ICGOO在线商城 > 集成电路(IC) > 时钟/计时 - 时钟发生器,PLL,频率合成器 > LMK04808BISQE/NOPB

- 型号: LMK04808BISQE/NOPB

- 制造商: Texas Instruments

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

LMK04808BISQE/NOPB产品简介:

ICGOO电子元器件商城为您提供LMK04808BISQE/NOPB由Texas Instruments设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 LMK04808BISQE/NOPB价格参考。Texas InstrumentsLMK04808BISQE/NOPB封装/规格:时钟/计时 - 时钟发生器,PLL,频率合成器, 。您可以下载LMK04808BISQE/NOPB参考资料、Datasheet数据手册功能说明书,资料中有LMK04808BISQE/NOPB 详细功能的应用电路图电压和使用方法及教程。

Texas Instruments(德州仪器)的LMK04808BISQE/NOPB是一款高性能、低抖动时钟发生器,广泛应用于需要高精度时钟信号的通信、网络设备、数据转换和测试测量等领域。其主要应用场景包括: 1. 通信基础设施:在基站、路由器、交换机等设备中,LMK04808BISQE/NOPB提供稳定的时钟信号,确保数据传输的同步性和准确性。它支持多种输出频率和协议,适应不同的通信标准。 2. 高速数据转换:在模数转换器(ADC)和数模转换器(DAC)中,该器件可以生成低抖动时钟信号,提高数据转换的精度和可靠性,适用于雷达、医疗成像和音频处理等应用。 3. 网络同步:在网络同步系统中,如SONET/SDH、PTP(精确时间协议)等,LMK04808BISQE/NOPB能够提供高精度的参考时钟,确保网络节点之间的同步,减少延迟和抖动。 4. 无线通信:在无线通信设备中,如Wi-Fi、蓝牙和5G模块,该器件用于生成稳定的射频(RF)时钟信号,确保通信链路的稳定性和性能。 5. 测试与测量设备:在示波器、频谱分析仪等测试设备中,LMK04808BISQE/NOPB提供高精度、低抖动的时钟信号,帮助提高测量的准确性和一致性。 6. 工业自动化:在工业控制系统中,如PLC(可编程逻辑控制器)和运动控制系统,该器件用于生成精确的时钟信号,确保系统的实时性和可靠性。 7. 消费电子:在高端音频设备、视频处理设备等消费电子产品中,LMK04808BISQE/NOPB可以提供高质量的时钟信号,提升音视频质量。 总之,LMK04808BISQE/NOPB凭借其低抖动、高精度和灵活性,成为各种需要高可靠性时钟信号的应用的理想选择。

| 参数 | 数值 |

| 产品目录 | 集成电路 (IC)半导体 |

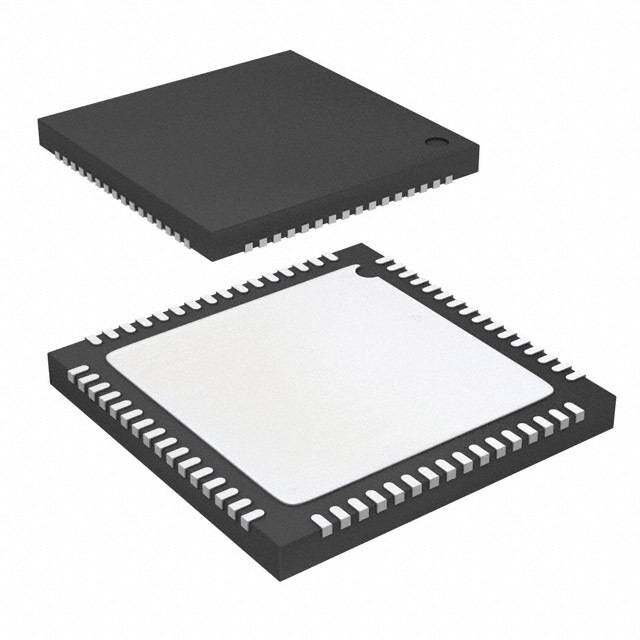

| 描述 | IC CLOCK DUAL PLL 64WQFN时钟合成器/抖动清除器 Lo-Noise Clock Jittr Cleaner Dual Lp PLL |

| 产品分类 | |

| 品牌 | Texas Instruments |

| 产品手册 | |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 时钟和计时器IC,时钟合成器/抖动清除器,Texas Instruments LMK04808BISQE/NOPBPLLatinum™ |

| 数据手册 | |

| 产品型号 | LMK04808BISQE/NOPB |

| PCN组件/产地 | |

| PLL | 是 |

| 产品种类 | 时钟合成器/抖动清除器 |

| 供应商器件封装 | 64-WQFN (9x9) |

| 其它名称 | *LMK04808BISQE/NOPB |

| 分频器/倍频器 | 是/无 |

| 包装 | 剪切带 (CT) |

| 商标 | Texas Instruments |

| 安装类型 | 表面贴装 |

| 安装风格 | SMD/SMT |

| 封装 | Reel |

| 封装/外壳 | 64-WFQFN 裸露焊盘 |

| 封装/箱体 | WQFN-64 |

| 工作温度 | -40°C ~ 85°C |

| 工厂包装数量 | 250 |

| 差分-输入:输出 | 是/是 |

| 最大工作温度 | + 85 C |

| 最大输出频率 | 3072 MHz |

| 最小工作温度 | - 40 C |

| 标准包装 | 1 |

| 比率-输入:输出 | 2:14 |

| 特色产品 | http://www.digikey.com/cn/zh/ph/ns/lmk04800-clock-conditioner.html |

| 电压-电源 | 3.15 V ~ 3.45 V |

| 电源电压-最大 | 3.45 V |

| 电源电压-最小 | 3.15 V |

| 电源电流 | 505 mA |

| 电路数 | 1 |

| 类型 | 抖动消除器 |

| 系列 | LMK04800 |

| 输入 | LVCMOS,LVDS,LVPECL |

| 输入电平 | LVPECL, LVDS, LVCMOS |

| 输出 | LVCMOS,LVDS,LVPECL |

| 输出电平 | LVCMOS, LVPECL, LVDS |

| 输出端数量 | 12 |

| 频率-最大值 | 1.536GHz |

PDF Datasheet 数据手册内容提取

Product Sample & Technical Tools & Support & Folder Buy Documents Software Community LMK04803,LMK04805,LMK04806,LMK04808 SNAS489K–MARCH2011–REVISEDDECEMBER2014 LMK0480x Low-Noise Clock Jitter Cleaner with Dual Loop PLLs 1 Features 3 Description • Ultra-LowRMSJitterPerformance The LMK0480x family is the industry's highest 1 performance clock conditioner with superior clock – 111fsRMSJitter(12kHzto20MHz) jitter cleaning, generation, and distribution with – 123fsRMSJitter(100Hzto20MHz) advanced features to meet next generation system • DualLoopPLLatinum™PLLArchitecture requirements. The dual loop PLLatinum™ architecture is capable of 111 fs rms jitter (12 kHz to • PLL1 20 MHz) using a low noise VCXO module or sub-200 – IntegratedLow-NoiseCrystalOscillatorCircuit fs rms jitter (12 kHz to 20 MHz) using a low cost – HoldoverModewhenInputClocksareLost externalcrystalandvaractordiode. – AutomaticorManualTriggering/Recovery The dual loop architecture consists of two high- • PLL2 performance phase-locked loops (PLL), a low-noise crystal oscillator circuit, and a high-performance – NormalizedPLLNoiseFloorof–227dBc/Hz voltage controlled oscillator (VCO). The first PLL – PhaseDetectorRateupto155MHz (PLL1) provides low-noise jitter cleaner functionality – OSCinFrequency-Doubler while the second PLL (PLL2) performs the clock generation. PLL1 can be configured to either work – IntegratedLow-NoiseVCO with an external VCXO module or the integrated • 2RedundantInputClockswithLOS crystal oscillator with an external tunable crystal and – AutomaticandManualSwitch-OverModes varactor diode. When paired with a very narrow loop bandwidth, PLL1 uses the superior close-in phase • 50%DutyCycleOutputDivides,1to1045(Even noise (offsets below 50 kHz) of the VCXO module or andOdd) the tunable crystal to clean the input clock. The • 12LVPECL,LVDS,orLVCMOSProgrammable outputofPLL1isusedasthecleaninputreferenceto Outputs PLL2 where it locks the integrated VCO. The loop • DigitalDelay:FixedorDynamicallyAdjustable bandwidth of PLL2 can be optimized to clean the far- out phase noise (offsets above 50 kHz) where the • 25psStepAnalogDelayControl. integrated VCO outperforms the VCXO module or • 14DifferentialOutputs.Upto26SingleEnded. tunablecrystalusedinPLL1. – Upto6VCXO/CrystalBufferedOutputs • ClockRatesofupto1536MHz DeviceInformation • 0-DelayMode PARTNUMBER VCOFREQUENCY REFERENCE INPUTS • ThreeDefaultClockOutputsatPowerUp LMK04803 1840to2030MHz • Multi-Mode:DualPLL,SinglePLL,andClock LMK04805 2148to2370MHz Distribution 2 LMK04806 2370to2600MHz • IndustrialTemperatureRange:–40to85°C LMK04808 2750to3072MHz • 3.15-Vto3.45-VOperation (1) For all available packages, see the orderable addendum at • 2DedicatedBuffered/DividedOSCinClocks theendofthedatasheet. • Package:64-PinWQFN(9.0× 9.0 ×0.8mm) SimplifiedSchematic 2 Applications OSCout0/ Recovered CVryCsXtaOl or OSCout1 LMX2541 0cloXcOWkLSsO Ha(cid:3)t³ FdOiHffDeQre´(cid:3)nt • DataConverterClocking ³GLUW\´(cid:3)FORFN(cid:3)RU(cid:3) PLL+VCO frequencies clean clock CLKin0 CLKout0, 1 • WirelessInfrastructure Backup LMK0480x CLKout2 • Networking,SONET/SDH,DSLAM RCelofcekrence CLKin1 Precision Clock CLKout3 FFPPGGAA DSeesreiarilaizliezre/r Conditioner • Medical/Video/Military/Aerospace I CLKout4, 5, 6, 7 • TestandMeasurement CLKout11 CLKout8A IF CLKout9 ADC DDAACC CPLD Q 1 An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications, intellectualpropertymattersandotherimportantdisclaimers.PRODUCTIONDATA.

