuous operation @ 250°F (121°C) Withstands reflow and solder temperature N/A -58 - 212°F (-50 - 100°C) -67 to 302°F (-55 to 150°C) 80 - 500°F (26 - 260°C) Q-Zorb: -85 - 350°F (-65 - 175°C) RF foam: -85 - 250°F (-65 - 120°C) Available Profiles Over 350 standard shapes available, as well Squares, rectangles, L-shapes, 90° inside N/A “D” shape bead Solid extrusions: rectangular, round ,“D”, and U-channel Rectangular, strip, flat sheets; die-cut Q-Zorb thickness: 0.006 - 0.375 (0,15 - 9,53) as cut-to lengths and modified standards that corners, and other custom shapes Hollow extrusions: square, round, “D”, “P”, modified shapes RF Foam thickness: 0.125 - 0.250 (3,18 - 6,35) include finger removal, notches, punch holes, etc. standards, cut-to length sheets Mounting Methods Clip-on, Sticky Fingers® (pressure-sensitive Surface mount/thru-hole, various pin styles Captive fastener thru-holes Directly applied to mounting surface Groove, pressure-sensitive adhesive, channel Groove, pressure-sensitive adhesive Pressure-sensitive adhesive adhesive tape), rivet, weld, solder, and slot mount available clip- on, mechanical fastening Custom Shapes Available Custom designs to meet specific applications Flexible fence with flat lid, photo etched Available in circular configurations and Infinite variety of patterns and larger Large variation on extruded shapes, complex Complex die-cut shapes, bonded or Infinite die-cut shapes and molded parts flat blanks for hand forming, solid can custom shapes custom bead sizes die-cuts, and molded parts vulcanized construction, supplied with dividers to provide isolation Environmental None N/A Drip-proof versions available Moisture, rain seal Moisture, rain, jet fuel, and nuclear biological Moisture and rain Moisture, rain, jet fuel, and nuclear Fluid Seal chemical (NBC) UL compounds biological chemical (NBC) UL compounds Air/Dust Limited to twist series with Poron seal N/A 95% open area for minimal pressure drop In limited applications Excellent sealing against air and dust Provides barrier against dust Available in limited applications Galvanic Compatibility Over 20 plating finishes available to ensure Compatible with all solder materials Gasket materials compatible with wide variety of Available in four compounds to provide 21 standard variations Monel and aluminum wire are compatible Moisture, rain, jet fuel, and nuclear galvanic compatibility with mating surface plated surfaces galvanic compatibility with most mating with a broad range of mating surfaces biological chemical (NBC) UL compounds 5 materials www.lairdtech.com All dimensions are in inches (millimeters) unless otherwise specified.

EMI ESSENTIALS BOARD LEVEL SHIELDS PRODUCT SELECTION GUIDE Corner Feature Unique Product Mounting Features Size & Shape Features Traditional Rigid Full Drawn Full Drawn ReMovl Pick & SMT Thru Hole Pins, Tabs, Interior Typical Low Height Typical Flatness Folded Corner w/ Flange Zero Flange Place Bridge Castellations Loc Pins Etc. Walls Material (less than 2 Length (Size Dep) Thickness mm) & Width Improves Flatness Most mechanically rigid, Similar to Full Easy removal of pick Through hole style by increasing but depth attainable is Drawn, Tooling and place bridge for pin that engages torsional rigidity material and configuration more complex. post reflow inspection to underside of BLS Design Key Attributes & dependent PCB by mechanical Type / Features Application Consideration engagement. SINGLE PIECE Single Piece Simple low cost BLS Solution Opt Std Opt (height/matl limits) Opt N/A Std Opt Opt No 0.2 Yes 10- 75 mm 0.08 TWO PIECE Traditional Post Reflow Component Access for inspect, test, cleaning, etc. Various Frame cover retention features available Opt Std Opt (height/matl limits) Low Height Opt Std Opt Opt Opt 0.2 Yes 10- 75 mm 0.08 to address rattling, EMI, and shock/ Option vibration concerns. Cover Std Opt Opt (height/matl limits) N/A N/A N/A N/A N/A N/A 0.15 Yes 10- 75 mm 0.15 Optional pre-assembled deliverable ReCovr Lower total cost 2 piece solution. N/A Req'd N/A N/A N/A Std N/A Opt No 0.3 No 10-40 mm 0.1 Eaveless side wall for maximum component access. EZ Peel Support for legacy products. Std N/A Opt N/A Std N/A Opt No 0.12 Yes 10-30 mm 0.1 ReCovr can often be a more reliable alternative. EZ Peel can utilize a separate replacement cover if desired. 97-2000 Large BLS Applications. Can accommodate internal walls for Frame N/A N/A N/A N/A N/A Std Opt Opt Opt 0.4 No 50-300 mm 0.2 EMI compartmentation. Cover Std N/A N/A N/A N/A N/A N/A N/A 0.25 0.25 No 50-300 mm 0.2 BLS MATERIALS Material Type Description / Specs Comments Cost Position Applications MATRIX CRS, Tin Plated 1010 / 1008 CRS High Permeability Material for low Freq Applications, Very Good Solderability, Best Most common BLS solutions Mitigation options for Tin Whisker Growth, Pre-plated, Bare stamped edges Nickel Silver CA770, CA752 Environmental Performance & Aesthetic Quality, Good Mechanical / Good Hi Performance BLS solutions Strength Properties, Good Solderability, Active Flux may be required (Mechanical & Environmental) Stainless Steel Typical 301 and 316 Series Environmental Performance, Good option for the cover of 2 piece designs Better BLS Covers, Specialty Military Copper Alloys Phosphor Bronze, Beryllium Copper, Brass Can be chosen for unique requirements that integrate spring contacts, Good Specialty BLS applications 6 Typically Plated for Solderability and/or corrosion resistance Integrated Spring Contacts www.lairdtech.com

