- 型号: R413F147000M1M

- 制造商: Kemet

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

R413F147000M1M产品简介:

ICGOO电子元器件商城为您提供R413F147000M1M由Kemet设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 R413F147000M1M价格参考。KemetR413F147000M1M封装/规格:薄膜电容器, 4700pF 薄膜电容器 300V 1000V(1kV) 聚丙烯(PP),金属化 径向。您可以下载R413F147000M1M参考资料、Datasheet数据手册功能说明书,资料中有R413F147000M1M 详细功能的应用电路图电压和使用方法及教程。

KEMET品牌的薄膜电容器型号R413F147000M1M是一款高性能的金属化聚丙烯薄膜电容器,其主要应用场景包括以下几类: 1. 电源滤波:该型号电容器适用于开关电源(SMPS)、逆变器和变频器中的输入/输出滤波电路。它可以有效抑制电磁干扰(EMI),提高电源系统的稳定性和效率。 2. 功率因数校正(PFC):在电力电子设备中,R413F147000M1M可用于功率因数校正电路,帮助减少电流谐波失真,提升系统的功率因数,满足相关能效标准。 3. 储能与能量转换:该电容器可应用于光伏逆变器、风力发电系统以及电动汽车(EV)充电站等场景中的能量存储和转换环节,提供高效的能量传递和缓冲功能。 4. 电机驱动:在工业自动化领域,此型号电容器常用于交流电机驱动器(VFD)的直流母线支撑或耦合电路中,确保电机运行平稳并降低能耗。 5. 音频设备:由于其低损耗特性和高稳定性,R413F147000M1M也适合用于高端音响设备中的信号耦合或滤波,以实现更清晰的声音表现。 6. 脉冲应用:在需要快速充放电的脉冲电路中(如激光器、闪光灯等),这款电容器能够提供稳定的性能支持。 总之,KEMET R413F147000M1M凭借其优异的电气特性(如高耐压、低ESR、高纹波电流能力等)及环境适应性,在各种工业、能源及消费电子领域中均有着广泛的应用价值。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | CAP FILM 4700PF 1KVDC RADIAL薄膜电容器 4700pF 300volts 20% |

