ICGOO在线商城 > 集成电路(IC) > PMIC - 电源控制器,监视器 > UCD3138RGCT

- 型号: UCD3138RGCT

- 制造商: Texas Instruments

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

UCD3138RGCT产品简介:

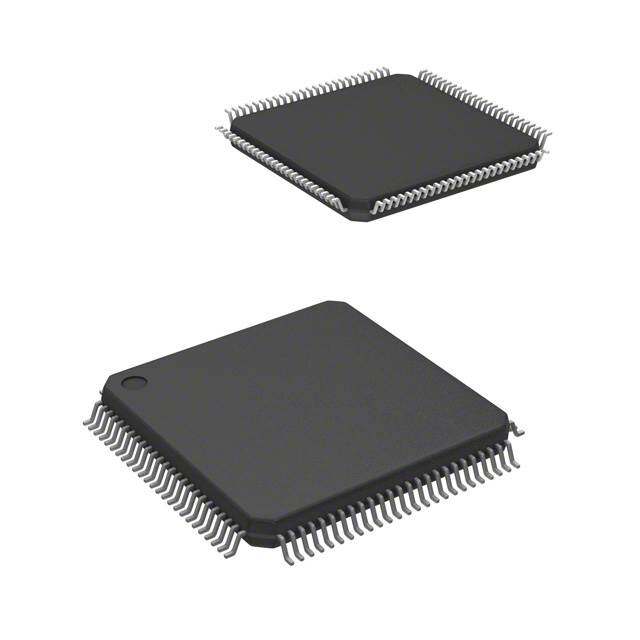

ICGOO电子元器件商城为您提供UCD3138RGCT由Texas Instruments设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 UCD3138RGCT价格参考¥59.19-¥109.42。Texas InstrumentsUCD3138RGCT封装/规格:PMIC - 电源控制器,监视器, Power Supply Controller Digital Power Controller 64-VQFN (9x9)。您可以下载UCD3138RGCT参考资料、Datasheet数据手册功能说明书,资料中有UCD3138RGCT 详细功能的应用电路图电压和使用方法及教程。

UCD3138RGCT 是 Texas Instruments(德州仪器)推出的一款数字电源控制器,属于 PMIC(电源管理集成电路)中的电源控制器和监视器类别。该芯片主要用于高精度、高性能的电源管理系统中,具备数字控制和实时监控功能。 其主要应用场景包括: 1. 服务器和通信电源系统:用于数据中心、通信基站等场合的电源管理,提供高效、稳定的电源控制和监测。 2. 工业自动化电源管理:在工业设备中实现对电源的精确控制与故障检测,提高系统可靠性和能效。 3. 高端电源模块:如数字电源模块、DC-DC 转换器、AC-DC 电源等,支持多种拓扑结构,如 LLC、移相全桥等。 4. 能源监控系统:可用于对电压、电流、功率等参数进行实时监控和数据采集,支持系统优化和故障预警。 5. 智能电网与储能系统:在新能源系统中实现对电能的高效管理与分配。 UCD3138RGCT 支持通过 I²C 或 UART 接口进行通信,便于系统集成和调试,适用于需要高精度控制与灵活配置的电源管理应用。

| 参数 | 数值 |

| 产品目录 | 集成电路 (IC)半导体 |

| 描述 | IC DGTL PWR CTRLR 64VQFNPMIC 解决方案 Hily Integrated Dig Controller |

| 产品分类 | |

| 品牌 | Texas Instruments |

| 产品手册 | http://www.ti.com/lit/gpn/ucd3138 |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 电源管理 IC,PMIC 解决方案,Texas Instruments UCD3138RGCT- |

| 数据手册 | |

| 产品型号 | UCD3138RGCT |

| 产品种类 | PMIC 解决方案 |

| 供应商器件封装 | 64-VQFN(9x9) |

| 其它名称 | 296-30510-2 |

| 包装 | 带卷 (TR) |

| 商标 | Texas Instruments |

| 安装类型 | 表面贴装 |

| 安装风格 | SMD/SMT |

| 封装 | Reel |

| 封装/外壳 | 64-VFQFN 裸露焊盘 |

| 封装/箱体 | VQFN-64 |

| 工作温度 | -40°C ~ 125°C |

| 工作温度范围 | - 40 C to + 125 C |

| 工厂包装数量 | 250 |

| 应用 | 数字电源控制器 |

| 最大工作温度 | + 125 C |

| 最小工作温度 | - 40 C |

| 标准包装 | 250 |

| 电压-电源 | 3 V ~ 3.6 V |

| 电压-输入 | - |

| 电流-电源 | 100mA |

| 电源电压 | 2.4 V to 3.6 V |

| 类型 | PWM Controller |

| 系列 | UCD3138 |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

Product Order Technical Tools & Support & Folder Now Documents Software Community UCD3138 SLUSAP2I–MARCH2012–REVISEDJANUARY2017 UCD3138 Highly Integrated Digital Controller for Isolated Power 1 Device Overview 1.1 Features 1 • DigitalControlofupto3IndependentFeedback – SynchronousRectifierSoftOn/Off Loops – LowICStandbyPower – DedicatedPID-Basedhardware • SoftStart/StopwithandwithoutPrebias – 2-Pole/2-ZeroConfigurable • FastInputVoltageFeedForwardHardware – NonlinearControl • PrimarySideVoltageSensing • Upto16MHzErrorAnalog-to-DigitalConverter • CopperTraceCurrentSensing (EADC) • FluxandPhaseCurrentBalancingforNonpeak – ConfigurableResolutionasSmallas1mV/LSB CurrentModeControlApplications – AutomaticResolutionSelection • CurrentShareBusSupport – Upto8xOversampling – AnalogAverage – Hardware-BasedAveraging(upto8x) – MasterandSlave – 14-BitEffectiveDigital-to-AnalogConverter • FeatureRichFaultProtectionOptions (DAC) – 7High-SpeedAnalogComparators – AdaptiveSampleTriggerPositioning – Cycle-by-CycleCurrentLimiting • Upto8HighResolutionDigitalPulseWidth – ProgrammableFaultCounting Modulated(DPWM)Outputs – ExternalFaultInputs – 250-psPulseWidthResolution – 10DigitalComparators – 4-nsFrequencyResolution – ProgrammableBlankingTime – 4-nsPhaseResolution • SynchronizationofDPWMWaveformsBetween – AdjustablePhaseShiftBetweenOutputs MultipleUCD3138devices – AdjustableDead-bandBetweenPairs • 14-Channel,12-Bit,267-kspsGeneral-Purpose – Cycle-by-CycleDutyCycleMatching ADCwithIntegrated – Upto2-MHzSwitchingFrequency – ProgrammableAveragingFilters • ConfigurablePWMEdgeMovement – DualSampleandHold – TrailingModulation • InternalTemperatureSensor – LeadingModulation • FullyProgrammableHigh-Performance31.25 – TriangularModulation MHz,32-BitARM7TDMI-S™Processor • ConfigurableFeedbackControl – 32KBofProgramFlash – VoltageMode – 2KBofDataFlashwithECC – AverageCurrentMode – 4KBofDataRAM – PeakCurrentModeControl – 4KBofBootROMEnablesFirmwareBoot-Load intheFieldviaI2CorUART – ConstantCurrent • CommunicationPeripherals – ConstantPower – I2C/PMBus • ConfigurableModulationMethods – 2UARTsonUCD3138RGC(64-PinQFN) – FrequencyModulation – 1UARTonUCD3138RHA/UCD3138RMH – PhaseShiftModulation (40-PinQFN)andUCD3138RJA(40-PinVQFN) – PulseWidthModulation • TimerCapturewithSelectableInputPins • Fast,Automatic,andSmoothModeSwitching • Upto5AdditionalGeneralPurposeTimers – FrequencyModulationandPWM • BuiltInWatchdog:BODandPOR – PhaseShiftModulationandPWM • 64-PinQFNand40-PinQFNPackages • HighEfficiencyandLightLoadManagement • OperatingTemperature: –40°Cto125°C – BurstMode • Fusion_Digital_Power_DesignerGUISupport – IdealDiodeEmulation 1 An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications, intellectualpropertymattersandotherimportantdisclaimers.PRODUCTIONDATA.

