ICGOO在线商城 > 光电元件 > LED 指示 - 分立 > LTL-4221NLC

- 型号: LTL-4221NLC

- 制造商: Lite-On

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

LTL-4221NLC产品简介:

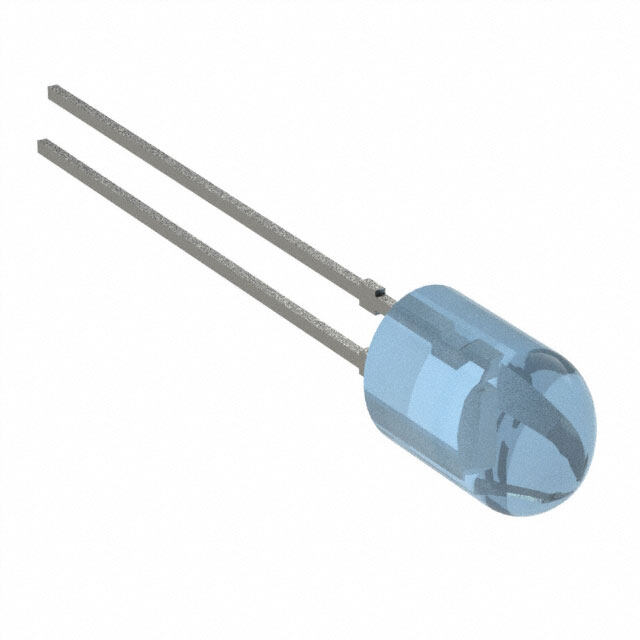

ICGOO电子元器件商城为您提供LTL-4221NLC由Lite-On设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 LTL-4221NLC价格参考。Lite-OnLTL-4221NLC封装/规格:LED 指示 - 分立, 红色 623nm LED 指示 - 分立 1.7V 径向。您可以下载LTL-4221NLC参考资料、Datasheet数据手册功能说明书,资料中有LTL-4221NLC 详细功能的应用电路图电压和使用方法及教程。

Lite-On Inc. 生产的LTL-4221NLC是一款LED指示灯,属于分立式LED指示器类别。这款LED指示灯具有多种应用场景,特别是在需要清晰、可靠视觉信号的设备和系统中。 1. 消费电子设备 LTL-4221NLC常用于消费电子产品中,如电视机、音响、投影仪等。它可以用作电源指示灯、工作状态提示灯或错误报警灯。例如,当设备通电时,LED会亮起,表示设备处于工作状态;当出现故障时,LED可以通过闪烁或其他方式提醒用户。 2. 工业控制面板 在工业自动化领域,LTL-4221NLC可以安装在控制面板上,作为操作按钮的状态指示灯。它可以显示机器的工作状态、报警信息或流程进度。由于其低功耗和长寿命特性,适合长时间连续工作的工业环境。 3. 通信设备 在网络路由器、交换机等通信设备中,LTL-4221NLC可以用作网络连接状态指示灯。通过不同的颜色或闪烁模式,它可以指示网络连接是否正常、数据传输状态等。这对于维护人员快速判断设备状态非常有帮助。 4. 医疗设备 在医疗设备中,LTL-4221NLC可以用于显示设备的工作状态、电池电量或警报信息。由于医疗设备对可靠性和稳定性要求较高,LTL-4221NLC的高稳定性和长寿命使其成为理想选择。 5. 汽车电子 在汽车内部,LTL-4221NLC可以用作仪表盘上的指示灯,显示油量、温度、车速等信息。它还可以用于车内氛围灯或安全带未系提醒灯等场景。其耐用性和抗震性能使其能够在复杂的车辆环境中稳定工作。 6. 家用电器 在微波炉、洗衣机、空调等家用电器中,LTL-4221NLC可以作为操作按钮的背光灯或状态指示灯。它可以帮助用户更直观地了解设备的运行状态,提升用户体验。 总之,LTL-4221NLC凭借其高效、可靠、长寿命的特点,广泛应用于各种需要清晰视觉信号的场合,确保设备状态一目了然,方便用户操作和维护。