| ESR(等效串联电阻) | - |

| 产品分类 | |

| 品牌 | Kemet |

| 产品手册 | |

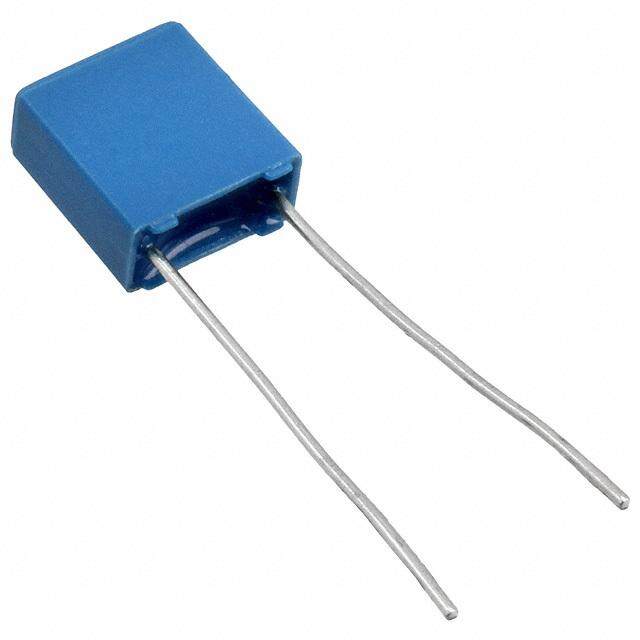

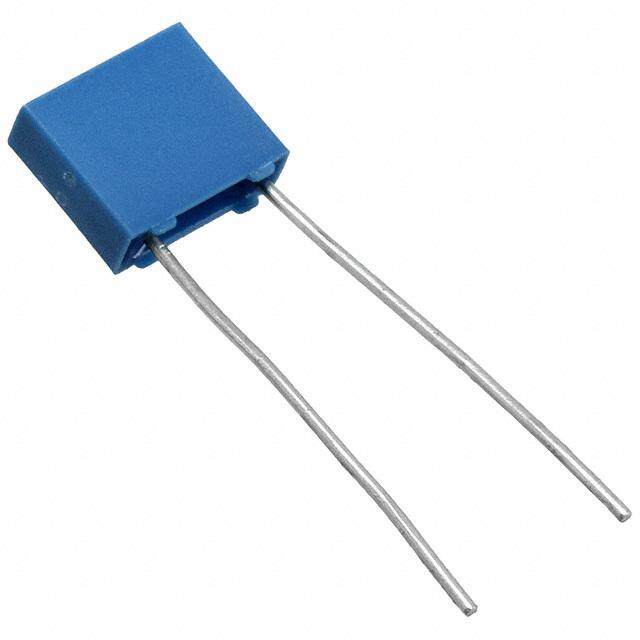

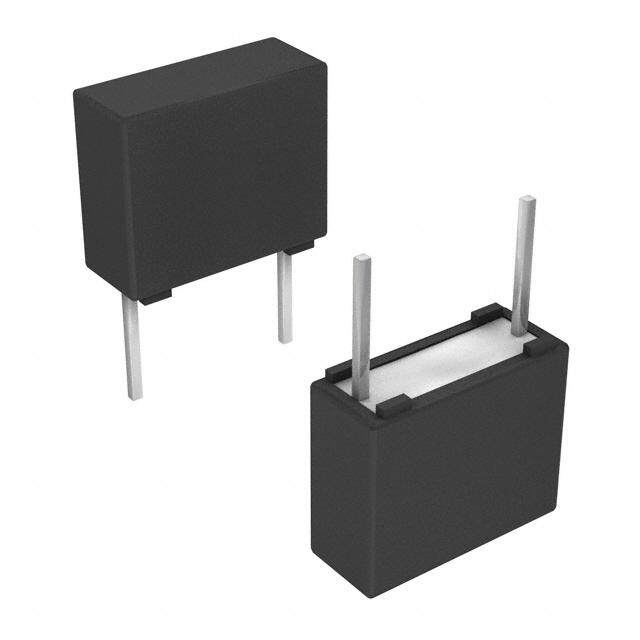

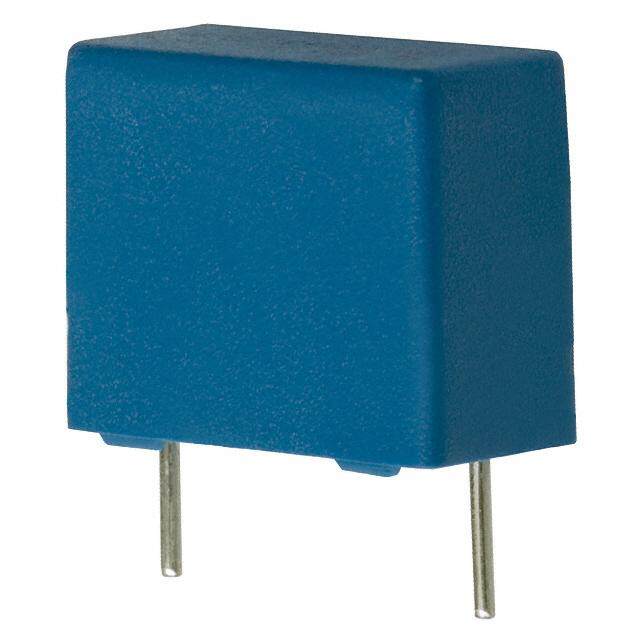

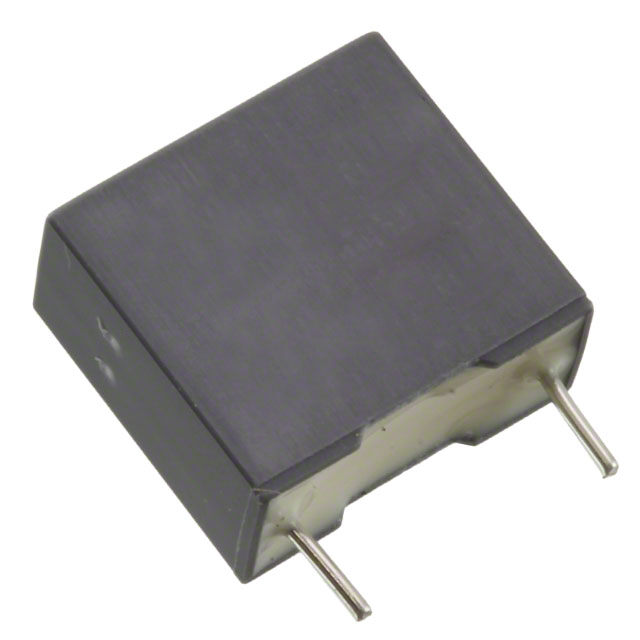

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 薄膜电容器,Kemet R413F147000M1MR41 |

| 数据手册 | http://www.kemet.com/docfinder?Partnumber=R413F147000M1M |

| 产品型号 | R413F147000M1M |

| 产品 | Safety Film Capacitors |

| 产品培训模块 | http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=25569http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=25853 |

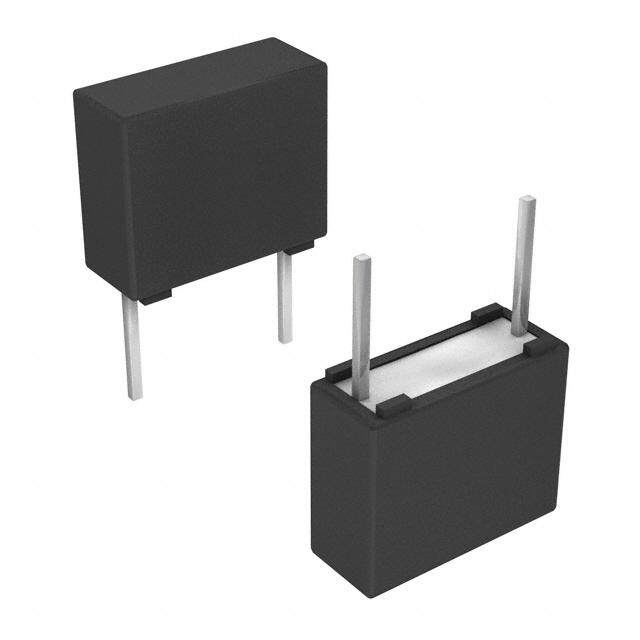

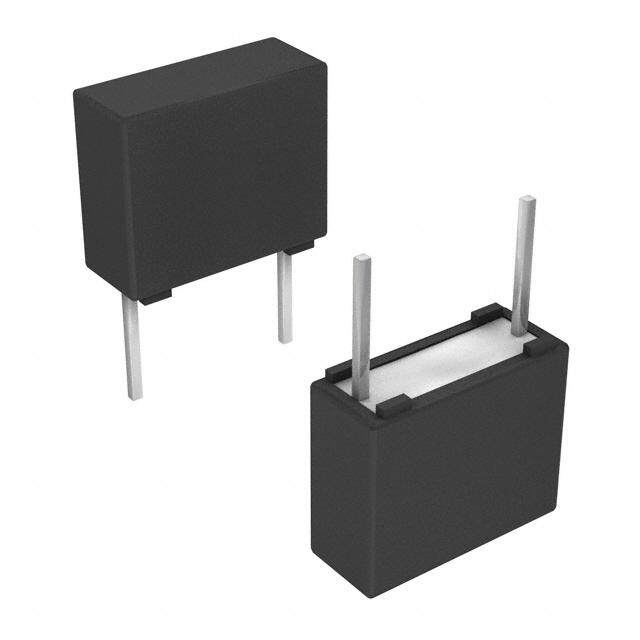

| 产品目录绘图 |

|

| 产品目录页面 | |

| 产品种类 | Metallized Polypropylene Film Capacitors |