UCD3138 SLUSAP2I–MARCH2012–REVISEDJANUARY2017 www.ti.com 1.2 Applications • PowerSuppliesandTelecomRectifiers • IsolatedDC-DCModules • PowerFactorCorrection 1.3 Description The UCD3138 is a digital power supply controller from Texas Instruments offering superior levels of integration and performance in a single-chip solution. The flexible nature of the UCD3138 makes it suitable for a wide variety of power conversion applications. In addition, multiple peripherals inside the device have been specifically optimized to enhance the performance of AC-DC and isolated DC-DC applicationsandreducethesolutioncomponentcountintheITandnetworkinfrastructurespace. The UCD3138 controller is a fully programmable solution offering customers complete control of their application, along with ample ability to differentiate their solution. At the same time, TI is committed to simplifying our customers' development effort by offering best-in-class development tools, including application firmware, Code Composer Studio™ software development environment, and TI’s power developmentGUIwhichletscustomersconfigureandmonitorkeysystemparameters. At the core of the UCD3138 controller are the digital control loop peripherals, also known as Digital Power Peripherals (DPPs). Each DPP implements a high-speed digital control loop consisting of a dedicated Error Analog-to-Digital Converter (EADC), a PID-based 2-pole/2-zero digital compensator and DPWM outputs with 250-ps pulse width resolution. The device also contains a 12-bit, 267-ksps general-purpose ADC with up to 14 channels, timers, interrupt control, PMBus, and UART communications ports. The device is based on a 32-bit ARM7TDMI-S RISC microcontroller that performs real-time monitoring, configures peripherals, and manages communications. The ARM microcontroller executes its program out ofprogrammableflashmemoryaswellason-chipRAMandROM. In addition to the FDPP, specific power management peripherals have been added to enable high efficiency across the entire operating range, high integration for increased power density, reliability, and lowest overall system cost and high flexibility with support for the widest number of control schemes and topologies. Such peripherals include: light load burst mode, synchronous rectification, LLC and phase- shifted full bridge mode switching, input voltage feed forward, copper trace current sense, ideal diode emulation, constant current constant power control, synchronous rectification soft on and off, peak current mode control, flux balancing, secondary side input voltage sensing, high-resolution current sharing, hardware-configurable soft start with pre bias, as well as several other features. Topology support has been optimized for voltage mode and peak current mode controlled phase-shifted full bridge, single and dual phase PFC, bridgeless PFC, hard-switched full bridge and half bridge, and LLC half bridge and full bridge. DeviceInformation(1) PARTNUMBER PACKAGEDRAWING PACKAGETYPE BODYSIZE RGC VQFN(64) 9.00mm×9.00mm RHA VQFN(40) 6.00mm×6.00mm UCD3138 RMH WQFN(40) 6.00mm×6.00mm RJA VQFN(40) (2) 6.00mm×6.00mm (1) Formoreinformation,seeSection11,MechanicalPackagingandOrderableInformation. (2) Recommendedfornew40-pindesigns,optimizedforimprovedperformanceundertemperaturecyclingtestforboardlevelreliability (BLR). 2 DeviceOverview Copyright©2012–2017,TexasInstrumentsIncorporated SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 www.ti.com SLUSAP2I–MARCH2012–REVISEDJANUARY2017 1.4 Functional Block Diagram Figure1-1showsafunctionalblockdiagramofthedevice. Loop MUX EAP0 DPWM0A Front End0 PID Based DPWM0 Filter0 EAN0 DPWM0B EAP1 DPWM1A PID Based Front End1 DPWM1 EAN1 Filter1 DPWM1B Front End2 PID Based DPWM2 DPWM2A AFE Filter2 DPWM2B Constant Power Constant DPWM3A 23-AFE Current DPWM3 DPWM3B EEAAPN22 2AFE EADC X Avg() Front EndAveraging SYNC Digital Comparators SAR/Prebias DAC0 A0 Ramp Input Voltage Feed Forward Filter x CPCC Σ Value Dither Abs() Peak Current Mode Control Comparator Advanced Power Control Mode Switching,Burst Mode,IDE, Synchronous Rectification soft on&off ADC_EXT_TRIG ADC12Control PMBUS_ALERT Sequencing,Averaging, PMBUS_CTRL Digital Compare,Dual PMBus AD[13:0] ADC12 Sample and hold PMBUS_DATA AD00 PMBUS_CLK AD01 InternalTemperature Sensor PWM0 Timers 4–16bit(PWM) PWM1 AD02 1–24bit AGND Current Share Oscillator TCAP AD13 Analog,Average,Master/Slave SCI_TX0 ARM7TDMI-S UART0 SCI_RX0 Analog 32bit,31.25MHz Comparators SCI_TX1 AD02 UART1 A SCI_RX1 Memory AD03 PFLASH32kB EXT_INT B DFLASH2kB RAM4kB FAULT0 C ROM4kB GPIO FAULT1 Control AD04 Fault MUX& FAULT2 D Control Power On Reset V33D AD13 FAULT3 Cycle by Cycle E V33DIO Current Limit /RESET Brown Out Detection AD06 BP18 Power and Digital TCK F 1.8V Voltage Comparators DGND Regulator JTAG TDI AD07 V33A G TMS AGND TDO Figure1-1.FunctionalBlockDiagram NOTE Front-end2RecommendedforPeakCurrentModeControl Copyright©2012–2017,TexasInstrumentsIncorporated DeviceOverview 3 SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 SLUSAP2I–MARCH2012–REVISEDJANUARY2017 www.ti.com Table of Contents 1 DeviceOverview......................................... 1 6.2 ARM Processor..................................... 25 .............................................. .............................................. 1.1 Features 1 6.3 Memory 25 ........................................... ...................................... 1.2 Applications 2 6.4 SystemModule 27 ............................................ ................................. 1.3 Description 2 6.5 FeatureDescription 29 ............................ ........................... 1.4 FunctionalBlockDiagram 3 6.6 DeviceFunctionalModes 48 2 Revision History......................................... 4 7 ApplicationandImplementation.................... 55 3 DeviceComparisonTable.............................. 7 7.1 ApplicationInformation.............................. 55 .......................... .................................. 3.1 ProductFamilyComparison 7 7.2 TypicalApplication 56 3.2 ProductSelectionMatrix ............................. 7 8 PowerSupplyRecommendations.................. 67 4 PinConfigurationandFunctions..................... 8 8.1 PowerSupplyDecouplingandBulkCapacitors.... 67 4.1 UCD3138RGC64QFNPinAttributes.............. 10 9 Layout.................................................... 68 4.2 UCD3138RHA,UCD3138RMHandUCD3138RJA 9.1 Layout Guidelines................................... 68 ........................................ PinAttributes 12 ..................................... 9.2 Layout Example 69 5 Specifications........................................... 13 10 DeviceandDocumentationSupport............... 70 ......................... 5.1 AbsoluteMaximumRatings 13 ...................................... 10.1 DeviceSupport 70 ........................................ 5.2 ESDRatings 13 ............................. 10.2 DocumentationSupport 72 ............... 5.3 RecommendedOperatingConditions 13 .. 10.3 ReceivingNotificationofDocumentationUpdates 72 ................................. 5.4 Thermal Information 13 .............................. 10.4 CommunityResources 72 ............................ 5.5 ElectricalCharacteristics 14 .......................................... 10.5 Trademarks 72 ............... 5.6 TimingandSwitchingCharacteristics 16 ..................... 10.6 ElectrostaticDischargeCaution 72 .......................... 5.7 PowerSupplySequencing 18 ............................................. 10.7 Glossary 72 .......................................... 5.8 Peripherals 18 11 MechanicalPackagingandOrderable 5.9 TypicalTemperatureCharacteristics................ 24 Information.............................................. 72 6 DetailedDescription................................... 25 11.1 PackagingInformation .............................. 72 ............................................ 6.1 Overview 25 2 Revision History NOTE:Pagenumbersforpreviousrevisionsmaydifferfrompagenumbersinthecurrentversion. ChangesfromRevisionH(October2016)toRevisionI Page • AddedupdatedLayoutGuidelinessection....................................................................................... 68 • AddedLayoutExampleimages. .................................................................................................. 69 4 RevisionHistory Copyright©2012–2017,TexasInstrumentsIncorporated SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 www.ti.com SLUSAP2I–MARCH2012–REVISEDJANUARY2017 ChangesfromRevisionG(September2016)toRevisionH Page • AddedPACKAGEDRAWINGcolumntotheDeviceInformationtable. ...................................................... 2 • ChangedNote2from"Recommendedfornew40-pindesignswithadvanceBLRperformance"to "Recommendedfornew40-pindesigns,optimizedforimprovedperformanceundertemperaturecyclingtestfor boardlevelreliability(BLR)." ....................................................................................................... 2 • DeletedFigure4-3note,"Thesefeatureshelptoimprovesolder-jointreliability". .......................................... 9 ChangesfromRevisionF(November2013)toRevisionG Page • AddedDeviceandDocumentationSupportsectionandESDRatingstable.................................................. 2 • ChangeddocumentflowtomatchUCD3138A.................................................................................... 2 • AddedRJApackagetoFeaturesandtheDeviceInformationtable........................................................... 2 • AddedRJApackage. .............................................................................................................. 10 • AddedtheRJApackagetotheThermalInformationtable. ................................................................... 13 ChangesfromRevisionE(August2013)toRevisionF Page • ChangedTopSideMarkinginfofrom"3138"to"3138RMH"intheOrderingInformationtable. ....................... 2 ChangesfromRevisionD(August2013)toRevisionE Page • AddedUCD3138RMHtoFeaturebullet........................................................................................... 1 • AddedRMHpackagepinoutdrawing.............................................................................................. 9 • AddedRMHpackagethermalspecifications.................................................................................... 13 • ChangedGlobalI/Oregistersorderedlist,item5textfrom"Connectingpin/pinstohighrailthroughinternalpull upresistors."to"Configuringpin/pinsasopendrainorpush-pull(Normal)"................................................ 45 ChangesfromRevisionC(March2013)toRevisionD Page • ChangedT spectoT inAbsMaxtablewithMAXtempof150°C....................................................... 13 OPT J • AddedBP18VoltagevsTemperaturegraphic.................................................................................. 24 ChangesfromRevisionB(July2012)toRevisionC Page • Deleted"JTAGDebugPort"featurebullet........................................................................................ 1 • Deletedtextstring"JTAGdebug"fromDescriptionsection..................................................................... 2 • AddedNOTEunderFunctionalBlockDiagram................................................................................... 3 • Deleted"JTAG"optionfromProductSelectionMatrix........................................................................... 8 • AddedtexttoPin54description.................................................................................................. 11 • AddedtexttoPin35description.................................................................................................. 12 • AddedBP18spectoAbsMaxRatingsandRecommendedOperatingConditionsTables............................... 13 • DeletedV specificationfromSystemPerformancesectionofElectricalCharacteristics................................ 15 DD • AddedfootnotetoTable5-1....................................................................................................... 16 • Addedtextstringregardingfront-end2intheFrontEndsection ............................................................ 