| 参数 | 数值 |

| 产品目录 | |

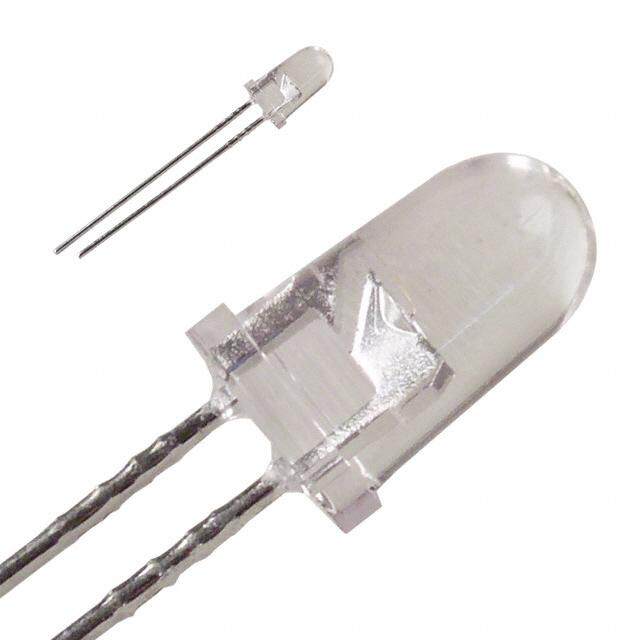

| 描述 | LED 3MM HI EFF RED RED DIFF标准LED-通孔 Red Diffused |

| 产品分类 | |

| LED大小 | T-1 |

| 品牌 | Lite-On Inc |

| 产品手册 | |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | LED发射器,标准LED-通孔,Lite-On LTL-4221NLC- |

| 数据手册 | |

| 产品型号 | LTL-4221NLC |

| 产品种类 | 标准LED-通孔 |

| 光强度 | 2.5 mcd |

| 其它名称 | 160-1957 |

| 包装 | 散装 |

| 商标 | Lite-On |

| 大小/尺寸 | - |

| 安装类型 | 通孔 |

| 安装风格 | Through Hole |

| 封装 | Bulk |

| 封装/外壳 | 径向 |

| 工厂包装数量 | 1000 |

| 显示角 | 60 deg |

| 最大工作温度 | + 100 C |

| 最小工作温度 | - 55 C |

| 标准包装 | 1,000 |

| 正向电压 | 1.7 V |

| 正向电流 | 2 mA |

| 毫烛光等级 | 2.5mcd |

| 波长-主 | 623nm |

| 波长-峰值 | 635nm |

| 波长/色温 | 635 nm |

| 测试电流时的光通量 | - |

| 照明颜色 | Red |

| 电压-正向(Vf)(典型值) | 1.7V |

| 电流-测试 | 2mA |

| 视角 | 60° |

| 透镜尺寸 | 3 mm |

| 透镜形状 | Dome |

| 透镜样式/尺寸 | 圆形,带圆顶,3mm |

| 透镜类型 | 散射,有色 |

| 透镜颜色/类型 | Diffused |

| 颜色 | 红 |

| 高度 | 4.45mm |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

LITE-ON TECHNOLOGY CORPORATION. Property of Lite-On Only Features * Lead (Pb) free product – RoHS compliant. * High efficiency. * Low power consumption. * CMOS/MOS compatible. * TTL compatible. * Wide viewing angle. Package Dimensions Part No. Lens Source Color LTL-4221NLC Red Diffused Hi-Eff.Red Notes: 1. All dimensions are in millimeters (inches). 2. Tolerance is ±0.25mm(.010") unless otherwise noted. 3. Protruded resin under flange is 1.0mm(.04") max. 4. Lead spacing is measured where the leads emerge from the package. 5. Specifications are subject to change without notice. 6. The LED lamp original is LTL-4221NLC Part No. : LTL-4221NLC-002 Page : 1 of 11 BNS-OD-C131/A4

LITE-ON TECHNOLOGY CORPORATION. Property of Lite-On Only Absolute Maximum Ratings at TA=25℃℃℃℃ Parameter Maximum Rating Unit Power Dissipation Tamb ≦ 90℃ 20 mW Forward Current 7 mA Forward Surge Current ( 10μsec pulse) 500 mA Reverse Voltage 5 V Operating Temperature Range -55℃ to + 100℃ Storage Temperature Range -55℃ to + 100℃ Lead Soldering Temperature 260℃ for 5 Seconds Max. [2mm (.0787") From Body] Part No. : LTL-4221NLC-002 Page : 2 of 11 BNS-OD-C131/A4

LITE-ON TECHNOLOGY CORPORATION. Property of Lite-On Only Electrical / Optical Characteristics at TA=25℃℃℃℃ Parameter Symbol Min. Typ. Max. Unit Test Condition IF = 2mA Luminous Intensity IV 0.75 2.5 50 mcd Note 1,4 Viewing Angle 2θ1/2 60 deg Note 2 (Fig.6) Measurement Peak Emission Wavelength λP 635 nm @Peak (Fig.1) Dominant Wavelength λd 623 nm Note 3 Spectral Line Half-Width Δλ 40 nm Forward Voltage VF 1.7 2.2 V IF = 2mA Reverse Current IR 10 μA VR = 5V Note: 1. Luminous intensity is measured with a light sensor and filter combination that approximates the CIE (Commission International De L'Eclairage) eye-response curve. 2. θ1/2 is the off-axis angle at which the luminous intensity is half the axial luminous intensity. 3. The dominant wavelength, λd is derived from the CIE chromaticity diagram and represents the single wavelength which defines the color of the device. 4. The Iv guarantee should be added ±15% . Part No. : LTL-4221NLC-002 Page : 3 of 11 BNS-OD-C131/A4

