ICGOO在线商城 > 连接器,互连器件 > 端子 - 磁线连接器 > 63218-1

- 型号: 63218-1

- 制造商: CORCOM/TYCO ELECTRONICS

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

63218-1产品简介:

ICGOO电子元器件商城为您提供63218-1由CORCOM/TYCO ELECTRONICS设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 63218-1价格参考¥0.34-¥0.46。CORCOM/TYCO ELECTRONICS63218-1封装/规格:端子 - 磁线连接器, Terminal Magnetic Connector 14-18 AWG IDC。您可以下载63218-1参考资料、Datasheet数据手册功能说明书,资料中有63218-1 详细功能的应用电路图电压和使用方法及教程。

TE Connectivity AMP Connectors 的型号为63218-1的端子 - 磁线连接器主要应用于需要安全、可靠电气连接的场景。这种连接器广泛用于汽车、工业设备和家电等领域,特别是在涉及高电流或高频信号传输的地方。 在汽车行业,63218-1连接器常用于发动机控制单元(ECU)、传感器接口、照明系统和其他关键电子组件中。它确保了这些部件之间的稳定通信和电力供应,从而提高了车辆的整体性能和安全性。例如,在电动汽车中,该连接器可以用于电池管理系统与电机控制器之间的连接,保证高效且稳定的能量传递。 在工业领域,此款连接器适用于各种自动化设备和控制系统,如机器人手臂、PLC(可编程逻辑控制器)以及变频驱动装置等。由于其良好的抗震性和耐久性,即使在恶劣的工作环境下也能保持长期可靠的运行状态。 对于家用电器而言,63218-1连接器同样发挥着重要作用。它可以出现在冰箱、洗衣机、空调等大型家电内部,负责将电源分配给不同的功能模块,并支持数据交换以实现智能化操作。此外,它还可能被用作智能插座或其他智能家居产品的接口,便于用户进行远程控制和监控。 总之,TE Connectivity AMP Connectors 的63218-1端子 - 磁线连接器凭借其卓越的设计和出色的性能,在众多行业中都得到了广泛应用,成为现代电子产品不可或缺的一部分。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | TERMINAL MAG-MATE |

| 产品分类 | |

| 品牌 | TE Connectivity |

| 数据手册 | http://www.te.com/commerce/DocumentDelivery/DDEController?Action=srchrtrv&DocNm=63218&DocType=Customer+Drawing&DocLang=English |

| 产品图片 | |

| 产品型号 | 63218-1 |

| rohs | 不适用 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | Mag-Mate,AMP |

| 其它名称 | 632181 |

| 包装 | 剪切带 (CT) |

| 尺寸 | - |

| 标准包装 | 1 |

| 样式 | - |

| 特性 | 90° 下 |

| 端子类型 | 插入式接片端子 |

| 端接 | IDC |

| 线规 | 14-18 AWG |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

MAGNET WIRE TERMINALS AND TERMINATION SYSTEMS MAG-MATE terminals, SIAMEZE terminals, AMPLIVAR terminals and splices, and cluster blocks APPLIANCES /// MAGNET WIRE TERMINATION

Magnet Wire Terminals and Termination Systems Catalog 82221 Table of Contents Standard MAG-MATE Terminals Introduction.....................................................................................................................................1 Interconnection System..................................................................................................................2 Termination Sequence ...................................................................................................................2 Test Results ....................................................................................................................................3 300 Box Poke-In Terminals ............................................................................................................4 500 Box Poke-In Terminals ............................................................................................................6 Poke-In Tab Terminals ...................................................................................................................7 MAG-MATE Terminals with extended leaf-spring ..........................................................................8 300 Box Poke-In Terminals ............................................................................................................9 Tab Receptacle Terminals ..............................................................................................................9 187 Box F-Crimp Terminals ..........................................................................................................10 300 Box F-Crimp Terminals ..........................................................................................................10 Posted PCB Terminals .................................................................................................................11 300 Box Posted PCB Terminals ...................................................................................................11 MAG-MATE Edge Leaf Terminals ................................................................................................12 187 Box Posted PCB Terminals ...................................................................................................13 187 Box Tab Terminals ................................................................................................................13 300 Box Tab Terminals ................................................................................................................14 Pin Receptacle Terminals .............................................................................................................15 Pin I/O Terminals ..........................................................................................................................16 110 Series FASTON Tab Terminals ..............................................................................................17 187 Series FASTON Tab Terminals ..............................................................................................18 187 Series Combination Poke-In FASTON Terminals .................................................................18 250 Series FASTON Tab Terminals ..............................................................................................21 Typical Plastic Cavity ....................................................................................................................23 Slim Line MAG-MATE Terminals Introduction...................................................................................................................................25 187 Series FASTON Tab Terminals ..............................................................................................26 250 Series FASTON Tab Terminals ..............................................................................................26 Posted PCB SOLDER Terminal ...................................................................................................26 Offset Tab Terminals.....................................................................................................................27 Mini MAG-MATE Terminals Introduction...................................................................................................................................29 Poke-In Terminal ..........................................................................................................................30 Posted Terminal ...........................................................................................................................31 FASTON Tab Terminals ................................................................................................................31 Crimp Wire Barrel Terminal ..........................................................................................................31 SIAMEZE Terminals Introduction...................................................................................................................................32 Lead Lok Terminals Introduction ..................................................................................................33 SIAMEZE Interconnection System...............................................................................................34 Lead Lok Interconnection System................................................................................................35 Wire-to-Wire Terminals .................................................................................................................36 Receptacle Terminals (Wire to Blade) .........................................................................................37 Pin Terminals ................................................................................................................................37 Post Terminals ..............................................................................................................................38 110 Series (2.8 mm wide) FASTON Tab Terminals ......................................................................39 187 Series (4.75 mm wide) FASTON Tab Terminals ....................................................................40 250 Series (6.3 mm wide) FASTON Tab Terminals ......................................................................41 Typical Plastic Cavity Pockets ......................................................................................................42 Dimensions are in inches and Dimensions are shown for www.te.com/appliances millimeters unless otherwise reference purposes only. specified. Values in brackets Specifications subject to change. are metric equivalents.

Magnet Wire Terminals and Termination Systems Catalog 82221 Table of Contents AMPLIVAR Splices Introduction...................................................................................................................................44 General Application Guidelines ....................................................................................................46 Suggested Splice Selection Procedure .......................................................................................46 Technical Documents ...................................................................................................................46 9 Serrations —Pigtail Type ...........................................................................................................47 7 Serrations —Pigtail Type ...........................................................................................................47 5 Serrations —Thru Type .............................................................................................................48 5 Serrations —Pigtail Type ...........................................................................................................49 Miniature Splice —Pigtail Type ....................................................................................................49 AMPLIVAR Terminals Introduction...................................................................................................................................50 Ring Tongue Terminals ................................................................................................................51 Stud Retaining Terminals .............................................................................................................52 Alternator Eyelet Terminal ............................................................................................................52 125 Series Blade..........................................................................................................................53 187 Series FASTON Tabs ..........................................................................................................53 250 Series FASTON Tabs ..........................................................................................................53 250 Series FASTON Receptacles ..............................................................................................64 187 Series FASTON Flag Receptacles .......................................................................................55 250 Series FASTON Flag Receptacles ........................................................................................55 Pin Receptacles............................................................................................................................55 250 Series Stator Receptacles —7 Serrations ............................................................................56 Stator Terminal —Receptacle .250 x .032 [6.35 x 0.81] ..............................................................56 Cluster Blocks Introduction...................................................................................................................................57 Cluster Blocks 2.29 [.090] Pin Size (Lead Wire and Direct Connect)...........................................58 Cluster Blocks 3.18 [.125] Pin Size (Lead Wire and Direct Connect)...........................................60 MTM Crimpband Splices - NOT RECOMMENDED FOR NEW DESIGNS Introduction...................................................................................................................................62 MTM Crimpband Interconnection System....................................................................................63 11 Serrations ................................................................................................................................64 9 Serrations..................................................................................................................................64 7 Serrations..................................................................................................................................65 RTM Crimpband Splices - NOT RECOMMENDED FOR NEW DESIGNS Introduction...................................................................................................................................66 RTM Crimpband Interconnection System .....................................................................................67 20 Ridges.....................................................................................................................................68 14 Ridges.....................................................................................................................................68 10 Ridges.....................................................................................................................................68 9 Ridges.......................................................................................................................................69 8 Ridges.......................................................................................................................................69 7 Ridges.......................................................................................................................................69 6 Ridges.......................................................................................................................................72 3 Ridges.......................................................................................................................................73 Power Splice Introduction...................................................................................................................................74 Dimensions are in inches and Dimensions are shown for www.te.com/appliances millimeters unless otherwise reference purposes only. specified. Values in brackets Specifications subject to change. are metric equivalents.

Magnet Wire Terminals and Termination Systems Catalog 82221 Table of Contents Application Tooling Introduction...................................................................................................................................76 AMPLIVAR Product Terminator (APT)Machine ............................................................................77 Power Splice Machine ..................................................................................................................77 AMPLIVAR Terminator for Parallel and End Connections ............................................................78 AMP-O-LECTRIC Model G Terminator with Thru-Splice Applicator .............................................78 Crimpband Application Tooling - NO LONGER AVAILABLE.......................................................... 79 MPT-5 MAG-MATE Product Terminator .......................................................................................80 MAG-MATE Terminal Cavity and Fixture Design ..........................................................................80 MPT-5 S/L Machine for SIAMEZE and Lead Lok Terminals .........................................................81 EMT -- Entry Level Magnet Wire Terminator ................................................................................81 Manual Hand Tool .........................................................................................................................82 Manual Arbor Press ......................................................................................................................82 Hand Insertion Tools .....................................................................................................................82 Full Line of Crimp Tooling .............................................................................................................82 MAG-MATE Inserter MK I with Pneumatic Control .......................................................................83 MAG-MATE Inserter MK I with Electro Pneumatic Control ...........................................................83 MAG-MATE and SIAMEZE Inserter MARK II with PLC ................................................................83 MAG-MATE and SIAMEZE Inserter MARK II with PLC and Insertion Force Control ...................84 Pneumatic Insertion Tool for MAG-MATE Terminals....................................................................84 Customer Specific Machines ........................................................................................................85 Custom Built IDC Terminal Insertion Head ...................................................................................85 Additional Data Technical Information ...................................................................................................................86 Terminal Stud Hole Size ...............................................................................................................90 Part Number Index .......................................................................................................................91 Dimensions are in inches and Dimensions are shown for www.te.com/appliances millimeters unless otherwise reference purposes only. specified. Values in brackets Specifications subject to change. are metric equivalents.

