- 型号: W2E142-BB05-01

- 制造商: EBM/PAPST

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

W2E142-BB05-01产品简介:

ICGOO电子元器件商城为您提供W2E142-BB05-01由EBM/PAPST设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 W2E142-BB05-01价格参考。EBM/PAPSTW2E142-BB05-01封装/规格:AC 风扇, 。您可以下载W2E142-BB05-01参考资料、Datasheet数据手册功能说明书,资料中有W2E142-BB05-01 详细功能的应用电路图电压和使用方法及教程。

ebm-papst Inc. 是一家德国知名的风机制造商,以其高效、可靠和节能的风机产品著称。型号 W2E142-BB05-01 属于其 AC 风扇系列,是一款双进风离心风机(也称“双进风涡轮风机”),具有高风压、大风量和高效率的特点。 该型号风机广泛应用于以下场景: 1. 暖通空调系统(HVAC):适用于商用和工业用空调系统,用于空气循环、通风和冷却。 2. 工业设备冷却:用于工业机械、电气柜、变频器、电源系统等设备的散热,确保设备在适宜温度下运行。 3. 洁净室与实验室通风:适用于对空气流动要求较高的洁净室、实验室通风系统,确保空气洁净度与环境稳定。 4. 热交换系统:用于热交换器中增强空气流动效率,提高热交换性能。 5. 干燥与输送系统:用于工业干燥设备、物料气力输送系统中,提供稳定气流支持。 该风机采用 AC 技术,具备良好的稳定性和较长的使用寿命,适合连续运行的工业环境。同时,其紧凑设计便于集成到各种设备中。

| 参数 | 数值 |

| 产品目录 | |

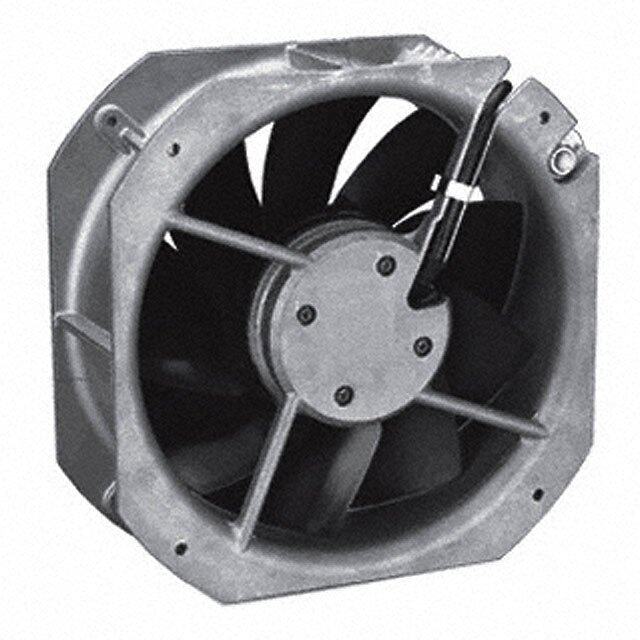

| 描述 | FAN EXH 172 X 150 X 38MM 115VAC交流风扇 150x172x38 230CF 24W 115V 3300RPM 57dB BB |

| 产品分类 | |

| 品牌 | EBM-Papst Industries Inc |

| 产品手册 | |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 风扇,交流风扇,ebm-papst W2E142-BB05-01W2E142 |