19 • Deletedtextstringreferenceto"JTAGport"inARMProcessorsection..................................................... 25 • ChangedillustrationinICGroundingandLayoutRecommendationssection.............................................. 68 • Changedtextstringsin ............................................................................................................ 70 • AddeddocumenttoReferenceslist............................................................................................... 72 ChangesfromRevisionA(March2012)toRevisionB Page • AddedFeaturebullets................................................................................................................ 1 • Changed"DualEdgeModulation"to"TriangularModulation"inFeaturessection.......................................... 1 • Changed"265ksps"to"267ksps"inFeaturessection......................................................................... 1 • ClarifiednumberofUARTsinFeaturesection ................................................................................... 1 Copyright©2012–2017,TexasInstrumentsIncorporated RevisionHistory 5 SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 SLUSAP2I–MARCH2012–REVISEDJANUARY2017 www.ti.com • Changed"FDPP"to"DDP"throughout. ........................................................................................... 2 • ChangedTotalGPIOpincountfortheUCD313840-pindevicefrom"17"to"18"intheProductSelectionMatrix table..................................................................................................................................... 8 • Changed"VREG"to"BP18"inconditionsstatementforElectricalCharacteristics........................................ 14 • ChangedEAP–EANErrorvoltagedigitalresolutionMINvaluesforAFE=3,AFE=2,AFE=1,AFE=0from 0.95,1.90,3.72,and7.3respectively;to,0.8,1.7,3.55,and6.90respectively............................................ 14 • ChangedconditionsforV andV specificationsinElectricalCharacteristics........................................... 15 OL OH • AddedTWDspecificationtoElectricalCharacteristics......................................................................... 15 • Changed"PWM"to"DPWM"in .................................................................................................. 20 • Changedwaveformsgraphicfor"PhaseShiftedFullBridgeExample"forclarification ................................... 30 • Addedtexttosection............................................................................................................... 31 • Changedtypicalconversionspeedfrom"268ksps"to"267ksps"intheGeneralPurposeADC12section............ 42 • AddedpackageIDinformationfortheUCD3138RGCandUCD3138RHAdevices........................................ 44 • Addedbullet"AD02hasaspecialESDprotectionmechanismthatpreventsthepinfrompullingdownthe current-sharebusifpowerismissingfromtheUCD3138"to................................................................. 46 • Changed"PWMA"and"PWMB"to"DPWMA"and"DPWMB"inSection6.6.1. ........................................... 50 • Addedsub-bullet"ThepowerpadofthedriverICshouldbetiedtoDGND"andchangedcapacitorvaluefrom "0.1µF"to"4.7µF"in .............................................................................................................. 68 • Changed"MechanicalData"sectionto"References"section................................................................ 72 ChangesfromOriginal(March2012)toRevisionA Page • AddedProductionDatastatementtofootnoteandremoved"ProductPreview"banner.................................... 1 • Deletedtable:SummaryofKeyDifferencesBetweenUCD3138xandUCD3138........................................... 7 6 RevisionHistory Copyright©2012–2017,TexasInstrumentsIncorporated SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 www.ti.com SLUSAP2I–MARCH2012–REVISEDJANUARY2017 3 Device Comparison Table 3.1 Product Family Comparison FEATURE UCD3138x80PINS ARM7TDMI-SCoreProcessor 31.25MHz HighResolutionDPWMOutputs(250-psresolution) 8 Numberofhighspeedindependentfeedbackloops(numberofregulatedoutputvoltages) 3 12-bit,267ksps,GeneralPurposeADCchannels 15 DigitalcomparatorsatADCoutputs 4 Flashmemory(program)(UCD3138A64) 64kB Flashmemory(program)(UCD3138128) 128kB Flashmemory(data) 2kB Flashsecurity √ RAM 8kB DPWMswitchingfrequency upto2MHz Programmablefaultinputs 4 Highspeedanalogcomparatorswithcycle-by-cyclecurrentlimiting 7 UART(SCI) 2 PMBus 1 I2C 1 SPI 1 Timers 4(16bit)and2(24bit) TimerPWMoutputs 4 Timercaptureinputs 2 Watchdog √ On-chiposcillator √ Power-onresetandbrown-outdetector √ SyncINandsyncOUTfunctions √ TotalGPIO(includesallpinswithmultiplexedfunctionssuchas,DPWM,FaultInputs,SCI,andso 43 forth) ExternalInterrupts 1 3.2 Product Selection Matrix UCD313864PIN UCD313840PIN FEATURE (RGC) (RHA/RMH/RJA) ARM7TDMI-Scoreprocessor 31.25MHz 31.25MHz HighresolutiondPWMoutputs(250-psresolution) 8 8 Numberofhighspeedindependentfeedbackloops(numberofregulatedoutput 3 3 voltages) 12-bit,267ksps,general-purposeADCchannels 14 7 DigitalcomparatorsatADCoutputs 4 4 Flashmemory(program) 32KB 32KB Flashmemory(data) 2KB 2KB Flashsecurity √ √ RAM 4KB 4KB DPWMswitchingfrequency upto2MHz upto2MHz Programmablefaultinputs 4 1+2(1) Highspeedanalogcomparatorswithcycle-by-cyclecurrentlimiting 7(2) 6(2) (1) Thisnumberrepresentsanalternatepinoutthatisprogrammableviafirmware.SeetheUCD3138DigitalPowerPeripherals Programmer’sManualfordetails. (2) TofacilitatesimpleOVPandUVPconnectionsbothcomparatorsBandCareconnectedtotheAD03pin. Copyright©2012–2017,TexasInstrumentsIncorporated DeviceComparisonTable 7 SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 SLUSAP2I–MARCH2012–REVISEDJANUARY2017 www.ti.com UCD313864PIN UCD313840PIN FEATURE (RGC) (RHA/RMH/RJA) UART(SCI) 2 1(1) PMBus √ √ Timers 4(16bit)and1(24bit) 4(16bit)and1(24bit) TimerPWMoutputs 2 1 Timercaptureinputs 1 1(1) Watchdog √ √ Onchiposcillator √ √ Power-onresetandbrown-outreset √ √ Packageoffering 64PinQFN(9mm×9mm) 40PinQFN(6mm×6mm) SyncINandsyncOUTfunctions √ √ TotalGPIO(includesallpinswithmultiplexedfunctionssuchas,DPWM,fault 30 18 inputs,SCI,andsoforth) Externalinterrupts 1 0 4 Pin Configuration and Functions 11D 90D 80D 50D 20D 10D 00D A33 DNG 2NA 2PA 1NA 1PA 0NA 0PA DNG A A A A A A A V A E E E E E E A 64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49 AGND 1 48 AGND AD13 2 47 V33D AD12 3 46 BP18 AD10 4 45 V33DIO AD07 5 44 DGND AD06 6 UCD3138RGC 43 FAULT3 AD04 7 42 FAULT2 AD03 8 41 TCAP (64 QFN) V33DIO 9 40 TMS DGND 10 39 TDI/SCI_RX0/PMBUS_CTRL/FAULT1 /RESET 11 38 TDO/SCI_TX0/PMBUS_ALERT/FAULT0 ADC_EXT_TRIG/TCAP/SYNC/PWM0 12 37 TCK/TCAP/SYNC/PWM0 SCI_RX0 13 36 FAULT1 SCI_TX0 14 35 FAULT0 PMBUS_CLK/SCI_TX0 15 34 INT_EXT PMBUS_DATA/SCI_RX0 16 33 DGND 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 A B A B A B A B D 0 T L T L 0 1 0 0 1 1 2 2 3 3 N M R R R R M M MWPD MWPD MWPD MWPD MWPD MWPD MWPD MWPD GD WP/GIRT_TXE ELA_SUBMP TC_SUBMP ELA_SUBMP/1 TC_SUBMP/1X WP WP _CDA/P XT_ICS R_ICS A C T /C N Y S Figure4-1.UCD3138RGC64QFNPinAttributes 8 PinConfigurationandFunctions Copyright©2012–2017,TexasInstrumentsIncorporated SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 www.ti.com SLUSAP2I–MARCH2012–REVISEDJANUARY2017 D02 D01 D00 33A GND AP2 AN1 AP1 AN0 AP0 A A A V A E E E E E 40 39 38 37 36 35 34 33 32 31 AGND 1 30 AGND UCD3138RHA AD13 2 29 AGND AD06 3 28 BP18 (40 QFN) AD04 4 27 V33D AD03 5 26 DGND DGND 6 25 FAULT2 /RESET 7 24 TMS ADC_EXT_TRIG/TCAP/SYNC/PWM0 8 23 TDI/SCI_RX0/PMBUS_CTRL/FAULT1 PMBUS_CLK/SCI_TX0 9 22 TDO/SCI_TX0/PMBUS_ALERT/FAULT0 PMBUS_DATA/SCI_RX0 10 21 TCK/TCAP/SYNC/PWM0 11 12 13 14 15 16 17 18 19 20 A B A B A B A B T L 0 0 1 1 2 2 3 3 R R M M M M M M M M E T W W W W W W W W L C A _ P P P P P P P P _ S D D D D D D D D S U U B B M M P P Figure4-2.UCD3138RHA40QFNPinAttributes D02 D01 D00 33A GND AP2 AN1 AP1 AN0 AP0 A A A V A E E E E E 40 39 38 37 36 35 34 33 32 31 AGND 1 30 AGND AD13 2 29 AGND UCD3138RMH AD06 3 28 BP18 AD04 4 27 V33D (40 QFN) AD03 5 26 DGND DGND 6 25 FAULT2 /RESET 7 24 TMS ADC_EXT_TRIG/TCAP/SYNC/PWM0 8 23 TDI/SCI_RX0/PMBUS_CTRL/FAULT1 PMBUS_CLK/SCI_TX0 9 22 TDO/SCI_TX0/PMBUS_ALERT/FAULT0 PMBUS_DATA/SCI_RX0 10 21 TCK/TCAP/SYNC/PWM0 11 12 13 14 15 16 17 18 19 20 A B A B A B A B T L 0 0 1 1 2 2 3 3 R R M M M M M M M M E T W W W W W W W W L C PD PD PD PD PD PD PD PD A_S _SU U B B M M P P NOTE:TheRMHpackagehasthinnerpackageheightcomparedtotheRHApackage.Therearealsofourcorner pinsontheRMHpackage.Thecorneranchorpinsandthermalpadshouldbesolderedforrobustmechanical performanceandshouldbetiedtotheappropriategroundsignal. Figure4-3.UCD3138RMH40QFNWithCornerAnchorsPinAttributes Copyright©2012–2017,TexasInstrumentsIncorporated PinConfigurationandFunctions 9 SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 SLUSAP2I–MARCH2012–REVISEDJANUARY2017 www.ti.com D02 D01 D00 33A GND AP2 AN1 AP1 AN0 AP0 A A A V A E E E E E 40 39 38 37 36 35 34 33 32 31 AGND 1 30 AGND AD13 2 29 AGND UCD3138RJA AD06 3 28 BP18 AD04 4 27 V33D (40 QFN) AD03 5 26 DGND DGND 6 25 FAULT2 /RESET 7 24 TMS ADC_EXT_TRIG/TCAP/SYNC/PWM0 8 23 TDI/SCI_RX0/PMBUS_CTRL/FAULT1 PMBUS_CLK/SCI_TX0 9 22 TDO/SCI_TX0/PMBUS_ALERT/FAULT0 PMBUS_DATA/SCI_RX0 10 21 TCK/TCAP/SYNC/PWM0 11 12 13 14 15 16 17 18 19 20 A B A B A B A B T L 0 0 1 1 2 2 3 3 R R M M M M M M M M E T W W W W W W W W L C PD PD PD PD PD PD PD PD A_S _SU U B B M M P P NOTE:TheRJApackagehasthickerpackageheightcomparedtotheRMHpackage.Therearealsofourcornerpins ontheRJApackage.Thesefeatureshelptoimprovesolder-jointreliability.Thecorneranchorpinsandthermalpad shouldbesolderedforrobustmechanicalperformanceandshouldbetiedtotheappropriategroundsignal. Figure4-4.UCD3138RJA40QFNWithCornerAnchorsPinAttributes 4.1 UCD3138RGC 64 QFN Pin Attributes Table4-1.UCD3138RGC64QFNPinAttributes ALTERNATEASSIGNMENT CONFIGURABLE PINNO. NAME PRIMARYASSIGNMENT NO.1 NO.2 NO.3 ASAGPIO? 1 AGND Analogground 2 AD13 12-bitADC,Ch13,comparatorE,I-share DACoutput 3 AD12 12-bitADC,Ch12 4 AD10 12-bitADC,Ch10 12-bitADC,Ch7,ConnectedtocomparatorFand 5 AD07 DACoutput referencetocomparatorG 6 AD06 12-bitADC,Ch6,ConnectedtocomparatorF DACoutput 7 AD04 12-bitADC,Ch4,ConnectedtocomparatorD DACoutput 8 AD03 12-bitADC,Ch3,ConnectedtocomparatorBandC 9 V33DIO DigitalI/O3.3Vcoresupply 10 DGND Digitalground 11 RESET DeviceResetInput,activelow 12 ADC_EXT_TRIG ADCconversionexternaltriggerinput TCAP SYNC PWM0 Yes 13 SCI_RX0 SCIRX0 Yes 14 SCI_TX0 SCITX0 Yes 15 PMBUS_CLK PMBUSClock(OpenDrain) SCITX0 Yes 16 PMBUS_DATA PMBusdata(OpenDrain) SCIRX0 Yes 17 DPWM0A DPWM0Aoutput Yes 18 DPWM0B DPWM0Boutput Yes 19 DPWM1A DPWM1Aoutput Yes 20 DPWM1B DPWM1Boutput Yes 21 DPWM2A DPWM2Aoutput Yes 22 DPWM2B DPWM2Boutput Yes 10 PinConfigurationandFunctions Copyright©2012–2017,TexasInstrumentsIncorporated SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 www.ti.com SLUSAP2I–MARCH2012–REVISEDJANUARY2017 Table4-1.UCD3138RGC64QFNPinAttributes(continued) ALTERNATEASSIGNMENT CONFIGURABLE PINNO. NAME PRIMARYASSIGNMENT NO.1 NO.2 NO.3 ASAGPIO? 23 DPWM3A DPWM3Aoutput Yes 24 DPWM3B DPWM3Boutput Yes 25 DGND Digitalground ADC_EXT_TRI 26 SYNC DPWMSynchronizepin TCAP PWM0 Yes G 27 PMBUS_ALERT PMBusAlert(OpenDrain) Yes 28 PMBUS_CTRL PMBusControl(OpenDrain) Yes PMBUS_ALER 29 SCI_TX1 SCITX1 Yes T 30 SCI_RX1 SCIRX1 PMBUS_CTRL Yes 31 PWM0 GeneralpurposePWM0 Yes 32 PWM1 GeneralpurposePWM1 Yes 33 DGND Digitalground 34 INT_EXT ExternalInterrupt Yes 35 FAULT0 Externalfaultinput0 Yes 36 FAULT1 Externalfaultinput1 Yes 37 TCK JTAGTCK(Formanufacturertestonly) TCAP SYNC PWM0 Yes PMBUS_ALER 38 TDO JTAGTDO(Formanufacturertestonly) SCI_TX0 FAULT0 Yes T 39 TDI JTAGTDI(Formanufacturertestonly) SCI_RX0 PMBUS_CTRL FAULT1 Yes 40 TMS JTAGTMS(Formanufacturertestonly) Yes 41 TCAP Timercaptureinput Yes 42 FAULT2 Externalfaultinput2 Yes 43 FAULT3 Externalfaultinput3 Yes 44 DGND Digitalground 45 V33DIO DigitalI/O3.3Vcoresupply 46 BP18 1.8VBypass 47 V33D Digital3.3Vcoresupply 48 AGND Substrateanalogground 49 AGND Analogground 50 EAP0 Channel0,differentialanalogvoltage,positiveinput 51 EAN0 Channel0,differentialanalogvoltage,negativeinput 52 EAP1 Channel1,differentialanalogvoltage,positiveinput 53 EAN1 Channel1,differentialanalogvoltage,negativeinput Channel2,differentialanalogvoltage,positiveinput 54 EAP2 (Recommendedforpeakcurrrentmodecontrol) 55 EAN2 Channel#2,differentialanalogvoltage,negativeinput 56 AGND Analogground 57 V33A Analog3.3-Vsupply 58 AD00 12-bitADC,Ch0,Connectedtocurrentsource 59 AD01 12-bitADC,Ch1,Connectedtocurrentsource 60 AD02 12-bitADC,Ch2,ConnectedtocomparatorA,I-share 61 AD05 12-bitADC,Ch5 62 AD08 12-bitADC,Ch8 63 AD09 12-bitADC,Ch9 64 AD11 12-bitADC,Ch11 Copyright©2012–2017,TexasInstrumentsIncorporated PinConfigurationandFunctions 11 SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 SLUSAP2I–MARCH2012–REVISEDJANUARY2017 www.ti.com 4.2 UCD3138RHA, UCD3138RMH and UCD3138RJA Pin Attributes Table4-2.UCD3138RHA,UCD3138RMHandUCD3138RJAPinAttributes ALTERNATEASSIGNMENT CONFIGURABLE PINNO. NAME PRIMARYASSIGNMENT NO.1 NO.2 NO.3 ASAGPIO? 