| 介电材料 | 聚丙烯(PP), 金属化 |

| 其它名称 | 399-5473 |

| 包装 | 散装 |

| 商标 | Kemet |

| 外壳宽度 | 5 mm |

| 外壳长度 | 13 mm |

| 外壳高度 | 11 mm |

| 大小/尺寸 | 0.512" 长 x 0.197" 宽(13.00mm x 5.00mm) |

| 安装类型 | 通孔 |

| 容差 | ±20% |

| 封装 | Bulk |

| 封装/外壳 | 径向 |

| 工作温度 | -40°C ~ 110°C |

| 工厂包装数量 | 1300 |

| 应用 | EMI、RFI 抑制 |

| 引线直径 | 0.6 mm |

| 引线间距 | 0.394"(10.00mm) |

| 引线间隔 | 10 mm |

| 最大工作温度 | + 110 C |

| 最小工作温度 | - 40 C |

| 标准包装 | 1,300 |

| 特性 | 达到 X1Y2 安全等级 |

| 电介质 | Polypropylene (PP) |

| 电压额定值AC | 300 V |

| 电压额定值DC | 1 kV |

| 电容 | 4700pF |

| 端接 | PC 引脚 |

| 端接类型 | Radial |

| 类型 | Metallized Polypropylene Film |

| 系列 | R41 |

| 零件号别名 | 413F147000M1M |

| 额定电压-AC | 300V |

| 额定电压-DC | 1000V(1kV) |

| 高度-安装(最大值) | 0.437"(11.10mm) |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