| 数据手册 | |

| 产品型号 | W2E142-BB05-01 |

| RPM | 3350 RPM |

| 产品 | Fans |

| 产品培训模块 | http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=24754 |

| 产品目录页面 | |

| 产品种类 | 交流风扇 |

| 侵入防护 | - |

| 其它名称 | 381-1063 |

| 其它有关文件 | |

| 功率(W) | 28.0W |

| 功率额定值 | 24 W |

| 单位重量 | 1 kg |

| 商标 | ebm-papst |

| 噪声 | 57 dB(A) |

| 外壳材料 | Aluminum |

| 大小/尺寸 | 矩形/圆形 - 172mm 长 x 150mm 高 x 38mm 宽 |

| 宽度 | 38 mm |

| 工作温度 | -40 ~ 176°F (-40 ~ 80°C) |

| 材料–刀片 | 钢 |

| 材料–框架 | 铝 |

| 标准包装 | 1 |

| 框架尺寸-mm | 172 mm x 38 mm x 150 mm |

| 气流 | 230.0 CFM (6.51m³/min) |

| 特性 | - |

| 电压-额定 | 115VAC |

| 电压范围 | - |

| 电流类型 | AC |

| 电源电压 | 115 V |

| 相关产品 | /product-detail/zh/LZ36/LZ36-ND/441870/product-detail/zh/50950-2-4039/50950-2-4039-ND/441447 |

| 端接 | 2 端子 |

| 端接类型 | Terminals |

| 类型 | Axial Fans |

| 轴承类型 | 滚珠 |

| 速度 | 3350 RPM |

| 重量 | 1.8 磅(816.5g) |

| 长度 | 172 mm |

| 静压力 | - |

| 预期寿命 | - |

| 额定电流 | 0.250A |

| 风扇类型 | 管轴式 |

| 高度 | 150 mm |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

Operating instructions W2E142-BB05-01 ebm-papstMulfingenGmbH&Co.KG 1.SAFETYREGULATIONSANDNOTES Bachmühle2 D-74673Mulfingen Pleasereadtheseoperatinginstructionscarefullybeforestartingtowork Phone:+49(0)7938/81-0 withthedevice.Observethefollowingwarningstopreventmalfunctions Fax:+49(0)7938/81-110 orphysicaldamagetobothpropertyandpeople. info1@de.ebmpapst.com Theseoperatinginstructionsaretoberegardedaspartofthisdevice. www.ebmpapst.com Ifthedeviceissoldortransferred,theoperatinginstructionsmust accompanyit. Theseoperatinginstructionsmaybeduplicatedandforwardedfor CONTENTS informationaboutpotentialdangersandtheirprevention. 1.1Levelsofhazardwarnings 1.SAFETYREGULATIONSANDNOTES 1 1.1Levelsofhazardwarnings 1 Theseoperatinginstructionsusethefollowinghazardlevelstoindicate potentiallyhazardoussituationsandimportantsafetyregulations: 1.2Staffqualification 1 DANGER 1.3Basicsafetyrules 1 Indicatesanimminentlyhazardoussituationwhich,ifnot 1.4Electricalvoltage 1 avoided,willresultindeathorseriousinjury.Compliancewith 1.5Safetyandprotectivefunctions 2 themeasuresismandatory. 1.6Mechanicalmovement 2 WARNING 1.7Emission 2 Indicatesapotentiallyhazardoussituationwhich,ifnotavoided, couldresultindeathorseriousinjury.Exerciseextreme 1.8Hotsurface 2 cautionwhileworking. 1.9Transport 2 CAUTION 1.10Storage 2 Indicatesapotentiallyhazardoussituationwhich,ifnotavoided, 1.11Disposal 2 mayresultinminorormoderateinjuryordamageofproperty. 2.PROPERUSE 3 NOTE Apotentiallyharmfulsituationcanoccurand,ifnotavoided,can 3.TECHNICALDATA 4 leadtopropertydamage. 3.1Graphicrenditionofproducts 4 1.2Staffqualification 3.2Nominaldata 5 Onlyspecialisedelectricalpersonnelmayinstallthedevice,performthe 3.3Technicaldescription 5 testrunandworkontheelectricalsystem. 3.4Mountingdata 5 Onlytrainedandauthorisedspecialistpersonnelarepermittedto 3.5Transportandstorageconditions 5 transport,unpack,assemble,operateormaintainthedevice,ortouseit inanyothermanner. 4.CONNECTIONANDSTART-UP 6 1.3Basicsafetyrules 4.1Connectingthemechanicalsystem 6 4.2Connectingtheelectricalsystem 6 Anysafetyhazardsstemmingfromthedevicemustbere-evaluated onceitisinstalledintheenddevice. 4.3Connectionviaplug 6 Observethefollowingwhenworkingontheunit: ns 4.4Connectiondiagram 7 ⇒Donotmakeanymodifications,additionsorconversionstothe o ucti 4.5Checkingtheconnections 8 devicewithouttheapprovalofebm-papst. nstr 4.6Switchondevice 8 g i 1.4Electricalvoltage eratin 4.7Switchingoffthedevice 8 ⇒Checktheelectricalequipmentofthedeviceatregularintervals. nal op 5C.AMUASIENSTEANNADNRCEEM,MEDAILEFSUNCTIONS,POSSIBLE 8 ⇒Removelooseconnectionsanddefectivecablesimmediately. gi e ori 5.1Cleaning 9 DANGER h Electricalloadonthedevice n of t 5.2Safetytest 9 Riskofelectricshock o ati →Standonarubbermatifyouareworkingonanelectrically sl an chargeddevice. Tr WARNING Terminalsandconnectionshavevoltageevenwitha unitthatisshutoff Electricshock →Waitforfiveminutesafterdisconnectingthevoltageatall polesbeforetouchingtheunit. Itemno.:10948-5-9970·Revisionstatus:KM70969·Print-outon02/12/2010·CreatedbyA.Kehm(VM---)·Page1of9 ebm-papstMulfingenGmbH&Co.KG·Bachmühle2·D-74673Mulfingen·Phone:+49(0)7938/81-0·Fax:+49(0)7938/81-110·info1@de.ebmpapst.com·www.ebmpapst.com