EMI ESSENTIALS Corner Feature Unique Product Mounting Features Size & Shape Features Traditional Rigid Full Drawn Full Drawn ReMovl Pick & SMT Thru Hole Pins, Tabs, Interior Typical Low Height Typical Flatness Folded Corner w/ Flange Zero Flange Place Bridge Castellations Loc Pins Etc. Walls Material (less than 2 Length (Size Dep) Thickness mm) & Width Improves Flatness Most mechanically rigid, Similar to Full Easy removal of pick Through hole style by increasing but depth attainable is Drawn, Tooling and place bridge for pin that engages torsional rigidity material and configuration more complex. post reflow inspection to underside of dependent PCB by mechanical engagement. Single Piece Simple low cost BLS Solution Opt Std Opt (height/matl limits) Opt N/A Std Opt Opt No 0.2 Yes 10- 75 mm 0.08 Traditional Post Reflow Component Access for inspect, test, cleaning, etc. Various Frame cover retention features available Opt Std Opt (height/matl limits) Low Height Opt Std Opt Opt Opt 0.2 Yes 10- 75 mm 0.08 to address rattling, EMI, and shock/ Option vibration concerns. Cover Std Opt Opt (height/matl limits) N/A N/A N/A N/A N/A N/A 0.15 Yes 10- 75 mm 0.15 Optional pre-assembled deliverable ReCovr Lower total cost 2 piece solution. N/A Req'd N/A N/A N/A Std N/A Opt No 0.3 No 10-40 mm 0.1 Eaveless side wall for maximum component access. EZ Peel Support for legacy products. Std N/A Opt N/A Std N/A Opt No 0.12 Yes 10-30 mm 0.1 ReCovr can often be a more reliable alternative. EZ Peel can utilize a separate replacement cover if desired. 97-2000 Large BLS Applications. Can accommodate internal walls for Frame N/A N/A N/A N/A N/A Std Opt Opt Opt 0.4 No 50-300 mm 0.2 EMI compartmentation. Cover Std N/A N/A N/A N/A N/A N/A N/A 0.25 0.25 No 50-300 mm 0.2 Material Type Description / Specs Comments Cost Position Applications CRS, Tin Plated 1010 / 1008 CRS High Permeability Material for low Freq Applications, Very Good Solderability, Best Most common BLS solutions Mitigation options for Tin Whisker Growth, Pre-plated, Bare stamped edges Nickel Silver CA770, CA752 Environmental Performance & Aesthetic Quality, Good Mechanical / Good Hi Performance BLS solutions Strength Properties, Good Solderability, Active Flux may be required (Mechanical & Environmental) Stainless Steel Typical 301 and 316 Series Environmental Performance, Good option for the cover of 2 piece designs Better BLS Covers, Specialty Military Copper Alloys Phosphor Bronze, Beryllium Copper, Brass Can be chosen for unique requirements that integrate spring contacts, Good Specialty BLS applications Typically Plated for Solderability and/or corrosion resistance Integrated Spring Contacts 7 www.lairdtech.com

EMI ESSENTIALS BOARD LEVEL SHIELDS Whether it’s a one-piece shield, multi-compartmental shield or precision contact, each solution Laird delivers is designed to provide maximum performance within a minimum timeline. Laird produces metal electronic components for surface mount applications in a variety of industries. Laird expertise in a number of key areas ensures that the part provided not only performs, but also optimizes applications. After determining the right board level shield or contact design for an application, Laird experts use the latest systems to develop part designs in just hours. Laird experienced engineers and technical specialists look beyond the component to the total application. They work with you to engineer the ideal finished product at the best value. 8 www.lairdtech.com

EMI ESSENTIALS BOARD LEVEL SHIELDS STANDARD DESIGN SHIELDS STANDARD SURFACE MOUNT SHIELDS — ONE-PIECE Off the Shelf, On Spec and On Budget Standard surface mount shields are available in both one-piece and two-piece designs. One-piece shields offer six sides of protection, with the sixth side being the board itself. One-piece designs offer economical shielding protection where access to covered components is not necessary. There are no tooling costs associated with either the one and/or two-piece standard design. TYPICAL PROPERTIES AND PERFORMANCE ALL PART NUMBERS Features and Benefits: • Available in both one-piece PROPERTY TEST METHOD RESULT and two-piece designs Co-planarity LTWI-1119 < 0.10 mm • One-piece designs offer economical Solderability ANSI/JSTD-002 >99% shielding protection • No tooling costs associated with one Solderability MIL-STD-202 Method 208 >99% or two-piece standard designs Surface mount solderability ANSI/EIA 638 Passes Appearance LTIES-125 Passes Adhesion ASTM B-571 Passes 3 Axis mechanical shock LTES-461 Passes STANDARD ONE-PIECE BOARD LEVEL SHIELDS PART MAXIMUM MAXIMUM MAXIMUM PARTS NUMBER OVERALL OVERALL OVERALL PER REEL LENGTH WIDTH HEIGHT in (mm) in (mm) in (mm) BMI-S-101 .538 .476 .100 1000 (13,66) (12,10) (2,54) BMI-S-102 .650 .650 .142 700 (16,50) (16,50) (3,60) BMI-S-103 1.032 1.032 .200 300 (26,21) (26,21) (5,08) BMI-S-104 1.260 1.260 .236 225 (32,00) (32,00) (6,00) BMI-S-105 1.500 1.000 .236 250 (38,10) (25,40) (6,00) BMI-S-106 1.450 1.326 .200 300 (36,83) (33,68) (5,08) BMI-S-107 1.747 1.747 .384 120 (44,37) (44,37) (9,75) BMI-S-111 1.032 1.032 .079 625 (26,21) (26,21) (2,00) 9 www.lairdtech.com