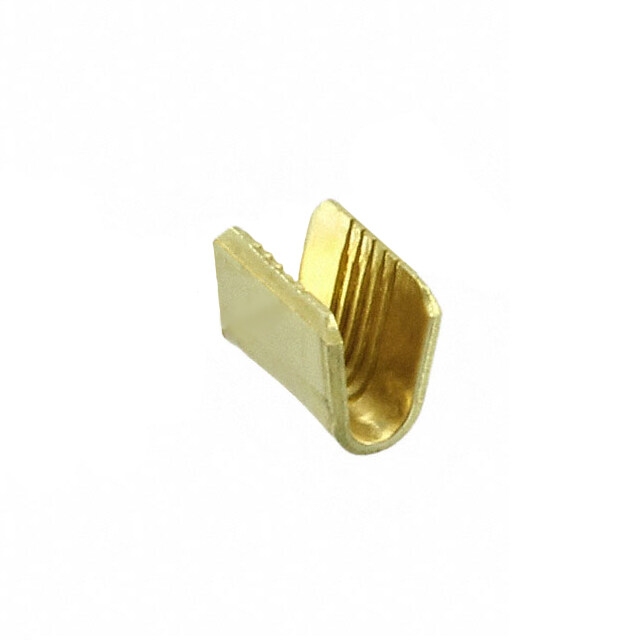

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals Product Facts Terminates film-insulated copperand aluminum TS magnetwire ermtan Eliminates need for inda ar pre-stripping conductors lsd M Eliminates need to post AG insulate termination -M A Excess magnetwire is T E automatically trimmed during the termination process Simultaneously terminates two magnetwires ofthe same size in one terminal (forsplicing orbi-filing) Various lead wire attachmentoptions available Available in strip form for semi-automaticorfully automaticinsertions Available in loose piece form forhand toolinsertions Varnish resisttabterminals are available forspecial applications TEoffersafullselectionof Twomagnetwireswiththe Wipingactionbetween High speed,fully automated StandardMAG-MATE samediametercanbe thewireandterminal integratedsystems provide InsulationDisplacement terminatedinoneterminal removesoxidesorother uniform terminations Crimp(IDC)terminalsfor exceptasnoted. contaminantspresenton reliably atthelowest magnetwireterminations. boththeconductorandthe possible applied cost AccordingtoTE terminalslotsidewalls, MAG-MATEterminalsare specifications MAG-MATE Clean metal-to-metal producingaclean,stable, availableinpoke-in, cavitiesareeither interface produces stable, gas-tightelectrical poke-intab,splice,crimp integratedintocoilbodies gas-tightelectrical termination. wirebarrel,solderpost, orspeciallydesignedcavity terminations free ofoxides quickconnecttab,pinand housings.Themagnet Residualspringenergyin and othercontaminants receptaclestyles. wiresareprecisely theterminalcausesthe Recognized underthe positionedintheplastic sidewallsofeachIDCslot StandardMAG-MATE ComponentRecognition cavityslots. tofunctionasopposing terminatesmagnetwire Program ofUnderwriters cantileverbeams. rangingfrom34-12AWG TheMAG-MATEInserter Laboratories Inc.,File No. [0.16-2.05mm]. cutstheterminalsfromthe Thisconstantpressure E13288,Vol. 1,Sec29 stripandplacesthe resultsinanintimate EachIDCslotsize terminalsoverthemagnet metal-to-metalinterface, terminatesarangeofupto R wireintotheplastic providingareliable, fourconsecutivemagnet cavities. long-termconnection. Applications wiresizes. Duringthisoperation,small The MAG-MATE Motor windings and strippingshouldersinthe Insertermaybeusedasa connections IDCslotremovethefilm semi-automaticbench Coil connections insulationfromthemagnet machineorintegratedinto wire. productionlinesfor Transformer windings fully-automaticapplications. and connections Bobbin connections Lighting ballasts Power supplies *Contact TE Engineering for guidance regarding aluminum 1 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) Standard MAG-MATE Interconnection System How the System Operates Trim Blade Locking Barbs This part cuts off the excess Terminal retention is secured magnet wire and the wire in the cavity by four locking support at the front of the barbs. cavity. Plastic Cavity Insertion Finger Integration of plastic cavities into final unit must be in The insertion finger is part of accordance with TE the MAG-MATE Inserter. It Application Specifications. pushes the terminal that was Consulting TE sheared from the carrier strip through the inserter is required for design in. “tube” into the positioned Cavity Slot for Wire cavity. The width has to be in Contact accordance with the wire Various wire attachments in size(see Application Specifi- three different sizes,.187, cation). .300,.500 cavity height (see Magnet Wire tables). The magnet wire is IDC Slot positioned down into the In different sizes for magnet plastic cavity slots. wire diameters from 34-12 Wire Support Block AWG[0.16-2.05 mm]. Strain relief slots available for high The block supports the vibration applications. magnet wire during the cutting process. The magnet Stripping Shoulders wire is cut flush to the cavity During the insertion process, front side. these shoulders strip the film 11 Support Anvil insulation from the magnet wire in four areas. The anvil supports the wire during the insertion process. Termination Sequence 11 A = Prepare B = Insert C = Finish A B C Trim Blade Insertion Finger Poke-In Contact Plastic Cavity Magnet Wire Support Anvil 2 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) Test Results Current Cycling— Humidity— Mini MAG-MATE Standard and Slim Line 480 cycles with each cycle Temperature Cycling products have been submitted to MAG-MATE products have consisting of 15 minutes “ON” 10 cycles between 25°C and the following tests in addition to TS btineecsertesn a wssuietbh:mouittt esdig ntoif itchaen fto mlloilwlivinoglt fT2o5hll ocewyrcmeldea sbl wyS i1thh5o emcaikcnh—u tceysc l“eO FF” 6H353e° daCat yaAst g9a5et %1—1 R8°HC tmVhiiolblsivreoa lltitsi iotnencdr— ewaistheo:ut significant erminatandar cfoolnloswisetidn gb yo f3 300 m mininuutetes sa at t- 6152°5C°C 1m0in-5u5te-0 a1t- .H06z itnracvheerss etodt ainl 1 lsd M A excursion; 2 hours in each of 3 G mutually perpendicular -M directions. A T Industrial Gas with E 3” Chlorine— I1 [7.62 mm ] I2 Current Leads 1000 exposure to 200 ppb each of sulphur dioxide, nitrogen E1 E2 Voltage dioxide, hydrogen sulphide and 50 ppb chlorine. Resistance vs Thermal Shock (Copper Wire) Resistance vs Current Cycles (Copper Wire) 35 30 25 s m ms 20 oh Millioh 15 Milli 10 5 0 0 5 10 15 20 25 Test Current produces 100°C Magnet Wire Operating Temperature Product Specifications GG GG G G G G G T(C) WW WW W W W W W describe technical performance AA AA A A A A A 3 0 7 6 4 2 9 6 5 characteristics and verification 33 22 2 2 1 1 1 tests. They are intended for the Design, Test and Quality Engineer. 108-2012 Standard .187 and .300 MAG-MATE Terminals 108-2053 Standard .500 Box Current Rating Curves MAG-MATE The diagram shows the Terminals temperature rise of the 108-1484 Slim Line MAG-MATE contact, depending on the Terminals magnet wire size being 108-2016 Mini MAG-MATE applied. Terminals Note:For all applications, TE I (A) recommends that samples of the magnet wire to be used be submitted for engineering evaluation. 3 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) 300 BoxPoke-In Terminals Materrial Tinplatedbrass Type Copper Magnet Wire Range1 Lead Wire Range3 Mating5 Stock Strip AWG mm AWG mm2 Tab ThicknessPart Number* .135 x .020 .010 34-33 0.16-0.18 20-18 0.5-0.9 63662-1 3.40 x 0.50 0.25 TypicalCavitySize2 .135 x .020 .010 (Seepage23) 33-31 0.18-0.23 20-18 0.5-0.9 3.40 x 0.50 0.25 62431-1 .135 x .020 .012 31-28 0.23-0.32 20-18 0.5-0.9 1217234-1 3.40 x 0.50 0.30 .135 x .020 .012 30-27 0.25-0.36 20-18 0.5-0.9 62429-1 3.40 x 0.50 0.30 A [ .73.0602 ] Sta3n0d0a Brdo IxDC 27-23 0.36-0.57 20-18 0.5-0.9 .31.3450 xx .00.2500 .00.1461 62935-1 [ .31.3453 ] LPoockkei-ning 25-222 0.45-0.64 20-18 0.5-0.9 .31.3450 xx .00.2500 .00.1461 63658-1 [ .31.1080 ] 22-202 0.64-0.81 20-18 0.5-0.9 .31.3450 xx .00.2500 .00.1461 62420-1 202 0.81 20-18 0.5-0.9 .135 x .020 .016 63591-1 A 3.40 x 0.50 0.41 19-172 0.91-1.15 20-18 0.5-0.9 .135 x .020 .016 62833-1 3.40 x 0.50 0.41 .135 x .020 .012 30 0.25 20-18 0.5-0.9 63786-1 B4 3.40 x 0.50 0.30 300 Box 29-28 0.29-0.32 20-18 0.5-0.9 .135 x .020 .012 1217011-1 .300 Standard IDC w/ 3.40 x 0.50 0.30 [ 7.62 ] StraiLno Rcekilniegf Slot 28-26 0.32-0.40 20-18 0.5-0.9 .31.3450 xx .00.2500 .00.1320 1217368-1 .135 Poke-In [ 3.43 ] .135 x .020 .016 27-23 0.36-0.57 20-18 0.5-0.9 63789-1 .118 3.40 x 0.50 0.41 [ 3.00 ] 1Twomagnetwiresmaybeterminatedinthesameterminalslotifdiametersareequal. 2Singlemagnetwireonly;22AWG[0.64mm]orlargerunlessotherwisenoted. B 3Solidorovercoatedstrandedleadwireonly.ProductwillalsoacceptPoke-InTabTerminalshownonpage 7. 4Strainreliefslotforhighvibrationapplications. 5Seepage7 for mating tab options. * RecognizedundertheComponentProgramofUnderwritersLaboratories,Inc. Solid Lead Wire Solid SOLID WIRE Lead Wire MAGMATE POKE-IN MAGMATE Terminal SOLID WIRE LOCKS Terminal IN “V” NOTCH Cavity Magnet Wire Cavity POKE-IN SYSTEM: SOLID WIRE CONNECTION Stranded Lead Wire Stranded Lead Wire POKE-IN TAB POKE-IN TAB Terminal MAGMATE POKE-IN TAB Terminal Locking Terminal Grooves Tab locks into POKE-IN MAGMATE edges of leaf Terminal Magnet Wire Cavity Cavity POKE-IN SYSTEM: STRANDED LEAD WIRE AND POKE-IN TAB CONNECTION 4 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) TS erta mn inda ar lsd M .300 [ 7.62 ] Type Copper Magnet Wire Range1 Mating Tab3 Stock Strip AG .135 AWG mm Thickness Part Number* - [ 3.43 ] .118 35-32 0.14-0.20 .31.3450 xx .00.2500 .00.1205 969082-1 MAT [ 3.00 ] E 33-30 0.18-0.265 .31.3450 xx .00.2500 .00.1205 926850-2 A Sta3n0d0aA Brdo IxDC 30-26 0.265-0.40 .31.3450 xx .00.2500 .00.1332 926851-2 NPoonke-L-Ionc kMinKgI 26-21.52 0.40-0.67 .31.3450 xx .00.2500 .00.1461 926852-2 21.5-18.52 0.67-0.95 .31.3450 xx .00.2500 .00.1461 928770-2 [ .73.0602 ] 19.5-172 0.91-1.13 .31.3450 xx .00.2500 .00.1461 1-928771-4 .135 x .020 .013 33-30 0.18-0.265 964337-2 3.40 x 0.50 0.32 .135 [ 3.43 ] .118 B 30-26 0.265-0.40 .135 x .020 .013 964338-2 [ 3.00 ] 300 Box 3.40 x 0.50 0.32 Standard IDC 26-222 0.40-0.63 .135 x .020 .013 964339-2 Non-Locking 3.40 x 0.50 0.32 B Poke-In MKII 22-19.52 0.63-0.85 .135 x .020 .013 964340-2 3.40 x 0.50 0.32 19.5-172 0.85-1.12 .135 x .020 .013 964341-2 3.40 x 0.50 0.32 Type Copper Magnet Wire Range1 Feature Stock Strip AWG mm Thickness Part Number .433 C 33-30 0.18-0.265 w/o Dimple .013 1-964114-1 [ 11.00 ] 433 Box Dimple 0.32 964114-1 Standard IDC w/o Dimple .013 1-964108-1 with Receptacle 30-26 0.265-0.40 Dimple 0.32 964108-1 for Tabs w/o Dimple .013 1-928854-1 .110 x .020 26-22 0.40-0.63 .135 .125 [2.8 mm x 0.5 mm] Dimple 0.32 928854-1 [ 3.43 ] [ 3.20 ] or .110 x .032 22-19.52 0.63-0.85 w/o Dimple .013 1-964106-1 [2.8 mm x 0.8 mm] Dimple 0.32 964106-1 33-31 0.18-0.265 Dimple .013 1740574-1 C D 0.32 433 Box 26-23 0.40-0.57 w/o Dimple .013 964252-1 Standard IDC 0.32 with Receptacle for Tabs 22.5 - 202 0.60-0.80 w/o Dimple .013 964110-1 0.32 .187 x .020 [4.8 mm x 0.5 mm] 19-172 0.90-1.13 w/o Dimple .013 964111-1 or .187 x .032 0.32 [ 1.413.030 ] [4.8 mm x 0.8 mm] 19-171 0.90-1.12 w/o Dimple .00.1332 1534234-1 1Twomagnetwiresmaybeterminatedinthesameterminalslotifdiametersareequal. 2Singlemagnetwireonly;22AWG[0.64mm]orlargerunlessotherwisenoted. [ .31.3453 ] [ .31.2250 ] *3SReeecopgangieze7d fuonr dmearttihnegC taobm oppotnioennst.ProgramofUnderwritersLaboratories,Inc. D 5 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) 300 Box Poke-In Terminals (Continued) .300 .300 Material [7.62] [7.62] .135 Tin plated brass [3.43] .455 .118 [11.56] .118 [3.00] [3.00] Typical Cavity Size 2 A B (See page 23) Type C o p p AeWr MGa g n e t W i r me Rmange1 Mating Tab4 ThSictkoncekss PartS Ntruipmber Note:Special cavity required for .135 x .020 .016 27-26 0.36-0.40 1217691-1 Tri-slot splice terminal. A3 3.40 x 0.50 0.41 300 Box .135 x .020 .016 See Application Spec. Standard IDC 25.5-24 0.43-0.51 3.40 x 0.50 0.41 1217690-1 114-2046. w/SNtroanin-L Roeclkieinf gSlot 23.5-222 0.54-0.64 .31.3450 xx .00.2500 .00.1461 1217689-1 Poke-In 21.5-202 0.68-0.81 .135 x .020 .016 1217688-1 3.40 x 0.50 0.41 .135 x .020 .016 30-27 0.25-0.36 1217221-1 3.40 x 0.50 0.41 .135 x .020 .016 B 27-23 0.36 -0.57 3.40 x 0.50 0.41 63632-1 300 Box Standard IDC 23-202 0.57-0.81 .135 x .020 .016 1217533-1 3.40 x 0.50 0.41 Non-Locking Poke-In 19-17 0.91-1.15 .135 x .020 .016 1742347-1 3.40 x 0.50 0.41 27-232 0.36-0.57 .135 x .020 .016 19-172 0.91-1.15 63975-1 182 0.8-0.9 3.40 x 0.50 0.41 1Twomagnetwiresmaybeterminatedinthesameterminalslotifdiametersareequal. 2Singlemagnetwireonly;22AWG[0.64mm]orlarger. 3Strainreliefslotforhighvibrationapplications. 4Seepage7formatingsmall tab options. * RecognizedundertheComponentProgramofUnderwritersLaboratories,Inc. 500 Box Poke-In Terminals Material Tin plated brass .505 .505 [ 12.83 ] [ 12.83 ] Typical Cavity Size 4 .281 [7.14] (See page 23) .118 .118 [3.00] .281 [ 3.00 ] [ 7.14 ] Note:Mating poke-in tab C D 1217324-1 Type Copper Magnet Wire Range1 Stock Strip (See Type H, Page 7) AWG mm Thickness Part Number .016 C 23-19.5 0.57-0.86 0.41 1217069-1 500 Box .016 Standard IDC 19-17 0.91-1.15 1217068-1 0.41 Non-Locking Poke-In 16-15 1.29-1.45 .016 1217067-1 0.41 .016 23-21.5 0.57-0.68 1217358-1 0.41 .016 D3 21-19.5 0.72-0.86 0.41 1217357-1 500 Box Standard IDC w/ 19-17 0.91-1.15 .016 1217356-1 Strain Relief Slot 0.41 Non-Locking .016 17-16 1.15-1.29 1742203-1 Poke-In 0.41 .016 16-15 1.29-1.45 1217355-1 0.41 14-132 1.61-1.83 .016 1217579-1 0.41 1Twomagnetwiresmaybeterminatedinthesameterminalslotifdiametersareequal. 2Singlemagnetwireonly. 3Strainreliefslotforhighvibrationapplications. 6 www.te.com/appliances