LMK04803,LMK04805,LMK04806,LMK04808 SNAS489K–MARCH2011–REVISEDDECEMBER2014 www.ti.com Table of Contents 1 Features.................................................................. 1 8.5 Programming...........................................................47 2 Applications........................................................... 1 8.6 RegisterMaps.........................................................51 3 Description............................................................. 1 9 ApplicationandImplementation........................ 97 4 RevisionHistory..................................................... 2 9.1 ApplicationInformation............................................97 9.2 TypicalApplications..............................................114 5 PinConfigurationandFunctions......................... 4 9.3 SystemExamples.................................................122 6 Specifications......................................................... 6 9.4 Do'sandDon'ts.....................................................124 6.1 AbsoluteMaximumRatings......................................6 10 PowerSupplyRecommendations................... 125 6.2 ESDRatings..............................................................6 10.1 PinConnectionRecommendations.....................125 6.3 RecommendedOperatingConditions.......................6 10.2 CurrentConsumptionandPowerDissipation 6.4 ThermalInformation..................................................7 Calculations............................................................126 6.5 ElectricalCharacteristics...........................................7 11 Layout................................................................. 129 6.6 TimingRequirements..............................................13 11.1 LayoutGuidelines...............................................129 6.7 TypicalCharacteristics:ClockOutputAC Characteristics.........................................................14 11.2 LayoutExample..................................................130 7 ParameterMeasurementInformation................15 12 DeviceandDocumentationSupport............... 131 7.1 ChargePumpCurrentSpecificationDefinitions......15 12.1 DeviceSupport....................................................131 7.2 DifferentialVoltageMeasurementTerminology......16 12.2 DocumentationSupport......................................131 12.3 RelatedLinks......................................................131 8 DetailedDescription............................................ 17 12.4 Trademarks.........................................................131 8.1 Overview.................................................................17 12.5 ElectrostaticDischargeCaution..........................131 8.2 FunctionalBlockDiagram.......................................21 12.6 Glossary..............................................................131 8.3 FeatureDescription.................................................22 13 Mechanical,Packaging,andOrderable 8.4 DeviceFunctionalModes........................................43 Information......................................................... 131 4 Revision History ChangesfromRevisionJ(March2013)toRevisionK Page • Changed90to80and80to90forf parameterinElectricalCharacteristics....................................................... 11 CLKout-startup • Added"SpecificationisnotvalidforCLKoutXorCLKoutYinanalogdelaymode"intablenoteforElectrical Characteristics ..................................................................................................................................................................... 11 • Changed"Temperature"to"AmbientTemperature"inheadingtitled"ChargePumpOutputCurrentMagnitude Variationvs.AmbientTemperature" .................................................................................................................................... 15 • Added"temporarily"inVCXO/CRYSTALBufferedOutputs ................................................................................................ 18 • Changedfrom"npossible"to"Dpossible"in0-Delay......................................................................................................... 20 • Changed"can"to"cannot"inInputClockSwitching-PinSelectMode.............................................................................. 24 • DeletedClockSwitchEventwithoutHoldoverinClockSwitchEventwithHoldover.......................................................... 25 • Addedparagraphbeginning"Forapplications..."inPLL2FrequencyDoubler................................................................... 29 • Changed5to15inTable11................................................................................................................................................. 42 • DeletedMode5rowinTable12.......................................................................................................................................... 43 • AddedMode15AdditionalConfigurationssection.............................................................................................................. 46 • InTable16,added[27:26],[23:22],and[21:20]forRegister27row.Added[31:20]forR28.Added[26:24]forR30. Added[7:6]........................................................................................................................................................................... 51 • InTable18,changed"ActualPLL2Ndividervalueusedincalibrationroutine".Addedfootnote"InversionforStatus 0and1pinsisonlyvalidforCLKin_SELECT_MODE=0x06"............................................................................................ 56 • InTable28,added"toreducesupply..."footnotefor9through14.Addedfootnote"Toreducesupplyswitchingand crosstalknoise,itisrecommendedtouseacomplementaryLVCMOSoutputtypesuchas6or7".................................. 64 • Addedfootnote"Toreducesupply"for8through14inTable32 ....................................................................................... 66 • Changed"Divide"to"Definition"inTable39,Table40,Table61,andTable62................................................................ 68 • Changedto"MUXOUTPUT"inTableheaderrowinTable42............................................................................................ 69 • InTable43,addedfootnote,"ContactTIApplicationsformoreinformationonusingthismode".Changedto"Dual 2 SubmitDocumentationFeedback Copyright©2011–2014,TexasInstrumentsIncorporated ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 www.ti.com SNAS489K–MARCH2011–REVISEDDECEMBER2014 Revision History (continued) PLL,ExternalVCO(Fin),0-Delay"for15(0x0F)................................................................................................................. 70 • Added"InversionforStatus0and1pinsisonlyvalidforCLKin_SELECT_MODE=0x06"inCLKin_Sel_INV.................78 • InFORCE_HOLDOVER,added"(EN_TRACK=0or1,EN_MAN_DAC=1)".Added"(EN_TRACK=1, EN_MAN_DAC=0,EN_VTUNE_RAIL_DET=0)".............................................................................................................. 82 • ChangedtoR[23:14]inDAC_CNT....................................................................................................................................... 83 • InTable90,added(0x0000),(0x0001),(0x0002),(0x0003).Changed"Divide"to"Value"intheheaderrow................... 87 • Added(0x00)through(0x04)inTable91............................................................................................................................. 88 • AddedPLL2FrequencyDoubler.......................................................................................................................................... 88 • Changedfrom"Divide"to"Value"inTable95..................................................................................................................... 89 • AddedPLL2FrequencyDoublerreferenceinTable103..................................................................................................... 92 • Addednote"Unlessin0-delay..."inPLL2_N_CAL,PLL2NCalibrationDivider ................................................................ 93 • Changed"Mode_MUX1"to"VCO_MUX"inPLL2_P,PLL2NPrescalerDivider................................................................. 94 • Changed"register"to"Defintion"intableheaderrowforTable110................................................................................... 95 • UpdatedMinimumDigitalLockDetectTimeCalculationExample ................................................................................... 107 • Added"PerformanceofotherLMK0480xdeviceswillbesimilar"inOptionalCrystalOscillatorImplementation (OSCin/OSCin*).................................................................................................................................................................. 110 • Changedto"(fsrms)"inTable125 ................................................................................................................................... 111 • AddedtextinredforFigure40 .......................................................................................................................................... 123 • InVcc2,Vcc3,Vcc10,Vcc11,Vcc12,Vcc13(CLKoutVccs),addedbulletpointstartingwith"Itisrecommended..." Changed≤10MHzto≤30MHz........................................................................................................................................ 125 • Addedparagraph"Itisrecommended..."inVcc5(CLKinandOSCout1),Vcc7(OSCinandOSCout0)........................... 