EMI ESSENTIALS BOARD LEVEL SHIELDS STANDARD DESIGN SHIELDS STANDARD SURFACE MOUNT SHIELDS — TWO-PIECE Reduce Board Damage From Inspection and Repairs Two-piece board level shields offer users the flexibility to inspect or repair shielded components without having to risk board damage by removing the entire shield or incur any tooling costs. Covers snap on and off with ease, which makes repair of the component under the shield quicker and easier and reduces board re-work. Two-piece shields are available unassembled*, and are designed to survive drop, shock and no-rattle tests. *Pre-assembly is an option. Consult sales STANDARD TWO-PIECE BOARD LEVEL SHIELDS Features and Benefits: PART OVERALL OVERALL OVERALL PARTS NUMBER LENGTH WIDTH HEIGHT PER REEL • Offers flexibility to inspect in (mm) in (mm) in (mm) or repair shield components without risking board BMI-S-201-F .538 .476 .100 1000 damage (13,66) (12,10) (2,54) • Covers snap on and off BMI-S-202-F .650 .650 .142 700 with ease (16,50) (16,50) (3,60) BMI-S-203-F 1.032 1.032 .200 300 (26,21) (26,21) (5,08) BMI-S-204-F 1.260 1.260 .236 225 (32,00) (32,00) (6,00) BMI-S-205-F 1.500 1.000 .236 250 (38,10) (25,40) (6,00) BMI-S-206-F 1.450 1.326 .200 300 (36,83) (33,68) (5,08) BMI-S-207-F 1.747 1.747 .384 120 (44,37) (44,37) (9,75) BMI-S-209-F 1.156 0.728 .275 400 (29,36) (18,50) (7,00) BMI-S-210-F 1.732 1.201 .118 370 (44,02) (30,50) (3,00) BMI-S-230-F 1.500 2.000 .200 250 (38,10) (50,80) (5,08) BMI-S-230-F-R 1.500 2.000 .200 250 (38,10) (50,80) (5,08) BMI-S-305 1.500 1.000 .236 250 (38,10) (25,40) (6,00) DESIGN PARAMETERS – ALL PART NUMBERS PICK-UP SPOT MATERIAL THICKNESS MATERIAL DIAMETER MATERIAL CARRIER TAPE 6 mm or greater 0,20 mm CRS Tin, Nickel Silver, 300 Series SS 0,20 mm LTIMS-LCB COVER TAPE MATERIAL REEL DIAMETER LTIMS-PSA 330 mm (101, 102, 103, 104, 201, 202, 203, 204) Plastic EIA-481 381 mm (105, 106, 107, 205, 206, 207) 10 www.lairdtech.com

EMI ESSENTIALS BOARD LEVEL SHIELDS EZ PEEL™ PATENTED SHIELDS ARE SCORED TO ALLOW PEEL-OFF WHEN ACCESS IS NEEDED These patented shields have a solid top, scored to allow peel-off when access to board level components within the shield is required. The peel-off feature prevents damage to the board and components by eliminating the need for labor intensive de-soldering, which can often result in increased scrap. Peeling off the cover is accomplished by using a small starter hole for simple removal. This hand operation requires minimal force using a hook scriber or tweezers. Features and Benefits: After repair, replacement or adjustment of internal components, the shield can be resealed using a replacement • Easy removal of scored cover area cover. Laird offers two replacement cover options: a snap-in cover and a dish cover. • Only requires 1.5 lbs force for The snap-in cover utilizes a lance and hole design. The replacement cover snaps into place and locks into a lance cover removal feature on the frame of the original shield. • Simple replacement technique The other option is a dish cover that gets soldered into place on the board. The dish shape allows for self-location for cover of the cover for soldering. • Use on surface mount or through-hole applications EZ Peel board level shields can be packaged in tape and reel formats for easy SMT installation using conventional • Shield retains all physical pick-and-place equipment. The four standard sizes are also available without the EZ Peel (scored) feature. properties after PCMCIA/JEIDA testing for shock, bending, torque, drop and vibration • CRS 1008/1010 (tin plated) for solderability RIGID CORNER The rigid corner board-level shield incorporates a corner design that optimizes component rigidity for increased part and printed circuit board (PCB) firmness. As PCB designers are increasingly using thinner substrates, a rigid frame reinforces the assembly, thereby improving overall ruggedness and performance. The shield has improved solder joint reliability and resistance to solder joint fracture, especially in drop testing performance with thin PCBs. Several standard Laird EMI style parts including single-piece, two-piece, and multi-compartmental board-level shields use this new rigid corner design, along with availability in custom sizes as well. The rigid corner shield is stronger and more robust than traditional formed shields, which results in coplanarity improvement of the solder castellations. The shield can tolerate more deflection (i.e., more handling) without plastic deformation. Elimination of drawn flange reduces the space needed on the PCB for shielding trace width by potentially ~0.3 mm, allowing for the shield to be more closely placed on the PCB. Elimination of draft allows for more undershield space and improved component clearance. The partially drawn corner is located near the top portion the shield, resulting in improved torsional rigidity with no drawn lip and no draft. For parts over 2 mm, the corner is both drawn and formed with an interlocking multi-radius corner, which provides superior EMI shielding effectiveness. The interlocking corner can be meshed and closed in during the forming and drawing process for additional improved rigidity for parts taller than 2 mm. For parts under 2 mm, the entire corner is drawn without an interlocking corner. FEATURES MARKETS • Corner openings are reduced, • Computing improving shielding performance • Telecommunications • Partially drawn corner located near the top • Data Transfer and Information portion of the corner combined with 90° Technology straight forming of wall sections for improved • Automotive torsional rigidity. • Consumer Electronics • U.S. Patent No. 7,488,902 • Aerospace / Defense • Medical • Portability • Industrial & Instrumentation • Public Utilities 11 www.lairdtech.com