1 AGND Analogground 2 AD13 12-bitADC,Ch13,ConnectedtocomparatorE,I-share 3 AD06 12-bitADC,Ch6,ConnectedtocomparatorF 4 AD04 12-bitADC,Ch4,ConnectedtocomparatorD 5 AD03 12-bitADC,Ch3,ConnectedtocomparatorBandC 6 DGND Digitalground 7 RESET DeviceResetInput,activelow 8 ADC_EXT_TRIG ADCconversionexternaltriggerinput TCAP SYNC PWM0 Yes 9 PMBUS_CLK PMBUSClock(OpenDrain) SCI_TX0 Yes 10 PMBUS_DATA PMBusdata(OpenDrain) SCI_RX0 Yes 11 DPWM0A DPWM0Aoutput Yes 12 DPWM0B DPWM0Boutput Yes 13 DPWM1A DPWM1Aoutput Yes 14 DPWM1B DPWM1Boutput Yes 15 DPWM2A DPWM2Aoutput Yes 16 DPWM2B DPWM2Boutput Yes 17 DWPM3A DPWM3Aoutput Yes 18 DPWM3B DPWM3Boutput Yes 19 PMBUS_ALERT PMBusAlert(OpenDrain) Yes 20 PMBUS_CTRL PMBusControl(OpenDrain) Yes 21 TCK JTAGTCK(Formanufacturertestonly) TCAP SYNC PWM0 Yes 22 TDO JTAGTDO(Formanufacturertestonly) SCI_TX0 PMBUS_ALERT FAULT0 Yes 23 TDI JTAGTDI(Formanufacturertestonly) SCI_RX0 PMBUS_CTRL FAULT1 Yes 24 TMS JTAGTMS(Formanufacturertestonly) Yes 25 FAULT2 Externalfaultinput2 Yes 26 DGND Digitalground 27 V33D Digital3.3Vcoresupply 28 BP18 1.8VBypass 29 AGND Substrateanalogground 30 AGND Analogground 31 EAP0 Channel0,differentialanalogvoltage,positiveinput 32 EAN0 Channel0,differentialanalogvoltage,negativeinput 33 EAP1 Channel1,differentialanalogvoltage,positiveinput 34 EAN1 Channel1,differentialanalogvoltage,negativeinput 35 EAP2 Channel2,differentialanalogvoltage,positiveinput (Recommendedforpeakcurrrentmodecontrol) 36 AGND Analogground 37 V33A Analog3.3-Vsupply 38 AD00 12-bitADC,Ch0,Connectedtocurrentsource 39 AD01 12-bitADC,Ch1,Connectedtocurrentsource 40 AD02 12-bitADC,Ch2,ConnectedtocomparatorA,I-share Corner Corner AllfouranchorsshouldbesolderedandtiedtoGND NA anchorpin (RMHandRJA only) 12 PinConfigurationandFunctions Copyright©2012–2017,TexasInstrumentsIncorporated SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 www.ti.com SLUSAP2I–MARCH2012–REVISEDJANUARY2017 5 Specifications 5.1 Absolute Maximum Ratings(1) overoperatingfree-airtemperaturerange(unlessotherwisenoted) MIN MAX UNIT V33D V33DtoDGND –0.3 3.8 V V33DIO V33DIOtoDGND –0.3 3.8 V V33A V33AtoAGND –0.3 3.8 V BP18 BP18toDGND –0.3 2.5 V |DGND–AGND| Grounddifference 0.3 V Allpins,excluding AGND(2) Voltageappliedtoanypin –0.3 3.8 V T Junctiontemperature –40 150 °C J T Storagetemperature –55 150 °C stg (1) StressesbeyondthoselistedunderAbsoluteMaximumRatingsmaycausepermanentdamagetothedevice.Thesearestressratings only,andfunctionaloperationofthedeviceattheseoranyotherconditionsbeyondthoseindicatedunderRecommendedOperating Conditionsisnotimplied.Exposuretoabsolute-maximum-ratedconditionsforextendedperiodsmayaffectdevicereliability. (2) ReferencedtoDGND 5.2 ESD Ratings VALUE UNIT Human-bodymodel(HBM),perANSI/ESDA/JEDECJS-001(1) ±2000 V Electrostaticdischarge V (ESD) Charged-devicemodel(CDM),perJEDECspecificationJESD22-C101(2) ±500 (1) JEDECdocumentJEP155statesthat500-VHBMallowssafemanufacturingwithastandardESDcontrolprocess. (2) JEDECdocumentJEP157statesthat250-VCDMallowssafemanufacturingwithastandardESDcontrolprocess. 5.3 Recommended Operating Conditions overoperatingfree-airtemperaturerange(unlessotherwisenoted) MIN NOM MAX UNIT V33D Digitalpower 3.0 3.3 3.6 V V33DIO DigitalI/Opower 3.0 3.3 3.6 V33A Analogpower 3.0 3.3 3.6 V T Junctiontemperature –40 125 °C J BP18 1.8-Vdigitalpower 1.6 1.8 2.0 V 5.4 Thermal Information UCD3138 UCD3138 UCD3138 UCD3138 THERMALMETRIC(1) 64PINQFN 40PINQFN 40PINQFN 40PINQFN UNIT (RGC) (RHA) (RMH) (RJA) R Junction-to-ambientthermalresistance 25.1 31.8 31.0 30.1 °C/W θJA R Junction-to-case(top)thermalresistance 10.5 18.5 16.5 13.5 °C/W θJC(top) R Junction-to-boardthermalresistance 4.6 6.8 6.3 4.9 °C/W θJB ψ Junction-to-topcharacterizationparameter 0.2 0.2 0.2 0.2 °C/W JT ψ Junction-to-boardcharacterizationparameter 4.6 6.7 6.3 4.8 °C/W JB R Junction-to-case(bottom)thermalresistance 1.2 1.8 1.1 0.7 °C/W θJC(bot) (1) Formoreinformationabouttraditionalandnewthermalmetrics,seeSemiconductorandICPackageThermalMetricsapplicationreport. Copyright©2012–2017,TexasInstrumentsIncorporated Specifications 13 SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 SLUSAP2I–MARCH2012–REVISEDJANUARY2017 www.ti.com 5.5 Electrical Characteristics V33A=V33D=V33DIO=3.3V;1μFfromBP18toDGND,T =–40°Cto125°C(unlessotherwisenoted) J PARAMETER TESTCONDITION MIN TYP MAX UNIT SUPPLYCURRENT MeasuredonV33A.Thedeviceis I33A poweredupbutallADC12andEADC 6.3 mA samplingisdisabled AllGPIOandcommunicationpinsare I33DIO 0.35 mA open I33D ROMprogramexecution 60 mA I33D FlashprogramminginROMmode 70 mA ThedeviceisinROMmodewithall I33 DPWMsenabledandswitchingat2 100 mA MHz.TheDPWMsareallunloaded. ERRORADCINPUTSEAP,EAN EAP–AGND –0.15 1.998 V EAP–EAN –0.256 1.848 V Typicalerrorrange AFE=0 –256 248 mV AFE=3 0.8 1 1.20 mV AFE=2 1.7 2 2.30 mV EAP–EANErrorvoltagedigitalresolution AFE=1 3.55 4 4.45 mV AFE=0 6.90 8 9.10 mV R Inputimpedance(SeeFigure5-4) AGNDreference 0.5 MΩ EA I Inputoffsetcurrent(SeeFigure5-4) –5 5 μA OFFSET Inputvoltage=0VatAFE=0 –2 2 LSB Inputvoltage=0VatAFE=1 –2.5 2.5 LSB EADCoffset Inputvoltage=0VatAFE=2 –3 -3 LSB Inputvoltage=0VatAFE=3 –4 4 LSB SampleRate 16 MHz AnalogFrontEndAmplifierBandwidth 100 MHz Gain SeeFigure5-5 1 V/V A 0 Minimumoutputvoltage 100 mV EADCDAC DACrange 0 1.6 V VREFDACreferenceresolution 10bit,Noditheringenabled 1.56 mV VREFDACreferenceresolution With4bitditheringenabled 97.6 μV INL –3.0 3.0 LSB DNL DoesnotincludeMSBtransition –2.1 1.6 LSB DNLatMSBtransition –1.4 LSB DACreferencevoltage 1.58 1.61 V τ SettlingTime From10%to90% 250 ns ADC12 I BiascurrentforPMBusaddresspins 9.5 10.5 μA BIAS Measurementrangeforvoltagemonitoring 0 2.5 V InternalADCreferencevoltage –40°Cto125°C 2.475 2.500 2.525 V –40°Cto25°C –0.4 ChangeinInternalADCreferencefrom 25°Creferencevoltage(1) 25°Cto85°C –1.8 mV 25°Cto125°C –4.2 (1) Asdesignedandcharacterized.Not100%testedinproduction. 14 Specifications Copyright©2012–2017,TexasInstrumentsIncorporated SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 www.ti.com SLUSAP2I–MARCH2012–REVISEDJANUARY2017 Electrical Characteristics (continued) V33A=V33D=V33DIO=3.3V;1μFfromBP18toDGND,T =–40°Cto125°C(unlessotherwisenoted) J PARAMETER TESTCONDITION MIN TYP MAX UNIT ADC12INLintegralnonlinearity(1) ±2.5 LSB ADC12DNLdifferentialnonlinearity(1) ADC_SAMPLINGSEL=6forallADC12 –0.7/+2.5 LSB ADCZeroScaleError data,25°Cto125°C –7 7 mV ADCFullScaleError –35 35 mV Inputbias 2.5Vappliedtopin 400 nA Inputleakageresistance(1) ADC_SAMPLINGSEL=6or0 1 MΩ InputCapacitance(1) 10 pF ADCsinglesampleconversiontime(1) ADC_SAMPLINGSEL=6or0 3.9 μs DIGITALINPUTS/OUTPUTS(2)(3) V Low-leveloutputvoltage(4) I =4mA,V33DIO=3V DGND V OL OH +0.25 V High-leveloutputvoltage (4) I =–4mA,V33DIO=3V V33DIO V OH OH –0.6 V High-levelinputvoltage V33DIO=3V 2.1 V IH V Low-levelinputvoltage V33DIO=3V 1.1 V IL I Outputsinkingcurrent 4 mA OH I Outputsourcingcurrent –4 mA OL SYSTEMPERFORMANCE Totaltimeis:TWD× TWD Watchdogtimeoutrange 14.6 17 20.5 ms (WDCTRL.PERIOD+1) TimetodisableDPWMoutputbasedon HighlevelonFAULTpin 70 ns activeFAULTpinsignal Processormasterclock(MCLK) 31.25 MHz t Digitalcompensatordelay(5) (1clock=32ns) 6 clocks Delay t Pulsewidthneededatreset(1) 10 µs (reset) Retentionperiodofflashcontent(data T =25°C 100 years retentionandprogram) J Programtimetoeraseonepageorblockin 20 ms dataflashorprogramflash Programtimetowriteonewordindata 20 µs flashorprogramflash f Internaloscillatorfrequency 240 250 260 MHz (PCLK) Sync-in/sync-outpulsewidth Syncpin 256 ns FlashRead 1 MCLKs FlashWrite 20 μs Currentsharecurrentsource(See I 238 259 μA SHARE Figure6-16) R Currentshareresistor(SeeFigure6-16) 9.75 10.3 kΩ SHARE POWERONRESETANDBROWNOUT(V33Dpin,SeeFigure5-3) VGH Voltagegoodhigh 2.7 V VGL Voltagegoodlow 2.5 V V VoltageatwhichIResetsignalisvalid 0.8 V res Timedelayafterpowerisgoodor T 1 ms POR RESET*relinquished (2) DPWMoutputsarelowafterreset.OtherGPIOpinsareconfiguredasinputsafterreset. (3) Onthe40-pinpackageV33DIOisconnectedtoV33Dinternally. (4) Themaximumtotalcurrent,IOHmaxandIOLmaxforalloutputscombined,shouldnotexceed12mAtoholdthemaximumvoltagedrop specified.Maximumsinkcurrentperpin=–6mAatV ;maximumsourcecurrentperpin=6mAatV . OL OH (5) TimefromcloseoferrorADCsamplewindowtotimewhendigitallycalculatedcontroleffort(dutycycle)isavailable.Thisdelay,which hasnovariationassociatedwithit,mustbeaccountedforwhencalculatingthesystemdynamicresponse. Copyright©2012–2017,TexasInstrumentsIncorporated Specifications 15 SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 SLUSAP2I–MARCH2012–REVISEDJANUARY2017 www.ti.com Electrical Characteristics (continued) V33A=V33D=V33DIO=3.3V;1μFfromBP18toDGND,T =–40°Cto125°C(unlessotherwisenoted) J PARAMETER TESTCONDITION MIN TYP MAX UNIT Internalsignalwarningofbrownout Brownout 2.9 V conditions TEMPERATURESENSOR(6) V Voltagerangeofsensor 1.46 2.44 V TEMP Voltageresolution V/°C 5.9 mV/ºC Temperatureresolution °Cperbit 0.1034 ºC/LSB Accuracy(6)(7) –40°Cto125°C –10 ±5 10 ºC Temperaturerange –40°Cto125°C –40 125 ºC I Currentdrawofsensorwhenactive 30 μA TEMP T Turnontime/settlingtimeofsensor 100 μs ON V Ambienttemperature Trimmed25°Creading 1.85 V AMB ANALOGCOMPARATOR DAC ReferenceDACRange 0 2.5 V ReferenceVoltage 2.478 2.5 2.513 V Bits 7 bits INL(6) –0.42 0.21 LSB DNL(6) 0.06 0.12 LSB Offset –5.5 19.5 mV TimetodisableDPWMoutputbasedon0 Vto2.5Vstepinputontheanalog 150 ns comparator.(1) ReferenceDACbufferedoutputload(8) 0.5 1 mA Bufferoffset(–0.5mA) 4.6 8.3 mV Bufferoffset(1.0mA) –0.05 17 mV (6) Characterizedbydesignandnotproductiontested. (7) AmbienttemperatureoffsetvalueshouldbeusedfromtheTEMPSENCTRLregistertomeetaccuracy. (8) AvailablefromreferenceDACsforcomparatorsD,E,F,andG. 5.6 Timing and Switching Characteristics The timing characteristics and timing diagram for the communications interface that supports I2C, SMBus, and PMBus in Slave or Master mode are shown in Table 5-1, Figure 5-1, and Figure 5-2. The numbers in Table 5-1 arµe for 400 kHz operating frequency. However, the device supports all three speeds, standard (100kHz),fast(400kHz),andfastmodeplus(1MHz). Table5-1.PMBus/SMBus/I2CTiming PARAMETER TESTCONDITIONS MIN TYP MAX UNIT TypicalvaluesatT =25°CandVCC=3.3V(unlessotherwisenoted) A f SMBus/PMBusoperatingfrequency Slavemode,SMBC50%dutycycle 100 1000 kHz SMB f I2Coperatingfrequency Slavemode,SCL50%dutycycle 100 1000 kHz I2C Busfreetimebetweenstartand t(BUF) stop(1) 1.3 µs t Holdtimeafter(repeated)start(1) 0.6 µs (HD:STA) t Repeatedstartsetuptime(1) 0.6 µs (SU:STA) t Stopsetuptime(1) 0.6 µs (SU:STO) t Dataholdtime Receivemode 0 ns (HD:DAT) t Datasetuptime 100 ns (SU:DAT) t Errorsignal/detect(2) 35 ms (TIMEOUT) (1) Fastmode,400kHz (2) Thedevicetimesoutwhenanyclocklowexceedst . (TIMEOUT) 16 Specifications Copyright©2012–2017,TexasInstrumentsIncorporated SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 www.ti.com SLUSAP2I–MARCH2012–REVISEDJANUARY2017 Table5-1.PMBus/SMBus/I2CTiming(continued) PARAMETER TESTCONDITIONS MIN TYP MAX UNIT t Clocklowperiod 1.3 µs (LOW) t Clockhighperiod(3) 0.6 µs (HIGH) Cumulativeclocklowslaveextend t(LOW:SEXT) time(4) 25 ms 20+0.1 tf Clock/datafalltime Risetimetr=(VILmax–0.15)to(VIHmin+0.15) Cb(5) 300 ns 20+0.1 tr Clock/datarisetime Falltimetf=0.9VDDto(VILmax–0.15) Cb(5) 300 ns C Totalcapacitanceofonebusline 400 pF b (3) t ,Max,istheminimumbusidletime.SMBC=SMBD=1fort>50mscausesresetofanytransactionthatisinprogress.This (HIGH) specificationisvalidwhentheNC_SMBcontrolbitremainsinthedefaultclearedstate(CLK[0]=0). (4) t isthecumulativetimeaslavedeviceisallowedtoextendtheclockcyclesinonemessagefrominitialstarttothestop. (LOW:SEXT) (5) C (pF) b Figure5-1.I2C/SMBus/PMBusTimingDiagram Figure5-2.BusTiminginExtendedMode 5.7 Power Supply Sequencing Copyright©2012–2017,TexasInstrumentsIncorporated Specifications 17 SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 SLUSAP2I–MARCH2012–REVISEDJANUARY2017 www.ti.com V33D 3.3 V Brown Out VGH VGL Vres t IReset TPOR TPOR t undefined Figure5-3.Power-OnReset(POR)andBrown-OutReset(BOR) Table5-2.Power-OnReset(POR)andBrown-OutReset(BOR)TermDefinitions TERM DEFINITION ThisistheV33Dthresholdwheretheinternalpowerisdeclaredgood.TheUCD3138comesoutofresetwhenabove VGH thisthreshold. ThisistheV33Dthresholdwheretheinternalpowerisdeclaredbad.Thedevicegoesintoresetwhenbelowthis VGL threshold. ThisistheV33Dthresholdwheretheinternalresetsignalisnolongervalid.Belowthisthresholdthedeviceisinan V res indeterminatestate. Thisistheinternalresetsignal.Whenlow,thedeviceisheldinreset.Thisisequivalenttoholdingtheresetpinon I Reset theIChigh. T ThetimedelayfromwhenVGHisexceededtowhenthedevicecomesoutofreset. POR ThisistheV33Dvoltagethresholdatwhichthedevicesetsthebrownoutstatusbit.Inadditionaninterruptcanbe Brownout triggeredifenabled. 