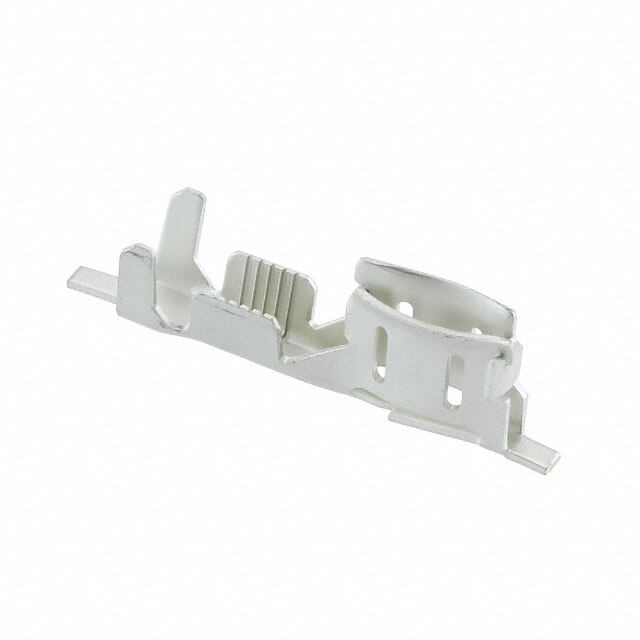

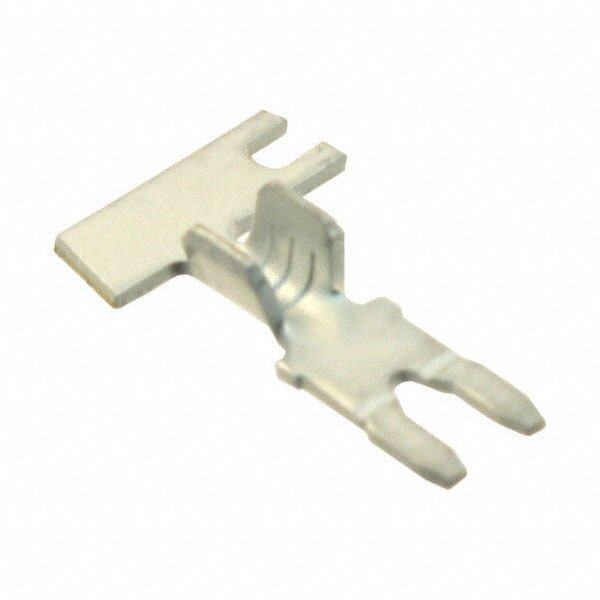

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) Poke-In Tab Terminals Material .135 TS Tin plated brass [ 3.43 ] ermtan [ .31.3453 ].312 [ .31.3453 ] inalsdard M [ 7.92 ].275 A [ 6.98 ] G - M .312 A [ 7.92 ].275 .255 T [ 6.98 ] [ 6.48 ] E .405 [ 10.29 ] .323 .203 [ 8.20 ] [ 5.28 ] A B C Lead Wire Size1 Stock Strip #20 OApWtioGn [a0l .S8 lmotm fo] rDia. Type AWG mm2 Ins. O.D. Thickness Part Number .135 Solid Copper Diode Slot .018 62895-1* [ 3.43 ] A 0.46 90° Up 22-18 0.3-0.9 .020 63410-1 0.51 .255 24 0.2 .10.4002--.10.6502 .00.1486 1742828-1 [ 6.48 ] B .060-.100 .018 90° Up 22-18 0.3-0.9 62896-1* .520 1.52-2.54 0.46 w/Ins. Sup. [ 13.21 ] .090-.140 .018 18-14 0.8-2.0 63218-1 2.29-3.56 0.46 22-18 0.3-0.9 .020 62897-1* C 0.51 Straight 18-14 0.8-2.0 .020 63775-1 0.51 D 22-18 0.3-0.9 .060-.100 .020 62898-1* 1.52-2.54 0.51 .090-.140 .020 18-14 0.8-2.0 63397-1 2.29-3.56 0.51 .208 [ 5.28 ] 22-17 0.3-1.0 .118 MAX. .018 281622-22 3.00 MAX. 0.45 D Straight w/Ins. Sup. 22-17 0.3-1.0 .118 MAX. .018 281623-22 .312 3.00 MAX. 0.45 [ 7.92 ] 20-17 0.5-1.0 .063-.090 .018 964101-23 1.60-2.30 0.45 .135 [ 3.43 ] 20-17 0.5-1.0 .063-.090 .018 964290-14 1.60-2.30 0.45 E .018 E 22-18 0.3-0.9 0.46 63364-1 90° Down .018 18-14 0.8-2.0 0.46 1742125-1 1Stranded,fusedstrandedorsolidleadwire. Note:Alltabterminalsacceptstranded,fusedstranded 2Canbeselectivelybentinsideapplicator.With supportflanges, or solidleadwire. can only be used in combination with modified cavity IA-84-5157 3Canbeselectivelybentinsideapplicator, Non-locking 4 Can be selectively bent inside applicator. Non-locking;use with housing * RecognizedundertheComponentProgramof UnderwritersLaboratories,Inc. 7 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) Poke-In Tab Terminals Material .340 Tin plated brass [8.64] .245 [ 6.22 ] Pre-Tin plated brass .312 [ 7.92 ] .110 .370[ 2.79 ] .285 .540 .135 [ 9.40 ] .347 [ 7.24 ] [ 13.72 ] [ 3.43 ] [ 8.81 ] .106 [ 2.70 ] F I J .315 [ 8.00 ] Lead Wire Size1 Stock Strip .135 .197 Type AWG mm2 Ins. O.D. Thickness Part Number [ 3.43 ] [ 5.00 ] .048-.078 .020 24-20 0.2-0.5 1742410-1 1.22-1.98 0.51 F K 90° Down 22-18 0.3-0.9 .060-.100 .020 1742211-1 w/Ins. Sup. 1.52-2.54 0.51 .090-.140 .020 18-14 0.8-2.0 63458-1 .135 2.29-3.56 0.51 [ 3.43 ] I .020 Flag - 300 Box only 20-16 0.5-1.4 0.51 1217406-1 J .080-.120 .020 Flag - 500 Box only 18-14 0.8-2.0 2.03-3.05 0.51 1217324-1 .250 K .020 1987199-1 [6.35] Bridge Contact 0.51 .150 L .020 [ 3.81 ] PCB Contact 0.51 1217041-1 .490 [ 12.45 ] Note:Alltabterminalsacceptstranded,fusedstranded orsolidleadwire. .200 [ 30.48 ] L MAG-MATE Terminals with extended leaf-spring Material Pre-tinned copper alloy Copper Magnet Wire Range Stock Strip Type AWG mm Thickness Part Number .013 33-30 0.18-0.265 0.32 1740603-1 .013 30-26 0.265-0.40 1740698-2 M 0.32 [ 1.535.9] [ 1.401.3] Meaxgte-Mndaeted TLeeramf-iSnaplr iwngith 26.5-22.5 0.375-0.60 .00.1332 1534110-1 .013 22.5-20 0.60-0.80 0.32 969125-1* .013 19.5-17 0.85-1.12 0.32 1418686-1 *Single magnet wire Note:Specialcavityisrequired,contactTEconnectivity forinformation. .120 .136 [ 3.05] [ 3.45] M 8 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) 300 Box Poke-In Terminals TS Material erta mn Tin plated brass inda .T3y0p0ic [a7l. 6C2a]v Sitye rSieizse B 2ox .300 alsrd M [ 7.62 ] A (See page 23) .300 G [ 7.62 ] -M Note:Special cavity required for A T Tri-slot splice terminal. .120 .455 E See application [ .31.3453 ] [ 3.05 ] [ 11.56 ] [ .31.2005 ] SPEC 114-2046 A B Copper Magnet Wire Range1 Stock Strip Type AWG mm Thickness Part Number A 22-20 0.64-0.81 .016 1217973-1 300 Box 0.41 StanSdpalircde IDC 19-17 0.91-1.15 .00.2501 1742159-14 28-24 0.32-0.51 .016 1217858-1 0.41 23-202 0.57-0.81 .00.1461 1217853-1 B 300 Box 27-23 0.36-0.57 Standard IDC 184 0.8-0.9 .016 1217613-1 Tri-Slot 0.41 Splice 19-172 0.91-1.15 25-223 0.45-0.64 184 0.8-0.9 .00.1461 1217209-1 23.5-202 0.54-0.81 1Twomagnetwiresmaybeterminatedinthesameterminalslotifdiametersareequal. 2Singlemagnetwireonly; 22AWG[0.64mm]orlarger. 3Singlesolidorfusedstrandedleadwireonly. 4Specialcavityrequiredfor1742159-1. Tab Receptacle Terminals Material Tin plated phos. bronze .345 [8.76] .185 Note:Special cavity required. [4.70] Contact TE Engineering for .110 details. [2.79] .070 [1.78] C Copper Magnet Wire Range1 Stock Strip Type Mating Tab AWG mm Thickness Part Number .070 x .020 .010 32-31 0.20-0.23 1.78 x 0.51 0.25 1217538-1 C .070 x .020 .010 185 Box 30-28 0.25-0.32 1.78 x 0.51 0.25 1217457-1 Standard IDC .070 x .020 .010 Tab Receptacle 29-28 0.29-0.32 1.78 x 0.51 0.25 1217458-1 .070 x .020 .010 28-27 0.32-0.36 1.78 x 0.51 0.25 1742781-1 1Twomagnetwiresmaybeterminatedinthe sameslotifdiametersareequal. 9 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) 187 Box F-Crimp Terminals Material Tin plated brass .T1y8p7ica[4l C.7a5v]it yS Seirziee s1 Box [ .93.6104 ][ .41.8775 ] [ .41.8775 ] [ 1.41.6876 ] (See page 23) .090 .070 .090 .070 [ 2.29 ] [ 1.78 ] [ 2.29 ] [ 1.78 ] A B Copper Magnet Wire Range1 Lead Wire Range3 Stock Strip Type Ins. O.D. AWG mm AWG mm2 Thickness Part Number .010 33-31 0.18-0.23 26-22 0.12-0.3 0.25 63039-1 .012 A 30-28 0.25-0.32 26-22 0.12-0.3 0.30 63036-1 Sta1n8d7aBrdoIxDC 27-25 0.36-0.46 26-22 0.12-0.3 .00.1320 62609-14 F-Crimp .012 26-24 0.40-0.51 22-18 0.3-1.0 0.30 1217146-1 24-222 0.51-0.64 26-22 0.12-0.3 .00.1320 62610-14 B .071-.088 .012 187BoxF-Crimp 27-25 0.36-0.46 22-18 0.3-1.0 63856-1 1.80 -2.23 0.30 w/InsSup. 1Twomagnetwiresmaybeterminatedinthesameterminalslotifdiametersareequal. 2Singlemagnetwireonly. 3Stranded,fusedstrandedorsolidleadwire. 4Striprereeledtofeedthroughmini-applicatortocrimpleadwirefirst,magnetwireterminationissecondaryoperation. 300 Box F-Crimp Terminals Material Copper Magnet Wire Range1 Dim. Lead Wire Range3 Stock Strip Type Tin plated brass AWG mm C AWG mm2 Thickness Part Number .300[7.62] Series Box .10.7708 22-18 0.3-1.0 .00.1320 63235-1 Typical Cavity Size 2, when 33-31 0.18-0.23 .120 .012 “C” dimension is .120 [3.05] 3.05 24-20 0.2-0.6 0.30 63420-1 .070 .012 (See page 23) 1.78 22-18 0.3-1.0 0.30 63236-1 31-28 0.23-0.32 Typical Cavity Size 6, when “C” .070 .012 dimension is .070 [1.78] 1.78 24-20 0.2-0.6 0.30 1742614-1 .120 .012 (See page 23) C 30-27 0.25-0.36 3.05 24-20 0.2-0.6 0.30 62992-1 300 Box .120 .012 Standard IDC 28-24 0.32-0.51 3.05 24-20 0.2-0.6 0.30 63641-1 F-Crimp .070 .012 27-24 0.36-0.51 1.78 22-18 0.3-1.0 0.30 63237-1 .480 .120 .016 [ 12.19 ] 27-23 0.36-0.57 3.05 24-20 0.2-0.6 0.41 62459-1 .070 .012 .300 25-22 0.45-0.64 1.78 22-18 0.3-1.0 0.30 63690-1 [ 7.62 ] 22-202 0.64-0.81 .31.2005 24-20 0.2-0.6 .00.1461 62458-1 19-172 0.91-1.15 .31.2005 22-18 0.3-1.0 .00.1461 63504-1 .135 1Twomagnetwiresmaybeterminatedinthe sameterminalslotifdiametersareequal. [ 3.43 ] 2Singlemagnetwireonly; 22AWG[0.64mm]orlarger. C 3Stranded,fusedstrandedor solidleadwire. 10 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) 300 Box Posted PCB Terminals TS Multi-Spring ermtan Solderless Terminal inda L alsrd M Material A .300 G- Tin over Copper Alloy [ 7.62 ] M A TE Cavity Size .132 .120 Application Spec. [ 3.35 ] [ 3.05 ] 114-74109 with 114-74109-5 A Copper Magnet Wire Range1 Dim Stock Thickness Strip Type AWG mm L Tab Section Mag Wire Section Part Number .583 .031 .013 33-29.5 0.18-0.265 14.80 0.80 0.32 1247000-2 .583 .031 .013 A 29.5-26 0.265-0.40 14.80 0.80 0.32 1247001-2 Multi-Spring .583 .031 .013 Solderless PCB 26-22.5 0.40-0.63 14.80 0.80 0.32 1247002-2 Tab Terminal 22.5-19.52 0.63-0.85 1.548.830 .00.3810 .00.1332 1247003-2 19.5-172 0.85-1.12 1.548.830 .00.3810 .00.1332 1247004-2 1Twomagnetwiresmaybeterminatedinthesameterminalslotifdiametersareequal. Note:PCBoardholesize.057[1.45]. 2Singlemagnetwireonly. 22awg[0.63mm]andlarger. 300 Box Posted PCB .042 Terminals [ 1.07 ] Solder Terminal L L Material .300 .300 Tin over copper plated brass [ 7.62 ] [ 7.62 ] Typical Cavity Size .070 .135 (See page 23) .135 .120 [ 3.43 ] [ 1.78 ] Type C—Cavity Size 2 [ 3.43 ] [ 3.05 ] Type D—Cavity Size 6 B C Copper Magnet Wire Range1 Dim. Stock Thickness Strip Type AWG mm L Tab Section Mag Wire Part Number .540 .010 .010 33-31 0.18-0.23 13.72 0.25 0.25 63253-1 .540 .010 .010 31-28 0.23-0.32 62928-1* 13.72 0.25 0.25 300BBox 29-26 0.29-0.40 1.534.702 .00.1320 .00.1320 62958-1* StandardIDC .460 .016 .016 PCBPost 27-23 0.36-0.57 11.68 0.41 0.41 63659-1 22-202 0.64-0.81 .460 .016 .016 63660-1 11.68 0.41 0.41 19-172 0.91-1.15 .460 .016 .016 63661-1 11.68 0.41 0.41 19-172 0.91-1.15 1.547.408 .00.1461 .00.1461 1742708-1 C PCBPost 33-31 0.18-0.23 .475 .020 .012 1217302-1 ShallowBox 12.07 0.51 0.30 1Twomagnetwiresmaybeterminatedinthesameterminalslot Note:PCBoardhole size.050[1.27]. ifdiametersareequal. 