Metallized Polypropylene Film EMI Suppression Capacitors R41, Class Y2, 300 VAC, 110°C (Automotive Grade) Overview Applications The R41 is constructed of metallized polypropylene film For use in electromagnetic interference (EMI) suppression encapsulated with self-extinguishing resin in a box of filter in "line-to-ground" and "across-the-line" applications material meeting the requirements of UL 94 V–0. requiring Y2/X1 safety classification. Suitable for use in situations where failure of the capacitor could lead to danger Automotive Grade devices (up to 22.5 mm Lead Spacing) of electric shock. Not for use in "series with mains" type meet the demanding Automotive Electronics Council's applications. AEC–Q200 qualification requirements. Benefits • Approvals: ENEC, UL, cUL, CQC • Class Y2 / X1 (IEC 60384-14) • Rated voltage: 300 VAC 50/60 Hz • Capacitance range: 0.001 – 1 µF • Lead spacing: 10 – 37.5 mm • Capacitance tolerance: ±20%, ±10% • Climatic category: 40/110/56, IEC 60068–1 • Tape and reel in accordance with IEC 60286–2 • RoHS Compliant and lead-free terminations • Operating temperature range of −40˚C to +110˚C • 100% screening factory test at 5,000 VDC/2,500 VAC • Self-healing properties • Automotive (AEC–Q200) grades available up to 22.5 mm Lead Spacing Part Number System R41 3 I 2330 00 M1 M Rated Voltage Lead Spacing Capacitance Capacitance Series Packaging Internal Use (VAC) (mm) Code (pF) Tolerance Y2, Metallized 3 = 300 F = 10.0 The last three See Ordering 00 K = ±10% Polypropylene I = 15.0 digits represent Options Table M1 M = ±20% N = 22.5 significant figures. R = 27.5 The first digit W = 37.5 specifies number of zeros to be added. One world. One KEMET © KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard F3100_R41_Y2_300 • 4/20/2020 1 Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Metallized Polypropylene Film EMI Suppression Capacitors R41 Series, Class Y2, 300 VAC, 110ºC (Automotive Grade) Ordering Options Table Lead Spacing Lead Length Lead and Nominal Type of Leads and Packaging (mm) Packaging Code (mm) Standard Lead and Packaging Options Bulk (Bag) – Short Leads 4 +2/−0 00 Ammo Pack H= 18.5 ±0.5 DQ 0 Other Lead and Packaging Options 10, Tape & Reel (Large Reel) H= 18.5 ±0.5 CK 0 15, Bulk (Bag) – Short Leads 3.5 +0.5/−0 JB 22.5 Bulk (Bag) – Short Leads 4.0 +0.5/−0 JE Bulk (Bag) – Short Leads 3.2 +0.3/−0.2 JH Bulk (Bag) – Long Leads 18 ±1 JM Bulk (Bag) – Long Leads 30 +5/−0 40 Bulk (Bag) – Long Leads 25 +2/−1 50 Standard Lead and Packaging Options Bulk (Tray) – Short Leads 4 +2/−0 00 Tape & Reel (Large Reel) H= 18.5 ±0.5 CK1 27.5 0 Other Lead and Packaging Options Bulk (Tray) – Long Leads 30 +5/−0 40 Bulk (Tray) – Long Leads 25 +2/−1 50 Standard Lead and Packaging Options Bulk (Tray) – Short Leads 4 +2/−0 00 37.5 Other Lead and Packaging Options Bulk (Tray) – Long Leads 30 +5/−0 40 Bulk (Tray) – Long Leads 25 +2/−1 50 1 Not for all sizes, see "Packaging Quantities" table © KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard F3100_R41_Y2_300 • 4/20/2020 2 Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Metallized Polypropylene Film EMI Suppression Capacitors R41 Series, Class Y2, 300 VAC, 110ºC (Automotive Grade) Dimensions – Millimeters FRONT VIEW SIDE VIEW L B H S LL d S B H L d Nominal Tolerance Nominal Tolerance Nominal Tolerance Nominal Tolerance Nominal Tolerance 10.0 ±0.4 4.0 +0.2/−0.5 9.0 +0.1/−0.5 13.0 +0.3/−0.5 0.6 ±0.05 10.0 ±0.4 5.0 +0.2/−0.5 11.0 +0.1/−0.5 13.0 +0.3/−0.5 0.6 ±0.05 10.0 ±0.4 6.0 +0.2/−0.5 12.0 +0.1/−0.5 13.0 +0.3/−0.5 0.6 ±0.05 15.0 ±0.4 5.0 +0.2/−0.5 11.0 +0.1/−0.5 18.0 +0.3/−0.5 0.6 ±0.05 15.0 ±0.4 6.0 +0.2/−0.5 12.0 +0.1/−0.5 18.0 +0.3/−0.5 0.6 ±0.05 15.0 ±0.4 7.5 +0.2/−0.5 13.5 +0.1/−0.5 18.0 +0.3/−0.5 0.6 ±0.05 15.0 ±0.4 8.5 +0.2/−0.5 14.5 +0.1/−0.5 18.0 +0.3/−0.5 0.6 ±0.05 15.0 ±0.4 11.0 +0.2/−0.5 19.0 +0.1/−0.5 18.0 +0.3/−0.5 0.8 ±0.05 22.5 ±0.4 6.0 +0.2/−0.5 15.0 +0.1/−0.5 26.5 +0.3/−0.5 0.8 ±0.05 22.5 ±0.4 7.0 +0.2/−0.5 16.0 +0.1/−0.5 26.5 +0.3/−0.5 0.8 ±0.05 22.5 ±0.4 8.5 +0.2/−0.5 17.0 +0.1/−0.5 26.5 +0.3/−0.5 0.8 ±0.05 22.5 ±0.4 10.0 +0.2/−0.5 18.5 +0.1/−0.5 26.5 +0.3/−0.5 0.8 ±0.05 22.5 ±0.4 13.0 +0.2/−0.5 22.0 +0.1/−0.5 26.5 +0.3/−0.5 0.8 ±0.05 27.5 ±0.4 13.0 +0.2/−0.7 22.0 +0.1/−0.7 32.0 +0.3/−0.7 0.8 ±0.05 27.5 ±0.4 14.0 +0.2/−0.7 28.0 +0.1/−0.7 32.0 +0.3/−0.7 0.8 ±0.05 27.5 ±0.4 18.0 +0.2/−0.7 33.0 +0.1/−0.7 32.0 +0.3/−0.7 0.8 ±0.05 37.5 ±0.4 13.0 +0.2/−0.7 24.0 +0.1/−0.7 41.5 +0.3/−0.7 1.0 ±0.05 37.5 ±0.4 16.0 +0.2/−0.7 28.5 +0.1/−0.7 41.5 +0.3/−0.7 1.0 ±0.05 37.5 ±0.4 20.0 +0.2/−0.7 40.0 +0.1/−0.7 41.5 +0.3/−0.7 1.0 ±0.05 Note: See Ordering Options Table for lead length (LL/H) options. 