Operating instructions W2E142-BB05-01 CAUTION 1.8Hotsurface Themotorrestartsautomaticallywhenoperatingvoltage isapplied,e.g.afterapowerfailure. CAUTION Dangerofinjury Hightemperatureatthemotorhousing →Keepoutofthedangerzoneofthedevice. Dangerofburninjuries →Whenworkingonthedevice,switchoffthemains →Ensurethatsufficientprotectionagainstaccidentalcontactis provided. supplyvoltageandsecurethelatterfrombeingswitchedon again. 1.9Transport →Waituntilthedevicestops. NOTE 1.5Safetyandprotectivefunctions Transportofdevice →Transportthedeviceinitsoriginalpackagingonly. DANGER Missingsafetydeviceandnon-functioningsafetydevice →Securethedevicesothatitdoesnotslip,e.g.byusinga Ifthereisnosafetydevice,youcouldbeseriouslyinjured,for clampingstrap. examplebyreachingintotherunningdevicewithyourhands. 1.10Storage →Operatethedeviceonlywithafixedandisolatingsafety protectionandafixedguardgrille.Theguardmustwithstand Storethedeviceinadryandweatherproofmannerintheoriginal thekineticenergyofafanbladedetachingatmaximum packinginacleanenvironment. speed. Protectthedevicefromenvironmentalimpactsanddirtuntilthefinal →Thedeviceisabuilt-incomponent.You,theowner/ installation. Werecommendstoringthedeviceforamaximumuptooneyearto operator,areresponsibleforprovidingadequateprotectionfor guaranteeproperoperationandlongestpossibleservicelife. thedevice. Evendevicesexplicitlysuitedforoutdoorusearetobestoredas →Instantlystopthedeviceonceyoudetectamissingor describedpriortobeingcommissioned.Maintainthestorage ineffectiveprotectivefeature. temperature,see chapter3.5Transportandstorageconditions. 1.6Mechanicalmovement 1.11Disposal DANGER Rotatingdevice Whendisposingofthedevice,pleasecomplywithallrelevant Bodypartscomingintocontactwiththerotorandimpellercan requirementsandregulationsapplicableinyourcountry. beinjured. →Securethedeviceagainstaccidentalcontact. →Beforeworkingonthesystem/machine,waituntilall partshavecometoastandstill. WARNING Rotatingdevice Longhair,looseitemsofclothingandjewellerycouldbecome entangledandpulledintothedevice.Youcouldbeinjured. →Donotwearanylooseclothingorjewellerywhileworking onrotatingparts. s n ctio →Protectlonghairbywearingacap. u nstr WARNING ng i Flyingparts erati Ifsafetydevicesaremissing,thismaycausefanbladestobe p o ejectedathighspeeds,causingbodilyharm. al gin →Takeappropriatesafetymeasures.Thesafetydevicesmust e ori preventcontactwithrotatingandelectricallyliveparts. h n of t 1.7Emission o ati sl WARNING n a Tr Dependingontheinstallationandoperatingconditions, asoundpressurelevelgreaterthan70dB(A)mayarise. Dangerofnoise-inducedhearingloss →Takeappropriatetechnicalsafetymeasures. →Protectoperatingpersonnelwithappropriatesafety equipment,e.g.hearingprotection. →Alsoobservetherequirementsoflocalagencies. Itemno.:10948-5-9970·Revisionstatus:KM70969·Print-outon02/12/2010·CreatedbyA.Kehm(VM---)·Page2of9 ebm-papstMulfingenGmbH&Co.KG·Bachmühle2·D-74673Mulfingen·Phone:+49(0)7938/81-0·Fax:+49(0)7938/81-110·info1@de.ebmpapst.com·www.ebmpapst.com