EMI ESSENTIALS BOARD LEVEL SHIELDS RECOVR™ The proprietary and patented ReCovr™ product line incorporates the functionality of a two-piece shield without the need for a separate frame and cover. The shield is specially designed with a locking mechanism that allows for easy removal of the shield cover when access to board-level components is required. The locking mechanism makes repair of components under the shield quick and easy by eliminating the need for removing the entire shield and reducing board re-work. The removable top shield also integrates Laird patented rigid corner board-level shield technology, which incorporates a new corner design that optimizes component rigidity for increased part and printed circuit board (PCB) firmness. 8 7 6 5 4 3 2 1 FEATURES MARKETS OR APPLICATIONS REV. DESCRIPTIROENVISIONS DATE APPROVED RSOEMLDOEVRA TBOL EB OLIDA RADFTER A INITAL RELEASE 06/28/2010 MF • S ingle-piece board-level shield with a removable • Computing D D top cover • Telecommunications / Datacom • Eave-less side walls when the cover is removed • Automotive 2.35 .093 4.05 5.00 TYP • SMT or through-hole pin configurations available • Consumer Electronics .159 .197 • U.S. Patent No. 7504592 8• SMART Met7ering 6 5 4 3E 2REV. DESCRIPTIROENVISIONS 1DATE APPROVED R.003.39 • Oh othlee rp achttaerrancst,e craissttiecsll atytipoincas,l ttroa coen cel-epaieracnec seh nieoldtcsh: evse,Dn ett c. •• AMeerdoiscpaalce / Defense C 5.1.092.107.7006 TYP RSOEMLDOEVRA TBOL EB OLIDA RADFTER 215..040000X A INITAL RELEASE 06/28/2010 MF D RMEACXOIMVURM SC SOHERAER L IRNEEQUIRED C 2.41 BENEFITS • Industrial & Instrumentation .095 • Eliminates need for replacement covers 4.1.0559 .51.9070 TYP .029.336 TYP 2.30.839.5310 0 SCDAELTAE I1L0 E : 1 2.0.4915 DETAIL F • Offered as an assembled product only: tape and reel, E 1.500 X R0.9 SCALE 10 : 1 B .033 B • tErxacye plleanckt ,f oorr plaeyreior dpiac ctkesting or rework applicatioCns. 5.02.10.7006 TYP 215..040000 X 6..203060 RMEACXOIMVURM SC SOHERAER L IRNEEQUIRED C F .197 X X • Limited footprint configurations (L-shapes, etc) 2 .525.401 T YP 2.200 TYP .1.00095 0.100 [.0039]ALL SURFACES .087 • Available in select Laird standard board-level sizes or .029.336 TYP 3.00D0E TTYAPIL E 3. .102.100.849015 T YP custom configurations 318..510000 A .11SC8ALE 10 : 1 NOTE: CRITICAL DIMENSIONS ARE DESIGNATED BSYCD AEXLTEA I1L0 F : 1 A B X 6..203060 X Tftnmtdroahooimo kistm3ed eds2 hepdna mols r dde3iwoodcirmnnda ess eweo.od l nn ilenfidso ngtio hrtm inaisos o sngvd dwyeer aeridnl lwld e.iam Rrirnalaweegwtfnae.e isndy3riosgd n sFCHDABmdrdcCRNeAAGloiioWDmsefE epnSIMcNt UeGAvrrlkNaeiI.cNenA MyTtnUA srAoTuesicIHNNoilOnUEodeeDnARinIr Lt ZsiaoEsn D psnno h3uclnyo BSrpeTl pywDaMls .aPo n nAaDcsRd eTIpau eSR saEprasF -eE orll1fRye oEnf No0trlCyo rE5.: UNTXXO...AI..XXXTXXLSNX XEX=:X G R =M= AU = =M N L. 4 A C.3(2 R.I.1EN10:.S0C:H)DE S P3IRGRODNJ AEECNDTG IIONLEN SOLIDWORKSMFIANTISE1HR:I.AF2LU5:B1-L510L.00 00H08% AM/ 1MRIC0DA1RT 0OTTEE NC MTSIRN PTSHEIRCK RTHPCOICHROSK NOCEONSMDS:T P)[ULR.A00OCIN.1T2TL:0 I5(LOBY0EAESDNE0S .P .0ADD0R02ORT)00AC8W]UIMNEGN TPA RDINTIS AFNBCONSULRDOMMCM SPBAEREDATORI O ITP:OLR-NI EEASCTNAO:-YR NOY23T NALT:AOEI1N0I RWLEDADI5T I TRHINEDOC TUTHHETNIC SWO HDRLNOOIMTORCTGEEOLUNOVIEDM :SGAAEEUILNME/TSSTDH. IOHISRT F ACRMEDIWOZAAANENY0TT FI ENOTBI6D:OYN E:/1T NF B2RTA EIOAOP8LMPR/MFO2 V20SEFBDI1Z B0EY: REMOVL™ X 8 7 6 5 4 3 2 1 2.550 TYP 2.200 TYP .100 0.100 [.0039]ALL SURFACES .087 3.000 TYP 3.000 TYP .118 .118 A NOTE: CRITICAL DIMENSIONS ARE DESIGNATED BY X A Ttsoehopela RlreaestMsio odnve lft oaferccahetm uwreeinl lti n aocllfoo trwhpeo f robarrt ieadsug tteoh amef atRetereC dtho dever f taraatcmthaemch iesmn seto.nltd emreedch taon tishme PaCpBp.l iEedas teoTftnmtdroah ooimo kistm3 oed eds2t hepdna molfhs r dde3iwoo dcirmnndaed ess eweo.od l nn il enfeidso ngtpio hrtm t inaisos o singavd dwyceer aeridnlc lwlkd e.iam Rrirhnalaweeugwtfnae.em isndy3rpiosgd n s ebCHDAnBmdrdcCRNerAAGloiioWDmsefE epntSiIMcNt UeGAvrrldkNaei I.cNenA MyTtnUaA srAoTuesicIHgNNoilOnUEodeeDnARlinIr Lt ZsiaoEseno D psnno h3uclny o BSnrpeTl pywDaoMls .aPo n nAaDgcsRd eTIfpau eSR saEpras F -eE orll1fRye awoEnf No0trlCyo rE5 .: iBtUhNTLXXO...AI..XXXTXXLSNX XSEX =:X G R =M=r AU = = M N L. e4 A f C.3(2 R.I.1ENr10:l.S0C:aiHa)mDbE S Ple3IRGReODN J A EEtCNDaoTG IIONLnE N SaOdLlI DlcWoOowRKnS sfMFIANoiTISEs1HR:I.AFr2LtU5: 1-Le510Le.00 00H0n8%a AM/ 1MRtIC0sDA 1RT y0OTTEE NC, MTS IRN PTSHEIRCK RTHPCOICHROSK NOCEONSMDS:T P)[ULR.A00OCIN.1T2TL:0 I5(LOBY0EAESDNE0S .P .0ADD0R02ORT)00AC8W]UIMNEGN TPA RDINTIS AFNBCONSULRDOMMCM SPBAEREDATORI O ITP:OLR-NI EEASCTNAO:-YR NOY23T NALT:AOEI1N0I RWLEDADI5T I TRHINEDOC TUTHHETNIC SWO HDRLNOOIMTORCTGEEOLUNOVIEDM :SGAAEEUILNME/TSSTDH. IOHISRT F