126 • AddedMode=15.RemovedMode=5inTable127........................................................................................................ 127 • Deleted"ofabout2squareinches"inLayoutGuidelines.................................................................................................. 129 ChangesfromRevisionI(March2013)toRevisionJ Page • ChangedlayoutofNationalDataSheettoTIformat............................................................................................................. 1 Copyright©2011–2014,TexasInstrumentsIncorporated SubmitDocumentationFeedback 3 ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 SNAS489K–MARCH2011–REVISEDDECEMBER2014 www.ti.com 5 Pin Configuration and Functions 64-PinWQFNwithExposedPad NKDPackage (TopView) 1 0 n n Vcc13 Status_CLKi Status_CLKi CLKout11 CLKout11* CLKout10* CLKout10 Vcc12 CLKout9 CLKout9* CLKout8* CLKout8 Vcc11 CLKout7 CLKout7* CLKout6* 64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49 CLKout0 1 48 CLKout6 CLKout0* 2 47 Vcc10 CLKout1* 3 46 DATAuWire CLKout1 4 45 CLKuWire NC 5 44 LEuWire SYNC 6 43 Vcc9 NC 7 42 CPout2 NC 8 41 Vcc8 Top Down View NC 9 40 OSCout0* Vcc1 10 39 OSCout0 LDObyp1 11 38 Vcc7 LDObyp2 12 37 OSCin* CLKout2 13 36 OSCin CLKout2* 14 35 Vcc6 CLKout3* 15 DAP 34 CPout1 CLKout3 16 33 Status_LD 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 Vcc2 Vcc3 CLKout4 CLKout4* CLKout5* CLKout5 GND Vcc4 CLKin/Fin/CLKin1 Kin*/Fin*/CLKin1* Status_Holdover CLKin0 CLKin0* Vcc5 OSCout1 OSCout1* FB BCL F PinFunctions(1) PIN I/O TYPE DESCRIPTION NUMBER NAME 1,2 CLKout0,CLKout0* O Programmable Clockoutput0(clockgroup0). 3,4 CLKout1*,CLKout1 O Programmable Clockoutput1(clockgroup0). 6 SYNC I/O Programmable CLKoutSynchronizationinputorprogrammablestatuspin. 5,7,8,9 NC – – NoConnection.Thesepinsmustbeleftfloating. 10 Vcc1 PWR PowersupplyforVCOLDO. 11 LDObyp1 ANLG LDOBypass,bypassedtogroundwith10µFcapacitor. 12 LDObyp2 ANLG LDOBypass,bypassedtogroundwitha0.1µFcapacitor. 13,14 CLKout2,CLKout2* O Programmable Clockoutput2(clockgroup1). 15,16 CLKout3*,CLKout3 O Programmable Clockoutput3(clockgroup1). 17 Vcc2 PWR Powersupplyforclockgroup1:CLKout2andCLKout3. 18 Vcc3 PWR Powersupplyforclockgroup2:CLKout4andCLKout5. (1) SeePinConnectionRecommendations. 4 SubmitDocumentationFeedback Copyright©2011–2014,TexasInstrumentsIncorporated ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 www.ti.com SNAS489K–MARCH2011–REVISEDDECEMBER2014 PinFunctions(1)(continued) PIN I/O TYPE DESCRIPTION NUMBER NAME 19,20 CLKout4,CLKout4* O Programmable Clockoutput4(clockgroup2). 21,22 CLKout5*,CLKout5 O Programmable Clockoutput5(clockgroup2). 23 GND PWR Ground. 24 Vcc4 PWR Powersupplyfordigital. CLKin1,CLKin1* ReferenceClockInputPort1forPLL1.ACorDCCoupled. Feedbackinputforexternalclockfeedbackinput(0-delay FBCLKin,FBCLKin* 25,26 I ANLG mode).ACorDCCoupled. ExternalVCOinput(ExternalVCOmode).ACorDC Fin/Fin* Coupled. Programmablestatuspin,defaultreadbackoutput. 27 Status_Holdover I/O Programmable Programmabletoholdovermodeindicator.Otheroptions availablebyprogramming. ReferenceClockInputPort0forPLL1. 28,29 CLKin0,CLKin0* I ANLG ACorDCCoupled. 30 Vcc5 PWR PowersupplyforclockinputsandOSCout1. 31,32 OSCout1,OSCout1* O LVPECL Bufferedoutput1ofOSCinport. Programmablestatuspin,defaultlockdetectforPLL1and 33 Status_LD I/O Programmable PLL2.Otheroptionsavailablebyprogramming. 34 CPout1 O ANLG Chargepump1output. 35 Vcc6 PWR PowersupplyforPLL1,chargepump1. FeedbacktoPLL1,ReferenceinputtoPLL2. 36,37 OSCin,OSCin* I ANLG ACCoupled. 38 Vcc7 PWR PowersupplyforOSCin,OSCout0,andPLL2circuitry.(2) 39,40 OSCout0,OSCout0* O Programmable Bufferedoutput0ofOSCinport.(2) 41 Vcc8 PWR PowersupplyforPLL2,chargepump2. 42 CPout2 O ANLG Chargepump2output. 43 Vcc9 PWR PowersupplyforPLL2. 44 LEuWire I CMOS MICROWIRELatchEnableInput. 45 CLKuWire I CMOS MICROWIREClockInput. 46 DATAuWire I CMOS MICROWIREDataInput. 47 Vcc10 PWR Powersupplyforclockgroup3:CLKout6andCLKout7. 48,49 CLKout6,CLKout6* O Programmable Clockoutput6(clockgroup3). 50,51 CLKout7*,CLKout7 O Programmable Clockoutput7(clockgroup3). 52 Vcc11 PWR Powersupplyforclockgroup4:CLKout8andCLKout9. 53,54 CLKout8,CLKout8* O Programmable Clockoutput8(clockgroup4). 55,56 CLKout9*,CLKout9 O Programmable Clockoutput9(clockgroup4). 57 Vcc12 PWR Powersupplyforclockgroup5:CLKout10andCLKout11. CLKout10, 58,59 O Programmable Clockoutput10(clockgroup5). CLKout10* CLKout11*, 60,61 O Programmable Clockoutput11(clockgroup5). CLKout11 Programmablestatuspin.Defaultisinputforpincontrolof 62 Status_CLKin0 I/O Programmable PLL1referenceclockselection.CLKin0LOSstatusand otheroptionsavailablebyprogramming. Programmablestatuspin.Defaultisinputforpincontrolof 63 Status_CLKin1 I/O Programmable PLL1referenceclockselection.CLKin1LOSstatusand otheroptionsavailablebyprogramming. 64 Vcc13 PWR Powersupplyforclockgroup0:CLKout0andCLKout1. DAP DAP – GND DIEATTACHPAD,connecttoGND. (2) SeeVcc5(CLKinandOSCout1),Vcc7(OSCinandOSCout0)forinformationonconfiguringdeviceforoptimumperformance. Copyright©2011–2014,TexasInstrumentsIncorporated SubmitDocumentationFeedback 5 ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 SNAS489K–MARCH2011–REVISEDDECEMBER2014 www.ti.com 6 Specifications 6.1 Absolute Maximum Ratings(1)(2)(3) overoperatingfree-airtemperaturerange(unlessotherwisenoted) (4) MIN MAX UNIT V SupplyVoltage (5) –0.3 3.6 V CC (V + V InputVoltage –0.3 CC V IN 0.3) T LeadTemperature(solder4seconds) +260 °C L T JunctionTemperature 150 °C J DifferentialInputCurrent(CLKinX/X*, I ±5 mA IN OSCin/OSCin*,FBCLKin/FBCLKin*,Fin/Fin*) MSL MoistureSensitivityLevel 3 T Storagetemperaturerange -65 150 °C stg (1) "AbsoluteMaximumRatings"indicatelimitsbeyondwhichdamagetothedevicemayoccur.OperatingRatingsindicateconditionsfor whichthedeviceisintendedtobefunctional,butdonotensurespecificperformancelimits.Forensuredspecificationsandtest conditions,seetheElectricalCharacteristics.Theensuredspecificationsapplyonlytothetestconditionslisted. (2) Stressesinexcessoftheabsolutemaximumratingscancausepermanentorlatentdamagetothedevice.Theseareabsolutestress ratingsonly.Functionaloperationofthedeviceisonlyimpliedattheseoranyotherconditionsinexcessofthosegivenintheoperation sectionsofthedatasheet.Exposuretoabsolutemaximumratingsforextendedperiodscanadverselyaffectdevicereliability. (3) IfMilitary/Aerospacespecifieddevicesarerequired,contacttheTexasInstrumentsSalesOffice/Distributorsforavailabilityand specifications. (4) StressesbeyondthoselistedunderAbsoluteMaximumRatingsmaycausepermanentdamagetothedevice.Thesearestressratings only,whichdonotimplyfunctionaloperationofthedeviceattheseoranyotherconditionsbeyondthoseindicatedunderRecommended OperatingConditions.Exposuretoabsolute-maximum-ratedconditionsforextendedperiodsmayaffectdevicereliability. (5) Nevertoexceed3.6V. 6.2 ESD Ratings VALUE UNIT Human-bodymodel(HBM),perANSI/ESDA/JEDECJS-001(1) ±2000 Machinemodel(MM) ±150 V Electrostaticdischarge V (ESD) Charged-devicemodel(CDM),perJEDECspecificationJESD22- C101(2) ±750 (1) JEDECdocumentJEP155statesthat500-VHBMallowssafemanufacturingwithastandardESDcontrolprocess.Manufacturingwith lessthan500-VHBMispossiblewiththenecessaryprecautions.Pinslistedas±2000Vmayactuallyhavehigherperformance. (2) JEDECdocumentJEP157statesthat250-VCDMallowssafemanufacturingwithastandardESDcontrolprocess.Manufacturingwith lessthan250-VCDMispossiblewiththenecessaryprecautions.Pinslistedas±750Vmayactuallyhavehigherperformance. 6.3 Recommended Operating Conditions MIN NOM MAX UNIT T JunctionTemperature 125 °C J T AmbientTemperature V =3.3V -40 25 85 °C A CC V SupplyVoltage 3.15 3.3 3.45 V CC 6 SubmitDocumentationFeedback Copyright©2011–2014,TexasInstrumentsIncorporated ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 www.ti.com SNAS489K–MARCH2011–REVISEDDECEMBER2014 6.4 Thermal Information LMK0480x THERMALMETRIC(1) NKD UNIT 64PINS R Junction-to-ambientthermalresistanceon4-layerJEDECPCB(2)(3) 25.2 θJA R Junction-to-case(top)thermalresistance(4)(5) 6.9 θJC(top) R Junction-to-boardthermalresistance(6) 4.0 θJB °C/W ψ Junction-to-topcharacterizationparameter(7) 0.1 JT ψ Junction-to-boardcharacterizationparameter(8) 4.0 JB R Junction-to-case(bottom)thermalresistance(9) 0.8 θJC(bot) (1) Formoreinformationabouttraditionalandnewthermalmetrics,seetheICPackageThermalMetricsapplicationreport,SPRA953. (2) Thejunction-to-ambientthermalresistanceundernaturalconvectionisobtainedinasimulationonaJEDEC-standard,High-Kboard,as specifiedinJESD51-7,inanenvironmentdescribedinJESD51-2a. (3) Specificationassumes32thermalviasconnectthedieattachpadtotheembeddedcopperplaneonthe4-layerJEDECPCB.These viasplayakeyroleinimprovingthethermalperformanceoftheWQFN.NotethattheJEDECPCBisastandardthermalmeasurement PCBanddoesnotrepresentbestperformanceaPCBcanachieve.Itisrecommendedthatthemaximumnumberofviasbeusedinthe boardlayout.R isuniqueforeachPCB. θJA (4) Thejunction-to-case(top)thermalresistanceisobtainedbysimulatingacoldplatetestonthepackagetop.NospecificJEDECstandard testexists,butaclosedescriptioncanbefoundintheANSISEMIstandardG30-88. (5) CaseisdefinedastheDAP(dieattachpad) (6) Thejunction-to-boardthermalresistanceisobtainedbysimulatinganenvironmentwitharingcoldplatefixturetocontrolthePCB temperature,asdescribedinJESD51-8. (7) Thejunction-to-topcharacterizationparameter,ψ ,estimatesthejunctiontemperatureofadeviceinarealsystemandisextracted JT fromthesimulationdataforobtainingR ,usingaproceduredescribedinJESD51-2a(sections6and7). θJA (8) Thejunction-to-boardcharacterizationparameter,ψ ,estimatesthejunctiontemperatureofadeviceinarealsystemandisextracted JB fromthesimulationdataforobtainingR ,usingaproceduredescribedinJESD51-2a(sections6and7). θJA (9) Thejunction-to-case(bottom)thermalresistanceisobtainedbysimulatingacoldplatetestontheexposed(power)pad.Nospecific JEDECstandardtestexists,butaclosedescriptioncanbefoundintheANSISEMIstandardG30-88. 