Operating instructions W2E142-BB05-01 2.PROPERUSE Thedeviceisexclusivelydesignedasabuilt-indeviceformovingair accordingtoitstechnicaldata. Anyotherorsecondaryuseisdeemedimproperandconstitutesa misuseofthedevice. Installationsonthecustomer'ssidemustmeetthemechanical,thermal andservicelife-relatedstressesthatcanoccur. Properusealsoincludes: • Movingairwithadensityof1.2kg/m³. • Usingthedeviceinaccordancewiththepermittedambient temperature,seechapter3.5Transportandstorageconditionsand chapter3.2Nominaldata. • Operatingthedevicewithallprotectivefeaturesinplace. • Mindingtheoperatinginstructions. Improperuse Usingthedeviceinthefollowingwaysisparticularlyprohibitedand maycausehazards: • Movingairthatcontainsabrasiveparticles. • Movinghighlycorrosiveair,e.g.saltspraymist.Exceptionsare devicesthatareintendedforsaltspraymistandprotectedaccordingly. • Movingairthatcontainsdustpollution,e.g.suctioningoffsawdust. • Operatingthedeviceclosetoflammablematerialsorcomponents. • Operatingthedeviceinanexplosiveatmosphere. • Usingthedeviceasasafetycomponentorfortakingonsafety- relatedfunctions. • Inaddition,allapplicationoptionsthatarenotlistedunderproperuse. s n o cti u str n g i n ati er p o al n gi ori e h of t n o ati sl n a Tr Itemno.:10948-5-9970·Revisionstatus:KM70969·Print-outon02/12/2010·CreatedbyA.Kehm(VM---)·Page3of9 ebm-papstMulfingenGmbH&Co.KG·Bachmühle2·D-74673Mulfingen·Phone:+49(0)7938/81-0·Fax:+49(0)7938/81-110·info1@de.ebmpapst.com·www.ebmpapst.com