ACRMEDIWOZAAANENY0TT FI ENOTBI6D:OYN E:/1T NF B2RTA EIOAOP8LMPR/MFO2 V20SEFBDI1Z B0EY: 8 7 6 5 4 3 2 1 FEATURES MARKETS • Detachment is permanent – cannot be replaced like • Ideal for customer manufacturing processes where ReCovr post reflow detachment of the pickup bridge is required or • Min Height: 2.0 mm (.080”) Lower heights required desired. Applications that often require the bridge to Product Development Review be detached include: • Top Flange Width: 1.8 mm (.071”) – Inspection • Flatness: Part Size Dependent, but typical to other – Rework Frame BLS parts – TIM Assembly into cover • Configurations Min 4 legs/branches required – Cover with contact fingers to chip, etc. (see BLS Style options) – Noise / Vibration concerns of bridge to cover • Limitations: Must be folded or rigid corner type BLS. (No fully drawn parts.) • Pull Force (Typ) 0.5 – 1.0 lbs Note: Due to delicate nature of the attachment of the pickup bridge, there will be some risk to the bridge separating during pick and place operations depending on customer manufacturing processes. Pick and place head depth tolerance (z axis) -.020” 12 www.lairdtech.com

EMI ESSENTIALS BOARD LEVEL SHIELDS INTRODUCTION The complexities of today's electronics pose several design challenges. Resolving EMI needs to be balanced with space, weight and production restraints. When designing a custom shielding solution, beginning in the earliest stages of the application design allows effective elimination of EMI while meeting all specifications. Laird board level shielding experts work through all phases of development. From design, rapid prototyping and pre-production through Series 97-2100 production and automated packaging, Laird has the experience to help speed a product to market and stay within budget. MULTI-COMPARTMENTAL SHIELD DESIGN To increase manufacturing throughout and reduce costs, Laird has developed SHIELD MULTIPLE CIRCUIT GROUPS SAVE PCB SPACE AND PRODUCTION a proprietary in-line production process that includes part TIME formation, wash, assembly, inspection and automated packaging. Multi-compartmental shields feature internal dividing walls of one material By integrating quality processes, board level shield quality and performance is thickness and meet all on-board shield requirements for FCC, VDE, CISPR ensured from design stage through final packaging. One process is the auto- and CE. These shields are available in two-piece designs, either assembled mated co-planarity inspection system. Laird replicates the customer application or unassembled. Our unassembled versions allow for automatic optical by measuring shields in the same plane as the printed circuit board. This is inspection prior to cover placement. As in all our shielding offerings, accomplished without "securing" or "touching" shields, which could throw Laird proprietary process for 100% automatic optical off measurement and/or deform parts. Laird measures shields immediately inspection verifies co-planarity including inner walls. prior to placement into carrier tape at speeds that match automation packing. DRAWN BOARD LEVEL SHIELDS Shield base materials include our exclusive Shield-LiteTM, CRS 1008/1010, SEAMLESS CORNERS ADDRESS HIGH-FREQUENCY LEAKAGE beryllium copper alloys, nickel-silver alloys, copper-based alloys and spring As microprocessor speeds continue to increase, so does the potential for EMI steels. All shields are fully solderable. leakage through the smallest apertures in board level shields. Laird drawn board level shields are designed to provide additional near-field and far-field circuit isolation (attenuation) at higher frequencies by eliminating the apertures found ONE-PIECE SHIELD DESIGN in the corners of traditional board level solutions. Drawn board level shields LOW COST/EXCELLENT EFFECTIVENESS utilize small ground trace sizes, thereby preserving space on the circuit board. Custom surface mount shields are available in both one-piece and • Solid corner designs when additional circuit isolation (attenuation) is two-piece designs. One-piece shields provide six sides of protection, required at higher frequencies with the sixth side being the board itself. One-piece designs offer • Available in custom heights up to .250" (6,4 mm) with length and width economical shielding alternatives where access to covered components for dimensions from .300" (7,6 mm) to 2.0" (50,8 mm) repair is not necessary. • Tape and reel packaging provides an economical and automated SMT TWO-PIECE SHIELD DESIGN attachment method QUICK, EASY REPAIR AND INSPECTION OF COVERED • Available in cold rolled steel, brass, stainless steel and nickel silver COMPONENTS • Molded Compartment Shields and Form-In-Place elastomers can be Two-piece board level shields offer users the flexibility to inspect or repair combined with drawn board level shields to achieve shielding of shielded components without having to risk board damage by removing multiple components with a single part the entire shield. Covers snap on and off with ease, making repairs quicker • Available with an EZ Peel scored cover feature; allows for easy top and easier, and reducing board re-work. Two-piece shields are available section removal for component repair and re-sealing pre-assembled or unassembled. Large locking dimples snap into