6.5 Electrical Characteristics 3.15V≤V ≤3.45V,-40°C≤T ≤85°C.TypicalvaluesrepresentmostlikelyparametricnormsatV =3.3V,T =25°C, CC A CC A attheRecommendedOperatingConditionsatthetimeofproductcharacterizationandarenotspecified.(1) PARAMETER TESTCONDITIONS MIN TYP MAX UNIT CURRENTCONSUMPTION NoDCpathtogroundon ICC_PD Powerdownsupplycurrent OSCout1/1*(2) 1 3 mA Allclockdelaysdisabled, I Supplycurrentwithallclocksenabled(3) CLKoutX_Y_DIV=1045, 505 590 mA CC_CLKS CLKoutX_TYPE=1(LVDS), PLL1andPLL2locked. CLKin0/0*andCLKin1/1*INPUTCLOCKSPECIFICATIONS f Clockinputfrequency(4) 0.001 500 MHz CLKin SLEW (1) Clockinputslewrate(5) 20%to80% 0.15 0.5 V/ns CLKin VIDCLKin ACcoupled 0.25 1.55 |V| V CLKin Clockinput CLKinX_BUF_TYPE=0(Bipolar) 0.5 3.1 Vpp SS Differentialinputvoltage(see (6)and VIDCLKin Figure4) ACcoupled 0.25 1.55 |V| V CLKin CLKinX_BUF_TYPE=1(MOS) 0.5 3.1 Vpp SS (1) Inordertomeetthejitterperformancelistedinthesubsequentsectionsofthisdatasheet,theminimumrecommendedslewrateforall inputclocksis0.5V/ns.Thisisespeciallytrueforsingle-endedclocks.Phasenoiseperformancewillbegintodegradeastheclockinput slewrateisreduced.However,thedevicewillfunctionatslewratesdowntotheminimumlisted.Whencomparedtosingle-ended clocks,differentialclocks(LVDS,LVPECL)willbelesssusceptibletodegradationinphasenoiseperformanceatlowerslewratesdueto theircommonmodenoiserejection.However,itisalsorecommendedtousethehighestpossibleslewratefordifferentialclocksto achieveoptimalphasenoiseperformanceatthedeviceoutputs. (2) IfemitterresistorsareplacedontheOSCout1/1*pins,therewillbeaDCcurrenttogroundwhichwillcausepowerdownIcctoincrease. (3) Loadconditionsforoutputclocks:LVDS:100-Ωdifferential.SeeCurrentConsumptionandPowerDissipationCalculationsforIccfor specificpartconfigurationandhowtocalculateIccforaspecificdesign. (4) CLKin0,CLKin1maximumisspecifiedbycharacterization,productiontestedat200MHz. (5) Specifiedbycharacterization. (6) SeeDifferentialVoltageMeasurementTerminologyfordefinitionofV andV voltages. ID OD Copyright©2011–2014,TexasInstrumentsIncorporated SubmitDocumentationFeedback 7 ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 SNAS489K–MARCH2011–REVISEDDECEMBER2014 www.ti.com Electrical Characteristics (continued) 3.15V≤V ≤3.45V,-40°C≤T ≤85°C.TypicalvaluesrepresentmostlikelyparametricnormsatV =3.3V,T =25°C, CC A CC A attheRecommendedOperatingConditionsatthetimeofproductcharacterizationandarenotspecified.(1) PARAMETER TESTCONDITIONS MIN TYP MAX UNIT ACcoupledtoCLKinX;CLKinX*AC coupledtoGround 0.25 2.4 Vpp Clockinput CLKinX_BUF_TYPE=0(Bipolar) VCLKin Single-endedinputvoltage(5) ACcoupledtoCLKinX;CLKinX*AC coupledtoGround 0.25 2.4 Vpp CLKinX_BUF_TYPE=1(MOS) DCoffsetvoltagebetween V CLKin0/CLKin0* 20 mV CLKin0-offset CLKin0*-CLKin0 EachpinACcoupled DCoffsetvoltagebetween CLKin0_BUF_TYPE=0(Bipolar) V CLKin1/CLKin1* 0 mV CLKin1-offset CLKin1*-CLKin1 DCoffsetvoltagebetween EachpinACcoupled V CLKinX/CLKinX* 55 mV CLKinX-offset CLKinX_BUF_TYPE=1(MOS) CLKinX*-CLKinX V V Highinputvoltage DCcoupledtoCLKinX;CLKinX*AC 2.0 V V CLKin- IH CC coupledtoGround VCLKin-VIL Lowinputvoltage CLKinX_BUF_TYPE=1(MOS) 0.0 0.4 V FBCLKin/FBCLKin*andFin/Fin*INPUTSPECIFICATIONS ACcoupled f Clockinputfrequency(5) (CLKinX_BUF_TYPE=0) 0.001 1000 MHz FBCLKin MODE=2or8;FEEDBACK_MUX= 6 ACcoupled f Clockinputfrequency(5) (CLKinX_BUF_TYPE=0) 0.001 3100 MHz Fin MODE=3or11 SingleEnded ACcoupled; VFBCLKin/Fin Clockinputvoltage(5) (CLKinX_BUF_TYPE=0) 0.25 2.0 Vpp SLEW SlewrateonCLKin(5) ACcoupled;20%to80%; 0.15 0.5 V/ns FBCLKin/Fin (CLKinX_BUF_TYPE=0) PLL1SPECIFICATIONS f PLL1phasedetectorfrequency 40 MHz PD1 V =V /2,PLL1_CP_GAIN=0 100 CPout1 CC PLL1charge VCPout1=VCC/2,PLL1_CP_GAIN=1 200 ICPout1SOURCE Pumpsourcecurrent(7) V =V /2,PLL1_CP_GAIN=2 400 µA CPout1 CC V =V /2,PLL1_CP_GAIN=3 1600 CPout1 CC V =V /2,PLL1_CP_GAIN=0 -100 CPout1 CC PLL1charge VCPout1=VCC/2,PLL1_CP_GAIN=1 -200 ICPout1SINK Pumpsinkcurrent(7) V =V /2,PLL1_CP_GAIN=2 -400 µA CPout1 CC V =V /2,PLL1_CP_GAIN=3 -1600 CPout1 CC Chargepump I %MIS V =V /2,T=25°C 3% 10% CPout1 Sink/sourcemismatch CPout1 CC Magnitudeofchargepumpcurrent 0.5V<V <V -0.5V I V CPout1 CC 4% CPout1 TUNE variationvs.chargepumpvoltage T =25°C A Chargepumpcurrentvs. I %TEMP 4% CPout1 temperaturevariation ChargePumpTRI-STATEleakage I TRI 0.5V<V <V -0.5V 5 nA CPout1 current CPout CC (7) Thisparameterisprogrammable 8 SubmitDocumentationFeedback Copyright©2011–2014,TexasInstrumentsIncorporated ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 www.ti.com SNAS489K–MARCH2011–REVISEDDECEMBER2014 Electrical Characteristics (continued) 3.15V≤V ≤3.45V,-40°C≤T ≤85°C.TypicalvaluesrepresentmostlikelyparametricnormsatV =3.3V,T =25°C, CC A CC A attheRecommendedOperatingConditionsatthetimeofproductcharacterizationandarenotspecified.(1) PARAMETER TESTCONDITIONS MIN TYP MAX UNIT PLL1/fnoiseat10kHzoffset.(8) PLL1_CP_GAIN=400µA -117 PN10kHz dBc/Hz Normalizedto1GHzOutputFrequency PLL1_CP_GAIN=1600µA -118 PLL1_CP_GAIN=400µA -221.5 PN1Hz Normalizedphasenoisecontribution(9) dBc/Hz PLL1_CP_GAIN=1600µA -223 PLL2REFERENCEINPUT(OSCin)SPECIFICATIONS f PLL2referenceinput(10) 500 MHz OSCin PLL2referenceclockminimumslewrate SLEWOSCin onOSCin(5) 20%to80% 0.15 0.5 V/ns V InputvoltageforOSCinorOSCin*(5) ACcoupled;Single-ended(Unused 0.2 2.4 Vpp OSCin pinACcoupledtoGND) V OSCin 0.2 1.55 |V| ID Differentialvoltageswing(seeFigure4) ACcoupled V OSCin 0.4 3.1 Vpp SS DCoffsetvoltagebetween V OSCin/OSCin* EachpinACcoupled 20 mV OSCin-offset OSCinX*-OSCinX f Doublerinputfrequency(5) EN_PLL2_REF_2X=1;(11) 155 MHz doubler_max OSCinDutyCycle40%to60% CRYSTALOSCILLATORMODESPECIFICATIONS f Crystalfrequencyrange(5) R <40Ω 6 20.5 MHz XTAL ESR VectronVXB1crystal,20.48MHz, P Crystalpowerdissipation(12) R <40Ω 100 µW XTAL ESR XTAL_LVL=0 Inputcapacitanceof C -40to+85°C 6 pF IN LMK0480xOSCinport PLL2PHASEDETECTORandCHARGEPUMPSPECIFICATIONS f Phasedetectorfrequency 155 MHz PD2 V =V /2,PLL2_CP_GAIN=0 100 CPout2 CC V =V /2,PLL2_CP_GAIN=1 400 I SOURCE PLL2chargepumpsourcecurrent(7) CPout2 CC µA CPout V =V /2,PLL2_CP_GAIN=2 1600 CPout2 CC V =V /2,PLL2_CP_GAIN=3 3200 CPout2 CC V =V /2,PLL2_CP_GAIN=0 -100 CPout2 CC V =V /2,PLL2_CP_GAIN=1 -400 I SINK PLL2chargepumpsinkcurrent(7) CPout2 CC µA CPout V =V /2,PLL2_CP_GAIN=2 -1600 CPout2 CC V =V /2,PLL2_CP_GAIN=3 -3200 CPout2 CC I %MIS Chargepumpsink/sourcemismatch V =V /2,T =25°C 3% 10% CPout2 CPout2 CC A Magnitudeofchargepumpcurrentvs. 0.5V<V <V -0.5V I V CPout2 CC 4% CPout2 TUNE chargepumpvoltagevariation T =25°C A (8) AspecificationinmodelingPLLin-bandphasenoiseisthe1/fflickernoise,L (f),whichisdominantclosetothecarrier.Flicker PLL_flicker noisehasa10dB/decadeslope.PN10kHzisnormalizedtoa10kHzoffsetanda1GHzcarrierfrequency.PN10kHz=L (10 PLL_flicker kHz)-20log(Fout/1GHz),whereL (f)isthesinglesidebandphasenoiseofonlytheflickernoise'scontributiontototalnoise, PLL_flicker L(f).TomeasureL (f)itisimportanttobeonthe10dB/decadeslopeclosetothecarrier.Ahighcomparefrequencyandaclean PLL_flicker crystalareimportanttoisolatingthisnoisesourcefromthetotalphasenoise,L(f).L (f)canbemaskedbythereference PLL_flicker oscillatorperformanceifalowpowerornoisysourceisused.ThetotalPLLin-bandphasenoiseperformanceisthesumofL (f) PLL_flicker andL (f). PLL_flat (9) AspecificationmodelingPLLin-bandphasenoise.ThenormalizedphasenoisecontributionofthePLL,L (f),isdefinedas: PLL_flat PN1HZ=L (f)-20log(N)-10log(f ).L (f)isthesinglesidebandphasenoisemeasuredatanoffsetfrequency,f,ina1Hz PLL_flat PDX PLL_flat bandwidthandf isthephasedetectorfrequencyofthesynthesizer.L (f)contributestothetotalnoise,L(f). PDX PLL_flat (10) F maximumfrequencyspecifiedbycharacterization.Productiontestedat200MHz. OSCin (11) TheEN_PLL2_REF_2Xbit(Register13)enables/disablesafrequencydoublermodeforthePLL2OSCinpath. (12) SeeApplicationSectiondiscussionofOptionalCrystalOscillatorImplementation(OSCin/OSCin*). Copyright©2011–2014,TexasInstrumentsIncorporated SubmitDocumentationFeedback 9 ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 SNAS489K–MARCH2011–REVISEDDECEMBER2014 www.ti.com Electrical Characteristics (continued) 3.15V≤V ≤3.45V,-40°C≤T ≤85°C.TypicalvaluesrepresentmostlikelyparametricnormsatV =3.3V,T =25°C, CC A CC A attheRecommendedOperatingConditionsatthetimeofproductcharacterizationandarenotspecified.