5.8 Peripherals 5.8.1 Digital Power Peripherals (DPPs) At the core of the UCD3138 controller are three DDPs. Each DPP can be configured to drive from one to eightDPWMoutputs.EachDPPconsistsof: • DifferentialinputerrorADC(EADC)withsophisticatedcontrols • Hardwareaccelerateddigital2-pole/2-zeroPIDbasedcompensator • DigitalPWMmodulewithsupportforavarietyoftopologies These can be connected in many different combinations, with multiple filters and DPWMs. They are capable of supporting functions like input voltage feed forward, current mode control, and constant current/constantpower,andsoforth.Thesimplestconfigurationisshowninthefollowingfigure: 18 Specifications Copyright©2012–2017,TexasInstrumentsIncorporated SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 www.ti.com SLUSAP2I–MARCH2012–REVISEDJANUARY2017 EAP DPWMA ErrorADC Digital Filter EAN (Front End) PWM DPWMB 5.8.1.1 FrontEnd Figure 5-4 shows the block diagram of the front end module. It consists of a differential amplifier, an adjustable gain error amplifier, a high speed flash analog to digital converter (EADC), digital averaging filtersandaprecisionhighresolutionsetpointDACreference.Theprogrammablegainamplifierinconcert withtheEADCandtheadjustabledigitalgainontheEADCoutputworktogethertoprovide9bitsofrange with 6 bits of resolution on the EADC output. The output of the Front End module is a 9-bit sign extended result with a gain of 1 LSB / mV. Depending on the value of AFE selected, the resolution of this output could be either 1, 2, 4 or 8 LSBs. In addition Front End 0 has the ability to automatically select the AFE value such that the minimum resolution is maintained that still allows the voltage to fit within the range of the measurement. The EADC control logic receives the sample request from the DPWM module for initiating an EADC conversion. EADC control circuitry captures the EADC-9-bit-code and strobes the digital compensator for processing of the representative error. The set point DAC has 10 bits with an additional 4 bits of dithering resulting in an effective resolution of 14 bits. This DAC can be driven from a variety of sources to facilitate things like soft start, nested loops, and so forth. Some additional features include the ability to change the polarity of the error measurement and an absolute value mode which automaticallyaddstheDACvaluetotheerror. It is possible to operate the controller in a peak current mode control configuration; front-end 2 is recommended for implementing peak current mode control. In this mode topologies like the phase shifted full bridge converter can be controlled to maintain transformer flux balance. The internal DAC can be ramped at a synchronously controlled slew rate to achieve a programmable slope compensation. This eliminates the sub-harmonic oscillation as well as improves input voltage feed-forward performance. A0 is a unity gain buffer used to isolate the peak current mode comparator. The offset of this buffer is specified inSection5.5. EAP Front End Differential Amplifier R I EA OFFSET AGND EAN R I EA OFFSET AGND Figure5-4.InputStageofEADCModule Copyright©2012–2017,TexasInstrumentsIncorporated Specifications 19 SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 SLUSAP2I–MARCH2012–REVISEDJANUARY2017 www.ti.com AFE_GAIN 3-AFE_GAIN 2 EAP0 6bitADC 8mV/LSB EAN0 2AFE_GAIN EADC X Averaging Signed9bit result (error)1mV/LSB SAR/Prebias Ramp A0 DAC0 Filter x CPCC 10bit DAC 1.5625mV/LSB S Value Dither 4bit dithering gives14bits of effective resolution 97.65625µV/LSB effective resolution Absolute Value 10bit result Calculation 1.5625mV/LSB Peak Current Detected Peak Current Mode Comparator Figure5-5.FrontEndModule (FrontEnd2RecommendedforPeakCurrentModeControl) 5.8.1.2 DPWMModule The DPWM module represents one complete DPWM channel with 2 independent outputs, A and B. Multiple DPWM modules within the UCD3138 system can be configured to support all key power topologies. DPWM modules can be used as independent DPWM outputs, each controlling one power supply output voltage rail. It can also be used as a synchronized DPWM—with user selectable phase shift between the DPWM channels to control power supply outputs with multiphase or interleaved DPWM configurations. The output of the filter feeds the high resolution DPWM module. The DPWM module produces the pulse width modulated outputs for the power stage switches. The compensator calculates the necessary duty ratio as a 24-bit number in Q23 fixed point format (23 bit integer with 1 sign bit). This represents a value within the range 0.0 to 1.0. This duty ratio value is used to generate the corresponding DPWM output ON time.TheresolutionoftheDPWMONtimeis250psec. Each DPWM module can be synchronized to another module or to an external sync signal. An input SYNC signal causes a DPWM ramp timer to reset. The SYNC signal outputs—from each of the four DPWM modules—occur when the ramp timer crosses a programmed threshold. In this way the phase of theDPWMoutputsformultiplepowerstagescanbetightlycontrolled. The DPWM logic is probably the most complex of the Digital Peripherals. It takes the output of the compensator and converts it into the correct DPWM output for several power supply topologies. It provides for programmable dead times and cycle adjustments for current balancing between phases. It controls the triggering of the EADC. It can synchronize to other DPWMs or to external sources. It can provide synchronization information to other DPWMs or to external recipients. In addition, it interfaces to several fault handling circuits. Some of the control for these fault handling circuits is in the DPWM registers.FaulthandlingiscoveredintheFaultMuxsection. EachDPWMmodulesupportsthefollowingfeatures: • Dedicated14bittime-basewithperiodandfrequencycontrol • Shadowperiodregisterforendofperiodupdates. • Quad-eventcontrolregisters(AandB,risingandfalling)(Events1to4) – Usedforon/offDPWMdutyratioupdates. 20 Specifications Copyright©2012–2017,TexasInstrumentsIncorporated SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 www.ti.com SLUSAP2I–MARCH2012–REVISEDJANUARY2017 • PhasecontrolrelativetootherDPWMmodules • SampletriggerplacementforoutputvoltagesensingatanypointduringtheDPWMcycle. • SupportfortwoindependentedgeplacementDPWMoutputs(samefrequencyorperiodsetting) • Dead-timebetweenDPWMAandBoutputs • HighResolutioncapabilities– 250ps • Pulsecycleadjustmentofupto ±8.192 µs(32768 ×250ps) • Activehigh/activelowoutputpolarityselection • ProvideseventstotriggerbothCPUinterruptsandstartofADC12conversions. 5.8.1.3 DPWMEvents EachDPWMcancontrolthefollowingtimingevents: 1. SampleTriggerCount–ThisregisterdefineswheretheerrorvoltageissampledbytheEADCin relationshiptotheDPWMperiod.Theprogrammedvaluesetintheregistershouldbeonefourthofthe valuecalculatedbasedontheDPWMclock.AstheDCLK(DCLK=62.5MHzmax)controllingthe circuitryrunsatonefourthoftheDPWMclock(PCLK=250MHzmax).Whenthissampletrigger countisequaltotheDPWMCounter,itinitiatesafrontendcalculationbytriggeringtheEADC, resultinginaCLAcalculation,andaDPWMupdate.Oversamplingcanbesetfor2,4,or8timesthe samplingrate. 2. PhaseTriggerCount –countoffsetforslavinganotherDPWM(Multi-Phase/Interleavedoperation). 3. Period –lowresolutionswitchingperiodcount.(countofPCLKcycles) 4. Event1–countoffsetforrisingDPWMAevent.(PCLKcycles) 5. Event2–DPWMcountforfallingDPWMAeventthatsetsthedutyratio.Last4bitsoftheregisterare forhighresolutioncontrol.Upper14bitsarethenumberofPCLKcyclecounts. 6. Event3–DPWMcountforrisingDPWMBevent.Last4bitsoftheregisterareforhighresolution control.Upper14bitsarethenumberofPCLKcyclecounts. 7. Event4–DPWMcountforfallingDPWMBevent.Last4bitsoftheregisterareforhighresolution control.Upper14bitsarethenumberofPCLKcyclecounts. 8. CycleAdjust–ConstantoffsetforEvent2andEvent4adjustments. Basic comparisons between the programmed registers and the DPWM counter can create the desired edgeplacementsintheDPWM.HighresolutionedgecapabilityisavailableonEvents2,3,and4. Figure 5-6 is for multi-mode, open loop. Open loop means that the DPWM is controlled entirely by its own registers,notbythefilteroutput.Inotherwords,thepowersupplycontrolloopisnotclosed. The Sample Trigger signals are used to trigger the front end to sample input signals. The Blanking signals are used to blank fault measurements during noisy events, such as FET turn on and turn off. Additional DPWMmodesaredescribedbelow. Copyright©2012–2017,TexasInstrumentsIncorporated Specifications 21 SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 SLUSAP2I–MARCH2012–REVISEDJANUARY2017 www.ti.com Multi Mode Open Loop Start of Period Start of Period Period Period Counter DPWM OutputA Event1 Event2(High Resolution) CycleAdjustA (High Resolution) SampleTrigger 1 To Other BlankingABegin Modules BlankingAEnd DPWM Output B Event3(High Resolution) Event4(High Resolution) CycleAdjust B (High Resolution) SampleTrigger 2 Blanking B Begin To Other Blanking B End Modules PhaseTrigger Events which change with DPWM mode: DPWMARising Edge =Event1 DPWMAFalling Edge =Event2+CycleAdjustA DPWM B Rising Edge=Event3 DPWM B Falling Edge=Event4+CycleAdjust B PhaseTrigger =PhaseTrigger Register value Events always set by their registers,regardless of mode: SampleTrigger 1,SampleTrigger 2,BlankingABegin,BlankingAEnd,Blanking B Begin, Blanking B End Figure5-6.MultiModeOpenLoop 5.8.1.4 HighResolutionDPWM Unlike conventional PWM controllers where the frequency of the clock dictates the maximum resolution of PWM edges, the UCD3138 DPWM can generate waveforms with resolutions as small as 250 ps. This is 16×theresolutionoftheclockdrivingtheDPWMmodule. 22 Specifications Copyright©2012–2017,TexasInstrumentsIncorporated SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 www.ti.com SLUSAP2I–MARCH2012–REVISEDJANUARY2017 This is achieved by providing the DPWM mechanism with 16 phase shifted clock signals of 250 MHz each.ThehighresolutionsectionofDPWMcanbeenabledordisabled,alsotheresolutioncanbedefined in several steps between 4ns to 250ps. This is done by setting the values of PWM_HR_MULTI_OUT_EN, HIRES_SCALE, and ALL_PHASE_CLK_ENA inside the DPWM Control register 1. See the Power Peripheralsprogrammer’smanualfordetails. 