slots on • Ventilation holes as needed for solder outgassing. covers to provide mechanical retention force. Smaller grounding dimples provide electrical grounding for proper shielding and to prevent rattle. • Online shielding effectiveness calculator Two-piece shields survive drop, shock and no-rattle tests. Here are critical test results: SURFACE MOUNT SHIELDS MATERIAL VARIATIONS • Able to withstand acceleration of 4g from 10 Hz to 2000 Hz for three hours in each of three planes as per SAE J1455 RAW MATERIAL* THinIC (KmNmE)SS COMMENTS • Pass EN 50 155 for railway electrical equipment including vibration test Col1d0 R0o8l/l1e0d 1S0teel 0.005 ttoo 02.,029806 )(0,127 Pre-plated Tin of 30g from 5 Hz to 200 Hz in 3 directions and a shock test with 500 m/s for 11/ms Nickel-silver alloys (00.,010042 ttoo 00.,041066 ) No psolaflodtiren rgSaM breiTlqi t uyired • Pass standard telecommunications drop tests [6 faces, dropped 1 meter onto concrete floor] Phosphor Bronze alloys (00.,010040 ttoo 00.,052100 ) Pre-tempered & Preplated Notice: The data set forth in all text, tables, charts, graphs and figures herein are based on samples tested and are *Other materials may be available, please consult sales. not guaranteed for all samples or applications. Such data are intended as guides and do not reflect product Note: Co-planarity dependant on design specification for any specific part. Material properties are for reference only. Product testing by purchaser is recommended to 13 confirm. Laird assumes no liability for product failure unless specifically stated in writing. www.lairdtech.com

EMI ESSENTIALS FINGERSTOCK PRODUCT SELECTION GUIDE Application Type Enclosure Shielding Continuous Length Std. Contact Strips Gaskets & Contact (Coil Products) Reverse Bend Strips Contact Strips Double Sided Contact Strip Twist Series Fixed Length Strips Tape Mount Fold Over Series Low Profile Low Profile with Mini-Clip On Edge Hook Clip-On Mount Symmetrical Large Enclosure Twist Std Contact Strips Contact Strips Reverse Bend Reverse Bend Contact Strips Contact Strips Double Sided Longitudinal Contact Strip Contacts All Purpose Perpendicular / S3 - Solid Top, PCB Edge Contact Symmetrical, Slotted No-Snag Track Mount Brass Track with Rivet Mount Direct to Chassis / Slot Mount Stainless Track Extrusion Mount Compact PCI - Stainless Track w/ Dot 10 Integral rivet Variable Slot Mount Internal Contact Contact Rings External Contact D-Sub Enclosure & PCB I/O's Back Plane DIN Connector Gaskets USB IEEE 1394 Fiber Optic GBIC SFP/XFP Contact / Grounding SMT 14 www.lairdtech.com

EMI ESSENTIALS FINGERSTOCK Engineered metal Fingerstock solutions from Laird dates from 1938. Laird specializes in designing miniature parts of thin strip metal in quantities ranging from thousands of pieces to millions of pieces. With over 3,400 standard parts, Laird probably already has an off-the- shelf solution that meets your application’s requirements. When custom designs are needed, Laird engineering staff helps construct efficiencies in performance, cost and manufacturability from the very beginning stages of the application. Laird specialized capabilities: • Assembly • Heat staking (both hand and automatic) • Heat treating • In-house die and fixture manufacturing • Multislide equipment • Photoetching • Plating • Progressive die stamping • Prototype fabrication • Resistance welding • Riveting • Secondary fabrication • Wire EDM 15 www.lairdtech.com

EMI ESSENTIALS FINGERSTOCK MOUNTING METHODS UNIVERSAL MOUNTING A stainless steel mounting track is available for use with our full line of gasketing materials. Its unique design offers a secure mounting option versatile enough for use with fingerstock, ElectroNit® mesh, ElectroSeal elastomers, UltraSoft® Knit and fabric-over-foam products. PART NUMBER WIDTH 0.356 X = TMHAICTKENRIEASLS (9.042) 0095-X996-00 0.310 (7.874) 0.205 0.205 0095-X997-00 0.430 (10.922) 0.145 (5.207) (5.207) 0.356 (3.683) X = TMHAICTKENRIEASLS (9.042) 0095-X998-00 0.600 (15.240) X = TMHAICTKENRIEASLS (03..164853) (09..305462) (05..220057) (05..220057) (03..164853) (05..220057) (00..041587) DETAIL “A(”05..220057) MAB A==T 00E..R00I43A50L T((10H..I17C46K32N))ESS W XX == TTMMHHAAIICCTTKKEENNRRIIEEAASSLLSS (00..041587) ((0303....161648485353)) SEED DEETATAILI L“ A“A””((0505....22220000((57570909))....303054546262)) ((0505....222200005757)) W 0.018 DETAIL “A” C = 0.060 (1.524) (0.457) SEE DETAIL “A” D = 0.090 (2.286) ((0000....040415158787)) DDEETTAAIILL ““AA”” W SEE DETAIL “A” Universal Mount E = 0.150 (3.810) 0.699 WW SSEEEE DDEETTAAIILL ““AA”” (17.755) 1.500 0.699 To identify proper mounting track, select width and (38.100) (17.755) 1.500 (107.6.79595) ((33117488..5.8.1409000809)) (38.100) cRoerprleascpeo tnhdein “gX p”a wrti tnhu rmeqbueirr efrdo mm athteer iaabl othviec kcnheasrst.. ((110077..6.6.7799559955)) (31748.8.49089) ((3311774488..8.8.4499008899)) ((331188..5.5.1100000000)) 14.898 (378.409) ^ Shielding gaskets may be mounted for either wiping or compression closing applications. Proper positioning of the shielding gasket must take into consideration the closing design and the configuration of the mounting surface. Rivet Mount Slot Mount Laird shielding devices may be mounted quickly and easily using any of several different methods. Each