Operating instructions W2E142-BB05-01 3.TECHNICALDATA 3.1Graphicrenditionofproducts Allmeasureshavetheunitmm. 1 2xflatplug2.8x0.5mm 2 Directionofairflow"V" s n o cti u str n g i n ati er p o al n gi ori e h of t n o ati sl n a Tr Itemno.:10948-5-9970·Revisionstatus:KM70969·Print-outon02/12/2010·CreatedbyA.Kehm(VM---)·Page4of9 ebm-papstMulfingenGmbH&Co.KG·Bachmühle2·D-74673Mulfingen·Phone:+49(0)7938/81-0·Fax:+49(0)7938/81-110·info1@de.ebmpapst.com·www.ebmpapst.com

Operating instructions W2E142-BB05-01 3.2Nominaldata 3.5Transportandstorageconditions Motor M2E052-BA ⇒Usethedeviceinaccordancewithitsprotectiontype. Max.permissible +80°C Phase 1~ 1~ ambientmotortemp. Nominalvoltage[V] 115 115 (transp./storage) Frequency[Hz] 50 60 Min.permissible -40°C Typeofdatadefinition rfa rfa ambientmotortemp. Validforapproval/ CE CE (transp./storage) standard Speed[min-1] 2800 3350 Powerinput[W] 27 28 Currentdraw[A] 0.24 0.25 Motorcapacitor[μF] 3 3 Capacitorvoltage[VDB] 220 220 Capacitorstandard P0(CE) P0(CE) Max.ambient 55 65 temperature[°C] ml=max.load·me=max.efficiency·rfa=runningatfreeair cs=customerspecs·cu=customerunit Subjecttoalterations 3.3Technicaldescription Leackagecurrent <0.75mA Size 142mm Operationmode S1 Directionofrotation Counter-clockwise,seenonrotor Mountingposition Any Directionofairflow "V" Insulationclass "B" Condensatedischarge None holes Bearingmotor Ballbearing Mass 0.8kg Housingmaterial Die-castaluminium,coatedinblack Materialofimpeller Sheetsteel,coatedinblack Motorprotection Thermaloverloadprotector(TOP)wired internally Productconforming CE;EN60335-1 tostandard s on Surfaceofrotor Coatedinblack ucti Numberofblades 7 str g in Typeofprotection IP22;Dependingoninstallationand atin position er Protectionclass I(ifearthwireisconnectedbycustomer) p o al Approval CCC;CSAC22.2Nr.113;GOST;UL n gi 507;VDE ori e h of t 3.4Mountingdata n atio Fordepthofscrew,seechapter3.1Graphicrenditionofproducts ansl ⇒Securethemountingscrewsagainstaccidentallycomingloose(e.g. Tr byusingself-lockingscrews). Strengthclassfor 8.8 mountingscrews Youcanobtainadditionalmountingdatafromtheproductdrawingif necessary. Itemno.:10948-5-9970·Revisionstatus:KM70969·Print-outon02/12/2010·CreatedbyA.Kehm(VM---)·Page5of9 ebm-papstMulfingenGmbH&Co.KG·Bachmühle2·D-74673Mulfingen·Phone:+49(0)7938/81-0·Fax:+49(0)7938/81-110·info1@de.ebmpapst.com·www.ebmpapst.com