5.8.1.5 Oversampling The DPWM module has the capability to trigger an oversampling event by initiating the EADC to sample the error voltage. The default 00 configuration has the DPWM trigger the EADC once based on the sample trigger register value. The over sampling register has the ability to trigger the sampling 2, 4 or 8 timesperPWMperiod.Thusthetimetheoversamplehappensisatthedivideby2,4,or8timesetinthe sampling register. The 01 setting triggers 2X oversampling, the 10 setting triggers 4X over sampling, and the11triggersoversamplingat8X. 5.8.1.6 DPWMInterruptGeneration The DPWM has the capability to generate a CPU interrupt based on the PWM frequency programmed in the period register. The interrupt can be scaled by a divider ratio of up to 255 for developing a slower interrupt service execution loop. This interrupt can be fed to the ADC circuitry for providing an ADC12 triggerforsequencesynchronization.Table5-3outlinesthedivideratiosthatcanbeprogrammed. 5.8.1.7 DPWMInterruptScaling/Range Table5-3.DPWMInterruptDivideRatio SwitchingPeriod InterruptDivide InterruptDivide InterruptDivide Numberof32-MHz Frames(Assume1-MHz Setting Count Count(hex) ProcessorCycles Loop) 1 0 00 1 32 2 1 01 2 64 3 3 03 4 128 4 7 07 8 256 5 15 0F 16 512 6 31 1F 32 1024 7 47 2F 48 1536 8 63 3F 64 2048 9 79 4F 80 2560 10 95 5F 96 3072 11 127 7F 128 4096 12 159 9F 160 5120 13 191 BF 192 6144 14 223 DF 224 7168 15 255 FF 256 8192 Copyright©2012–2017,TexasInstrumentsIncorporated Specifications 23 SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 SLUSAP2I–MARCH2012–REVISEDJANUARY2017 www.ti.com 5.9 Typical Temperature Characteristics 2.1 1.81 2 1.79 V) m ze ( 1.9 V) 1.77 B Si ge ( S a C L 1.8 Volt1.75 D A E 1.7 1.73 Minimum Maximum Typical 1.6 1.71 −40 −20 0 20 40 60 80 100 120 -50 0 50 100 150 Temperature (°C) Figure5-7.EADCLSBSizeWith4XGain(mV)vsTemperGa00t5uare Temperature ((cid:131)C) C001 Figure5-8.BP18VoltagevsTemperature ADC12 Measurement Temperature Sensor Voltage ADC12 2.5-V Reference 2.6 2.515 2.510 2.4 2.505 age (V) 2.2 erence 2.500 Volt 2.0 Ref 2.495 or 12 ens 1.8 DC 2.490 S A 2.485 1.6 2.480 1.4 2.475 −60 −40 −20 0 20 40 60 80 100 120 140 160 −40 −20 0 20 40 60 80 100 120 Temperature (°C) Temperature (°C) Figure5-9.ADC12MeasurementTemperatureSensorVoltaG0g06eb vs Figure5-10.ADC122.5-VReferencevsTemperatureG003b Temperature ADC12 Temperature Sensor Measurement Error UCD3138 Oscillator Frequency 8 2.08 6 2.04 B) e S 4 c Error (L 2 Referen 2 2 Z 1 H ADC 0 2-M 1.96 −2 −4 1.92 −40 −20 0 20 40 60 80 100 120 −40 −20 0 20 40 60 80 100 120 Temperature (°C) Temperature (°C) Figure5-11.ADC12TemperatureSensorMeasurementErGr0o02rbvs Figure5-12.UCD3138OscillatorFrequency(2-MHzRefereG0n04cbe, Temperature DividedDownfrom250MHz)vsTemperature 24 Specifications Copyright©2012–2017,TexasInstrumentsIncorporated SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 www.ti.com SLUSAP2I–MARCH2012–REVISEDJANUARY2017 6 Detailed Description 6.1 Overview The UCD3138 family is a digital power supply controller from Texas Instruments offering superior levels of integrationandperformanceinasinglechipsolution.TheUCD3138x,incomparisontoTexasInstruments UCD3138 digital power controller offers 32 kB of program Flash memory. The flexible nature of the UCD3138familymakesitsuitableforawidevarietyofpowerconversionapplications. In addition, multiple peripherals inside the device have been specifically optimized to enhance the performance of AC/DC and isolated DC/DC applications and reduce the solution component count in the IT and network infrastructure space. The UCD3138 family is a fully programmable solution offering customers complete control of their application, along with ample ability to differentiate their solution. At the same time, TI is committed to simplifying our customer’s development effort through offering best in class development tools, including application firmware, Code Composer StudioTM software development environment, and TI’s Fusion Power Development GUI which enables customers to configure and monitor keysystemparameters. 6.2 ARM Processor The ARM7TDMI-S processor is a synthesizable member of the ARM family of general purpose 32-bit microprocessors. The ARM architecture is based on RISC (Reduced Instruction Set Computer) principles where two instruction sets are available. The 32-bit ARM instruction set and the 16-bit Thumb instruction set. The Thumb instruction allows for higher code density equivalent to a 16-bit microprocessor, with the performanceofthe32-bitmicroprocessor. The three-staged pipelined ARM processor has fetch, decode and execute stage architecture. Major blocksintheARMprocessorincludea32-bitALU,32x8multiplier,andabarrelshifter. 6.3 Memory The UCD3138 (ARM7TDMI-S) is a Von-Neumann architecture, where a single bus provides access to all of the memory modules. All of the memory module addresses are sequentially aligned along the same addressrange.Thisappliestoprogramflash,dataflash,ROMandallotherperipherals. Within the UCD3138 architecture, there is a Boot ROM that contains the initial firmware startup routines for PMBUS communication and non-volatile (FLASH) memory download. This boot ROM is executed after power-up-reset checks if there is a valid FLASH program written. If a valid program is present, the ROM codebranchestothemainFLASH-programexecution. UCD3138 also supports customization of the boot program by allowing an alternative boot routine to be executed from program FLASH. This feature enables assignment of a unique address to each device; therefore, enabling firmware reprogramming even when several devices are connected on the same communicationbus. Two separate FLASH memory areas are present inside the device. The 32 kB Program FLASH is organized as an 8 k x 32 bit memory block and is intended to be for the firmware program. The block is configured with page erase capability for erasing blocks as small as 1kB per page, or with a mass erase for erasing the entire program FLASH array. The FLASH endurance is specified at 1000 erase/write cycles and the data retention is good for 100 years. The 2 kB data FLASH array is organized as a 512 x 32 bit memory (32 byte page size). The Data FLASH is intended for firmware data value storage and data logging. Thus, the Data FLASH is specified as a high endurance memory of 20 k cycles with embedded errorcorrectioncode(ECC). Forruntimedatastorageandscratchpadmemory,a4kBRAMisavailable.TheRAMisorganizedasa1 kx32bitarray. Copyright©2012–2017,TexasInstrumentsIncorporated DetailedDescription 25 SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 SLUSAP2I–MARCH2012–REVISEDJANUARY2017 www.ti.com 6.3.1 CPU Memory Map and Interrupts When the device comes out of power-on-reset, the data memories are mapped to the processor as follows: Table6-1.MemoryMap(AfterResetOperation) Address Size Module 0x0000_0000–0x0000_FFFF 16X4K BootROM In16repeatedblocksof4Keach 0x0001_0000–0x0001_7FFF 32K Programflash 0x0001_8800–0x0001_8FFF 2K Dataflash 0x0001_9000–0x0001_9FFF 4K DataRAM Just before the boot ROM program gives control to FLASH program, the ROM configures the memory as follows: Table6-2.MemoryMap(NormalOperation) Address Size Module 0x0000_0000–0x0000_7FFF 32K Programflash 0x0001_0000–0x0001_AFFF 4K BootROM 0x0001_8800–0x0001_8FFF 2K Dataflash 0x0001_9000–0x0001_9FFF 4K DataRAM Table6-3.MemoryMap(SystemandPeripheralsBlocks) Address Size Module 0x0002_0000-0x0002_00FF 256 LoopMux 0x0003_0000-0x0003_00FF 256 FaultMux 0x0004_0000-0x0004_00FF 256 ADC 0x0005_0000-0x0005_00FF 256 DPWM3 0x0006_0000-0x0006_00FF 256 Filter2 0x0007_0000-0x0007_00FF 256 DPWM2 0x0008_0000-0x0008_00FF 256 FrontEnd/RampI/F2 0x0009_0000-0x0009_00FF 256 Filter1 0x000A_0000-0x000A_00FF 256 DPWM1 0x000B_0000–0x000B_00FF 256 FrontEnd/RampI/F1 0x000C_0000-0x000C_00FF 256 Filter0 0x000D_0000-0x000D_00FF 256 DPWM0 0x000E_0000-0x000E_00FF 256 FrontEnd/RampI/F0 0xFFF7_EC00-0xFFF7_ECFF 256 UART0 0xFFF7_ED00-0xFFF7_EDFF 256 UART1 0xFFF7_F000-0xFFF7_F0FF 256 MiscellaneousAnalogControl 0xFFF7_F600-0xFFF7_F6FF 256 PMBusInterface 0xFFF7_FA00-0xFFF7_FAFF 256 GIO 0xFFF7_FD00-0xFFF7_FDFF 256 Timer 0xFFFF_FD00-0xFFFF_FDFF 256 MMC 0xFFFF_FE00-0xFFFF_FEFF 256 DEC 0xFFFF_FF20-0xFFFF_FF37 23 CIM 0xFFFF_FF40-0xFFFF_FF50 16 PSA 0xFFFF_FFD0-0xFFFF_FFEC 28 SYS 26 DetailedDescription Copyright©2012–2017,TexasInstrumentsIncorporated SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 www.ti.com SLUSAP2I–MARCH2012–REVISEDJANUARY2017 The registers and bit definitions inside the system and peripheral blocks are detailed in the programmer’s guideforeachperipheral. 6.3.2 Boot ROM TheUCD3138incorporatesa4kbootROM.ThisbootROMincludessupportfor: • ProgramdownloadthroughthePMBus • Deviceinitialization • Examiningandmodifyingregistersandmemory • VerifyingandexecutingprogramFLASHautomatically • Jumpingtoacustomerdefinedbootprogram The Boot ROM is entered automatically on device reset. It initializes the device and then performs checksums on the Program FLASH. If the first 2 kB of program FLASH has a valid checksum, the program jumps to location 0 in the Program FLASH. This permits the use of a customer boot program. If the first checksum fails, it performs a checksum on the complete 32 kB of program flash. If this is valid, it also jumps to location 0 in the program flash. This permits full automated program memory checking, whenthereisnoneedforacustombootprogram. If neither checksum is valid, the Boot ROM stays in control, and accepts commands via the PMBus interface These functions can be used to read and write to all memory locations in the UCD3138. Typically they are usedtodownloadaprogramtoProgramFlash,andtocommanditsexecution 6.3.3 Customer Boot Program As described above, it is possible to generate a user boot program using 2 kB or more of the program flash.ThiscansupportthingswhichtheBootROMdoesnotsupport,including: • Program download via UART – useful especially for applications where the UCD3138 is isolated from thehost(forexample,PFC) • Encrypteddownload–usefulforcodesecurityinfieldupdates. 6.3.4 Flash Management The UCD3138 offers a variety of features providing for easy prototyping and easy flash programming. At the same time, high levels of security are possible for production code, even with field updates. Standard firmware will be provided for storing multiple copies of system parameters in data flash. This is minimizes theriskoflosinginformationifprogrammingisinterrupted. 6.4 System Module The System Module contains the interface logic and configuration registers to control and configure all the memory, peripherals and interrupt mechanisms. The blocks inside the system module are the address decoder, memory management controller, system management unit, central interrupt unit, and clock controlunit. 6.4.1 Address Decoder (DEC) The Address Decoder generates the memory selects for the FLASH, ROM and RAM arrays. The memory map addresses are selectable through configurable register settings. These memory selects can be configured from 1 kB to 16 MB. Power on reset uses the default addresses in the memory map for ROM execution, which is then configured by the ROM code to the application setup. During access to the DEC registers, a wait state is asserted to the CPU. DEC registers are only writable in the ARM privilege mode forusermodeprotection. Copyright©2012–2017,TexasInstrumentsIncorporated DetailedDescription 27 SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 SLUSAP2I–MARCH2012–REVISEDJANUARY2017 www.ti.com 6.4.2 Memory Management Controller (MMC) The MMC manages the interface to the peripherals by controlling the interface bus for extending the read and write accesses to each peripheral. The unit generates eight peripheral select lines with 1 kB of addressspacedecoding. 6.4.3 System Management (SYS) The SYS unit contains the software access protection by configuring user privilege levels to memory or peripherals modules. It contains the ability to generate fault or reset conditions on decoding of illegal address or access conditions. A clock control setup for the processor clock (MCLK) speed, is also available. 