- 型号: PR36MF22NSZF

- 制造商: Sharp Microelectronics

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

PR36MF22NSZF产品简介:

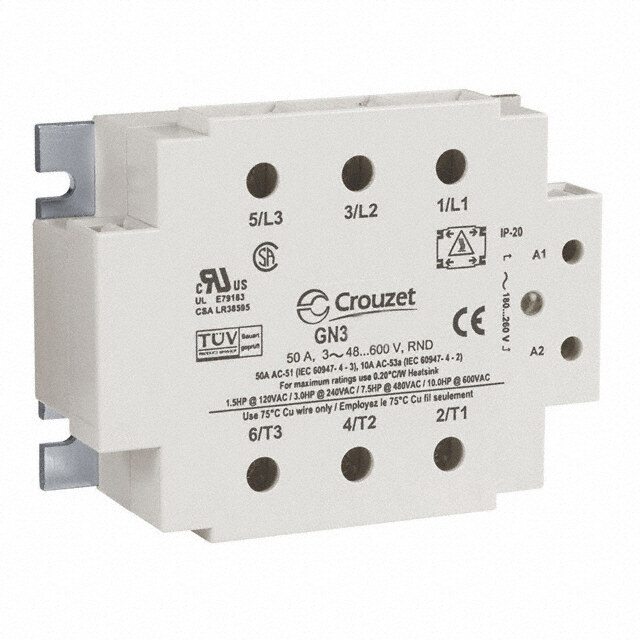

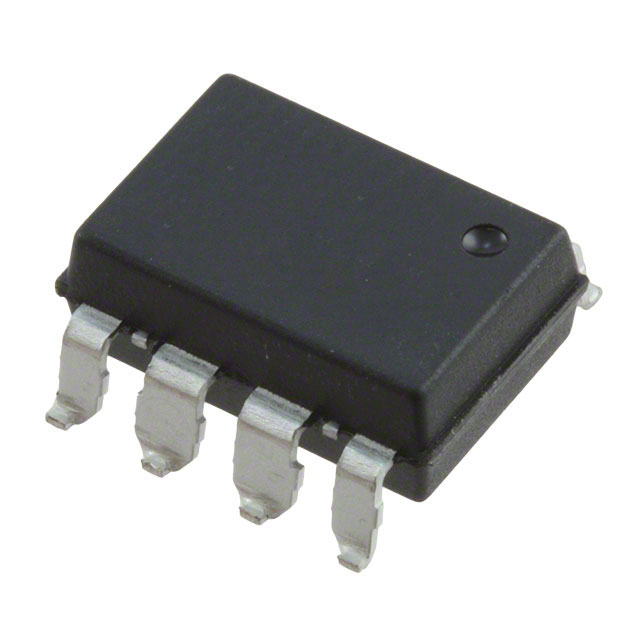

ICGOO电子元器件商城为您提供PR36MF22NSZF由Sharp Microelectronics设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 PR36MF22NSZF价格参考。Sharp MicroelectronicsPR36MF22NSZF封装/规格:固态继电器, Solid State Relay SPST-NO (1 Form A) 8-DIP (0.300", 7.62mm), 7 Leads。您可以下载PR36MF22NSZF参考资料、Datasheet数据手册功能说明书,资料中有PR36MF22NSZF 详细功能的应用电路图电压和使用方法及教程。

SHARP(现由Socle Technology运营)生产的固态继电器PR36MF22NSZF,是一款采用光耦隔离技术的直流输入控制、交流输出型固态继电器。该型号广泛应用于需要高可靠性、长寿命及低噪声开关控制的工业自动化与电子控制系统中。 典型应用场景包括:工业设备中的加热系统控制,如电炉、烘干机、恒温箱等温度调节装置,通过无触点开关实现平稳启停,减少电弧干扰;在自动化生产线中用于驱动交流电机、电磁阀、照明负载等感性或阻性负载,提升系统稳定性;也适用于医疗设备、测试仪器等对电磁干扰敏感的精密电子设备中,因其无机械触点、响应速度快、抗震动能力强,可有效提高设备运行的可靠性和安全性。 此外,PR36MF22NSZF具备良好的电气隔离性能和过零触发功能,能有效抑制浪涌电流,保护负载并延长使用寿命,适合在环境较复杂或维护困难的场合使用。其紧凑的封装设计也便于在空间受限的控制模块中集成。 综上,该固态继电器适用于工业控制、自动化设备、温控系统及精密仪器等领域,是传统电磁继电器的理想替代方案。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | RELAY SSR 240VAC .6A ZC 8-DIP |