installation method is described in the text that follows. However, if you should run into a unique situation not resolved by any of these methods, give us a call. More than Sticky Fingers® Clip-On Mounting Tape Track Mount likely we can provide the exact answer you need. RIVET MOUNT 4. Allow 24 hours minimum curing time. Riveting produces a tight, long-lasting installation. Either plastic or metal rivets may be used. Standard parts are supplied with nonconductive tape. For rough surface applications, such as flame-sprayed surfaces, 0.010 in. (0.254 mm) thick SLOT MOUNT nonconductive tape is recommended. Optional conductive tape is also available. Slot mounted parts are easily installed using slots where bi-directional movement is required. Contact a sales department representative for additional ordering information. Simply install part into one slot and snap it into the second slot or over the edge of the frame. CLIP-ON MOUNTING ADHESIVE MOUNTING Clip-on gaskets hold firmly in place due to their own spring characteristics. Sticky Fingers® is an instant, pressure-sensitive adhesive bonding system, ideal for all-purpose Simply push the strips onto the edge or flange of the door or enclosure. contact strips for metal cabinets and electronic enclosures, and is unaffected by temperatures Also available are clip-on gaskets with either “T” or “D” lances. from -67 to +250°F (-55 to +121°C). Simply follow these four easy steps: TAPE TRACK MOUNTING 1. Remove all grease and oily residue with solvent. Smooth the mounting surface with emery Stainless Steel mounting track with PSA (pressure sensitive adhesive) is available cloth. on the Symmetrical Slotted Series and Slot Mount Series. 2. Peel off protective paper backing. WELDING 3. Place gasket in correct position. (See mounting methods diagrams A through E.) Press firmly Welded mounting requires simple, traditional welding techniques. to ensure a good adhesive bond. Avoid repositioning, which might impair the effectiveness of SOLDERING the adhesive or may bend or kink the strip. Solder mounting requires normal low temperature soldering techniques, NOTE: On items where fingers cover the solid portion of the gasket, pressure may be applied including cleaning and fluxing of parts with common copper flux materials. 16 by inserting a mandrel in the strip and pressing down. For contact strips with Magnefil® insert, simply press down on the fingers. www.lairdtech.com

EMI ESSENTIALS FINGERSTOCK ORDERING INFORMATION Part Number Format Example: Stock Item Unique Part No. Finish I.D. 0 0 9 7 — 0 5 2 0 — 0 2 • In the above example, Laird part number 0097-0520-02 is a 0.00005 in. (0.0013 mm) min.] but can be varied to meet 97-520 RFI/EMI shielding gasket with a bright finish your custom needs • When ordering UltraSoft® items, the stock item prefix will • Modifications to standard parts are specified by an X be 0098 or 0078. The above example in UltraSoft would be (following finish I.D.) for quoting only. Upon ordering, 0098-0520-02. a specific part number will be assigned. • When ordering coil, the prefix 0C should precede the stock • For tape options, see Adhesive Mounting — Sticky Fingers® item number; for example: 0C97, 0C98, 0C77 or 0C78 on page 16 • When ordering stainless steel items, the stock item prefix will • Use the catalog number for the unique part number and refer be 0095 to the following chart for finish I.D. • Standard plating finish is 0.0001 in. (0.0025 mm) min. [gold Plating Finishes Finish Designation Finishes for Fingerstock Products Laird Specifications Specification Details* (BeCu and RCC) ID Unplated Bright Finish 02 Laird Designation Unplated, Bright or Ultrasoft surface Solderable Unplated 21 Laird Designation Solderable bright finish Gold Gold 03 ASTM B 488 / SAE AMS 2422 Type I & II, grade C, 1.27 - 2.5 µm thick Gold/Nickel Underplate 10 ASTM B 488 / SAE AMS 2403 Type I & II, grade C, 1.27 - 2.5 µm thick Silver Silver (matte) 04 ASTM B 700 / QQ-S-305 Type II, grade A, 2.5 - 7.6 µm thick Cadmium** Cadmium + Yellow Chromate 05 ASTM B 766 / AMS QQ P 416 Type II, class 5, min 5 µm thick Cadmium + Clear Chromate 06 ASTM B 766 / AMS QQ P 416 Type III, class 5, min 5 µm thick Tin Lead** Tin Lead [60/40] Solder 07 ASTM B 579 / SAE AMS P 81728 7.6 - 12.7 µm thick Nickel Dull Nickel 09 ASTM B 689 / SAE AMS 2403 (QQ-N-290) 2.5 - 7.6 µm thick* Bright Nickel 19 ASTM B 689 / SAE AMS 2403 (QQ-N-290) 2.5 - 7.6 µm thick* Sulfamate Nickel 24 ASTM B 689 / SAE AMS 2424 2.5 - 7.6 µm thick (1.27 - 2.5 µm underplate) Electroless Nickel Electroless Nickel 18 ASTM B 733 / SAE AMS C 26074 2.5 - 7.6 µm thick Tin Satin / Matte Tin 08 ASTM B 545 / MIL-T-10727C Type I, 2.5 - 7.6 µm thick Bright Tin 17 ASTM B 545 / MIL-T-10727C Type I, 2.5 - 7.6 µm thick Zinc*** Zinc + Yellow Chromate 16 SAE AMS 2402 / ASTM B 633 Type II, 2.5 - 7.6 µm thick Zinc + Clear Chromate 15 SAE AMS 2402 / ASTM B 633 Type III, 2.5 - 7.6 µm thick Notes: - Laird standard plating codes are defined according to the above specifications. Any non-standard requirements (different classes or types within a specification) must be clearly identified on the production prints. - The plating thickness indicates the thickness measured on the primary out-surface of fingerstock products. * Class 1, Grade G in QQ-N-290 ** Outsourced process *** Laird provides RoHS compliant Trivalent Chromate 17 www.lairdtech.com