0 © KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard F3100_R41_Y2_300 • 4/20/2020 3 Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Metallized Polypropylene Film EMI Suppression Capacitors R41 Series, Class Y2, 300 VAC, 110ºC (Automotive Grade) Performance Characteristics Dielectric Polypropylene film Plates Metal layer deposited by evaporation under vacuum Winding Non-inductive type Leads Tinned wire Protection Plastic case, thermosetting resin filled. Box material is solvent resistant and flame retardant according to UL94. Related documents IEC 60384-14, EN 60384-14 Rated Voltage (V ) 300 VAC (50/60 Hz), 1,000 VDC R Capacitance Range 0.0010 to 1 µF Capacitance Values E6 series (IEC 60063) Capacitance Tolerance ±10%, ±20% Temperature Range −40°C to +110°C Climatic Category 40/110/56 IEC 60068-1 Storage time: ≤ 24 months from the date marked on the label package Average relative humidity per year ≤ 70% Storage Conditions RH ≤ 85% for 30 days randomly distributed throughout the year Dew is absent Temperature: −40 to 80°C (see "Maximum Humidity in Storage Conditions" graph below) Approvals ENEC, UL, cUL, CQC Dissipation Factor (tanδ) ≤ 0.3% (0.2%*) at 1 kHz , +25°C ±5°C (* typical value) The 100% screening factory test is carried out at 5,000 VDC/2,500 VAC. The voltage level is selected to meet the requirements in applicable equipment standards. All electrical characteristics are checked after the test. Test Voltage Between Terminals It is not permitted to repeat this test as there is a risk to damage the capacitor. KEMET is not liable in such case for any failures. Measured at +25°C ±5°C Minimum Values Between Terminals Insulation Resistance Voltage Charge Voltage Charge Time C ≤ 0.33 μF C > 0.33 μF ≥ 1 • 105 MΩ ≥ 30,000 MΩ • µF 100 VDC 1 minute ( ≥ 5 • 105 MΩ )* ( ≥ 150,000 MΩ • µF )* In DC Applications Recommended voltage ≤ 1,000 VDC * Typical value © KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard F3100_R41_Y2_300 • 4/20/2020 4 Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Metallized Polypropylene Film EMI Suppression Capacitors R41 Series, Class Y2, 300 VAC, 110ºC (Automotive Grade) Performance Characteristics cont. Maximum Humidity in Storage Condition Maximum I vs. T rms h 100 120% 90 ) % ( 80 100% ty 70 i d i 60 ms 80% um 50 m Ir e H 40 ximu 60% tiv 30 30 Days Ma 40% a Annual Average l 20 e R 10 20% 0 −40 −20 0 20 40 60 80 0% Temperature (°C) 25 35 45 55 65 75 85 95 105 115 Temperature T(°C) h Maximum Overtemperature ∆T vs T lim h 25 20 C)15 ° (m Tli ∆10 5 0 0 10 20 30 40 50 60 70 80 90 100 110 120 Temperature T(°C) h T is the maximum ambient temperature surrounding the capacitor or hottest contact point (e.g. tracks), whichever is higher, in the worst operation h conditions in °C. © KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard F3100_R41_Y2_300 • 4/20/2020 5 Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Metallized Polypropylene Film EMI Suppression Capacitors R41 Series, Class Y2, 300 VAC, 110ºC (Automotive Grade) Maximum Voltage (V ) Versus Frequency (Sinusoidal Waveform/Th ≤ 40°C) rms Lead Spacing 10 mm Lead Spacing 15 mm 1,000 1,000 100 100 V) rms V) rms Voltage ( 00..000618 µµFF Voltage ( 00..00417 µµFF 10 10 1 1 0.1 1.0 10.0 100.0 0.1 1.0 10.0 100.0 Frequency (kHz) Frequency (kHz) Lead Spacing 22.5 mm Lead Spacing 27.5 mm 1,000 1,000 100 100 V) rms V) rms Voltage ( 00.00..24127 µµµFFF Voltage ( 00..2427 µµFF 10 10 0.68 µF 1 1 0.1 1.0 10.0 100.0 0.1 1.0 10.0 100.0 Frequency (kHz) Frequency (kHz) Lead Spacing 37.5 mm 1,000 100 ) ms Vr ge ( Volta 0.47 µF 10 1 µF 1 0.1 1.0 10.0 100.0 Frequency (kHz) © KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard F3100_R41_Y2_300 • 4/20/2020 6 Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Metallized Polypropylene Film EMI Suppression Capacitors R41 Series, Class Y2, 300 VAC, 110ºC (Automotive Grade) Maximum Current (I ) Versus Frequency (Sinusoidal Waveform/Th ≤ 40°C) rms Lead Spacing 10 mm Lead Spacing 15 mm 1 1 )ms 0.001 µF )ms Current (Ar0.1 0.068 µF Current (Ar0.1 0.01 µF 0.047 µF 0.01 0.01 0.1 1.0 10.0 100.0 0.1 1.0 10.0 100.0 Frequency (kHz) Frequency (kHz) Lead Spacing 22.5 mm Lead Spacing 27.5 mm 1 10 1 )ms )ms Ar Ar Current (0.1 000...0124 2 7 µ µ µFFF Current ( 000...246278 µµµFFF 0.1 0.01 0.01 0.1 1.0 10.0 100.0 0.1 1.0 10.0 100.0 Frequency (kHz) Frequency (kHz) Lead Spacing 37.5 mm 10 1 )ms Ar 0.47 µF nt ( 1 µF Curre 0.1 0.01 0.1 1.0 10.0 100.0 Frequency (kHz) © KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard F3100_R41_Y2_300 • 4/20/2020 7 Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Metallized Polypropylene Film EMI Suppression Capacitors R41 Series, Class Y2, 300 VAC, 110ºC (Automotive Grade) Qualification Automotive grade products meet or exceed the requirements outlined by the Automotive Electronics Council. Details regarding test methods and conditions are referenced in document AEC–Q200, Stress Test Qualification for Passive Components. For additional information regarding the Automotive Electronics Council and AEC–Q200, please visit their website at www.aecouncil.com. Impedance Graph 100 10 Ω) |Z| ( 1 00..00011 µµFF 0.1µF 0.1 0.01 0.1 1 10 100 Frequency (MHz) Environmental Test Data Test IEC Publication Procedure 1.7 x V VAC 50 Hz, once every hour increase to 1,000 VAC for 0.1 Endurance EN/IEC 60384–14 R second, 1,000 hours at upper rated temperature Vibration IEC 60068–2–6 Test Fc 3 directions at 2 hours each 10 – 55 Hz at 0.75 mm or 98 m/s2 Bump IEC 60068–2–29 Test Eb 1,000 bumps at 390 m/s2 Change of Temperature IEC 60068–2–14 Test Na Upper and lower rated temperature 5 cycles Active Flammability IEC 60384–14 V +20 surge pulses at 5 kV (pulse every 5 