2Singlemagnetwireonly. * RecognizedundertheComponentProgramofUnderwritersLaboratories,Inc. 11 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) MAG-MATE Edge Leaf Terminal Material Pre-tinned brass Brass Cavity 411-18517 Copper Magnet Wire Range Stock Strip Cavity Size AWG mm Thickness Part Number 16.2 33-30 0.18-0.265 2 .00.1332 1394429-2 .013 30-26 0.265-0.40 2 1394430-2 A 0.32 MAG-MATE .013 26-22 0.40-0.63 2 1394431-2 Contact RAST 5D 0.32 .013 7.6 22-20 0.63-0.80 2 0.32 1394432-2 .013 20-17 0.85-1.12 2 0.32 1394433-2 3 3.15 Note:Specialcavityrequired.Contact A TEConnectivityforinformation Material Unplated brass Cavity 411-18517 Copper Magnet Wire Range Stock Strip Type Cavity Size AWG mm Thickness Part Number B MAG-MATE 33-30 0.18-0.265 2 .013 1-1987143-1 .64 0.32 [ 16.2] Edge Leaf Contact Note:Specialcavityrequired.Contact TEConnectivityforinformation .31 [ 7.8] .12 [ 3.0] B 12 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) 187 Box Posted PCB Terminals Material Type C o pApWeGr Magnet Wi r me mRange1 DiLm. Stock Thickness PartS Ntruipmber TerSta Tin plated brass .62.6778 .00.1205 63565-1 minnda 33-31 0.18-0.23 ar Typical Cavity Size 1 .83.3308 .00.1205 62938-1 lsd M A (See page 23) .62.6778 .00.1320 63160-1 G-M 30-28 0.25-0.32 .287 .012 A 185ABox 7.29 0.30 63818-1 TE StandardIDC .330 .012 62430-1 .050 PCBPost 8.38 0.30 [1.27] 27-25 0.36-0.46 .330 .012 62438-1 8.38 0.30 L .187 .287 .012 63819-1 [4.75] 24-222 0.51-0.64 7.29 0.30 .330 .012 62439-1 8.38 0.30 1Twomagnetwiresmaybeterminatedinthesameterminalslotifdiametersareequal. 2Singlemagnetwireonly. .090 [2.29] .070 [1.78] A 187 Box Tab Terminals Material Tin plated brass Copper Magnet Wire Range1 Dim. Stock Thickness Strip Typical Cavity Size 1 Type AWG mm L Tab Size Tab Section Mag Wire Part Number .432 .110x.020 .020 .012 (See page 23) 30-28 0.25-0.32 10.97 2.79x0.51 0.51 0.30 63702-1 .432 .110x.020 .020 .012 29-27 0.29-0.36 1217196-1 10.97 2.79x0.51 0.51 0.30 .512 .110x.020 .020 .012 30-28 0.25-0.32 160810-2 B 13.00 2.79x0.51 0.51 0.30 187Box .512 .110x.020 .020 .012 27-25 0.25-0.32 160809-2 StandardIDC 13.00 2.79x0.51 0.51 0.30 F-Crimp .512 .110x.020 .020 .012 24-22 0.25-0.32 160897-2 13.00 2.79x0.51 0.51 0.30 L .550 .071 x .025 .025 .012 30 0.25 1217405-1 14.00 1.80 x 0.63 0.63 0.30 .700 .059 x .032 .032 .012 29-27 0.29-0.36 1742605-1 .187 17.78 1.50 x 0.81 0.81 0.30 .090 [4.75] 25-222 0.46-0.64 1.770.708 .10.5590 xx .00.3821 .00.3821 .00.1320 1217013-1 [2.29] 1Twomagnetwiresmaybeterminatedinthesameterminalifdiametersareequal. .070 [1.78] 2Singlemagnetwireonly. B 13 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) 300 Box Tab Terminals Material Tin plated brass .870 [22.1] Typical Cavity Size 2 L (See page 23) .300 .300 [7.62] [7.62] .135 [3.43] .120 .135 C [3.05] [1.78] A B Copper Magnet Wire Range1 Dim. Stock Thickness Strip Type AWG mm L Tab Size Tab Section Mag Wire Part Number .750 .063x.025 .025 .016 19.05 1.60x0.63 0.63 0.41 63965-12 A 20 0.79 300Box .895 .063 x .025 .025 .016 1217595-12 StandardIDC 22.73 1.60 x 0.63 0.63 0.41 StraightTab .870 .062 x .032 .032 .010 31 0.23 22.10 1.57 x 0.81 0.81 0.25 63810-1 1Twomagnetwiresmaybeterminatedinthe sameterminalslotifdiametersareequal. 2Tinselwireonly. Copper Magnet Wire Range1 Dim. Stock Thickness Strip TypicalCavitySize2 Type AWG mm C Tab Size Tab Section Mag Wire Part Number when“C”dimensionis.120[3.05] 33-31 0.18-0.23 .070 .125x.020 .020 .012 63806-1 (Seepage23) 1.78 3.17x0.51 0.51 0.30 TypicalCavitySize6 31-28 0.23-0.32 .10.7708 .31.2157xx.00.2501 .00.2501 .00.1320 63807-1 when“C”dimensionis.070[1.78] B (Seepage23) Sta3n0d0aBrdoIxDC 27-24 0.36-0.50 .10.7708 .31.2157xx0.0.5201 .00.2501 .00.1320 63808-1 TwistedTab 212 0.72 .120 .118 x .030 .030 .016 63463-1 3.05 3.00 x 0.76 0.76 0.41 19.52 0.86 .120 .118 x .030 .030 .016 63216-1 3.05 3.00 x 0.76 0.76 0.41 1Twomagnetwiresmaybeterminatedinthesameterminalslotifdiametersareequal. 2Singlemagnetwireonly. Material Copper Magnet Wire Range1 Dim. Stock Thickness Strip Tin plated brass Type AWG mm L Tab Size Tab Section Mag Wire Part Number .585 .118x.020 .020 .010 33-31 0.18-0.23 1217746-1 Typical Cavity Size 2 14.86 3.00x0.51 0.51 0.25 (See page 23) 30 -28 0.25-0.32 .585 .118x.020 .020 .010 1217745-1 14.86 3.00x0.51 0.51 0.25 .585 .118x.020 .020 .016 63973-1 14.86 3.00x0.51 0.51 0.41 27-23 0.36-0.57 .585 .125 x .020 .020 .016 63489-1 14.86 3.17 x 0.51 0.51 0.41 C 300Box 25-222 0.45-0.64 .585 .118 x .020 .020 .016 1217596-1 StandardIDC 14.86 3.00 x 0.51 0.51 0.41 L TimerTab 23.5-21.52 0.54-0.68 1.548.856 .31.1080 xx .00.2501 .00.2501 .00.1461 1217593-1 .775 .125 x .020 .020 .016 27-23 0.36-0.57 1742167-1 19.68 3.17 x 0.51 0.51 0.41 .300 [7.62] 23-202 0.57-0.81 .775 .125 x .020 .020 .016 63899-1 19.68 3.17 x 0.51 0.51 0.41 19-172 0.91-1.15 .585 .118 x .020 .020 .016 63972-1 14.86 3.00 x 0.51 0.51 0.41 .120 [.31.3325] [3.05] 18 Lead 1.02 .585 .118 x .020 .020 .016 63974-1 14.86 3.00 x 0.51 0.51 0.41 1Two magnet wires maybeterminatedinthesameterminalslotifdiameters areequal. C 2Singlemagnet wireonly;22AWG[0.64mm]orlarger. 14 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) Pin Receptacle Terminals TS Material .75 erta mn A: Tin plated brass .748 [ 19] inda B: Unplated brass [19] alsrd M .30 Typical Cavity Size 2 [.73.0602] [ 7.6] AG (See page 23) -M A T [.31.3325] .120 E [3.05] .12 .138 [ 3.0] [ 3.5] A B Copper Magnet Wire Range1 Strip Type Mating Pin Dia. Stock Thickness AWG mm Part Number .079 .013 30-27 0.25-0.36 2.00 0.32 1394403-1 .079 .013 26-23 0.40-0.57 2.00 0.32 1394475-1 PAin 21-182 0.72-1.00 .20.7090 .00.1332 1394476-1 Receptacle .150 .013 26-23 0.40-0.57 3.80 0.32 1394638-1 21-182 0.72-1.00 .150 .013 1394639-1 3.80 0.32 .150 .013 30-27 0.25-0.36 3.80 0.32 1740417-1 B .150 .013 Pin 26-23 0.40-0.57 3.80 0.32 1740418-1 Receptacle 21-183 0.72-1.00 .31.5800 .00.1332 1740419-1 1Twomagnetwiresmaybeterminatedinthesameterminalslotifdiametersareequal. 2Singlemagnetwireonly;20.5AWG[0.76mm]orlarger. 3 Single magnet wire only 15 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) Pin I/O Terminals Material .048 Tin plated brass .060 [1.22] [1.52] .300[7.62] Series Box Styles A, B and C Typical Cavity Size 2 .668 .789 .300 [16.76] (See page 23) [20.29] [7.62] .300 .500 [12.7] Series Box [7.62] Style D .120 Typical Cavity Size 4 [3.05] .135 (See page 23) [3.43] .120 .120 [3.05] [3.05] A B .048 .090 [1.22] [2.29] .300 .660 .500 .860 [7.62] [16.76] [17.7] [21.84] .120 .280 [3.05] [7.11] .120 .120 [3.05] [3.05] C D Copper Magnet Wire Range1 Pin Stock Thickness Strip Type AWG mm Dia. I/O Mag Wire Part Number A .060 .010 .010 300Box 27-23 0.36-0.57 63722-1 1.52 0.25 0.25 StraightPin B .048 .010 .010 300Box 33-31 0.18-0.23 63443-1 1.22 0.25 0.25 OffsetPin-R.H. .048 .010 .010 33-31 0.18-0.23 63444-1 1.22 0.25 0.25 .048 .010 .010 C 31-28 0.23-0.32 1.22 0.25 0.25 63569-1 300Box OffsetPin-L.H. 27-23 0.36-0.57 .10.4282 .00.1205 .00.1265 63570-1 25-222 0.45-0.64 .10.4282 .00.1205 .00.1461 63788-1 D 27-23 0.86-1.15 .20.9209 .00.1461 .00.1461 63278-1 500Box StraightPin 22-20 0.64-0.81 .20.9209 .00.1461 .00.1461 63277-1 1Twomagnetwiresmaybeterminatedinthe sameterminalslotifdiametersareequal. 2Singlemagnetwireonly; 22AWG[0.64mm]orlarger. 16 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) 110 Series FASTON Tab Terminals TS erta Material mn inda Tin plated brass .625 .625 [1.666.706] alsrd M [15.88] [15.88] A Typical Cavity Size 2 .300 .310 G- (See page 23) [7.62] [7.87] MA T E Note:.110[2.79] Tab Terminals .300 mate with compatible .135 [7.62] [3.43] FASTON receptacles. Request Catalog 82004. [.31.3453] [.31.2005] [.31.2005] [.31.3453] [.31.2005] A B C Copper Magnet Wire Range1 Tab Stock Thickness Strip Type AWG mm Size Tab Mag Wire Part Number .110 x .020 .020 .012 30-27 0.25-0.36 63777-1 2.79 x 0.51 0.51 0.30 A4 .110x.020 .020 .016 300Box 27-23 0.36-0.57 2.79x0.51 0.51 0.41 63746-1 StandardIDC .110[2.79] 23-202 0.45-0.64 .110x.020 .020 .016 63486-1 2.79x0.51 0.51 0.41 FASTONTab .110x.020 .020 .020 19-17 0.91-1.15 63145-1 2.79x0.51 0.51 0.51 B4.5 27-23 0.36-0.57 .110x.020 .020 .016 63827-1 300Box 2.79x0.51 0.51 0.41 SingleIDCw/ 3.5-202 0.54-0.81 .110x.020 .020 .016 1217783-1 StrainReliefSlot 2.79x0.51 0.51 0.41 .110x.020 .020 .012 C3.4 28-24 0.32-0.51 2.79x0.51 0.51 0.30 63062-1 Poke-In CombinationTab 25-222 0.45-0.64 .110x.020 .020 .012 63063-2 2.79x0.51 0.51 0.30 1Twomagnetwiresmaybeterminatedinthesameterminalslotifdiametersareequal. 2Singlemagnetwireonly; 22AWG[0.64mm]orlarger. 3Poke-Infeatureaccepts 20-18AWG[0.5-0.8mm2]Solidorovercoatedstrandedleadwireor90°Poke-Intab. 4Afterinsertionintoplasticcavity,tabportionmustbebentover45°-90°orpottedintopreventpulloutwhenmating receptacleisdisconnected. 