| 产品分类 | |

| 品牌 | Sharp Microelectronics |

| 数据手册 | http://www.sharpsma.com/webfm_send/336 |

| 产品图片 | |

| 产品型号 | PR36MF22NSZF |

| rohs | 无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | PR36MF |

| 产品目录绘图 |

|

| 产品目录页面 | |

| 供应商器件封装 | 8-DIP |

| 其它名称 | 425-2371-5 |

| 包装 | 管件 |

| 安装类型 | 通孔 |

| 导通电阻 | - |

| 封装/外壳 | 8-DIP(0.300",7.62mm),7 引线 |

| 标准包装 | 50 |

| 电压-负载 | 0 ~ 240 V |

| 电压-输入 | 1.2VDC |

| 电路 | SPST-NO(1 A 形) |

| 端子类型 | PC 引脚 |

| 继电器类型 | |

| 负载电流 | 600mA |

| 输出类型 | AC,过零 |

.jpg)

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

PR36MF22NSZF Series PR36MF22NSZF I (rms)≦0.6A, Zero Cross type T DIP 8pin Series Triac output SSD ■ Agency approvals/Compliance ■Description 1. Approved by UL508 file No.E94758 PR36MF22NSZF Solid State Device (SSD) is an (as model No.R36MF2) integration of an infrared emitting diode (IRED), 2. Approved by CSA file No.063705 a Phototriac Detector and a main output Triac. This (as model No.R36MF2) device is ideally suited for controlling high voltage 3. Optionary approved by VDE AC loads with solid state reliability while providing (DIN EN 60747-5-5), file No.40008898 4kV isolation (V (rms)) from input to output. (as model No.R36MF2) iso 4. Package resin : UL flammability grade (94V-0) ■Features ■ Applications 20 sleeves *Maximum (51. lOinuetpsu×t c4u rsretanitr, sIT)( rms)≤0.6A 1. Isolated interface between high voltage AC devices 2. Zero crossing functionary and lower voltage DC control circuitry. 3. 8 pin DIP package (SMT gullwing also available) 2. Switching motors, fans, heaters, solenoids, and 4. High repetitive peak off-state voltage (V : 600V) valves. DRM 5. Superior noise immunity (dV/dt : MIN. 100V/μs) 3. Power control in applications such as lighting and 6. Response time, t : MAX. 100μs temperature control equipment.. on 7. High isolation voltage between input and output (V (rms) : 4kV) iso 8. RoHS directive compliant Notice The content of data sheet is subject to change without prior notice. In the absence of confirmation by device specification sheets, SHARP takes no responsibility for any defects that may occur in equipment using any SHARP devices shown in catalogs, data books, etc. Contact SHARP in order to obtain the latest device specification sheets before using any SHARP device. Sheet No.: D4-A00501FEN Date: July. 2015 © SHARP Corporation 1

PR36MF22NSZF Series ■Pin-Number and internal connection diagram ① ⑧ ① : Cathode ⑤ : Gate ② ② : Anode ⑥ : T 1 ③ : Cathode ⑧ : T2 ③ ⑥ ④ : Cathode ④ ⑤ ■Outline Dimensions (Unit : mm) [ex. PR36MF22NSZF] [ex. PR36MF22NIPF] Under Development 2 2 (3digit) (3digit) [ex. PR36MF22YSZF] may not be available [ex. PR36MF22YIPF] Under Development 2 2 (3digit) (3digit) Plating material : SnCu (Cu : TYP.2%) Sheet No.: D4-A00501FEN 2