seconds) R Passive Flammability IEC 60384–14 IEC 60384–1, IEC 60695–11–5 Needle flame test Damp Heat Steady State IEC 60068–2–78 Test Cab +40°C and 93% RH, 56 days © KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard F3100_R41_Y2_300 • 4/20/2020 8 Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Metallized Polypropylene Film EMI Suppression Capacitors R41 Series, Class Y2, 300 VAC, 110ºC (Automotive Grade) Approvals Mark Specification File Number EN/IEC 60384-14 V4160 UL 60384-14 and CAN/CSA E60384-14 E97797 (300 VAC) CQC14001116018 CQC13001101264 IEC 60384-14 CQC15001128704 CQC19001218777 CQC13001087758 Environmental Compliance All KEMET EMI capacitors are RoHS Compliant. © KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard F3100_R41_Y2_300 • 4/20/2020 9 Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Metallized Polypropylene Film EMI Suppression Capacitors R41 Series, Class Y2, 300 VAC, 110ºC (Automotive Grade) Table 1 – Ratings & Part Number Reference Capacitance Dimensions in mm Lead Spacing dV/dt New KEMET Legacy Part Value (µF) B H L (p) (V/µs) Part Number Number 0.0010 4.0 9.0 13.0 10.0 800 413F1100(1)00(2) R413F1100(1)00(2) 0.0015 4.0 9.0 13.0 10.0 800 413F1150(1)00(2) R413F1150(1)00(2) 0.0022 4.0 9.0 13.0 10.0 800 413F1220(1)00(2) R413F1220(1)00(2) 0.0033 4.0 9.0 13.0 10.0 800 413F1330(1)M1(2) R413F1330(1)M1(2) 0.0047 5.0 11.0 13.0 10.0 800 413F1470(1)M1(2) R413F1470(1)M1(2) 0.0068 6.0 12.0 13.0 10.0 800 413F1680(1)00(3) R413F1680(1)00(3) 0.010 6.0 12.0 13.0 10.0 800 413F2100(1)M1(3) R413F2100(1)M1(3) 0.0033 5.0 11.0 18.0 15.0 600 413I1330(1)00(2) R413I1330(1)00(2) 0.0047 5.0 11.0 18.0 15.0 600 413I1470(1)00(2) R413I1470(1)00(2) 0.0068 5.0 11.0 18.0 15.0 600 413I1680(1)00(2) R413I1680(1)00(2) 0.010 5.0 11.0 18.0 15.0 600 413I2100(1)00(2) R413I2100(1)00(2) 0.015 5.0 11.0 18.0 15.0 600 413I2150(1)M1(2) R413I2150(1)M1(2) 0.022 6.0 12.0 18.0 15.0 600 413I2220(1)M1(2) R413I2220(1)M1(2) 0.033 7.5 13.5 18.0 15.0 600 413I2330(1)M1(2) R413I2330(1)M1(2) 0.047 8.5 14.5 18.0 15.0 600 413I2470(1)M1(2) R413I2470(1)M1(2) 0.068 11.0 19.0 18.0 15.0 600 413I2680(1)00(2) R413I2680(1)00(2) 0.047 6.0 15.0 26.5 22.5 500 413N2470(1)00(2) R413N2470(1)00(2) 0.068 6.0 15.0 26.5 22.5 500 413N2680(1)M1(3) R413N2680(1)M1(3) 0.068 7.0 16.0 26.5 22.5 500 413N2680(1)00(2) R413N2680(1)00(2) 0.10 8.5 17.0 26.5 22.5 500 413N3100(1)M1(2) R413N3100(1)M1(2) 0.15 10.0 18.5 26.5 22.5 500 413N3150(1)M1(2) R413N3150(1)M1(2) 0.22 13.0 22.0 26.5 22.5 500 413N3220(1)00(2) R413N3220(1)00(2) 0.22 13.0 22.0 32.0 27.5 400 413R3220(1)00(2) R413R3220(1)00(2) 0.33 14.0 28.0 32.0 27.5 400 413R3330(1)00(2) R413R3330(1)00(2) 0.33 13.0 22.0 32.0 27.5 400 413R3330(1)M1(2) R413R3330(1)M1(2) 0.47 18.0 33.0 32.0 27.5 400 413R3470(1)00(2) R413R3470(1)00(2) 0.68 18.0 33.0 32.0 27.5 400 413R3680(1)00(2) R413R3680(1)00(2) 0.47 13.0 24.0 41.5 37.5 300 413W3470(1)00(2) R413W3470(1)00(2) 0.68 16.0 28.5 41.5 37.5 300 413W3680(1)00(2) R413W3680(1)00(2) 1.0 20.0 40.0 41.5 37.5 300 413W4100(1)00(2) R413W4100(1)00(2) Lead New KEMET Capacitance Value (µF) B (mm) H (mm) L (mm) dV/dt (V/µs) Legacy Part Number Spacing (p) Part Number (1) Insert lead and packaging code. See Ordering Options Table for available options. (2) M = ±20%, K = ±10% (3) M = ±20% (only available tolerance). © KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard F3100_R41_Y2_300 • 4/20/2020 10 Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Metallized Polypropylene Film EMI Suppression Capacitors R41 Series, Class Y2, 300 VAC, 110ºC (Automotive Grade) Soldering Process The implementation of the RoHS directive has resulted in the selection of SnAgCu (SAC) alloys or SnCu alloys as primary solder. This has increased the liquidus temperature from that of 183°C for SnPb eutectic alloy to 217 – 221°C for the new alloys. As a result, the heat stress to the components, even in wave soldering, has increased considerably due to higher pre-heat and wave temperatures. Polypropylene capacitors are especially sensitive to heat (the melting point of polypropylene is 160 – 170°C). Wave soldering can be destructive, especially for mechanically small polypropylene capacitors (with lead spacing of 5 mm to 15 mm), and great care has to be taken during soldering. The recommended solder profiles from KEMET should be used. Please consult KEMET with any questions. In general, the wave soldering curve from IEC Publication 61760-1 Edition 2 serves as a solid guideline for successful soldering. Please see Figure 1. Reflow soldering is not recommended for through-hole film capacitors. Exposing capacitors to a soldering profile in excess of the above the recommended limits may result to degradation or permanent damage to the capacitors. Do not place the polypropylene capacitor through an adhesive curing oven to cure resin for surface mount components. Insert through-hole parts after the curing of surface mount parts. Consult KEMET to discuss the actual temperature profile in the oven, if through-hole components must pass through the adhesive curing process. A maximum two soldering cycles is recommended. Please allow time for the capacitor surface temperature to return to a normal