5Strainrelief slotforhighvibrationapplications. 17 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) 187 Series Copper Magnet Stock Thickness FASTON Tab Terminals Type Wire Range1 DiLm. FeTaatubre Tab Size Tab Mag. Wire PartS Ntruipmber AWG mm Section Section Material .630 Dimple .187 x .020 .020 .010 62513-1* 16.00 4.75 x 0.51 0.51 0.25 Tin plated brass 33-31 0.18-0.23 .660 .187 x .020 .020 .012 Hole 63584-1 16.76 4.75 x 0.51 0.51 0.30 .187 x .020 .020 .012 Dimple 62512-1* Typical Cavity Size .630 4.75 x 0.51 0.51 0.30 30-27 0.25-0.36 (See page 23) 16.00 Dimple .187 x .032 .032 .012 62678-1†* 4.75 x 0.81 0.81 0.30 Type A—Cavity Size 2 .187 x .020 .020 .016 Dimple 62514-1* 4.75 x 0.51 0.51 0.41 .630 .187 x .020 .020 .016 16.00 Hole 4.75 x 0.51 0.51 0.41 63664-1 27-23 0.36-0.57 .187 x .020 .020 .016 63461-1 Hole or 4.75 x 0.51 0.51 0.41 Dimple A3 .660 Hole .187 x .020 .020 .016 63585-1 300Box 16.76 4.75 x 0.51 0.51 0.41 L StandardIDC .630 .187 x .020 .020 .016 .187[4.75] 23 0.57 16.00 4.75 x 0.51 0.51 0.41 63776-1 FASTON .187 x .020 .020 .016 Tab Dimple 62511-1* .300 4.75 x 0.51 0.51 0.41 [7.62] 22-202 0.64-0.81 1.663.000 Hole .41.8775 xx .00.2501 .00.2501 .00.1461 63663-1 .187 x .032 .032 .016 .120 Dimple 4.75 x 0.81 0.81 0.41 1217065-1 [3.05] .135 .187 x .032 .032 .016 [3.43] Hole 4.75 x 0.81 0.81 0.41 1217128-1 A 20-182 0.81-1.02 .630 Dimple .41.8775 xx .00.2501 .00.2501 .00.2501 62904-14 16.00 .187 x .020 .020 .020 Hole 63670-1 4.75 x 0.51 0.51 0.51 .187 x .020 .020 .020 63273-12 187 Series .630 Dimple 4.75 x 0.51 0.51 0.51 1742160-11 19-17 0.91-1.15 Combination Poke-In 16.00 Hole .187 x .020 .020 .020 63665-1 4.75 x 0.51 0.51 0.51 FASTON Terminals 1Twomagnetwiresmaybeterminatedinthesameterminalslotifdiametersareequal. 2Singlemagnetwireonly. 3Afterinsertionintoplasticcavity,tabportionmustbebentover45°-90°orpottedintopreventpulloutwhen Material matingreceptacleisdisconnected. 4Singlebarecopperwireonly. Tin plated brass * RecognizedundertheComponentProgramofUnderwritersLaboratories,Inc. †Thesepartnumbersareavailableuponspecialrequest;contactTEEngineeringfordetails. Typical Cavity Size (See page 23) Copper Magnet Stock Thickness Type B—Cavity Size 2 Type Wire Range1 DiLm. FeTaatubre Tab Size Tab Mag. Wire PartS Ntruipmber AWG mm Section Section .630 .187 x .020 .020 .010 33-31 0.81-0.23 16.00 Hole 4.75 x 0.51 0.51 0.25 63018-1 B3.4 27-222 0.35-0.63 1.663.000 w/Ho oHleole .41.8775 xx .00.2501 .00.2501 .00.1461 2-331166330000--47 Poke-In 22-192 0.64-0.89 .630 Hole .187 x .020 .020 .016 316300-5 Combination 16.00 w/o Hole 4.75 x 0.51 0.51 0.41 2-316300-8 .310 Tab 19-172 0.90-1.15 1.663.000 w/Ho oHleole .41.8775 xx .00.2501 .00.2501 .00.1461 2-331166330000--69 [7.87] 17-162 1.20-1.30 1.663.000 Hole .41.8775 xx .00.2501 .00.2501 .00.1461 6-316300-7 .135 .120 1Twomagnetwiresmaybeterminatedinthesameterminalslotifdiametersareequal. [3.43] [3.05] 2Singlemagnetwireonly;22AWG[0.64mm]orlarger. 3Poke-Infeatureaccepts20-18AWG[0.5-0.8mm2]solid,fusedstrandedleadwireor90°poke-intabterminal. 4Afterinsertionintoplasticcavity,tabportionmustbebentover45°-90°orpottedintopreventpulloutwhenmating receptacleisdisconnected. B Note:.187[4.75] Tab Terminals mate with compatible FASTON receptacles. Request Catalog 82004. Chart continued on next page 18 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) 187 Series .187 [4.75] FASTON Tab Terminals (Continued) TerSta mn Material HDoimlep oler Dimple inadar Tin plated brass L lsd M A .300 G .300 [7.62] -M Typical Cavity Size [7.62] A T (See page 23) .120 E Type A—Cavity Size 5 [3.05] .135 .120 Type B—Cavity Size 5 [3.43] [3.05] .135 [3.43] A B Copper Magnet Stock Thickness Type Wire Range1 DiLm. FeTaatubre Tab Size Tab Mag. Wire PartS Ntruipmber AWG mm Section Section 33-31 0.18-0.23 .630 Dimple .187 x .020 .020 .010 63108-1† 16.00 4.75 x 0.51 0.51 0.25 31-28 0.23-0.32 .630 Dimple .187 x .020 .020 .010 62743-1† 16.00 4.75 x 0.51 0.51 0.25 30-27 0.25-0.36 .630 Dimple .187 x .020 .020 .012 63109-1† 16.00 4.75 x 0.51 0.51 0.30 A .630 Dimple .41.8775 xx .00.2501 .00.2501 .00.1461 63107-1 Sta3n0d0aBrdoxIDC 27-23 0.36-0.57 16.00 Dimple .187 x .020 .020 .016 1217493-1 NarrowBody 4.75 x 0.51 0.51 0.41 LatchType 23-202 0.57-0.81 .630 Dimple .187 x .020 .020 .016 63340-1 16.00 4.75 x 0.51 0.51 0.41 22-202 0.64-0.81 .630 Dimple .187 x .020 .020 .016 63429-1 16.00 4.75 x 0.51 0.51 0.41 Dimple .187 x .020 .020 .016 62888-1 19-172 0.91-1.15 1.663.000 Hole .41.8775 xx .00.2501 .00.2501 .00.1461 63782-1 4.75 x 0.51 0.51 0.41 18 lead20.80-0.92 mm2 .630 .187 x .020 .020 .016 1217592-1† 16.00 4.75 x 0.51 0.51 0.41 B3 LNaatcrrhowTyBpeodwy/ 23.5-202 0.54-0.81 1.663.000 Dimple .41.8775 xx .00.2501 .00.2501 .00.1461 1217004-1 StrainReliefSlot 1Twomagnetwiresmaybeterminatedinthesameterminalslotifdiametersareequal. 2Singlemagnetwireonly;22AWG[0.64mm]orlarger. 3Strainreliefslotforhighvibrationapplications. †Thesepartnumbersareavailableuponspecialrequest;contactTEEngineeringfordetails. Chart continued on next page 19 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) 187 Series FASTON Tab Terminals (Continued) Material Tin plated brass Typical Cavity Size (See page 23) Type A—Cavity Size 4 Type B—Cavity Size 4 Copper Magnet Stock Thickness Type Wire Range1 DiLm. FeTaatubre Tab Size Tab Mag. Wire PartS Ntruipmber AWG mm Section Section Hole or 22-20 0.64-0.81 .830 Hole .187 x .020 .020 .020 1742819-1 Dimple 21.08 4.75 x 0.51 0.51 0.51 .830 .187 x .020 .020 .020 19-17 0.91-1.15 Hole 1742820-1 21.08 4.75 x 0.51 0.51 0.51 .187 x .020 .020 .020 Hole 63667-1 .505 4.75 x 0.51 0.51 0.51 [12.83] .830 .187 x .020 .020 .020 17.5-16 1.09-1.29 Hole 63427-1 21.08 4.75 x 0.51 0.51 0.51 A3 .187 x .032 .032 .020 .120 500Box Hole 4.75 x 0.81 0.81 0.51 1217075-1 [3.05] StandardIDC .187 x .020 .020 .020 .280 Hole 4.75 x 0.51 0.51 0.51 63666-1 [7.11] .830 .187 x .020 .020 .020 16-15 1.29-1.45 Hole 63762-1 21.08 4.75 x 0.51 0.51 0.51 A .187 x .020 .020 .020 Dimple 63353-1 4.75 x 0.51 0.51 0.51 14.5-132 1.54-1.83 .830 Hole .187 x .020 .020 .020 1217902-1 21.08 4.75 x 0.51 0.51 0.51 .830 .187 x .020 .020 .020 27-23 0.36-0.57 Hole 1217042-1 21.08 4.75 x 0.51 0.51 0.51 [.41.8775] Hole .187 x .020 .020 .020 63983-1 .830 4.75 x 0.51 0.51 0.51 22-20 0.64-0.81 L Hole B3.4 21.08 Hole .41.8775 xx .00.3821 .00.3821 .00.2501 1217339-1 500Box SingleIDCw/ .187 x .020 .020 .020 Hole 63995-1 StrainReliefSlot .830 4.75 x 0.51 0.51 0.51 19-17 0.91-1.15 .505 21.08 .187 x .032 .032 .020 [12.83] Hole 4.75 x 0.81 0.81 0.51 1217090-1 .281 [7.14] .120 16-15 1.29-1.45 .830 Hole .187 x .020 .020 .020 63996-1 [3.05] 21.08 4.75 x 0.51 0.51 0.51 1Twomagnetwiresmaybeterminatedinthesameterminalslotifdiametersareequal. B 2Singlemagnetwireonly. 3Afterinsertionintoplasticcavity,tabportionmustbebentover45°-90°orpottedintopreventpulloutwhen matingreceptacleisdisconnected. 4Strainreliefslotforhighvibrationapplications. 20 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) 250 Series FASTON Tab Terminals Hole or TS Material HDoimlep oler L Dimple L Dimple L Locking ermintanda Tin plated brass [.73.0602] [.73.0602] [.73.0602] La(2tc)h lsard M A G T(Syepei cpaagl eC 2a3v)ity Size [.31.3453] [.31.2005] [.31.3453] [.31.2005] [.31.3453] [.31.2005] -MA T Type A—Cavity Size 2 A B C E Type B—Cavity Size 5 Copper Magnet Stock Thickness Type C—Cavity Size 3 Type Wire Range1 DiLm. FeTaatubre Tab Size Tab Mag. Wire PartS Ntruipmber AWG mm Section Section Note:.250[6.35] tab terminals 33-31 0.18-0.23 .750 Dimple .250 x .032 .032 .010 62600-1* 19.05 6.35 x 0.81 0.81 0.25 mate with compatible FASTON .750 .250 x .032 .032 .012 receptacles. Request A3 30-27 0.25-0.36 19.05 Dimple 6.35 x 0.81 0.81 0.30 62651-1* 300 Box .750 .250 x .032 .032 .016 Catalog 82004. Standard IDC 28-24 0.32-0.51 19.05 Hole 6.35 x 0.81 0.81 0.41 63607-1 .250 [6.35] FASTON 27-23 0.36-0.57 .750 Dimple .250 x .032 .032 .016 62652-1* Tab 19.05 6.35 x 0.81 0.81 0.41 .750 .250 x .032 .032 .016 22-20 0.64-0.81 Dimple 1217924-1 19.05 6.35 x 0.81 0.81 0.41 .750 .250 x .032 .032 .020 19-17 0.91-1.15 Dimple 1742398-1 19.05 6.35 x 0.81 0.81 0.51 33-31 0.18-0.231 .750 Dimple .250 x .032 .032 .010 63026-1 19.05 6.35 x 0.81 0.81 0.25 B 30-27 0.25-0.361 .750 Dimple .250 x .032 .032 .012 63027-1. Narrow 19.05 6.35 x 0.81 0.81 0.30 Body .750 .250 x .032 .032 .016 Latch Type 27-23 0.36-0.57 19.05 Dimple 6.35 x 0.81 0.81 0.41 1217860-1 23-202 0.57-0.81 .750 Dimple .250 x .032 .032 .016 1217870-1 19.05 6.35 x 0.81 0.81 0.41 .750 .250 x .032 .032 .010 33-31 0.18-0.23 Hole 63309-1 19.05 6.35 x 0.81 0.81 0.25 .750 .250 x .032 .032 .012 31-28 0.23-0.32 Dimple 63403-2 19.05 6.35 x 0.81 0.81 0.30 .750 .250 x .032 .032 .012 30-28 0.25-0.32 Hole 1217152-1 19.05 6.35 x 0.81 0.81 0.30 C Wide Body 30-27 0.25-0.36 .750 Dimple .250 x .032 .032 .012 63132-1 Latch Type 19.05 Hole 6.35 x 0.81 0.81 0.30 63499-1 .750 Hole .250 x .032 .032 .016 63571-1 27-23 0.36-0.57 19.05 Dimple 6.35 x 0.81 0.81 0.41 63128-1 22-202 0.64-0.81 .750 Dimple .250 x .032 .032 .016 63601-2 19.05 6.35 x 0.81 0.81 0.41 19-172 0.91-1.15 .750 Hole .250 x .032 .032 .016 63614-1 19.05 6.35 x 0.81 0.81 0.41 1Twomagnetwiresmaybeterminatedinthe same * RecognizedundertheComponentProgramof terminalslotifdiametersareequal. UnderwritersLaboratories,Inc. 2Singlemagnetwireonly; 22AWG[0.64mm]orlarger. 