PR36MF22NSZF Series Date code (3 digit) 1st digit 2nd digit 3rd digit Year of production Month of production Day of production A.D. Mark A.D. Mark Month Mark Day Mark Day Mark Day Mark 2010 A 2022 P January 1 1 1 13 D 25 S 2011 B 2023 R February 2 2 2 14 E 26 T 2012 C 2024 S March 3 3 3 15 F 27 U 2013 D 2025 T April 4 4 4 16 G 28 V 2014 E 2026 U May 5 5 5 17 H 29 X 2015 F 2027 V June 6 6 6 18 J 30 Y 2016 H 2028 W July 7 7 7 19 K 31 Z 2017 J 2029 X August 8 8 8 20 L - - 2018 K 2030 A September 9 9 9 21 N - - 2019 L 2031 B October O 10 A 22 O - - 2020 M 2032 C November N 11 B 23 P - - 2021 N … … December D 12 C 24 R - - repeats in a 20 year cycle Factory identification mark Factory identification Mark Country of origin China * This factory marking is for identification purpose only. Please contact the local SHARP sales representative to see the actural status of the production. Sheet No.: D4-A00501FEN 3

PR36MF22NSZF Series ■Absolute maximum ratings Ta=25°C Parameter Symbol Rating Unit Forward current I 50 *3 mA F Input Reverse voltage V 6 V R m RMS on-state current IT(rms) 0.6 *3 A m 1 Output Peak one cycle surge current Isurge 6 *4 A Repetitive peak off-state voltage V 600 V DRM Isolation voltage *1 Viso(rms) 4.0 kV Soldering area Operating temperature Topr -30 to +85 °C Storage temperature Tstg -40 to +125 °C Soldering temperature *2 Tsol 270 °C *1 40 to 60%RH, AC for 1minute, f=60Hz *2 for 10s *3 Refer to Fig.1,Fig.2 *4 f=50Hz sine wave ■Electrical Characteristics Ta=25°C Parameter Symbol Conditions MIN. TYP. MAX. Unit Forward voltage V I =20mA - 1.2 1.4 V F F Input Reverse current I V =3V - - 10 μA R R Repetitive peak I V =V - - 100 μA off-state current DRM D DRM On-state voltage V I =1.2A - - 2.5 V T T Output Holding current I V =6V - - 25 mA H D Critical rate of rise of dv/dt V =1/√2· V 100 - - V/μs off-state voltage D DRM Minimum trigger current I V =6V, R =100Ω - - 5 mA FT D L Transfer Isolation resistance R DC500V 40 to 60%RH 5×1010 1011 - Ω ISO charac- teristics Turn on time t VD=6V, RL=100Ω, - - 100 μs ON I =20mA F ■Model Line-up Lead Form Through-Hole SMT Gullwing Shipping Sleeve Taping Rating I [mA] V Rank FT Packege 50 pcs/sleeve 1,000 pcs/reel DRM Voltage (V =6V, [V] mark D DIN [V] R =100Ω) - Approved - Approved L EN60747-5-5 Model No. PR36MF22NSZF PR36MF22YSZF PR36MF22NIPF PR36MF22YIPF 600 AC250 1 MAX.5 Please contact a local SHARP sales representative to inquire about production status. Sheet No.: D4-A00501FEN 4