6.4.4 Central Interrupt Module (CIM) The CIM accepts 32 interrupt requests for meeting firmware timing requirements. The ARM processor supports two interrupt levels: FIQ and IRQ. FIQ is the highest priority interrupt. The CIM provides hardware expansion of interrupts by use of FIQ/IRQ vector registers for providing the offset index in a vector table. This numerical index value indicates the highest precedence channel with a pending interrupt and is used to locate the interrupt vector address from the interrupt vector table. Interrupt channel 0 has the lowest precedence and interrupt channel 31 has the highest precedence. To remove the interrupt request, the firmware should clear the request as the first action in the interrupt service routine. The requestchannelsaremaskable,allowingindividualchannelstobeselectivelydisabledorenabled. Table6-4.InterruptPriorityTable MODULECOMPONENTOR NAME DESCRIPTION PRIORITY REGISTER BRN_OUT_INT Brownout Brownoutinterrupt 0(lowest) EXT_INT Externalinterrupts Interruptonexternalinputpin 1 WDRST_INT Watchdogcontrol Interruptfromwatchdogexceeded(reset) 2 Wakeupinterruptwhenwatchdogequalshalfofset WDWAKE_INT Watchdogcontrol 3 watchtime SCI_ERR_INT UARTorSCIcontrol UARTorSCIerrorInterrupt.Frame,parityoroverrun 4 SCI_RX_0_INT UARTorSCIcontrol UART0RXbufferhasabyte 5 SCI_TX_0_INT UARTorSCIcontrol UART0TXbufferempty 6 SCI_RX_1_INT UARTorSCIcontrol UART1RXbufferhasabyte 7 SCI_TX_1_INT UARTorSCIcontrol UART1TXbufferempty 8 PMBUS_INT PMBusrelatedinterrupt 9 DIG_COMP_INT 12-bitADCcontrol Digitalcomparatorinterrupt 10 “Prebiascomplete”,“RampDelayComplete”,“Ramp FE0_INT FrontEnd0 Complete”,“LoadStepDetected”, 11 “Over-VoltageDetected”,“EADCsaturated” “Prebiascomplete”,“RampDelayComplete”,“Ramp FE1_INT FrontEnd1 Complete”,“LoadStepDetected”, 12 “Over-VoltageDetected”,“EADCsaturated” “Prebiascomplete”,“RampDelayComplete”,“Ramp FE2_INT FrontEnd2 Complete”,“LoadStepDetected”, 13 “Over-VoltageDetected”,“EADCsaturated” PWM3_INT 16-bittimerPWM3 16-bitTimerPWM3counteroverfloworcompareinterrupt 14 16-bitTimerPWM2counterOverfloworcompare PWM2_INT 16-bittimerPWM2 15 interrupt PWM1_INT 16-bittimerPWM1 16-bitTimerPWM1counteroverfloworcompareinterrupt 16 PWM0_INT 16-bittimerPWM0 16-bitTimerPWM1counteroverfloworcompareinterrupt 17 OVF24_INT 24-bittimercontrol 24-bitTimercounteroverflowinterrupt 18 CAPTURE_1_INT 24-bittimercontrol 24-bitTimercapture1interrupt 19 COMP_1_INT 24-bittimercontrol 24-bitTimercompare1interrupt 20 28 DetailedDescription Copyright©2012–2017,TexasInstrumentsIncorporated SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 www.ti.com SLUSAP2I–MARCH2012–REVISEDJANUARY2017 Table6-4.InterruptPriorityTable(continued) MODULECOMPONENTOR NAME DESCRIPTION PRIORITY REGISTER CAPTURE_0_INT 24-bittimercontrol 24-bitTimercapture0interrupt 21 COMP_0_INT 24-bittimercontrol 24-bitTimercompare0interrupt 22 ModeswitchedinCPCCmoduleFlagneedstoberead CPCC_INT Constantpowerconstantcurrent 23 fordetails ADC_CONV_INT 12-bitADCcontrol ADCendofconversioninterrupt 24 Analogcomparatorinterrupts,overvoltagedetection, FAULT_INT FaultMuxinterrupt 25 undervoltagedetection,LLMloadstepdetection DPWM3 DPWM3 SameasDPWM1 26 DPWM2 DPWM2 SameasDPWM1 27 1)Every(1to256)switchingcycles DPWM1 DPWM1 2)Faultdetection 28 3)Modeswitching DPWM0 DPWM0 SameasDPWM1 29 EXT_FAULT_INT ExternalFaults Faultpininterrupt 30 SYS_SSI_INT SystemSoftware Systemsoftwareinterrupt 31(highest) 6.5 Feature Description 6.5.1 Sync FET Ramp and IDE Calculation The UCD3138 has built in logic for controlling MOSFETs for synchronous rectification (Sync FETs). This comesintwoforms: • SyncFETramp • IdealDiodeEmulation(IDE)calculation When starting up a power supply, sometimes there is already a voltage on the output – this is called prebias. It is very difficult to calculate the ideal Sync FET on-time for this case. If it is not calculated correctly,itmaypulldowntheprebiasvoltage,causingthepowersupplytosinkcurrent. To avoid this, Sync FETs are not turned on until after the power supply has ramped up to the nominal voltage. The Sync FETs are turned on gradually in order to avoid an output voltage glitch. The Sync FET Ramplogiccanbeusedtoturnthemonataratebelowthebandwidthofthefilter. Indiscontinuousmode,theidealon-timefortheSyncFETsisafunctionofVin,Vout,andtheprimaryside duty cycle (D). The IDE logic in the UCD3138 takes Vin and Vout data from the firmware and combines it with D data from the filter hardware. It uses this information to calculate the ideal on-time for the Sync FETs. 6.5.2 Automatic Mode Switching Automatic Mode switching enables the DPWM module to switch between modes automatically, with no firmware intervention. This is useful to increase efficiency and power range. The following paragraphs describephase-shiftedfullbridgeandLLCexamples: 6.5.2.1 PhaseShiftedFullBridgeExample In phase shifted full bridge topologies, efficiency can be increased by using pulse width modulation, rather thanphaseshift,atlightload.Thisisshownbelow: Copyright©2012–2017,TexasInstrumentsIncorporated DetailedDescription 29 SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 SLUSAP2I–MARCH2012–REVISEDJANUARY2017 www.ti.com DPWM3A (QB1) DPWM3B (QT1) DPWM2A (QT2) DPWM2B (QB2) VTrans DPWM1B (QSYN1,3) DPWM0B (QSYN2,4) IPRI Figure6-1.PhaseShiftedFullBridge 30 DetailedDescription Copyright©2012–2017,TexasInstrumentsIncorporated SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 www.ti.com SLUSAP2I–MARCH2012–REVISEDJANUARY2017 T1 L1 Q7 +12V Q6 VBUS I_pri C1 RL PRIM CURRENT ORING CTL T2 Q5 VOUT C2 QT1 D1 QT2 R2 VA Lr T1 Current Sensing QB1 D2 QB2 Vref Duty for mode DPWM0 DPWM0B switching Vout EADC0 CLA0 CPCC < DPWM1 DPWM1B Iout EADC1 CLA1 DPWM2A Load Current DPWM2 DPWM2B I_pri EADC2 PCM DPWM3 DDPPWWMM33AB ISOLATED AD00 FAULT0 ACFAIL_IN GATETransformer SYNCHRONOUS AD01 GATE DRIVE I_SHARE AD02/CMP0 FAULT FAULT1 ACFAIL_OUT DPWM3A DPWM3B DPWM2A DPWM2B DPWM0B DPWM1B VII_oopuurtti AD0AAA3DDD/C000456M///CCCP1MMM/CPPPM345P2 CBC FAGGUPPLIIOTO212 OOFNAR/IOILNUFGRF_ECRTL temp AD07/CMP6 Vin AD08 GPIO3 P_GOOD VA AD09 ARM7 WD PMBus RST OSC UART0 Primary UART1 Memory Figure6-2.Secondary-ReferencedPhase-ShiftedFullBridgeControl WithSynchronousRectification 6.5.2.2 LLCExample In LLC, three modes are used. At the highest frequency, a pulse width modulated mode (Multi Mode) is used. As the frequency decreases, resonant mode is used. As the frequency gets still lower, the synchronous MOSFET drive changes so that the on-time is fixed and does not increase. In addition, the LLC control supports cycle-by-cycle current limiting. This protection function operates by a comparator monitoring the maximum current during the DPWMA conduction time. Any time this current exceeds the programmable comparator reference the pulse is immediately terminated. Due to classic instability issues associated with half-bridge topologies it is also possible to force DPWMB to match the truncated pulse widthofDPWMA.HerearethewaveformsfortheLLC: PWM Mode LLC Mode fr fs=fr_max fs>fr fs<fr y Q1T ar m Pri Q1B ET QSR1 Tr=1/fr F n SyQSR2 Tr=1/fr ISEC(t) Copyright©2012–2017,TexasInstrumentsIncorporated DetailedDescription 31 SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 SLUSAP2I–MARCH2012–REVISEDJANUARY2017 www.ti.com VBUS Q1T ILR(t) Transformer LRES LK QSR2 RLRES NS ISEC(t) Driver DPWM1B Oring Circuitry Q1B ILM(t) LM NP VOUT RF1 AD03 NS COUT1 COUT2 EAP0 VOUT(t) VBUS ESR1 ESR2 RF2 CF QSR1 CRES Rectifier and filter AD04 Driver DPWM1A RS EAN0 CS VCR(t) CRES RS1 RS2 ADC13 Driver DPWM0B EAP1 Driver DPWM0A Figure6-3.Secondary-ReferencedHalf-BridgeResonantLLCControl WithSynchronousRectification 32 DetailedDescription Copyright©2012–2017,TexasInstrumentsIncorporated SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 www.ti.com SLUSAP2I–MARCH2012–REVISEDJANUARY2017 6.5.2.3 MechanismforAutomaticModeSwitching The UCD3138 allows the customer to enable up to two distinct levels of automatic mode switching. These differentmodesareusedtoenhancelightloadoperation,shortcircuitoperationandsoftstart.Manyofthe configuration parameters for the DPWM are in DPWM Control Register 1. For automatic mode switching, someoftheseparametersareduplicatedintheAutoConfigMidandAutoConfigHighregisters. If automatic mode switching is enabled, the filter duty signal is used to select which of these three registers is used. There are 4 registers which are used to select the points at which the mode switching takesplace.Theyareusedasshownbelow. Automatic Mode Switching With Hysteresis Filter Duty Full Range Auto Config High High–UpperThreshold High–LowerThreshold Auto Config Mid Low–UpperThreshold Low–LowerThreshold Control Register 1 0 Figure6-4.AutomaticModeSwitching As shown, the registers are used in pairs for hysteresis. The transition from Control Register 1 to Auto Config Mid only takes place when the Filter Duty goes above the Low Upper threshold. It does not go back to Auto Config Mid until the Low Lower Threshold is passed. This prevents oscillation between modesifthefilterdutyisclosetoamodeswitchingpoint. Copyright©2012–2017,TexasInstrumentsIncorporated DetailedDescription 33 SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 SLUSAP2I–MARCH2012–REVISEDJANUARY2017 www.ti.com 6.5.3 DPWMC, Edge Generation, IntraMux The UCD3138 has hardware for generating complex waveforms beyond the simple DPWMA and DPWMB waveformsalreadydiscussed– DPWMC,theEdgeGenerationModule,andtheIntraMux. DPWMC is a signal inside the DPWM logic. It goes high at the Blanking A begin time, and low at the BlankingAendtime. The Edge Gen module takes DPWMA and DPWMB from its own DPWM module, and the next one, and uses them to generate edges for two outputs. For DPWM3, the DPWM0 is considered to be the next DPWM.Eachedge(risingandfallingforDPWMAandDPWMB)has8optionswhichcancauseit. Theoptionsare: 0=DPWM(n)ARisingedge 1=DPWM(n)AFallingedge 2=DPWM(n)BRisingedge 3=DPWM(n)BFallingedge 4=DPWM(n+1)ARisingedge 5=DPWM(n+1)AFallingedge 6=DPWM(n+1)BRisingedge 7=DPWM(n+1)BFallingedge Where“n"isthenumericalindexoftheDPWMmoduleofinterest.Forexamplen=1referstoDPWM1. TheEdgeGeniscontrolledbytheDPWMEDGEGENregister.Italsohasanenable/disablebit. The IntraMux is controlled by the Auto Config registers. Intra Mux is short for intra multiplexer. The IntraMux takes signals from multiple DPWMs and from the Edge Gen and combines them logically to generate DPWMA and DPWMB signals This is useful for topologies like phase-shifted full bridge, especially when they are controlled with automatic mode switching. Of course, it can all be disabled, and DPWMA and DPWMB will be driven as described in the sections above. If the Intra Mux is enabled, high resolutionmustbedisabled,andDPWMedgeresolutiongoesdownto4ns. HereisadrawingoftheEdgeGen/IntraMux: A/B/C(N) A/B/C(N+1) C(N+2) INTRAMUX C(N+3) PWMA EDGE GEN PWM B A(N) EGENA B(N) EGEN B A(N+1) B(N+1) B SELECT ASELECT AON SELECT AOFF SELECT B ON SELECT B OFF SELECT Figure6-5.EdgeGen/IntraMux HereisalistoftheIntraMuxmodesforDPWMA: 0=DPWMA(n)passthrough(default) 1=Edge-genoutput,DPWMA(n) 2=DPWNC(n) 3=DPWMB(n)(Crossover) 34 DetailedDescription Copyright©2012–2017,TexasInstrumentsIncorporated SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 www.ti.com SLUSAP2I–MARCH2012–REVISEDJANUARY2017 4=DPWMA(n+1) 5=DPWMB(n+1) 6=DPWMC(n+1) 7=DPWMC(n+2) 8=DPWMC(n+3) andforDPWMB: 0=DPWMB(n)passthrough(default) 1=Edge-genoutput,DPWMB(n) 2=DPWNC(n) 3=DPWMA(n)(Crossover) 4=DPWMA(n+1) 5=DPWMB(n+1) 6=DPWMC(n+1) 7=DPWMC(n+2) 8=DPWMC(n+3) TheDPWMnumberwrapsaroundjustliketheEdgeGenunit.ForDPWM3thefollowingdefinitionsapply: DPWM(n) DPWM3 DPWM(n+1) DPWM0 DPWM(n+2) DPWM1 DPWM(n+3) DPWM2 6.5.4 Filter The UCD3138 filter is a PID filter with many enhancements for power supply control. Some of its features include: • TraditionalPIDArchitecture • Programmable non-linear limits for automated modification of filter coefficients based on received EADCerror • Multiplecoefficientsetsfullyconfigurablebyfirmware • Full24-bitprecisionthroughoutfiltercalculations • Programmableclampsonintegratorbranchandfilteroutput • Abilitytoloadvaluesintointernalfilterregisterswhilesystemisrunning • Abilitytostallcalculationsonanyoftheindividualfilterbranches • Abilitytoturnoffcalculationsonanyoftheindividualfilterbranches • Dutycycle,resonantperiod,orphaseshiftgenerationbasedonfilteroutput. • Fluxbalancing • Voltagefeedforward Copyright©2012–2017,TexasInstrumentsIncorporated DetailedDescription 35 SubmitDocumentationFeedback ProductFolderLinks:UCD3138