(1) PARAMETER TESTCONDITIONS MIN TYP MAX UNIT Chargepumpcurrentvs. I %TEMP 4% CPout2 Temperaturevariation I TRI Chargepumpleakage 0.5V<V <V -0.5V 10 nA CPout2 CPout2 CC PLL1/fNoiseat10kHzoffset(8) PLL2_CP_GAIN=400µA -118 PN10kHz Normalizedto dBc/Hz 1GHzoutputfrequency PLL2_CP_GAIN=3200µA -121 PLL2_CP_GAIN=400µA -222.5 PN1Hz NormalizedPhaseNoiseContribution(9) dBc/Hz PLL2_CP_GAIN=3200µA -227 INTERNALVCOSPECIFICATIONS LMK04803 1840 2030 LMK04805 2148 2370 f VCOtuningrange MHz VCO LMK04806 2370 2600 LMK04808 2750 3072 Finetuningsensitivity (Therangedisplayedinthetypical columnindicatesthelowersensitivityis K typicalatthelowerendofthetuning LMK04808 20to36 MHz/V VCO range,andthehighertuningsensitivityis typicalatthehigherendofthetuning range). AfterprogrammingR30forlock,no AllowableTemperatureDriftfor |ΔTCL| ContinuousLock(13)(5) changestooutputconfigurationare 125 °C permittedtoensurecontinuouslock CLKoutCLOSEDLOOPJITTERSPECIFICATIONSUSINGaCOMMERCIALQUALITYVCXO(14) Offset=1kHz -122.5 Offset=10kHz -132.9 LMK04808 Offset=100kHz -135.2 f =245.76MHz CLKout Offset=800kHz -143.9 L(f) SSBPhasenoise dBc/Hz CLKout Measuredatclockoutputs Offset=10MHz;LVDS -156.0 Valueisaverageforalloutputtypes(15) Offset=10MHz;LVPECL1600 -157.5 mVpp Offset=10MHz;LVCMOS -157.1 LMK04803(15) BW=12kHzto20MHz 112 f =245.76MHz CLKout IntegratedRMSjitter BW=100Hzto20MHz 121 LMK04805(15) BW=12kHzto20MHz 113 f =245.76MHz CLKout JCLKout IntegratedRMSjitter BW=100Hzto20MHz 122 LVDS/LVPECL/ fsrms LVCMOS LMK04806(15) BW=12kHzto20MHz 115 f =245.76MHz CLKout IntegratedRMSjitter BW=100Hzto20MHz 123 LMK04808(15) BW=12kHzto20MHz 111 f =245.76MHz CLKout IntegratedRMSjitter BW=100Hzto20MHz 123 (13) MaximumAllowableTemperatureDriftforContinuousLockishowfarthetemperaturecandriftineitherdirectionfromthevalueitwas atthetimethattheR30registerwaslastprogrammed,andstillhavethepartstayinlock.TheactionofprogrammingtheR30register, eventothesamevalue,activatesafrequencycalibrationroutine.Thisimpliesthepartwillworkovertheentirefrequencyrange,butif thetemperaturedriftsmorethanthemaximumallowabledriftforcontinuouslock,thenitwillbenecessarytoreloadtheR30registerto ensureitstaysinlock.Regardlessofwhattemperaturethepartwasinitiallyprogrammedat,thetemperaturecanneverdriftoutsidethe frequencyrangeof-40°Cto85°Cwithoutviolatingspecifications. (14) VCXOusedisa122.88MHzCrystekCVHD-950-122.880. (15) f =2949.12MHz,PLL1parameters:F =1.024MHz,I =100μA,loopbandwidth=10Hz.122.88MHzCrystekCVHD- VCO PD1 CP1 950–122.880.PLL2parameters:PLL2_R=1,F =122.88MHz,I =3200μA,C1=47pF,C2=3.9nF,R2=620Ω,PLL2_C3_LF PD2 CP2 =0,PLL2_R3_LF=0,PLL2_C4_LF=0,PLL2_R4_LF=0,CLKoutX_Y_DIV=12,andCLKoutX_ADLY_SEL=0. 10 SubmitDocumentationFeedback Copyright©2011–2014,TexasInstrumentsIncorporated ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 www.ti.com SNAS489K–MARCH2011–REVISEDDECEMBER2014 Electrical Characteristics (continued) 3.15V≤V ≤3.45V,-40°C≤T ≤85°C.TypicalvaluesrepresentmostlikelyparametricnormsatV =3.3V,T =25°C, CC A CC A attheRecommendedOperatingConditionsatthetimeofproductcharacterizationandarenotspecified.(1) PARAMETER TESTCONDITIONS MIN TYP MAX UNIT CLKoutCLOSEDLOOPJITTERSPECIFICATIONSUSINGTHEINTEGRATEDLOWNOISECRYSTALOSCILLATORCIRCUIT (16) BW=12kHzto20MHz LMK04808 XTAL_LVL=3 192 f =245.76MHz fsrms CLKout IntegratedRMSjitter BW=100Hzto20MHz 450 XTAL_LVL=3 DEFAULTPOWERONRESETCLOCKOUTPUTFREQUENCY CLKout8,LVDS,LMK04803 69 77 87 Defaultoutputclockfrequencyatdevice CLKout8,LVDS,LMK04805 80 90 99 fCLKout-startup poweron(17) CLKout8,LVDS,LMK04806 90 98 110 MHz CLKout8,LVDS,LMK04808 90 110 130 CLOCKSKEWandDELAY LVDS-to-LVDS,T=25°C, F =800MHz,R =100Ω 30 CLK L ACcoupled LVPECL-to-LVPECL, MaximumCLKoutXtoCLKoutY(5)(18) T=25°C, F =800MHz,R =100Ω |T | CLK L 30 ps SKEW emitterresistors= 240ΩtoGND ACcoupled Maximumskewbetweenanytwo R =50Ω,C =5pF, LVCMOSoutputs,sameCLKoutor L L 100 differentCLKout(5)(18) T=25°C,FCLK=100MHz. Samedevice,T=25°C, MixedT LVDSorLVPECLtoLVCMOS 750 ps SKEW 250MHz MODE=2 1850 PLL1_R_DLY=0;PLL1_N_DLY=0 MODE=2 PLL1_R_DLY=0;PLL1_N_DLY=0; td CLKintoCLKoutXdelay(18) VCOFrequency=2949.12MHz ps 0-DELAY Analogdelayselect=0; 0 Feedbackclockdigitaldelay=11; Feedbackclockhalfstep=1; Outputclockdigitaldelay=5; Outputclockhalfstep=0; (16) Crystalusedisa20.48MHzVectronVXB1-1150-20M480andSkyworksvaractordiode,SMV-1249-074LF. (17) CLKout6andOSCout0alsooscillateatstart-upatthefrequencyoftheVCXOattachedtoOSCinport. (18) Equalloadingandidenticalclockoutputconfigurationoneachclockoutputisrequiredforspecificationtobevalid.Specificationisnot validforCLKoutXorCLKoutYinanalogdelaymode. Copyright©2011–2014,TexasInstrumentsIncorporated SubmitDocumentationFeedback 11 ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 SNAS489K–MARCH2011–REVISEDDECEMBER2014 www.ti.com Electrical Characteristics (continued) 3.15V≤V ≤3.45V,-40°C≤T ≤85°C.TypicalvaluesrepresentmostlikelyparametricnormsatV =3.3V,T =25°C, CC A CC A attheRecommendedOperatingConditionsatthetimeofproductcharacterizationandarenotspecified.(1) PARAMETER TESTCONDITIONS MIN TYP MAX UNIT LVDSCLOCKOUTPUTS(CLKoutX),CLKoutX_TYPE=1 f Maximumfrequency(5)(19) R =100Ω 1536 MHz CLKout L V 250 400 450 |mV| OD Differentialoutputvoltage(seeFigure5) V 500 800 900 mVpp SS ChangeinmagnitudeofV for T=25°C,DCmeasurement ΔV OD -50 50 mV OD complementaryoutputstates ACcoupledtoreceiverinput R=100-Ωdifferentialtermination V Outputoffsetvoltage 1.125 1.25 1.375 V OS ChangeinV forcomplementaryoutput ΔV OS 35 |mV| OS states Outputrisetime 20%to80%,RL=100Ω T /T 200 ps R F Outputfalltime 80%to20%,RL=100Ω I Outputshortcircuitcurrent Single-endedoutputshortedtoGND SA -24 24 mA I singleended T=25°C SB I Outputshortcircuitcurrent-differential Complimentaryoutputstiedtogether -12 12 mA SAB LVPECLCLOCKOUTPUTS(CLKoutX) f Maximumfrequency(5)(19) 1536 MHz CLKout 20%to80%outputrise RL=100Ω,emitterresistors=240Ω toGND T /T 150 ps R F 80%to20%outputfalltime CLKoutX_TYPE=4or5 (1600or2000mVpp) 700mVppLVPECLCLOCKOUTPUTS(CLKoutX),CLKoutX_TYPE=2 V - V Outputhighvoltage CC V OH 1.03 T=25°C,DCmeasurement V - VOL Outputlowvoltage Termination=50Ωto 1C.C41 V V -1.4V CC V 305 380 440 |mV| OD Outputvoltage(seeFigure5) V 610 760 880 mVpp SS 1200mVppLVPECLCLOCKOUTPUTS(CLKoutX),CLKoutX_TYPE=3 V - V Outputhighvoltage CC V OH 1.07 T=25°C,DCmeasurement V - VOL Outputlowvoltage Termination=50Ωto 1C.C69 V V -1.7V CC V 545 625 705 |mV| OD Outputvoltage(seeFigure5) V 1090 1250 1410 mVpp SS 1600mVppLVPECLCLOCKOUTPUTS(CLKoutX),CLKoutX_TYPE=4 V - V Outputhighvoltage CC V OH 1.10 T=25°C,DCMeasurement V - VOL Outputlowvoltage Termination=50Ωto 1C.C97 V V -2.0V CC V 660 870 965 |mV| OD Outputvoltage(seeFigure5) V 1320 1740 1930 mVpp SS 2000mVppLVPECL(2VPECL)CLOCKOUTPUTS(CLKoutX),CLKoutX_TYPE=5 V - V Outputhighvoltage CC V OH 1.13 T=25°C,DCMeasurement V - VOL Outputlowvoltage Termination=50Ωto 2C.C20 V V -2.3V CC V 800 1070 1200 |mV| OD OutputvoltageFigure5 V 1600 2140 2400 mVpp SS (19) RefertoTypicalCharacteristics:ClockOutputACCharacteristicsforoutputoperationperformanceathigherfrequenciesthanthe minimummaximumoutputfrequency. 12 SubmitDocumentationFeedback Copyright©2011–2014,TexasInstrumentsIncorporated ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 www.ti.com SNAS489K–MARCH2011–REVISEDDECEMBER2014 Electrical Characteristics (continued) 3.15V≤V ≤3.45V,-40°C≤T ≤85°C.TypicalvaluesrepresentmostlikelyparametricnormsatV =3.3V,T =25°C, CC A CC A attheRecommendedOperatingConditionsatthetimeofproductcharacterizationandarenotspecified.(1) PARAMETER TESTCONDITIONS MIN TYP MAX UNIT LVCMOSCLOCKOUTPUTS(CLKoutX) f Maximumfrequency(5)(19) 5pFLoad 250 MHz CLKout V - V Outputhighvoltage 1mALoad CC V OH 0.1 V Outputlowvoltage 1mALoad 0.1 V OL I Outputhighcurrent(source) V =3.3V,V =1.65V 28 mA OH CC O I Outputlowcurrent(sink) V =3.3V,V =1.65V 28 mA OL CC O DUTY Outputdutycycle(5) VCC/2toVCC/2,FCLK=100MHz 45% 50% 55% CLK T=25°C 20%to80%,RL=50Ω, T Outputrisetime 400 ps R CL=5pF 80%to20%,RL=50Ω, T Outputfalltime 400 ps F CL=5pF DIGITALOUTPUTS(Status_CLKinX,Status_LD,Status_Holdover,SYNC) V - V High-Leveloutputvoltage I =-500µA CC V OH OH 0.4 V Low-Leveloutputvoltage I =500µA 0.4 V OL OL DIGITALINPUTS(Status_CLKinX,SYNC) V High-Levelinputvoltage 1.6 V V IH CC V Low-Levelinputvoltage 0.4 V IL Status_CLKinX_TYPE=0 -5 5 (HighImpedance) High-Levelinputcurrent Status_CLKinX_TYPE=1 I -5 5 µA IH V =V (Pull-up) IH CC Status_CLKinX_TYPE=2 10 80 (Pull-down) Status_CLKinX_TYPE=0 -5 5 (HighImpedance) Low-Levelinputcurrent Status_CLKinX_TYPE=1 I -40 -5 µA IL V =0V (Pull-up) IL Status_CLKinX_TYPE=2 -5 5 (Pull-down) DIGITALINPUTS(CLKuWire,DATAuWire,LEuWire) V High-Levelinputvoltage 1.6 V V IH CC V Low-Levelinputvoltage 0.4 V IL I High-Levelinputcurrent V =V 5 25 µA IH IH CC I Low-Levelinputcurrent V =0 -5 5 µA IL IL 6.6 Timing Requirements SeeSerialMICROWIRETimingDiagramandAdvancedMICROWIRETimingDiagramsforadditionalinformation MIN NOM MAX UNIT T LEtoClockSetUpTime SeeFigure6 25 ns ECS T DatatoClockSetUpTime SeeFigure6 25 ns DCS T ClocktoDataHoldTime SeeFigure6 8 ns CDH T ClockPulseWidthHigh SeeFigure6 25 ns CWH T ClockPulseWidthLow SeeFigure6 25 ns CWL T ClocktoLESetUpTime SeeFigure6 25 ns CES T LEPulseWidth SeeFigure6 25 ns EWH T FallingClocktoReadbackTime SeeFigure9 25 ns CR Copyright©2011–2014,TexasInstrumentsIncorporated SubmitDocumentationFeedback 13 ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 SNAS489K–MARCH2011–REVISEDDECEMBER2014 www.ti.com 6.7 Typical Characteristics: Clock Output AC Characteristics 500 1200 2000 mVpp 450 1600 mVpp 400 1000 1720000 m mVVpppp 350 800 V) 300 V) m m (D250 (D600 O O V 200 V 400 150 100 200 50 0 0 0 500 1000 1500 2000 2500 3000 0 500 1000 1500 2000 2500 3000 FREQUENCY (MHz) FREQUENCY (MHz) Figure1.LVDSV vs.Frequency Figure2.LVPECL/w240-ΩEmitterResistorsV vs. OD OD Frequency 1200 1000 2000 mVpp 800 V) m (D600 O 1600 mVpp V 400 200 0 0 500 1000 1500 2000 2500 3000 FREQUENCY (MHz) Figure3.LVPECL/w120-ΩEmitterResistorsV vs.Frequency OD 14 SubmitDocumentationFeedback Copyright©2011–2014,TexasInstrumentsIncorporated ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 www.ti.com SNAS489K–MARCH2011–REVISEDDECEMBER2014 7 Parameter Measurement Information 7.1 Charge Pump Current Specification Definitions I1=ChargePumpSinkCurrentatV =V -ΔV CPout CC I2=ChargePumpSinkCurrentatV =V /2 CPout CC I3=ChargePumpSinkCurrentatV =ΔV CPout I4=ChargePumpSourceCurrentatV =V -ΔV CPout CC I5=ChargePumpSourceCurrentatV =V /2 CPout CC I6=ChargePumpSourceCurrentatV =ΔV CPout ΔV=Voltageoffsetfromthepositiveandnegativesupplyrails.Definedtobe0.5Vforthisdevice. 