EMI ESSENTIALS FINGERSTOCK ULTRASOFT® SERIES Series UltraSoft® fingers have been designed for communications, computers and electronic systems designers concerned with EMI compliance and lightweight enclosure designs. Available in the same full range of standard configurations, UltraSoft fingers offer designers greater flexibility and versatility than ever before—permitting more extensive use of lighteFr,O tLhDiOnVnEeRr S cERoInESstruction materials Standard No.97-541 to help cut costs and/or enhance system performance. UltraSoft No.98-541 The unique advantages of UltraSoft (98-Series) fingers include: • The lowest compression forces in the industry 160 140 • Shielding effectiveness comparable to similarly configured standard 97-Series parts 120 •• WLoiwde c soemlepcrteiosnsi oonf sfoizrecse avnedrs icoonn fiagvauirlaatbiolen sfo r virtually every standard Attenuation (dB)shie1860l000ding product UltraSoft (98-Series) products are available in the same lengths as the stand40ard (97-Series) products. Please refer to the appropriate 20 standard product pages for specific information. All UltraSoft products are also available in your choice of finishes. 0 10K 100K 1M 10M 100M 1G Frequency (Hz) Shielding Effectiveness Comparison Compression Force Comparison Standard No.97-541 FOLDOVER SERIES UltraSoft No.98-541 Standard No.97-541 UltraSoft No.98-541 Height (Millimeters) 1.500 2.000 2.500 3.000 100 140 160 90 140 80 120 Attenuation (dB) 118642000000 Load (Lbs./linear ft.) 7654300000 186400000 Load (Kg/linear m) 20 20 20 0 10 10K 100K 1M Frequency (H1z)0M 100M 1G 0 0 0.040 0.050 0.060 0.070 0.080 0.090 0.100 0.110 0.120 Height (Inches) Standard No.97-541 RECYCLABUltraLSoft ENo.9 8-C541 LEAN COPPER™ Height (Millimeters) 1.500 2.000 2.500 3.000 100 140 Recyc90lable Clean Copper products meld The product is targeted at high stron8g0 stability and tensile strength volume desig1n20s. Custom stampings Recyclable Clean Copper (RCC) beryllium- wefsLoad (Lbs./linear ft.)ohleirit echutl d76543rth00000iiiclinigazghal t calioeopnvnped liilucnsac obttiifovo ttinthhyse gmramrtoa aaukl ni cnadognisn dtitg t shauanittd ai sb le aAfiCrnose gp waepirvetsahrt io liaascl bklc l ooegmf a1864 u0000Lsp0pakloLoad (Kg/linear m)eiernttdes ,clm yuR esflettcaoaymmlc leeaprb rlroeeo qCfu.leeastn. feaarxlpelcopeeyl ilEscle Ma(nBtIit eo saCnhlustie.e) Tl rdinhniaen at gci v wooenif dftveoeer rsbrsa eiconrunygsl etloio ufom mfp ea scrlrosot tnanttenuad min binegr comp20arable with traditional metal EMI (Stock Item) of BeCu to RCC: For mounting2 0methods and other spe- shield10s. Shielding effectiveness is similar to oth0er copper alloys with values over cific product i0nformation, please BeCu RCC 0.040 0.050 0.060 0.070 0.080 0.090 0.100 s e e 0 .1L10a i r d 0 .1c20atalog 100 dB shielding effectiveneHsesig hrt e(Inacheds)ily 0077- 0067- “Fingerstock, Gaskets and Metal achieved. Grounding Products”. 0c77- 0c67- Recyclable Clean Copper is fully To find out more about this exciting 0097- 0087- compliant to EU Directive 2002/95/EC new product available from Laird please 0c97- 0c87- and alleviates the environmental, safety contact sales for assistance or visit us at and segregation concerns associated 0078- 0068- www.lairdtech.com. with the traditional use and recycling 0c78- 0c68- of beryllium-based copper alloys. 0098- 0088- This alternative material exhibits 0c98- 0c88- excellent corrosion resistance, platability, solderability and stress 18 relaxation properties. www.lairdtech.com

EMI ESSENTIALS FINGERSTOCK SLOT MOUNT SERIES Laird Slot Mount Series of beryllium copper shielding gaskets is designed for use in a wide variety of slotted applications. This economical product line is ideal for both grounding and shielding applications. • Minimal slot fabrication cost • Easy and cost-effective installation since fasteners and adhesives are not 77-011 required 77-011 • Bi-directional wiping and compression action to accommodate a wide variety of designs • Ideal for grounding and shielding in the following electronic enclosure 77-015 applications: 77-015 – Front panel handles – Chassis covers 77-018 77-010 – Plug-in units – Backplanes 77-018 77-010 – Subrack assemblies • Standard (77-Series) and UltraSoft® (78-Series low compression versions) are also supplied in 25.0 ft. (7.6 m) coils The Slot Mount Series is available in your choice of finishes, see page 17. TOP VIEW TOP VIEW *N *N *O A *O A E D PitchD Pitch SlEot Slot T*hPMickanteers*isaPl Ltheen gntuhm Ltohebfene s grnl otouhtfm iofsbi fnde sgerl eoportefs n i fsudi nsdeegendeptr eosn nudseendt on Approx.Length Material Thickness Approx.Length forS deiem peangseio 2n-s2. Recommended Mounting Hole Pattern forS deiem peangseio 2n-s2. forS deiem peangseio 2n-s2. Recommended Mounting Hole Pattern forS deiem peangseio 2n-s2. RIGHT VIEW RIGHT VIEW B B H H M M C C See page 2-2 Q Radius (R) See page 2-2 for dimensions. for dimensions. See page 2-2 Q Radius (R) See page 2-2 for dimensions. for dimensions. Slot Mount Series are available with Universal and Tape Track mounting Slot Mopotuionnt sS,esreiees p aargee a 1va-9il,a1bl-e1 0w.ith Universal and Tape Track mounting options,see page 1-9,1-10. 19 www.lairdtech.com