Operating instructions W2E142-BB05-01 4.CONNECTIONANDSTART-UP 4.2.2Voltagecontrol Withopenloopspeedcontrolusingtransformersorelectronic 4.1Connectingthemechanicalsystem voltageregulators(e.g.phaseanglecontrol),excessivecurrent mayoccur. CAUTION Inaddition,noisescanoccurwithphaseanglecontrol Cuttingandcrushinghazardwhenremovingthefan dependingonthemountingsituation. fromthepackaging →Carefullyliftthefanoutofitspackaging,onlytouchingthe 4.2.3Frequencyinverter housing.Makesuretoavoidanyshock. →Wearsafetyshoesandcut-resistantsafetygloves. Fitsinusoidalfiltersthatworkonallpoles(live-liveandlive- earth)betweenthefrequencyinverterandthemotorfor ⇒Checkthedevicefortransportdamage.Damageddevicesmustno operationwithfrequencyinverters. longerbeinstalled. Dependingonhowthedeviceisinstalled,noisesmayoccur. ⇒Installtheundamageddeviceaccordingtoyourapplication. 4.3Connectionviaplug 4.2Connectingtheelectricalsystem 4.3.1Preparingconnectionlinesfortheconnection DANGER Electricvoltageonthedevice Thelines,includingcustomer-sideinterface,fallwithinthe Electricshock standardoftheinternalconnection. →Alwaysinstallaprotectiveearth. Observeproductconformitytostandardsandthetypeof protectioninyourenddeviceafteryouhaveinstalledtheebm- →Checktheprotectiveearth. papstdevice. DANGER ⇒Connecttheconnectionlinestothematingconnectors. Incorrectinsulation Riskoffatalinjuryfromelectricshock →Useonlycablesthatmeetthespecifiedinstallation requirementsforvoltage,current,insulationmaterial,loadetc. →Routecablessuchthattheycannottouchanyrotating parts. CAUTION Electricalvoltage Thefanisabuilt-incomponentandfeaturesnoelectrically isolatingswitch. →Onlyconnectthefantocircuitsthatcanbeswitchedoffwith anall-poleseparatingswitch. →Whenworkingonthefan,youmustswitchoffthe installation/machineinwhichthefanisinstalledandsecureit frombeingswitchedonagain. NOTE Waterpenetrationintoleadsorwires s n Waterentersatthecableendonthecustomerssideandcan o ucti damagethedevice. nstr →Makesurethatthecableendisconnectedinadry g i n environment. ati er p Connectthedeviceonlytocircuitsthatcanbeswitchedoff o al usinganall-poledisconnectingswitch. n gi ori e of th 4.2.1Prerequisites on ⇒Checkwhetherthedataonthetypeplateagreewiththeconnection slati dataandthedataoftheoperatingcapacitor. n Tra ⇒Beforeconnectingthedevice,ensurethatthesupplyvoltagematches theoperatingvoltageofthedevice. ⇒Onlyusecablesdesignedforcurrentaccordingtothetypeplate. Itemno.:10948-5-9970·Revisionstatus:KM70969·Print-outon02/12/2010·CreatedbyA.Kehm(VM---)·Page6of9 ebm-papstMulfingenGmbH&Co.KG·Bachmühle2·D-74673Mulfingen·Phone:+49(0)7938/81-0·Fax:+49(0)7938/81-110·info1@de.ebmpapst.com·www.ebmpapst.com

Operating instructions W2E142-BB05-01 4.4Connectiondiagram s n o cti u str n g i n ati er p o al n gi ori e h of t n o ati sl n a Tr Itemno.:10948-5-9970·Revisionstatus:KM70969·Print-outon02/12/2010·CreatedbyA.Kehm(VM---)·Page7of9 ebm-papstMulfingenGmbH&Co.KG·Bachmühle2·D-74673Mulfingen·Phone:+49(0)7938/81-0·Fax:+49(0)7938/81-110·info1@de.ebmpapst.com·www.ebmpapst.com