7.1.1 ChargePumpOutputCurrentMagnitudeVariationVs.ChargePumpOutputVoltage 7.1.2 ChargePumpSinkCurrentVs.ChargePumpOutputSourceCurrentMismatch 7.1.3 ChargePumpOutputCurrentMagnitudeVariationvs.AmbientTemperature Copyright©2011–2014,TexasInstrumentsIncorporated SubmitDocumentationFeedback 15 ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 SNAS489K–MARCH2011–REVISEDDECEMBER2014 www.ti.com 7.2 Differential Voltage Measurement Terminology The differential voltage of a differential signal can be described by two different definitions causing confusion whenreadingdatasheetsorcommunicatingwithotherengineers.Thissectionwilladdressthemeasurementand description of a differential signal so that the reader will be able to understand and discern between the two differentdefinitionswhenused. The first definition used to describe a differential signal is the absolute value of the voltage potential between the inverting and non-inverting signal. The symbol for this first measurement is typically V or V depending on if ID OD aninputoroutputvoltageisbeingdescribed. The second definition used to describe a differential signal is to measure the potential of the non-inverting signal with respect to the inverting signal. The symbol for this second measurement is V and is a calculated SS parameter. Nowhere in the IC does this signal exist with respect to ground, it only exists in reference to its differential pair. V can be measured directly by oscilloscopes with floating references, otherwise this value can SS becalculatedastwicethevalueofV asdescribedinthefirstdescription. OD Figure 4 illustrates the two different definitions side-by-side for inputs and Figure 5 illustrates the two different definitions side-by-side for outputs. The V and V definitions show V and V DC levels that the non-inverting ID OD A B and inverting signals toggle between with respect to ground. V input and output definitions show that if the SS inverting signal is considered the voltage potential reference, the non-inverting signal voltage potential is now increasing and decreasing above and below the non-inverting reference. Thus the peak-to-peak voltage of the differentialsignalcanbemeasured. V andV areoftendefinedasvolts(V)andV isoftendefinedasvoltspeak-to-peak(V ). ID OD SS PP VID Definition VSS Definition for Input Non-Inverting Clock VA VID 2·VID VB Inverting Clock VID = | VA - VB | VSS = 2·VID GND Figure4. TwoDifferentDefinitionsforDifferentialInputSignals VOD Definition VSS Definition for Output Non-Inverting Clock VA VOD 2·VOD VB Inverting Clock VOD = | VA - VB | VSS = 2·VOD GND Figure5. TwoDifferentDefinitionsforDifferentialOutputSignals Refer to Application Note AN-912, Common Data Transmission Parameters and their Definitions (SNLA036) for moreinformation. 16 SubmitDocumentationFeedback Copyright©2011–2014,TexasInstrumentsIncorporated ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 www.ti.com SNAS489K–MARCH2011–REVISEDDECEMBER2014 8 Detailed Description 8.1 Overview In default mode of operation, dual PLL mode with internal VCO, the Phase Frequency Detector in PLL1 compares the active CLKinX reference divided by CLKinX_PreR_DIV and PLL1 R divider with the external VCXO or crystal attached to the PLL2 OSCin port divided by PLL1 N divider. The external loop filter for PLL1 should be narrow to provide an ultra clean reference clock from the external VCXO or crystal to the OSCin/OSCin*pinsforPLL2. The Phase Frequency Detector in PLL2 compares the external VCXO or crystal to the internal VCO after the reference and feedback dividers. The VCXO or crystal on the OSCin input is divided by PLL2 R divider. The feedback from the internal VCO is divided by the PLL2 Prescaler, the PLL2 N divider, and optionally the VCO divider. The bandwidth of the external loop filter for PLL2 should be designed to be wide enough to take advantage of the low in-band phase noise of PLL2 and the low high offset phase noise of the internal VCO. The VCO output is also placed on the distribution path for the Clock Distribution section. The clock distribution consists of 6 groups of dividers and delays which drive 12 outputs. Each clock group allows the user to select a divide value, a digital delay value, and an analog delay. The 6 groups drive programmable output buffers. Two groups allow their input signaltobefromtheOSCinportdirectly. When a 0-delay mode is used, a clock output will be passed through the feedback mux to the PLL1 N Divider for synchronizationand0-delay. When an external VCO mode is used, the Fin port will be used to input an external VCO signal. PLL2 Phase comparison will now be with this signal divided by the PLL2 N divider and N2 pre-scaler. The VCO divider may notbeused.OnelessclockinputisavailablewhenusinganexternalVCOmode. WhenasinglePLLmodeisused,PLL1ispowereddown.OSCinisusedasareferencetoPLL2. 8.1.1 SystemArchitecture The dual loop PLL architecture of the LMK0480x provides the lowest jitter performance over the widest range of output frequencies and phase noise integration bandwidths. The first stage PLL (PLL1) is driven by an external reference clock and uses an external VCXO or tunable crystal to provide a frequency accurate, low phase noise reference clock for the second stage frequency multiplication PLL (PLL2). PLL1 typically uses a narrow loop bandwidth (10 Hz to 200 Hz) to retain the frequency accuracy of the reference clock input signal while at the same time suppressing the higher offset frequency phase noise that the reference clock may have accumulated alongitspathorfromothercircuits.This“cleaned”referenceclockprovidesthereferenceinputtoPLL2. The low phase noise reference provided to PLL2 allows PLL2 to operate with a wide loop bandwidth (50 kHz to 200 kHz). The loop bandwidth for PLL2 is chosen to take advantage of the superior high offset frequency phase noise profile of the internal VCO and the good low offset frequency phase noise of the reference VCXO or tunablecrystal. Ultra low jitter is achieved by allowing the external VCXO or crystal’s phase noise to dominate the final output phase noise at low offset frequencies and the internal (or external) VCO’s phase noise to dominate the final outputphasenoiseathighoffsetfrequencies.Thisresultsinbestoverallphasenoiseandjitterperformance. The LMK0480x allows subsets of the device to be used to increase the flexibility of device. These different modesareselectedusingMODE:DeviceMode.Forinstance: • Dual Loop Mode - Typical use case of LMK04808. CLKinX used as reference input to PLL1, OSCin port is connectedtoVCXOortunablecrystal. • SingleLoopMode-PowersdownPLL1.OSCinportisusedasreferenceinput. • Clock Distribution Mode - Allows input of CLKin1 to be distributed to output with division, digital delay, and analogdelay. SeeDeviceFunctionalModesformoreinformationonthesemodes. Copyright©2011–2014,TexasInstrumentsIncorporated SubmitDocumentationFeedback 17 ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 SNAS489K–MARCH2011–REVISEDDECEMBER2014 www.ti.com Overview (continued) 8.1.2 PLL1RedundantReferenceInputs(CLKin0/CLKin0*andCLKin1/CLKin1*) The LMK0480x has two reference clock inputs for PLL1: CLKin0 and CLKin1. Ref Mux selects CLKin0 or CLKin1.Automaticormanualswitchingoccursbetweentheinputs. CLKin0 and CLKin1 each have input dividers. The input divider allows different clock input frequencies to be normalized so that the frequency input to the PLL1 R divider remains constant during automatic switching. By programming these dividers such that the frequency presented to the input of the PLL1_R divider is the same prevents the user from needing to reprogram the PLL1 R divider when the input reference is changed to another CLKinportwithadifferentfrequency. CLKin1issharedforuseasanexternal0-delayfeedback(FBCLKin),orforusewithanexternalVCO(Fin). Fast manual switching between reference clocks is possible with external pins Status_CLKin0 and Status_CLKin1. 8.1.3 PLL1TunableCrystalSupport The LMK0480x integrates a crystal oscillator on PLL1 for use with an external crystal and varactor diode to performjittercleaning. TheLMK0480xmustbeprogrammedtoenableCrystalmode. 8.1.4 VCXO/CRYSTALBufferedOutputs The LMK0480x provides 2 dedicated outputs which are a buffered copy of the PLL2 reference input. This reference input is typically a low noise VCXO or Crystal. When using a VCXO, this output can be used to clock externaldevicessuchasmicrocontrollers,FPGAs,CPLDs,andsoforth,beforetheLMK0480xisprogrammed. The OSCout0 buffer output type is programmable to LVDS, LVPECL, or LVCMOS. The OSCout1 buffer is fixed toLVPECL. The dedicated output buffers OSCout0 and OSCout1 can output frequency lower than the VCXO or Crystal frequency by programming the OSC Divider. The OSC Divider value range is 2 to 8. Each OSCoutX can individuallychoosetousetheOSCDivideroutputortobypasstheOSCDivider. Two clock output groups can also be programmed to be driven by OSCin. This allows a total of 4 additional differential outputs to be buffered outputs of OSCin. When programmed in this way, a total of 6 differential outputscanbedrivenbyabufferedcopyofOSCin. VCXO/Crystal buffered outputs cannot be synchronized to the VCO clock distribution outputs. The assertion of SYNC will still cause these outputs to become low temporarily. Since these outputs will turn off and on asynchronously with respect to the VCO sourced clock outputs during a SYNC, it is possible for glitches to occur on the buffered clock outputs when SYNC is asserted and unasserted. If the NO_SYNC_CLKoutX_Y bits are set these outputs will not be affected by the SYNC event except that the phase relationship will change with the othersynchronizedclocksunlessabufferedclockoutputisusedasaqualificationclockduringSYNC. 