PR36MF22NSZF Series Sheet No.: D4-A00501FEN 5

PR36MF22NSZF Series Sheet No.: D4-A00501FEN 6

PR36MF22NSZF Series ■ Design Considerations ● Recommended Operating Conditions Parameter Symbol Condition MIN MAX Unit Input signal current I (ON) - 20 25 mA at ON state F Input Input signal current I (OFF) - 0 0.1 mA at OFF state F Load supply voltage V (rms) - - 240 V OUT Locate snubber circuit between output terminals I (rms)× Output Load supply current I (rms) - T A OUT (Cs=0.022μ F, Rs=47Ω) 80%(*) Frequency f - 50 60 Hz Operating temperature T - -20 80 ˚C opr (*) See Fig.2 about derating curve (IT(rms) vs. ambient temperature). ●Design guide In order for the SSD to turn off, the triggering current (I ) must be 0.1mA or less F In case that L (Inductance) load such as motor etc. is used, please use this device after confirming whether it operates normally in actual condition since there is a case that the zero cross circuit works and the load does not turn on due to the phase difference of load current. In case that pulse drive is carried out, it shall be recommended to use that the pulse width of input signal is 1ms or more. Particular attention needs to be paid when utilizing SSDs that incorporate zero crossing circuitry. If the phase difference between the voltage and the current at the output pins is large enough, zero crossing type SSDs cannot be used. The result, if zero crossing SSDs are used under this condition, is that the SSD may not turn on and off irregardless of the input current. In this case, only a non zero cross type SSD should be used in combination with the above mentioned snubber circuit selection process. When the input current (I ) is below 0.1mA, the output Triac will be in the open circuit mode. However, if F the voltage across the Triac, V , increases faster than rated dV/dt, the Triac may turn on. To avoid this situa- D tion, please incorporate a snubber circuit. Due to the many different types of load that can be driven, we can merely recommend some circuit values to start with : Cs=0.022μF and Rs=47Ω. The operation of the SSD and snubber circuit should be tested and if unintentional switching occurs, please adjust the snubber circuit component values accordingly When making the transition from On to Off state, a snubber circuit should be used ensure that sudden drops in current are not accompanied by large instantaneous changes in voltage across the Triac. This fast change in voltage is brought about by the phase difference between current and voltage. Primarily, this is experienced in driving loads which are inductive such as motors and solenods. Following the procedure outlined above should provide sufficient results. Any snubber or Varistor used for the above mentioned scenarios should be located as close to the main out- put triac as possible. All pins shall be used by soldering on the board. (Socket and others shall not be used.) ● Degradation In general, the emission of the IRED used in SSD will degrade over time. In the case where long term operation and / or constant extreme temperature fluctuations will be applied to the devices, please allow for a worst case scenario of 50% degradation over 5years. Therefore in order to maintain proper operation, a design implementing these SSDs should provide at least twice the minimum required triggering current from initial operation. Sheet No.: D4-A00501FEN 7

PR36MF22NSZF Series ● Recommended Foot Print (reference) SMT Gullwing Lead-form 8.2 4 5 2. 4 5 2. 4 5 2. 7 1. 2.2 (Unit : mm) ● Standard Circuit R1 +Vcc ② ⑧ Load D1 SSD Zs AC Line ③ ⑥ V1 Tr1 ✩ For additional design assistance, please review our corresponding Optoelectronic Application Notes. Sheet No.: D4-A00501FEN 8

PR36MF22NSZF Series ■ Manufacturing Guidelines ● Soldering Method Reflow Soldering: Reflow soldering should follow the temperature profile shown below. Soldering should not exceed the curve of temperature profile and time. Please don't solder more than twice. (℃) 300 Terminal : 260˚C peak (package surface : 250˚C peak) 200 Reflow 220˚C or more, 60s or less Preheat 100 150 to 180˚C, 120s or less 0 0 1 2 3 4 (min) Flow Soldering (No Solder bathing) Flow soldering should be completed below 270˚C and within 10s. Preheating is within the bounds of 100 to 150˚C and 30 to 80s. Please don't solder more than twice. Hand soldering Hand soldering should be completed within 3s when the point of solder iron is below 400 C. Please don't solder more than twice. Other notice Please test the soldering method in actual condition and make sure the soldering works fine, since the im- pact on the junction between the device and PCB varies depending on the tooling and soldering conditions Sheet No.: D4-A00501FEN 9

PR36MF22NSZF Series ● Cleaning instructions Solvent cleaning : Solvent temperature should be 45˚C or below. Immersion time should be 3minutes or less. Ultrasonic cleaning : The impact on the device varies depending on the size of the cleaning bath, ultrasonic output, cleaning time, size of PCB and mounting method of the device. Therefore, please make sure the device withstands the ultrasonic cleaning in actual conditions in advance of mass production. Recommended solvent materials : Ethyl alcohol, Methyl alcohol and Isopropyl alcohol In case the other type of solvent materials are intended to be used, please make sure they work fine in actual using conditions since some materials may erode the packaging resin. ● Presence of ODC This product shall not contain the following materials. And they are not used in the production process for this device. Regulation substances : CFCs, Halon, Carbon tetrachloride, 1.1.1-Trichloroethane (Methylchloroform) Specific brominated flame retardants such as the PBB and PBDE are not used in this product at all. The RoHS directive(2011/65/EU) This product complies with the RoHS directive(2011/65/EU) . Object substances: mercury, lead, cadmium, hexavalent chromium, polybrominated biphenyls(PBB)and polybrominated diphenyl ethers(PBDE) Content of six substances specified in Management Methods for Control of Pollution Caused by Electronic Information Products Regulation (Chinese : 电子信息产品污染控制管理办法). Marking Styles for the Names and Contents of the Hazardous Substances Hazardous Substances Polybrominate Hexavalent Polybrominate Category Lead Mercury Cadmium d diphenyl chromium d biphenyls (Pb) (Hg) (Cd) ethers (Cr6+) (PBB) (PBDE) Solid State × ○ ○ ○ ○ ○ Device This table is prepared in accordance with the provisions of SJ/T 11364. ○:Indicates that said hazardous substance contained in all of the homogeneous materials for this part is below the limit requirement of GB/T 26572 ×:Indicates that said hazardous substance contained in at least one of the homogeneous materials used for this part is above the limit requirement of GB/T 26572 The marking "×" in the above table indicates the exemption of RoHS directive (2011/65/EU), where the elimination or substitution of the restrictive substances is still immature technically and impracticable economically from a current scientific view. Sheet No.: D4-A00501FEN 10