LITE-ON TECHNOLOGY CORPORATION. Property of Lite-On Only Typical Electrical / Optical Characteristics Curves (25℃ Ambient Temperature Unless Otherwise Noted) Part No. : LTL-4221NLC-002 Page : 4 of 11 BNS-OD-C131/A4

LITE-ON TECHNOLOGY CORPORATION. Property of Lite-On Only Features * Compatible with radial lead automatic insertion equipment. * Most radial lead plastic lead lamps available packaged in tape and folding. * 2.54mm (0.1") straight lead spacing available. * Folding packaging simplifies handling and testing. Package Dimensions Specification Item Symbol Minimum Maximum mm inch mm inch Tape Feed Hole Diameter D 3.8 0.149 4.2 0.165 Component Lead Pitch F 2.3 0.091 3.0 0.118 Front to Rear Deflection △H -- -- 2.0 0.078 Feed Hole to Bottom of Component H1 17.5 0.688 18.5 0.728 Feed Hole to Overall Component Height H2 21.7 0.854 23.2 0.913 Lead Length After Component Height L W0 11.0 0.433 Feed Hole Pitch P 12.4 0.488 13.0 0.511 Lead Location P1 4.4 0.173 5.8 0.228 Center of Component Location P2 5.05 0.198 7.65 0.301 Total Tape Thickness T -- -- 0.90 0.035 Feed Hole Location W0 8.5 0.334 9.75 0.384 Adhesive Tape Width W1 14.5 0.571 15.5 0.610 Adhesive Tape Position W2 0 0 3.0 0.118 Tape Width W3 17.5 0.689 19.0 0.748 Part No. : LTL-4221NLC-002 Page : 5 of 11 BNS-OD-C131/A4

LITE-ON TECHNOLOGY CORPORATION. Property of Lite-On Only Packing Spec 2 reel per inner carton total 3000pcs per inner carton 6 Inner cartons per outer carton total 18000 pcs per outer carton In every shipping lot, only the last pack will be non-full packing Part No. : LTL-4221NLC-002 Page : 6 of 11 BNS-OD-C131/A4

LITE-ON TECHNOLOGY CORPORATION. Property of Lite-On Only Bin Table Specification Luminous Intensity Unit : mcd @2mA Bin Code Min. Max. H5 0.75 1.12 H4 1.12 1.70 H3 1.70 2.50 H2 2.50 3.75 H1 3.75 50 Note: Tolerance of each bin limit is ±15% Part No. : LTL-4221NLC-002 Page : 7 of 11 BNS-OD-C131/A4

LITE-ON TECHNOLOGY CORPORATION. Property of Lite-On Only CAUTIONS 1. Application The LEDs described here are intended to be used for ordinary electronic equipment (such as office equipment, communication equipment and household applications).Consult Liteon’s Sales in advance for information on applications in which exceptional reliability is required, particularly when the failure or malfunction of the LEDs may directly jeopardize life or health (such as in aviation, transportation, traffic control equipment, medical and life support systems and safety devices). 2. Storage The storage ambient for the LEDs should not exceed 30°C temperature or 70% relative humidity. It is recommended that LEDs out of their original packaging are used within three months. For extended storage out of their original packaging, it is recommended that the LEDs be stored in a sealed container with appropriate desiccant or in desiccators with nitrogen ambient. 3. Cleaning Use alcohol-based cleaning solvents such as isopropyl alcohol to clean the LEDs if necessary. 4. Lead Forming & Assembly During lead forming, the leads should be bent at a point at least 3mm from the base of LED lens. Do not use the base of the lead frame as a fulcrum during forming. Lead forming must be done before soldering, at normal temperature. During assembly on PCB, use minimum clinch force possible to avoid excessive mechanical stress. 5. Soldering When soldering, For Lamp without stopper type and must be leave a minimum of 3 mm clearance from the base of the lens to the soldering point. To avoided the Epoxy climb up on lead frame and was impact to non-soldering problem, Dipping the lens into the solder must be avoided. Do not apply any external stress to the lead frame during soldering while the LED is at high temperature. Recommended soldering conditions : Soldering iron Wave soldering Temperature 300°C Max. Pre-heat 100°C Max. Soldering time 3 sec. Max. Pre-heat time 60 sec. Max. (one time only) Solder wave 260°C Max. Soldering time 5 sec. Max. Note: Excessive soldering temperature and/or time might result in deformation of the LED lens or catastrophic failure of the LED Part No. : LTL-4221NLC-002 Page : 8 of 11 BNS-OD-C131/A4