8.1.5 FrequencyHoldover The LMK0480x supports holdover operation to keep the clock outputs on frequency with minimum drift when the referenceislostuntilavalidreferenceclocksignalisre-established. 8.1.6 IntegratedLoopFilterPoles The LMK0480x features programmable 3rd and 4th order loop filter poles for PLL2. These internal resistors and capacitor values may be selected from a fixed range of values to achieve either a 3rd or 4th order loop filter response.Theintegratedprogrammableresistorsandcapacitorscomplimentexternalcomponentsmountednear thechip. These integrated components can be effectively disabled by programming the integrated resistors and capacitors totheirminimumvalues. 18 SubmitDocumentationFeedback Copyright©2011–2014,TexasInstrumentsIncorporated ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 www.ti.com SNAS489K–MARCH2011–REVISEDDECEMBER2014 Overview (continued) 8.1.7 InternalVCO The output of the internal VCO is routed to a mux which allows the user to select either the direct VCO output or a divided version of the VCO for the Clock Distribution Path. This same selection is also fed back to the PLL2 phasedetectorthroughaprescalerandN-divider. The mux selectable VCO divider has a divide range of 2 to 8 with 50% output duty cycle for both even and odd dividevalues. TheprimaryuseoftheVCOdivideristoachievedividesgreaterthantheclockoutputdividersupportsalone. 8.1.8 ExternalVCOMode TheFin/Fin*inputallowsanexternalVCOtobeusedwithPLL2oftheLMK0480x. UsinganexternalVCOreducesthenumberofavailableclockinputsbyone. 8.1.9 ClockDistribution TheLMK0480xfeaturesatotalof12outputsdrivenfromtheinternalorexternalVCO. All VCO driven outputs have programmable output types. They can be programmed to LVPECL, LVDS, or LVCMOS. When all distribution outputs are configured for LVCMOS or single ended LVPECL a total of 24 outputsareavailable. If the buffered OSCin outputs OSCout0 and OSCout1 are included in the total number of clock outputs the LMK0480x is able to distribute, then up to 14 differential clocks or up to 28 single ended clocks may be generatedwiththeLMK0480x. The following sections discuss specific features of the clock distribution channels that allow the user to control variousaspectsoftheoutputclocks. 8.1.9.1 CLKoutDIVIDER Each clock group, which is a pair of outputs such as CLKout0 and CLKout1, has a single clock output divider. The divider supports a divide range of 1 to 1045 (even and odd) with 50% output duty cycle. When divides of 26 orgreaterareused,thedivider/delayblockusesextendedmode. The VCO Divider may be used to reduce the divide needed by the clock group divider so that it may operate in normal mode instead of extended mode. This can result in a small current saving if enabling the VCO Divider allows3ormoreclockoutputdividestochangefromextendedtonormalmode. 8.1.9.2 CLKoutDelay See Clock Distribution section for details on both a fine (analog) and coarse (digital) delay for phase adjustment oftheclockoutputs. The fine (analog) delay allows a nominal 25 ps step size and range from 0 to 475 ps of total delay. Enabling the analog delay adds a nominal 500 ps of delay in addition to the programmed value. When adjusting analog delay, glitches may occur on the clock outputs being adjusted. Analog delay may not operate at frequencies above the minimum-ensuredmaximumoutputfrequencyof1536MHz. The coarse (digital) delay allows a group of outputs to be delayed by 4.5 to 12 clock distribution path cycles in normal mode, or from 12.5 to 522 VCO cycles in extended mode. The delay step can be as small as half the period of the clock distribution path by using the CLKoutX_Y_HS bit provided the output divide value is greater than 1. For example, a 2-GHz VCO frequency without the use of the VCO divider results in 250 ps coarse tuning steps..Thecoarse(digital)delayvaluetakeseffectontheclockoutputsafteraSYNCevent. Thereare3differentwaystousethedigital(coarse)delay: 1. FixedDigitalDelay 2. AbsoluteDynamicDigitalDelay 3. RelativeDynamicDigitalDelay ThesearefurtherdiscussedinClockDistribution. Copyright©2011–2014,TexasInstrumentsIncorporated SubmitDocumentationFeedback 19 ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 SNAS489K–MARCH2011–REVISEDDECEMBER2014 www.ti.com Overview (continued) 8.1.9.3 ProgrammableOutputType For increased flexibility all LMK0480x clock outputs (CLKoutX) and OSCout0 can be programmed to an LVDS, LVPECL,orLVCMOSoutputtype.OSCout1isfixedasLVPECL. Any LVPECL output type can be programmed to 700, 1200, 1600, or 2000 mVpp amplitude levels. The 2000 mVpp LVPECL output type is a Texas Instruments proprietary configuration that produces a 2000 mVpp differentialswingforcompatibilitywithmanydataconvertersandisalsoknownas2VPECL. 8.1.9.4 ClockOutputSynchronization Using the SYNC input causes all active clock outputs to share a rising edge. See Clock Output Synchronization (SYNC)formoreinformation. TheSYNCeventalsocausesthedigitaldelayvaluestotakeeffect. 8.1.10 0-Delay The 0-delay mode synchronizes the input clock phase to the output clock phase. The 0-delay feedback may be performed with an internal feedback loop from any of the clock groups or with an external feedback loop into the FBCLKinportasselectedbytheFEEDBACK_MUX. Without using 0-delay mode there will be D possible fixed phase relationships from clock input to clock output dependingontheclockoutputdividevalue. Usinganexternal0-delayfeedbackreducesthenumberofavailableclockinputsbyone. 8.1.11 DefaultStartupClocks Before the LMK0480x is programmed, CLKout8 is enabled and operating at a nominal frequency and CLKout6 and OSCout0 are enabled and operating at the OSCin frequency. These clocks can be used to clock external devicessuchasmicrocontrollers,FPGAs,CPLDs,andsoforth,beforetheLMK0480xisprogrammed. For CLKout6 and OSCout0 to work before the LMK0480x is programmed, the device must not be using Crystal mode. 8.1.12 StatusPins The LMK0480x provides status pins which can be monitored for feedback or in some cases used for input dependingupondeviceprogramming.Forexample: • TheStatus_Holdoverpinmayindicateifthedeviceisinhold-overmode. • TheStatus_CLKin0pinmayindicatetheLOS(loss-of-signal)forCLKin0. • TheStatus_CLKin0pinmaybeaninputforselectingtheactiveclockinput. • TheStatus_LDpinmayindicateifthedeviceislocked. The status pins can be programmed to a variety of other outputs including analog lock detect, PLL divider outputs,combinedPLLlockdetectsignals,PLL1Vtunerailing,readback,andsoforth.RefertotheProgramming ofthisdatasheetformoreinformation.DefaultpinprogrammingiscapturedinTable18. 8.1.13 RegisterReadback Programmed registers may be read back using the MICROWIRE interface. For readback, one of the status pins mustbeprogrammedforreadbackmode. Atnotimemayregistersbeprogramedtovaluesotherthanthevalidstatesdefinedinthedatasheet. 20 SubmitDocumentationFeedback Copyright©2011–2014,TexasInstrumentsIncorporated ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 www.ti.com SNAS489K–MARCH2011–REVISEDDECEMBER2014 8.2 Functional Block Diagram ut1 CLKin0* CLKin0 Divider Ref R Delay R1 Divider Po Status_LD CFCBLLCCKKLiiLKnnK11ini*/n0/F*in* C((L11K,, 22in,,1 44 D,, ooivrri d88e))r Mux N Delay ((11N tt1oo D116i6v,,i33d88e33r)) DPPehtLeaLcs1teo r C SYNC CDoenvticroel SSStttaaatttuuusss___HCCoLLlKKdiionnv01er Fin/FBCLKin Fin/Fin* FBMux CLKuWire CLKout0 Holdover DATAuWire PWire Control CLKout2 FB Port Registers CLKout4 LEuWire Mux Mode CLKout6 CCLLKKoouut1t80 Mux2 2X Pout2 Partially 2X R2 Divider C Integrated OSCout0 OOSSCCoouutt00 OSC Divider Mux (1 to 4,095) Phase Loop Filter Internal VCO OSCout0* __MMUUXX (2 to 8) Detector PLL2 FBMux MMoudx3e (1N to2 2D6iv2i,d1e4r3) OSCout1 OSCout1 OSCout1* _MUX VCO N2 Prescaler Clock Distribution Path Mode Mux VCO Divider (2 to 8) OSCin* (2 to 8) Mux1 OSCin Fin/Fin* CLKout0 CLKout6 Mux Mux CLKout0* Osc CLKout6* Clock Group 0 Divider Digital Mux1 Digital Divider Clock Group 3 (1 to 1045) Delay Delay (1 to 1045) CLKout1 Delay Delay CLKout7 Mux Mux CLKout1* Clock Buffer 1 CLKout7* CLKout2 CLKout8 Mux Mux CLKout2* Osc CLKout8* Clock Group 1 Divider Digital Mux2 Digital Divider Clock Group 4 (1 to 1045) Delay Delay (1 to 1045) CLKout3 Delay Delay CLKout9 Mux Mux CLKout3* Clock Buffer 3 CLKout9* CLKout4 CLKout10 Mux Mux CLKout4* CLKout10* Divider Digital Digital Divider Clock Group 2 Clock Group 5 (1 to 1045) Delay Delay (1 to 1045) CLKout5 Delay Delay CLKout11 Mux Mux CLKout5* Clock Buffer 2 Clock Buffer 1 CLKout11* Copyright©2011–2014,TexasInstrumentsIncorporated SubmitDocumentationFeedback 21 ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 SNAS489K–MARCH2011–REVISEDDECEMBER2014 www.ti.com 8.3 Feature Description 8.3.1 SerialMICROWIRETimingDiagram For timing specifications, see Timing Requirements. Register programming information on the DATAuWire pin is clocked into a shift register on each rising edge of the CLKuWire signal. On the rising edge of the LEuWire signal, the register is sent from the shift register to the register addressed. A slew rate of at least 30 V/µs is recommended for these signals. After programming is complete the CLKuWire, DATAuWire, and LEuWire signals should be returned to a low state. If the CLKuWire or DATAuWire lines are toggled while the VCO is in lock, as is sometimes the case when these lines are shared with other parts, the phase noise may be degraded duringthisprogramming. MSB LSB DATAuWire D26 D25 D24 D23 D22 D0 A4 A1 A0 CLKuWire tCES tECS tDCS tCDH tCWH tCWL tECS LEuWire tEWH Figure6. MICROWIREInputTimingDiagram 8.3.2 AdvancedMICROWIRETimingDiagrams 8.3.2.1 ThreeExtraClocksorDoubleProgram Fortimingspecifications,seeTimingRequirements.Figure7showsthetimingfortheprogrammingsequencefor