UCD3138 SLUSAP2I–MARCH2012–REVISEDJANUARY2017 www.ti.com HereisthefirstsectionoftheFilter: Limit Comparator Limit6 Limit5 ….. PID Filter Branch Stages Limit0 Kp Coef Coefficient select EADC_DATA <> Xn 16 9 24 24 X P Xn-1 Reg Ki Coef Ki_yn reg 9 9 Ki High Optional 16 24 Selbeycted 9 9 9 24 24 24 24 + X + Clamp I KI_ADDER_ 24 MODE 24 Ki Low Kd alpha 9 24 Kd coef X Kd yn_reg 32 24 9 Round 16 24 9 - Xn–Xn-1 9 X 24 + 24 Clamp 24 D Figure6-6.FirstSectionoftheFilter The filter input, Xn, generally comes from a front end. Then there are three branches, P, I. and D. Note that the D branch also has a pole, Kd Alpha. Clamps are provided both on the I branch and on the D alphapole. The filter also supports a nonlinear mode, where up to 7 different sets of coefficients can be selected depending on the magnitude of the error input Xn. This can be used to increase the filter gain for higher errorstoimprovetransientresponse. Here is the output section of the filter (S0.23 means that there is 1 sign bit, 0 integer bits and 23 fractional bits): FilterYn Yn Scale Clamp High 24 P 24 I + 26 24 24 24 FilterYn Saturate Yn Shifter Clamp 24 D S2.23 S0.23 S0.23 S0.23 All are S0.23 FilterYn Clamp Low Figure6-7.OutputSectionoftheFilter 36 DetailedDescription Copyright©2012–2017,TexasInstrumentsIncorporated SubmitDocumentationFeedback ProductFolderLinks:UCD3138