3Afterinsertionintoplasticholder,tabportionmust be bentover45°-90°orpottedintopreventpulloutwhen matingreceptacleisdisconnected. Chart continued on next page 21 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) 250 Series FASTON Tab Terminals (Continued) Hole or Hole or Dimple Dimple Material Tin plated brass L L .500 .500 [12.7] [12.7] Typical Cavity Size (See page 23) .120 Type A—Cavity Size 4 [3.05] .120 [3.05] Type B—Cavity Size 4 .280 .280 [7.11] [7.11] A B Copper Magnet Stock Thickness Type Wire Range1 DiLm. FeTaatubre Tab Size Tab Mag. Wire PartS Ntruipmber AWG mm Section Section .952 .250 x .032 .032 .020 22-20 0.64-0.81 Hole 63495-1 24.18 6.35 x 0.81 0.81 0.51 .952 .250 x .032 .032 .020 19-17 0.91-1.15 Hole 63464-3 A3 24.18 6.35 x 0.81 0.81 0.51 500 Box .952 .250 x .032 .032 .020 Standard IDC 16-15 1.29-1.45 24.18 Hole 6.35 x 0.81 0.81 0.51 63459-2 Wide Neck .250 x .032 .032 .020 Dimple 63460-1 14-132 1.61-1.83 .952 6.35 x 0.81 0.81 0.51 24.18 .250 x .032 .032 .020 Hole 63816-1 6.35 x 0.81 0.81 0.51 .952 .250 x .032 .032 .020 22-20 0.64-0.81 Dimple 63155-1 24.18 6.35 x 0.81 0.81 0.51 .952 .250 x .032 .032 .020 B3 19-17 0.91-1.15 24.18 Dimple 6.35 x 0.81 0.81 0.51 62923-1 500 Box .952 .250 x .032 .032 .020 Standard IDC 16-15 1.29-1.45 Dimple 63064-1 24.18 6.35 x 0.81 0.81 0.51 Narrow Neck 14-132 1.61-1.83 .952 Dimple .250 x .032 .032 .020 63465-1 24.18 6.35 x 0.81 0.81 0.51 122 2.05 .952 Dimple .250 x .032 .032 .020 63425-1 24.18 6.35 x 0.81 0.81 0.51 1Twomagnetwiresmaybeterminatedinthesameterminalslotifdiametersareequal. 2Singlemagnetwireonly. 3Afterinsertionintoplasticholder,tabportionmust bebentover45°-90°orpottedintopreventpulloutwhenmating receptacleisdisconnected. 22 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) Typical Plastic Cavity Illustrations shown are for reference only. They are not TS a purchased item. erta Mtoa TnEu fSacpteucriefi coantliyo na.ccording .235 [.93.5058] [.93.5058] minandar [5M.9in7.] Min. Min. lsd M A G - M Technical Documents AT Adepspclriicbaet iroenq uSirpeemceifnictsa tfioorn ussing [.4M1.74in55.] [.3M1.58in01.] [.5M2.14in56.] [.5M2.02in51.] [.9M3.50in58.] [.5M2.39in57.] E the product in its intended CavitySize1 CavitySize2 CavitySize3 187[4.75]Box .300[7.62]Box .300[7.62]Box application and or crimping MAG-MATE MAG-MATE Latch-In MAG-MATE Wide Body information. They are intended (ApplicationSpec.114-2069) (ApplicationSpec.114-2046) (ApplicationSpec.114-2094) for the Packaging and Design Engineer and the Machine Setup Person. 114-2050—Poke-In Tab MAG-MATE Terminals .550 114-2069—SMtAanGd-aMrAdTE.187 [1M3.in9.7] [.93.5058] [.93.5058] Min. [4.75] Box Height Min. Terminals 114-2046—Standard MAG-MATE.300 [7.62] Box Height 114-2066—STMetAarnmGd-inaMarAdlsTE.500 [.9M3.75in53.] [.7M3.06in02.] [.5M2.14in56.] [.5M2.39in57.] [.5M2.14in56.] [.3M1.58in01.] [12.7] Box Height CavitySize4 CavitySize5 CavitySize6 .500[12.70]Box .300[7.62]Box .300[7.62]Box Terminals MAG-MATE Latch-In MAG-MATE, MAG-MATE 114-2067—Standard (ApplicationSpec.114-2066) NarrowBody (ApplicationSpec.114-2046) MAG-MATE .300 (ApplicationSpec.114-2067) [7.62] Box Height Latch-In Terminals Note:The MAG-MATE Unraveling is prevented by a Excess magnet wire is Narrow Body typical plastic cavities shown slight friction fit, suitable trimmed flush with the 114-2094—Standard above are for reference only. bend or by wrapping the outside of the plastic cavity MAG-MATE .300 They are not a purchased magnet wire around a tie-off by a shear blade traveling [7.62] Box Height item. Refer to appropriate TE post. with the terminal insertion Latch-In Terminals application specification for Wide Body details. During insertion, two ram. insulation displacing terminal The sheared wire end can Plastic cavities, designed to slots strip the film insulation be tucked inside the plastic TE specifications, may be from the magnet wire cavity, if necessary, by molded as part of the coil producing a stable electrical cutting the wire off before the bobbin or attached to a termination. terminal is fully seated lamination stack in the area of the magnet wire coil. The plastic anvil supports allowing the terminal to drag the magnet wire, helping to the severed end of the wire Each cavity is a rectangular prevent it from being into the pocket inside the box with two narrow slots on dragged down when the cavity. opposing walls and a plastic terminal is inserted. TE will provide design post or anvil extending and mold engineering upward from the bottom Terminal retention is secured resources to manufac- surface. During or after the in the plastic cavities by ture any specifically winding process, the magnet either locking barbs or designed MAG-MATE wire is placed across the locking latches in addition to cavity housing. plastic cavities and into the locking barbs for quick slots, either manually or by disconnect FASTON tab coil winding equipment. terminals. 23 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Standard MAG-MATE Terminals (Continued) Typical Plastic Cavities Illustrations shown are for reference only. They are not a purchased item. Manufacture only according .375 to TE Specification. [9.53] Min. .375 [9.53] Min. .225 [.62.7806] [.21.1952] [5M.7in1.] Min. Min. .250 [6.35] Min. SlimLineMAG-MATE MiniMAG-MATE ReferenceApplication ReferenceApplication Spec.114-2147 Spec.114-2047 Technical Documents Technical Documents Application Specifications Application Specifications describe requirements for using describe requirements for using the product in its intended the product in its intended application and or crimping application and or crimping information. They are intended information. They are intended for the Packaging and Design for the Packaging and Design Engineer and the Machine Engineer and the Machine Setup Person. Setup Person. 114-2140—Slim Line 114-2047—Mini MAG-MATE MAG-MATE Terminals Terminals 24 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Slim Line MAG-MATE Terminals Product Facts Terminates all magnet wire film insulations TS ermlim Eplriem-sintraitpepsi nnge ecdo nfodru ctors ina Lin lse M Eliminates need to A post-insulate terminations G- M Excess magnet wire is A T automatically trimmed during E the termination process 187 and 250 Series Faston Tab and posted PCB Tab terminals available Terminates 33-17 AWG [0.18-1.15 mm ] magnet wire Simultaneously terminates two magnet wires of the same size in one terminal from 33-23 AWG [0.18-0.57 mm] Available in strip form for semi-automatic or fully automatic insertions TE offers a full selection of The MAG-MATE Inserter This constant pressure High speed, fully automated 187 and 250 Series Faston cuts the terminals from the results in an intimate integrated systems provide and posted PCB Slim Line strip and places the termi- metal-to-metal interface, uniform terminations MAG-MATE Tab insulation nals over the magnet wire providing a reliable, long- reliably at the lowest displacement(IDC) termi- into the plastic cavities. term connection. possible applied cost nals for magnet wire During this operation, small The MAG-MATE terminations. Clean metal-to-metal stripping shoulders in the Inserter may be used as a interface produces stable, Slim Line MAG-MATE IDC slot remove the film semi-automatic bench gas-tight electrical termina- terminals with a single IDC insulation from the magnet machine or integrated in tions free of oxides and slot terminate 33-17 AWG wire. production lines for other contaminants [0.18 to 1.15 mm]. fully-automatic applications. Wiping action between Recognized under the Each IDC slot terminates the wire and terminals Component Recognition a range of up to four removes oxides or other Program of Underwriters consecutive magnet wire contaminants present on Laboratories Inc., sizes. both the conductor and the File No. E13288 R terminal slot side walls, Two magnet wires with the producing a clean, stable, Applications same diameter can be gas-tight electrical termina- terminated in one terminal. Motor windings and tion. Except as noted. connections MAG-MATE cavities are Residual spring energy in Coil Connections either integrated into coil the terminal causes the side