Operating instructions W2E142-BB05-01 4.5Checkingtheconnections 5.MAINTENANCE,MALFUNCTIONS,POSSIBLE ⇒Makesurethatthepowerisoff(allphases). CAUSESANDREMEDIES ⇒Secureitfrombeingswitchedonagain. Motorandelectronicsenclosurearesealedbyebm-papst.Changesor ⇒Checkthatthematingconnectoriscorrectlylockedintothepanel repairsmaybecarriedoutbyebm-papstonly. connector. Donotperformanyrepairsonyourdevice.Returnthedevicetoebm- ⇒Checkthatthematingconnectoriscorrectlycrimpedtothe papstforrepairorreplacement. connectionline. WARNING Terminalsandconnectionshavevoltageevenwitha 4.6Switchondevice unitthatisshutoff WARNING Electricshock Hotmotorhousing →Waitforfiveminutesafterdisconnectingthevoltageatall Firehazard polesbeforetouchingtheunit. →Ensurethatnocombustibleorflammablematerialsare CAUTION locatedclosetothefan. Electricalloadonthecapacitorafterdeviceisswitchedoff ⇒Inspectthedeviceforvisibleexternaldamageandtheproperfunction Electricshock,riskofinjury oftheprotectivefeaturesbeforeswitchingiton. →Dischargethecapacitorsbeforeworkingonthedevice. ⇒Checktheairflowpathsofthefanforforeignobjectsandremoveany CAUTION thatarefound. Themotorrestartsautomaticallywhenoperatingvoltage ⇒Applythenominalvoltagetothevoltagesupply. isapplied,e.g.afterapowerfailure. Dangerofinjury 4.7Switchingoffthedevice →Keepoutofthedangerzoneofthedevice. ⇒Disconnectthedevicefromthesupplyvoltage. →Whenworkingonthedevice,switchoffthemains supplyvoltageandsecurethelatterfrombeingswitchedon again. →Waituntilthedevicestops. Ifthedeviceremainsoutofuseforsometime,e.g.whenin storage,werecommendswitchingthedeviceonforatleast2 hourstoallowanycondensatetoevaporateandtomovethe bearings. Malfunction/error Possiblecause Possibleremedy Motordoesnotturn Mechanicalblockage Switchoff,de- energise,and removemechanical blockage Mainssupply Checkmainssupply voltagefaulty voltage,restore powersupply ns Faultyconnection Correctconnection, o cti seeconnectiondiagram u str Thermaloverload Allowmotortocool n ng i protectorresponded off,locateandrectify erati causeoferror,if p o necessarycancel al gin restartlock-out ori Impellerrunning Imbalanceinrotating Cleanthedevice;if e of th roughly parts imbalanceisstill n evidentafter o slati cleaning,replace n a device. Tr Ifyouhave attachedanyweight clipsduringcleaning, makesureto removethem afterwards. Itemno.:10948-5-9970·Revisionstatus:KM70969·Print-outon02/12/2010·CreatedbyA.Kehm(VM---)·Page8of9 ebm-papstMulfingenGmbH&Co.KG·Bachmühle2·D-74673Mulfingen·Phone:+49(0)7938/81-0·Fax:+49(0)7938/81-110·info1@de.ebmpapst.com·www.ebmpapst.com

Operating instructions W2E142-BB05-01 Overtemperatureof Ambienttemperature Lowerambient motor toohigh temperatureifpossible Unacceptable Checkoperatingpoint operatingpoint Insufficientcooling Improvecooling Ifyouhaveanyotherproblems,contactebm-papst. 5.1Cleaning NOTE Damagetothedeviceduringcleaning. Malfunctionpossible →Donotcleanthedeviceusingawaterjetorhigh-pressure washer. →Donotuseanycleanerscontainingacids, basesorsolvents. 5.2Safetytest Whathastobe Howtotest? Frequency tested? Protectivecasing Visualinspection atleastevery6 againstaccidental months contact Devicefordamage Visualinspection atleastevery6 months Mountingofdevice Visualinspection atleastevery6 months Mountingof Visualinspection atleastevery6 connectingcables months Insulationofthecables Visualinspection atleastevery6 months Weldseamsfor Visualinspection atleastevery6 crackformation months s n o cti u str n g i n ati er p o al n gi ori e h of t n o ati sl n a Tr Itemno.:10948-5-9970·Revisionstatus:KM70969·Print-outon02/12/2010·CreatedbyA.Kehm(VM---)·Page9of9 ebm-papstMulfingenGmbH&Co.KG·Bachmühle2·D-74673Mulfingen·Phone:+49(0)7938/81-0·Fax:+49(0)7938/81-110·info1@de.ebmpapst.com·www.ebmpapst.com

Datasheet下载

Datasheet下载