LITE-ON TECHNOLOGY CORPORATION. Property of Lite-On Only 6. Drive Method An LED is a current-operated device. In order to ensure intensity uniformity on multiple LEDs connected in parallel in an application, it is recommended that a current limiting resistor be incorporated in the drive circuit, in series with each LED as shown in Circuit A below. Circuit model A Circuit model B LED LED (A) Recommended circuit (B) The brightness of each LED might appear different due to the differences in the I-V characteristics of those LEDs 7. ESD (Electrostatic Discharge) Static Electricity or power surge will damage the LED. Suggestions to prevent ESD damage: (cid:1) Use a conductive wrist band or anti- electrostatic glove when handling these LEDs (cid:1) All devices, equipment, and machinery must be properly grounded (cid:1) Work tables, storage racks, etc. should be properly grounded (cid:1) Use ion blower to neutralize the static charge which might have built up on surface of the LEDs plastic lens as a result of friction between LEDs during storage and handing Part No. : LTL-4221NLC-002 Page : 9 of 11 BNS-OD-C131/A4

LITE-ON TECHNOLOGY CORPORATION. Property of Lite-On Only Suggested checking list : Training and Certification 1. Everyone working in a static-safe area is ESD-certified? 2. Training records kept and re-certification dates monitored? Static-Safe Workstation & Work Areas 1. Static-safe workstation or work-areas have ESD signs? 2. All surfaces and objects at all static-safe workstation and within 1 ft measure less than 100V? 3. All ionizer activated, positioned towards the units? 4. Each work surface mats grounding is good? Personnel Grounding 1. Every person (including visitors) handling ESD sensitive (ESDS) items wear wrist strap, heel strap or conductive shoes with conductive flooring? 2. If conductive footwear used, conductive flooring also present where operator stand or walk? 3. Garments, hairs or anything closer than 1 ft to ESD items measure less than 100V*? 4. Every wrist strap or heel strap/conductive shoes checked daily and result recorded for all DSL? 5. All wrist strap or heel strap checkers calibration up to date? Note: *50V for Blue LED. Device Handling 1. Every ESDS items identified by EIA-471 labels on item or packaging? 2. All ESDS items completely inside properly closed static-shielding containers when not at static-safe workstation? 3. No static charge generators (e.g. plastics) inside shielding containers with ESDS items? 4. All flexible conductive and dissipative package materials inspected before reuse or recycle? Others 1. Audit result reported to entity ESD control coordinator? 2. Corrective action from previous audits completed? 3. Are audit records complete and on file? Part No. : LTL-4221NLC-002 Page : 10 of 11 BNS-OD-C131/A4

LITE-ON TECHNOLOGY CORPORATION. Property of Lite-On Only 8. Reliability Test Classification Test Item Test Condition Reference Standard Ta= Under Room Temperature As MIL-STD-750D:1026 (1995) Operation Life Per Data Sheet Maximum Rating MIL-STD-883D:1005 (1991) *Test Time= 1000HRS (-24HRS,+72HRS) JIS C 7021:B-1 (1982) High Temperature Ta= 65±5°C MIL-STD-202F: 103B(1980) High Humidity RH= 90 ~ 95% JIS C 7021 : B-11(1982) Storage Test Time= 240HRS±2HRS Endurance Test High Temperature Ta= 105±5°C MIL-STD-883D:1008 (1991) Storage *Test Time= 1000HRS (-24HRS,+72HRS) JIS C 7021:B-10 (1982) Low Temperature Ta= -55±5°C JIS C 7021:B-12 (1982) Storage *Test Time=1000HRS (-24HRS,+72HRS) MIL-STD-202F:107D (1980) 105°C ~ 25°C ~ -55°C~ 25°C Temperature MIL-STD-750D:1051(1995) 30mins 5mins 30mins 5mins Cycling MIL-STD-883D:1010 (1991) 10 Cycles JIS C 7021: A-4(1982) 105 ± 5°C ~ -55°C ± 5°C MIL-STD-202F:107D(1980) Thermal 10mins 10mins MIL-STD-750D:1051(1995) Shock Environmental 10 Cycles MIL-STD-883D:1011 (1991) Test MIL-STD-202F:210A(1980) Solder T.sol = 260 °C Max. MIL-STD-750D:2031(1995) Resistance Dwell Time= 5 secs Max. JIS C 7021: A-1(1982) MIL-STD-202F:208D(1980) T. sol = 230 ± 5°C MIL-STD-750D:2026(1995) Solderability Dwell Time= 5 ± 1secs MIL-STD-883D:2003(1991) JIS C 7021: A-2(1982) 9. Others The appearance and specifications of the product may be modified for improvement, without prior notice. Part No. : LTL-4221NLC-002 Page : 11 of 11 BNS-OD-C131/A4

Datasheet下载

Datasheet下载