Transformer windings and bodies or especially walls of each IDC slot to connections designed cavity housings. function as opposing Bobbin connections The magnet wires are cantilever beams. precisely positioned in the Lighting Ballasts plastic cavity slots. Power Supplies 25 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Slim Line MAG-MATE Terminals (Continued) 187Series FASTONTabTerminals Material Tin plated brass Copper Magnet Stock Thickness Type Wire Range1 DiLm. FeTaatubre Tab Size Tab Mag.Wire PartS Ntruipmber .187 AWG mm Section Section [4.75] Hole .187 x .020 .020 .012 63710-2 .020 [0.51] 33-31 0.18-0.23 .630 Dimple 4.75 x 0.51 0.51 0.30 63738-2 16.00 .187 x .032 .032 .012 Hole or Hole 4.75 x 0.81 0.81 0.30 1217666-1 Dimple .630 Hole .187 x .020 .020 .012 63711-2 30-28 0.25-0.32 16.00 Dimple 4.75 x 0.51 0.51 0.30 63737-2 .630 Hole .187 x .020 .020 .016 63712-2 L .187A[4.75] 27-24 0.36-0.51 16.00 Dimple 4.75 x 0.51 0.51 0.41 63736-2 FASTON Tab .760 Plain .187 x .020 .020 .016 1217497-1 19.31 4.75 x 0.51 0.51 0.41 Hole .187 x .020 .020 .016 63713-2 [.31.3453] 23-202 0.57-0.81 1.663.000 Dimple .41.8775 xx .00.3521 .00.3521 .00.1461 63735-2 .016 Hole 1217516-1 [0.41] 4.75 x 0.81 0.81 0.41 19-172 0.91-1.15 .630 Hole .187 x .020 .020 .016 63714-2 A 16.00 Dimple 4.75 x 0.51 0.51 0.41 63734-2 1 Two magnet wires may be terminated in the same terminal slot if diameters are equal. 2 Single magnet wire only; 22 AWG [0.64] or larger. 250Series FASTONTabTerminals Material Tin plated brass Copper Magnet Stock Thickness .250 Type Wire Range1 DiLm. FeTaatubre Tab Size Tab Mag.Wire PartS Ntruipmber [6.35] AWG mm Section Section .032 .752 Hole .250 x .032 .032 .012 63716-2 [0.81] 33-31 0.18-0.23 19.10 Dimple 6.35 x 0.81 0.81 0.30 63744-2 .752 Hole .250 x .032 .032 .012 63717-2 30-28 0.25-0.32 Hole or 19.10 Dimple 6.35 x 0.81 0.81 0.30 63743-2 Dimple B .250[6.35] 27-24 0.36-0.51 .752 Hole .250 x .032 .032 .016 63718-2 19.10 Dimple 6.35 x 0.81 0.81 0.41 63742-2 FASTON Tab L 23-202 0.57-0.81 1.795.120 DHimoplele .62.5305 xx .00.3821 .00.3821 .00.1461 6633771491--22 19-172 0.91-1.15 .752 Hole .250 x .032 .032 .016 63720-2 19.10 Dimple 6.35 x 0.81 0.81 0.41 63740-2 .135 1 Two magnet wires may be terminated in the same terminal slot if diameters are equal. [3.43] 2 Single magnet wire only; 22 AWG [0.64] or larger. .016 [0.41] B PostedPCB SOLDERTerminal Material Copper Magnet Stock Thickness Tin plated brass Type Wire Range1 DiLm. FeTaatubre Tab Size Tab Mag.Wire PartS Ntruipmber AWG mm Section Section .323 .040 x .024 .024 .013 33.5-30 0.17-0.25 8.20 Embossment 1.00 x 0.60 0.60 0.32 1534684-1 .323 .040 x .024 .024 .013 .0322 C 29.5-26 0.27-0.40 8.20 Embossment 1.00 x 0.60 0.60 0.32 1534685-1 [8.20] .0P4C0B[ 1T.0a0b] 26-22 0.40-0.63 8.3.2203 Embossment 1.0.0400 xx .00.2640 0.0.6204 0.0.3123 1534686-1 .323 .040 x .024 .024 .013 22-20 0.63-0.81 8.20 Embossment 1.00 x 0.60 0.60 0.32 1740829-1 .0125 21.5-19.5 0.67-0.85 8.3.2203 Embossment 1.0.0400 xx .00.2640 0.0.6204 0.0.3123 1534687-1 [.31.3425] [0.32] 1 Two magnet wires may be terminated in the same terminal slot if diameters are equal. C 2 Single magnet wire only; 22 AWG [0.64] or larger. 26 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Slim Line MAG-MATE Terminals (Continued) OffsetTabTerminals MTAlipnap tPleiclraaitateioldn Bs rwashsere I/O Tab TerminaSlim Lin spacing must be less than lse M IDC connection spacing A G Example: automotive -M accessory coils A T E .139 [3.53] .032 [0.81] .059 [1.50] Copper Magnet Stock Thickness .135 L Type Wire Range1 DiLm. DSioizdee Tab Size Tab Mag.Wire PartS Ntruipmber [3.43] AWG mm Section Section .725 #20 .059 x .032 0.032 0.012 A 33-31 0.18-0.23 63888-1 18.42 0.8 1.50 x 0.81 0.81 0.30 Combination [.52.2509] Diode Slot/Tab 33-31 0.18-0.23 1.782.452 #202.6.5 .10.5590 xx .00.3821 00.0.8312 00.0.3102 63903-1 .013 [0.33] 1 Two magnet wires may be terminated in the same terminal slot if diameters are equal. A PostedPCBTerminals Multi-SpringSolderless Terminal Material Tin Plated Copper Alloy CavitySize Application Spec. Contact TE Engineering Copper Magnet Stock Thickness Type Wire Range1 DiLm. Tab Mag.Wire PartS Ntruipmber AWG mm Section Section .583 .031 .013 33-29.5 0.18-0.265 2120743-2 14.80 0.81 0.32 .583 .031 .013 L B 29.5-26 0.265-0.40 14.80 0.81 0.32 2120744-2 Multi-Spring .583 .031 .013 26-22.5 0.40-0.63 2120745-2 Solderless PCB 14.80 0.81 0.32 [.92.8393] Tab Terminal 22.5-19.52 0.63-0.85 .583 .031 .013 2120746-2 14.80 0.81 0.32 19.5-172 0.85-1.12 .583 .031 .013 2120747-2 14.80 0.81 0.32 .132 1 Two magnet wires may be terminated in the same terminal slot Note:PCBoardholesize.057[1.45] [3.35] [.00.1332] if diameters are equal. 2 Single magnet wire only. 22 awg [0.63 mm] and larger. B 27 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Slim Line MAG-MATE Terminals (Continued) PostedPCB SolderTerminals Material Unplated brass Copper Magnet Wire Range Stock Strip Type AWG mm Thickness Part Number 33-30 0.256-0.40 Varied 331 0.40-0.561 thickness 1-1987222-1 30-26 0.256-0.40 Varied 30-261 0.40-0.561 thickness 1-1987223-1 A 26-22 0.40-0.63 Varied MAG-MATE 26-231 0.40-0.561 thickness 1-1987224-1 Terminal Varied with MQS Pins 22-20 0.63-0.80 thickness 1-1987225-1 Varied 20-17 0.85-1.12 1-1987226-1 thickness A 1 For double magnet wires 28 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Mini MAG-MATE Terminals Product Facts Terminates all fine gauge magnet wire film TM insulations erminini M Eliminates need to pre-strip aA conductors lsG- M A Eliminates need to post T E insulate terminations Terminates 52-30 AWG [0.02-0.25 mm] diameter copper magnet wire Poke-In leaf style accepts 22 -18 AWG [0.3-0.9 mm] overcoated stranded or solid lead wire Available in strip form for semi-automatic or fully automatic insertions High speed, fully automated integrated systems provide uniform terminations and reliability at the lowest possible applied cost Recognized under the Component Recognition TE offers Mini MAG-MATE receiving slot and wire tie-off the termination process. Program of Underwriters poke-in, crimp wire post that is either integrated Laboratories Inc, File No. barrel, post and quick into coil bodies or specially The fully seated terminal fits E13288 disconnect tab insulation designed cavity housings. squarely into the cavity,while R displacement(IDC) termi- the serrated leg of the nals for fine gauge magnet The magnet wire is wrapped terminal cams against the Applications wire terminations. around the tie-off post and pre-positioned magnet wire Ignition coils placed across the cavity slot. to penetrate the film insula- Mini MAG-MATE terminals After the coil is wound, the tion and provide a stable Small motors are designed to terminate finish end of the magnet wire electrical termination. Synchronist timers 52-30 AWG [0.02-0.25 mm] is dressed through the diameter copper magnet second cavity slot and tied to Electric meter coils wire. its tie-off post. Solenoids Relays Poke-in leaf terminals accept The Mini MAG-MATE 22-18 AWG [0.3-0.9 mm2] Inserter shears the terminal overcoated stranded or solid from the carrier strip and lead wire. inserts the terminal into the cavity by a dual ram The terminal design uses the insertion mechanism. AMPLIVAR serrated burr technology to penetrate the As the unexpanded terminal film insulation of copper approaches the bottom of magnet wire. the cavity, the upper ram stops. The lower ram Mini MAG-MATE cavity continues to push to a pockets, designed to TE prescribed depth to expand specifications,include a wire the terminal and complete 29 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Mini MAG-MATE Terminals (Continued) Wire Split ram Wire tie-off post Wire Upper ram stops Lower ram continues Sheared post and excess wire to scrap chute Lower ram stops Termination Complete Poke-In Terminal Material .010[0.25] tin plated brass .138 Copper Magnet Wire Range Lead Wire Range1 Mating Stock Thickness Strip [3.51] [.10.6502] Type AWG mm AWG mm2 Tab Poke-In Beam Mag Wire Part Number [.83.4756] A 52-42 0.02-0.06 22-18 0.3-0.9 — 00.0.2150 00.0.2150 62781-1 A Lead 44-36 0.05-0.13 22-18 0.3-0.9 — 0.010 0.010 62780-1 Wire 0.25 0.25 Poke-In 0.010 0.010 38-30 0.10-0.25 22-18 0.3-0.9 — 62606-1 0.25 0.25 .138 [3.51] .060 .060 x .020 0.010 0.010 [1.52] 52-42 0.02-0.06 — — 1.52 x 0.51 0.25 0.25 63613-1 [.83.4756] TBab 44-36 0.05-0.13 — — .060 x .020 0.010 0.010 63795-12 1.52 x 0.51 0.25 0.25 B Poke-In 38-30 0.10-0.25 — — .060 x .020 0.010 0.010 63844-22 1.52 x 0.51 0.25 0.25 .047 L [1.20] C 40-34.5 0.08-0.15 — — .040 x .020 0.010 0.010 1718165-1 Skinny Mini 1.00 x 0.51 0.25 0.25 1 Solid or overcoated stranded lead wire only. .345 2 Radius on beam leaf tip. [8.76] C 30 www.te.com/appliances