temperature before the second soldering cycle. Manual Soldering Recommendations Wave Soldering Recommendations The following is the recommendation for 300 manual soldering with a soldering iron. 2+3 seconds max 260°C 250 First Wave Second Wave Recommended Soldering Temperature 400 e (°C)200 ∆15 T0 °<C Cooling 350 eratur150 Preheating ca. 2°C/second mperature (°C)235000 Temp100 Tpreheat Typical ctyap. i3c.a5l°C/second Bit Te200 50 Soldering Iron 110500 00 40 80 120 160 200 240 Time (seconds) 50 0 0 1 2 3 4 5 6 7 8 Soldering Time (seconds) The soldering iron tip temperature should be set at 350°C (+10°C maximum) with the soldering duration not to exceed more than 3 seconds. © KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard F3100_R41_Y2_300 • 4/20/2020 11 Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Metallized Polypropylene Film EMI Suppression Capacitors R41 Series, Class Y2, 300 VAC, 110ºC (Automotive Grade) Soldering Process cont. Wave Soldering Recommendations cont. 1. The table indicates the maximum set-up temperature of the soldering process Figure 1 Maximum Maximum Preheat Peak Soldering Dielectric Temperature Temperature Film Material Capacitor Capacitor Capacitor Capacitor Pitch Pitch Pitch Pitch ≤ 15 mm > 15 mm ≤ 15 mm > 15 mm Polyester 130°C 130°C 270°C 270°C Polypropylene 110°C 130°C 260°C 270°C Paper 130°C 140°C 270°C 270°C Polyphenylene 150°C 160°C 270°C 270°C Sulphide 2. The maximum temperature measured inside the capacitor: Set the temperature so that inside the element the maximum temperature is below the limit: Maximum temperature Dielectric Film Material measured inside the element Polyester 160°C Polypropylene 110°C Paper 160°C Polyphenylene 160°C sulphide Temperature monitored inside the capacitor. Selective Soldering Recommendations Selective dip soldering is a variation of reflow soldering. In this method, the printed circuit board with through-hole components to be soldered is preheated and transported over the solder bath as in normal flow soldering without touching the solder. When the board is over the bath, it is stopped and pre-designed solder pots are lifted from the bath with molten solder only at the places of the selected components, and pressed against the lower surface of the board to solder the components. The temperature profile for selective soldering is similar to the double wave flow soldering outlined in this document, however, instead of two baths, there is only one bath with a time from 3 to 10 seconds. In selective soldering, the risk of overheating is greater than in double wave flow soldering, and great care must be taken so that the parts are not overheated. © KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard F3100_R41_Y2_300 • 4/20/2020 12 Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Metallized Polypropylene Film EMI Suppression Capacitors R41 Series, Class Y2, 300 VAC, 110ºC (Automotive Grade) Construction 2 Sections Detailed Cross Section Molded Plastic Single-sided Metallized Molded Plastic Self-Extinguishing Case Polypropylene Film Case Resin (First Layer) Single-sided Metallized Polypropylene Film (Second Layer) Margin Margin Metal Contact Metal Contact Layer Layer FILM WINDINGM SargCinHEME OPTIONS Leads Single-sided Metallized Polypropylene Film Double-sided Metallized Polyester Film Winding Scheme Polypropylene Double-sided Film Dielectric Metallized Single-sided Single-sided Double-sided Polypropylene Polyester Carrier Metallized Metallized Metallized Film Dielectric Film Polypropylene Polypropylene Polyester Single-sided Film Film Carrier Metallized Film Polypropylene Film 1 Section 2 Sections 1 Section 2 Sections Polypropylene Double-sided Film Dielectric Metallized Single-sided Single-sided Double-sided Polypropylene Polyester Carrier Metallized Metallized Metallized Film Dielectric Film Polypropylene Polypropylene Polyester Single-sided Film Film Carrier Metallized Film Polypropylene Film 3 Sections 4 Sections 3 Sections 4 Sections Metallized Impregnated Paper ©M KeEtMaEllTiz Eeledc tProonliycps hCeornpyolreantioen • KEMET Tower • One East Broward Boulevard F3100_R41_Y2_300 • 4/20/2020 13 Polypropylene Film/Foil Fort LSauudlfeirddeal eF, iFlLm 3 3(S30M1 RU)SA • 954-766-2800 • www.kemet.com Single-sided Metallized Metal Foil Metal Foil Polypropylene Metallized Polypropylene Film Impregnated Metallized Polyphenyl- Film Dielectric Paper ene Sulfide Film with Polypropylene Vacuum-Evaporated Film Dielectric Aluminum Electrodes 1 Section 1 Section 1 Section 2 Sections Single-sided Metallized Polyester Film AXIAL - Polypropylene Film/Foil Single-sided Polypropylene Single-sided Metallized Film Dielec- Metallized Polyester tric Polypropylene Film Film Polypropylene 1 Section Metal Foil Metal Foil Film Dielectric 1 Section 2 Sections AXIAL - Single-sided Metallized AXIAL - Single-sided Metallized AXIAL - Double-sided Polypropylene Film Polyester Film Metallized Polyester Film Single-sided Single-sided Double-sided Polypropylene Metallized Metallized Metallized Film Dielectric Polypropylene Polyester Polyester Carrier Film Film Film Single-sided Metallized Polypropylene Film 1 Section 1 Section 2 Sections