PR36MF22NSZF Series ■ Package specification ● Sleeve package Trough-Hole Package materials Sleeve : HIPS or ABS with preventing static electricity Stopper : Styene-Elastomer Package method MAX. 50pcs of products shall be packaged in a sleeve. 80th ends shall be closed by tabbed and tabless stoppers. The product shall be arranged in the sleeve with its anode mark on the tabless stopper side. MAX. 20 sleeves in one case. Sleeve outline dimensions 12 520±2 8 10. 8 5. 8-R0.5 6.7 (Unit : mm) Sheet No.: D4-A00501FEN 11

PR36MF22NSZF Series ● Tape and Reel package SMT Gullwing Package materials Carrier tape : A-PET or PS (with preventing anti-static material) Cover tape : PET (three layer system) Reel : PS Carrier tape structure and Dimensions Sheet No.: D4-A00501FEN 12

PR36MF22NSZF Series ■Important Notices · The circuit application examples in this publication with equipment that requires higher reliability such are provided to explain representative applications as: of SHARP devices and are not intended to --- Transportation control and safety equipment guarantee any circuit design or license any (i.e.,aircraft, trains, automobiles, etc.) intellectual property rights. SHARP takes no --- Traffic signals responsibility for any problems related to any --- Gas leakage sensor breakers intellectual property right of a third party resulting --- Alarm equipment from the use of SHARP's devices. --- Various safety devices, etc. (iii) SHARP devices shall not be used for or in · Contact SHARP in order to obtain the latest connection with equipment that requires an device specification sheets before using any extremely high level of reliability and safety such SHARP device. SHARP reserves the right to make as: changes in the specifications, characteristics, data, --- Space applications materials, structure, and other contents described --- Telecommunication equipment [trunk lines] herein at any time without notice in order to --- Nuclear power control equipment improve design or reliability. Manufacturing --- Medical and other life support equipment locations are also subject to change without notice. (e.g.,scuba). · Observe the following points when using any · If the SHARP devices listed in this publication fall devices in this publication. SHARP takes no within the scope of strategic products described in responsibility for damage caused by improper use the Foreign Exchange and Foreign Trade Law of of the devices which does not meet the conditions Japan, it is necessary to obtain approval to export and absolute maximum ratings to be used specified such SHARP devices. in the relevant specification sheet nor meet thefollowing conditions: · This publication is the proprietary product of (i) The devices in this publication are designed for SHARP and is copyrighted, with all rights reserved. use in general electronic equipment designs such Under the copyright laws, no part of this publication as: may be reproduced or transmitted in any form or by --- Personal computers any means, electronic or mechanical, for any --- Office automation equipment purpose, in whole or in part, without the express --- Telecommunication equipment [terminal] written permission of SHARP. Express written --- Test and measurement equipment permission is also required before any use of this --- Industrial control publication may be made by a third party. --- Audio visual equipment --- Consumer electronics · Contact and consult with a SHARP representative (ii) Measures such as fail-safe function and if there are any questions about the contents of this redundant design should be taken to ensure publication. reliability and safety when SHARP devices are used for or in connection Sheet No.: D4-A00501FEN 13

Datasheet下载

Datasheet下载