Magnet Wire Terminals and Termination Systems Catalog 82221 Mini MAG-MATE Terminals (Continued) PostedTerminal MTina toevreiar lpremilled brass TerminMini M aA lsG - M .138 [3.51] .060 A [1.52] T E .169 [4.29] Type Copper Magnet Wire Range Post Size Stock Thickness Strip AWG mm Post Mag Wire Part Number .540 [13.72] A .024 x .020 0.020 0.010 PCB Post 38-30 0.10-0.25 0.62 x 0.51 0.51 0.25 63675-4 A FASTONTabTerminals Material Tin over premilled brass .138 [3.51] [.10.6502] Type Copper Magnet Wire Range Tab Size Stock Thickness Strip .690 G W A m m Post Mag Wire Part Number [17.53] .187 x .020 .020 .010 B 44-36 0.05-0.13 4.75 x 0.51 0.51 0.25 63778-1 .187[4.75] FASTON Tab 38-30 0.10-0.25 .187 x .020 .020 .010 1217529-1 4.75 x 0.51 0.51 0.25 B CrimpWireBarrelTerminal Material Tin plated brass .060 .138 [1.52] Copper Magnet Wire Range Lead Wire Range Stock Thickness Strip [3.51] Type AWG mm AWG mm2 Crimp Barrel Mag Wire Part Number C Crimp Wire 38-30 0.10-0.25 22-18 0.3-0.9 00.0.2150 00.0.2150 63199-11 Barrel .620 [15.75] 1 Wire and insulation barrel reversed so lead wire exits over magnet wire termination area. C 31 www.te.com/appliances