Metallized Polypropylene Film EMI Suppression Capacitors R41 Series, Class Y2, 300 VAC, 110ºC (Automotive Grade) Marking Lead Spacing 10 mm FRONT TOP Capacitance Tolerance Approval Series, Marks Dielectric Code, Safety Class, Self Healing Manufacturer’s Capacitance, Logo Rated Voltage IEC Climatic Date Code Category Manufacturing NOTE: Hot imprinting with or without Plant color or ink jet or laser marking Passive Flammability Category Lead Spacing 15 mm, 22.5 mm (small case sizes) FRONT TOP Capacitance Tolerance Approval Series, Marks Dielectric Code, Safety Class, Self Healing Manufacturer’s Capacitance, Logo Rated Voltage IEC Climatic Date Code Category Manufacturing NOTE: Hot imprinting with or without Plant color or ink jet or laser marking Passive Flammability Category: B for volume ≥ 1750 mm3 C for volume < 1750 mm3 * Differences caused by technology (clichee, laser or ink jet) and production line Lead Spacing 22.5 and 27.5 mm (alternatives*) and 37.5 mm FRONT TOP Series Dielectric Safety Self Code Class Healing Capacitance, Approval Manufacturer’s Capacitance Marks Logo Tolerance, Rated Voltage IEC Climatic Category QA Number Passive Flammability Manufacturing Date Code © KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard Category PlFa3n1t00_R41_Y2_300 • 4/20/2020 14 Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Lead Spacing 10 mm FRONT TOP Capacitance Tolerance Approval Series, Marks Dielectric Code, Safety Class, Self Healing Manufacturer’s Capacitance, Logo Rated Voltage IEC Climatic Date Code Category Manufacturing NOTE: Hot imprinting with or without Plant color or ink jet or laser marking Passive Flammability Category Lead Spacing 15 mm, 22.5 mm (small case sizes) FRONT TOP Capacitance Tolerance Approval Series, Marks Dielectric Code, Safety Class, Self Healing Manufacturer’s Capacitance, Logo Rated Voltage IEC Climatic Date Code Category Manufacturing NOTE: Hot imprinting with or without Metallized Polypropylene Film EMI Suppression Capacitors Plant color or ink jet or laser marking Passive Flammability R41 Series, Class Y2, 300 VAC, 110ºC (CAautteogmoroyt:ive Grade) B for volume ≥ 1750 mm3 C for volume < 1750 mm3 Marking cont. Lead Spacing 22.5 and 27.5 mm (alternatives*) and 37.5 mm FRONT TOP Series Dielectric Safety Self Code Class Healing Capacitance, Approval Manufacturer’s Capacitance Marks Logo Tolerance, Rated Voltage IEC Climatic Category QA Number Passive Flammability Manufacturing Date Code Category Plant * Differences caused by technology (clichee, laser or ink jet) and production line Manufacturing Date Code (IEC 60062) Y = Year, Z = Month Year Code Month Code 2010 A January 1 2011 B February 2 2012 C March 3 2013 D April 4 2014 E May 5 2015 F June 6 2016 H July 7 2017 J August 8 2018 K September 9 2019 L October O 2020 M November N 2021 N December D 2022 P 2023 R 2024 S 2025 T 2026 U 2027 V 2028 W 2029 X 2030 M © KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard F3100_R41_Y2_300 • 4/20/2020 15 Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Metallized Polypropylene Film EMI Suppression Capacitors R41 Series, Class Y2, 300 VAC, 110ºC (Automotive Grade) Packaging Quantities Standard Lead Spacing Thickness Height Length Bulk Bulk Large Reel Ammo Reel (mm) (mm) (mm) (mm) Short Leads Long Leads ø 500 mm Taped ø 355 mm 4.0 9.0 13.0 2000 1800 750 1,500 1000 10 5.0 11.0 13.0 1300 1500 600 1,250 800 6.0 12.0 13.0 1000 1200 500 1,000 680 5.0 11.0 18.0 2000 1000 600 1,250 800 6.0 12.0 18.0 1750 900 500 1,000 680 15 7.5 13.5 18.0 1000 700 350 800 500 8.5 14.5 18.0 1000 500 270 700 440 11.0 19.0 18.0 450 350 270 500 340 6.0 15.0 26.5 805 500 300 700 464 7.0 16.0 26.5 700 500 250 550 380 22.5 8.5 17.0 26.5 468 300 250 450 280 10.0 18.5 26.5 396 300 160 350 235 13.0 22.0 26.5 300 200 130 300 – 13.0 22.0 32.0 480 288 – 300 – 27.5 14.0 28.0 32.0 352 176 – – – 18.0 33.0 32.0 256 128 – – – 13.0 24.0 41.5 360 216 – – – 37.5 16.0 28.5 41.5 216 108 – – – 20.0 40.0 41.5 126 84 – – – © KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard F3100_R41_Y2_300 • 4/20/2020 16 Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Metallized Polypropylene Film EMI Suppression Capacitors R41 Series, Class Y2, 300 VAC, 110ºC (Automotive Grade) Lead Taping & Packaging (IEC 60286–2) Figure 1 Figure 2 Figure 3 Lead Spacing 10 mm Lead Spacing 15 mm Lead Spacing 22.5 – 27.5 mm P P h h P 2 W2 H0 ød A B W1 W0 W F P1 P0 D0 P1 P2 A-B t Taping Specifi cation Dimensions (mm) Lead Space Description Symbol 10 15 22.5 27.5 Tol. Fig. 1 Fig. 2 Fig. 3 Fig. 3 Lead wire diameter d 0.6 0.6–0.8 0.8 0.8 ±0.05 Taping lead space P 25.4 25.4 38.1 38.1 ±1 Feed hole lead space * P 12.7 12.7 12.7 12.7 ±0.2 ** 0 Centering of the lead wire P 7.7 5.2 7.8 5.3 ±0.7 1 Centering of the body P 12.7 12.7 19.05 19.05 ±1.3 2 Lead spacing (pitch) *** F 10 15 22.5 27.5 +0.6/−0.1 Component alignment ∆h 0 0 0 0 ±2 Height of component H **** 18.5 18.5 18.5 18.5 ±0.5 from tape center 0 Carrier tape width W 18 18 18 18 +1/−0.5 Hold down tape width W 9 10 10 10 Minimum 0 Hole position W 9 9 9 9 ±0.5 1 Hold down tape position W 3 3 3 3 Maximum 2 Feed hole diameter D 4 4 4 4 ±0.2 0 Total tape thickness t 0.7 0.7 0.7 0.7 ±0.2 * 15 mm also available ** Maximum of 1 mm on 20 lead spaces *** Pitches 15 mm and 10 mm taped to 7.5 mm (crimped leads) available upon request **** H = 16.5 mm is available upon request 0 © KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard F3100_R41_Y2_300 • 4/20/2020 17 Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Metallized Polypropylene Film EMI Suppression Capacitors R41 Series, Class Y2, 300 VAC, 110ºC (Automotive Grade) Lead Taping & Packaging (IEC 60286–2) cont. Ammo Specifi cations Dimensions (mm) H W T 360 340 59 H W T Reel Specifi cations Dimensions (mm) Reel Size D H W Standard 355 30 55 Maximum Large 500 25 D H W © KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard F3100_R41_Y2_300 • 4/20/2020 18 Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Metallized Polypropylene Film EMI Suppression Capacitors R41 Series, Class Y2, 300 VAC, 110ºC (Automotive Grade) KEMET Electronics Corporation Sales Offi ces For a complete list of our global sales offi ces, please visit www.kemet.com/sales. Disclaimer All product specifi cations, statements, information and data (collectively, the “Information”) in this datasheet are subject to change. The customer is responsible for checking and verifying the extent to which the Information contained in this publication is applicable to an order at the time the order is placed. All Information given herein is believed to be accurate and reliable, but it is presented without guarantee, warranty, or responsibility of any kind, expressed or implied. Statements of suitability for certain applications are based on KEMET Electronics Corporation’s (“KEMET”) knowledge of typical operating conditions for such applications, but are not intended to constitute – and KEMET specifi cally disclaims – any warranty concerning suitability for a specifi c customer application or use. The Information is intended for use only by customers who have the requisite experience and capability to determine the correct products for their application. Any technical advice inferred from this Information or otherwise provided by KEMET with reference to the use of KEMET’s products is given gratis, and KEMET assumes no obligation or liability for the advice given or results obtained. Although KEMET designs and manufactures its products to the most stringent quality and safety standards, given the current state of the art, isolated component failures may still occur. Accordingly, customer applications which require a high degree of reliability or safety should employ suitable designs or other safeguards (such as installation of protective circuitry or redundancies) in order to ensure that the failure of an electrical component does not result in a risk of personal injury or property damage. Although all product–related warnings, cautions and notes must be observed, the customer should not assume that all safety measures are indicted or that other measures may not be required. KEMET is a registered trademark of KEMET Electronics Corporation. © KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard F3100_R41_Y2_300 • 4/20/2020 19 Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Mouser Electronics Authorized Distributor Click to View Pricing, Inventory, Delivery & Lifecycle Information: K EMET: R413N310000M1M R413N310000M1K R413N3100DQ00M R413I2220DQM1K R413I2150JCM1M R413I22200000K R413F11000000M R413F12200000M R413F13300000M R413F147000M1M R413I21000000M R413I22200000M R413F11500000K R413F12205000M R413F1330CK00M R413F147040M1M R413F147050M1M R413I14700000M R413I14704000M R413I21000000K R413I21005000K R413I21005000M R413I2100DQ00K R413I2100JH00M R413I2100JU00M R413I21504000M R413I22204000M R413I22205000K R413I22205000M R413I2220JB00M R413I2220JU00M R413I23300000M R413I23304000M R413I2330DQ00K R413I2330JU00M R413I24700000K R413I24700000M R413I24704000M R413I2470JU00M R413N31004000K R413N3100DQ00K R4133N3100DQ00M R413R33300000M R413I2220DQ00K R413F14705000M R413N24704000K R413F1100JY00K R413I2150JE00M R413I22704000M R413R3330JB00M R413F13300000K R413I2220JH00M R413F16800000M R413F1470DQM1K R413F1100JY00M R413F1330DQ00M R413N31005000M R413I21500000K R413F1330JU00M R413F1680DQ00M R413F11000000K R413F1470JY00K R413I2330DQM1M R413N32204000M R413I21505000M R413F14700000K R413N3100JB00M R413N3150JHM1M R413F1100CK00M R413F12704000M R413N2470JP00M R413N2470DQ00K R413F1470JBM1M R413F1250JY00M R413F1470JY00M R413R3220JE00M R413I16800000M R413I21505000K R413N31000000K R413N2680JU00M R413W3470JB00M R413F1220JY00M R413I2100CK00M R413F1470JYM1M R413N3220JU00M R413I13300000M R413I2100JU00K R413F1470JHM1K R413F1330JH00M R413N3100CK00M R413N31000000M R413I2330DQ00M R413F1100JU00M R413I1470DQ00K R413F1470DQ00M R413N31500000M R413F1680JH00M R413F1470CKM1M R413I247050M1M R413N2470JU00M

Datasheet下载

Datasheet下载