loading CLKoutX_Y_DIV > 25 or CLKoutX_Y_DDLY > 12 as described in Special Programming Case for R0 to R5forCLKoutX_Y_DIVandCLKoutX_Y_DDLY. MSB LSB DATAuWire D26 A0 CLKuWire tECS tCES tCWL tCWH LEuWire tEWH Figure7. MICROWIRETimingDiagram:ExtraCLKuWirePulsesforR0toR5 22 SubmitDocumentationFeedback Copyright©2011–2014,TexasInstrumentsIncorporated ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 www.ti.com SNAS489K–MARCH2011–REVISEDDECEMBER2014 Feature Description (continued) 8.3.2.2 ThreeExtraClockswithLEuWireHigh For timing specifications, see Timing Requirements. Figure 8 shows the timing for the programming sequence which allows SYNC_EN_AUTO = 1 when loading CLKoutX_Y_DIV > 25 or CLKoutX_Y_DDLY > 12. When SYNC_EN_AUTO = 1, a SYNC event is automatically generated on the falling edge of LEuWire. See Special ProgrammingCaseforR0toR5forCLKoutX_Y_DIVandCLKoutX_Y_DDLY. MSB LSB DATAuWire D26 A0 CLKuWire tCES tECS tCES LEuWire Figure8. MICROWIRETimingDiagram:ExtraCLKuWirePulsesforR0toR5withLEuWireAsserted 8.3.2.3 Readback For timing specifications, see Timing Requirements. See Readback for more information on performing a readbackoperation.Figure9 showstimingforLEuWireforbothREADBACK_LE=1and0. The rising edges of CLKuWire during MICROWIRE readback continue to clock data on DATAuWire into the device during readback. If after the readback, LEuWire transitions from low to high, this data will be latched to the decoded register. The decoded register address consists of the last 5 bits clocked on DATAuWire as shown inFigure9. MSB LSB DATAuWire D26 A0 CLKuWire tECS tCR LEuWire tCWL tCR tCWH READBACK_LE = 0 tCES tEWH tECS LEuWire READBACK_LE = 1 Readback Pin RD26 RD25 RD24 RD23 RD0 Register Write Register Read Figure9. MICROWIREReadbackTimingDiagram 8.3.3 Inputs/Outputs 8.3.3.1 PLL1ReferenceInputs(CLKin0andCLKin1) The reference clock inputs for PLL1 may be selected from either CLKin0 or CLKin1. The user has the capability to manually select one of the inputs or to configure an automatic switching mode of operation. See Input Clock Switchingformoreinfo. Copyright©2011–2014,TexasInstrumentsIncorporated SubmitDocumentationFeedback 23 ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 SNAS489K–MARCH2011–REVISEDDECEMBER2014 www.ti.com Feature Description (continued) CLKin0 and CLKin1 have dividers which allow the device to switch between reference inputs of different frequencies automatically without needing to reprogram the PLL1 R divider. The CLKin pre-divider values are 1, 2,4,and8. CLKin1 input can alternatively be used for external feedback in 0-delay mode (FBCLKin) or for an external VCO inputport(Fin). 8.3.3.2 PLL2OSCin/OSCin*Port The feedback from the external oscillator being locked with PLL1 drives the OSCin/OSCin* pins. Internally this signalisroutedtothePLL1NDividerandtothereferenceinputforPLL2. This input may be driven with either a single-ended or differential signal and must be AC coupled. If operated in singleendedmode,theunusedinputmustbeconnectedtoGNDwitha0.1 µFcapacitor. 8.3.3.3 CrystalOscillator The internal circuitry of the OSCin port also supports the optional implementation of a crystal based oscillator circuit. A crystal, a varactor diode, and a small number of other external components may be used to implement theoscillator.TheinternaloscillatorcircuitisenabledbysettingtheEN_PLL2_XTALbit.SeeEN_PLL2_XTAL. 8.3.4 InputClockSwitching Manual, pin select, and automatic are three different kinds clock input switching modes can be set with the CLKin_SELECT_MODEregister. Below is information about how the active input clock is selected and what causes a switching event in the variousclockinputselectionmodes. 8.3.4.1 InputClockSwitching-ManualMode When CLKin_SELECT_MODE is 0 or 1 then CLKin0 or CLKin1 respectively is always selected as the active input clock. Manual mode will also override the EN_CLKinX bits such that the CLKinX buffer will operate even if CLKinXisdisabledwithEN_CLKinX=0. • Entering Holdover: If holdover mode is enabled, then holdover mode is entered if Digital lock detect of PLL1 goeslowandDISABLE_DLD1_DET=0. • ExitingHoldover:Theactiveclockforautomaticexitofholdovermodeisthemanuallyselectedclockinput. 8.3.4.2 InputClockSwitching-PinSelectMode When CLKin_SELECT_MODE is 3, the pins Status_CLKin0 and Status_CLKin1 select which clock input is active. • Clock Switch Event: Pins: Changing the state of Status_CLKin0 or Status_CLKin1 pins causes an input clockswitchevent. • Clock Switch Event: PLL1 DLD: To prevent PLL1 DLD high to low transition from causing a input clock switch event and causing the device to enter holdover mode, disable the PLL1 DLD detect by setting DISABLE_DLD1_DET=1.ThisisthepreferredbehaviorforPinSelectMode. • ConfiguringPinSelectMode: – The Status_CLKin0_TYPE must be programmed to an input value for the Status_CLKin0 pin to function asaninputforpinselectmode. – The Status_CLKin1_TYPE must be programmed to an input value for the Status_CLKin1 pin to function asaninputforpinselectmode. – IftheStatus_CLKinX_TYPEissetasoutput,theinputvalueisconsidered0. – The polarity of Status_CLKin1 and Status_CLKin0 input pins cannot be inverted with the CLKin_SEL_INV bit. – Table1 defineswhichinputclockisactivedependingonStatus_CLKin0andStatus_CLKin1state. 24 SubmitDocumentationFeedback Copyright©2011–2014,TexasInstrumentsIncorporated ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 www.ti.com SNAS489K–MARCH2011–REVISEDDECEMBER2014 Feature Description (continued) Table1.ActiveClockInput-PinSelectMode STATUS_CLKin1 STATUS_CLKin0 ACTIVECLOCK 0 0 CLKin0 0 1 CLKin1 1 0 Reserved 1 1 Holdover The pin select mode will override the EN_CLKinX bits such that the CLKinX buffer will operate even if CLKinX is disabled with EN_CLKinX = 0. To switch as fast as possible, keep the clock input buffers enabled (EN_CLKinX = 1)thatcouldbeswitchedto. 8.3.4.2.1 PinSelectModeandHost When in the pin select mode, the host can monitor conditions of the clocking system which could cause the host to switch the active clock input. The LMK0480x device can also provide indicators on the Status_LD and Status_HOLDOVER like "DAC Rail," "PLL1 DLD", "PLL1 and PLL2 DLD" which the host can use in determining whichclockinputtouseasactiveclockinput. 8.3.4.2.2 SwitchEventwithoutHoldover When an input clock switch event is triggered and holdover mode is disabled, the active clock input immediately switches to the selected clock. When PLL1 is designed with a narrow loop bandwidth, the switching transient is minimized. 8.3.4.2.3 SwitchEventwithHoldover Whenaninputclockswitcheventistriggeredandholdovermodeisenabled,thedevicewillenterholdovermode and remain in holdover until a holdover exit condition is met as described in Holdover Mode. Then the device will completethereferenceswitchtothepinselectedclockinput. 8.3.4.3 InputClockSwitching-AutomaticMode When CLKin_SELECT_MODE is 4, the active clock is selected in priority order of enabled clock inputs starting uponaninputclockswitchevent.ThepriorityorderoftheclocksisCLKin0 →CLKin1 →CLKin0,andsoforth. Foraclockinputtobeeligibletobeswitchedthrough,itmustbeenabledusingEN_CLKinX. 8.3.4.3.1 StartingActiveClock Upon programming this mode, the currently active clock remains active if PLL1 lock detect is high. To ensure a particular clock input is the active clock when starting this mode, program CLKin_SELECT_MODE to the manual mode which selects the desired clock input (CLKin0 or 1). Wait for PLL1 to lock PLL1_DLD = 1, then select this modewithCLKin_SELECT_MODE=4. 8.3.4.3.2 ClockSwitchEvent:PLL1DLD A loss of lock as indicated by PLL1’s DLD signal (PLL1_DLD = 0) will cause an input clock switch event if DISABLE_DLD1_DET=0.PLL1DLDmustgohigh(PLL1_DLD=1)inbetweeninputclockswitchingevents. 8.3.4.3.3 ClockSwitchEvent:PLL1V Rail tune If Vtune_RAIL_DET_EN is set and the PLL1 Vtune voltage crosses the DAC high or low threshold, holdover modewillbeentered.SincePLL1_DLD=0inholdoveraclockinputswitchingeventwilloccur. 8.3.4.3.4 ClockSwitchEventwithHoldover Clock switch event with holdover enabled is recommended in this input clock switching mode. When an input clock switch event occurs, holdover mode is entered and the active clock is set to the clock input defined by the Status_CLKinX pins. When the new active clock meets the holdover exit conditions, holdover is exited and the active clock will continue to be used as a reference until another input clock switch event. PLL1 DLD must go highinbetweeninputclockswitchingevents. Copyright©2011–2014,TexasInstrumentsIncorporated SubmitDocumentationFeedback 25 ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 SNAS489K–MARCH2011–REVISEDDECEMBER2014 www.ti.com 8.3.4.4 InputClockSwitching-AutomaticModewithPinSelect When CLKin_SELECT_MODE is 6, the active clock is selected using the Status_CLKinX pins upon an input clockswitcheventaccordingtoTable2. 8.3.4.4.1 StartingActiveClock Upon programming this mode, the currently active clock remains active if PLL1 lock detect is high. To ensure a particular clock input is the active clock when starting this mode, program CLKin_SELECT_MODE to the manual mode which selects the desired clock input (CLKin0 or 1). Wait for PLL1 to lock PLL1_DLD = 1, then select this modewithCLKin_SELECT_MODE=6. 8.3.4.4.2 ClockSwitchEvent:PLL1DLD AninputclockswitcheventisgeneratedbyalossoflockasindicatedbyPLL1'sDLDsignal(PLL1DLD=0). 8.3.4.4.3 ClockSwitchEvent:PLL1V Rail tune If Vtune_RAIL_DET_EN is set and the PLL1 Vtune voltage crosses the DAC threshold, holdover mode will be entered.SincePLL1_DLD=0inholdover,aclockinputswitchingeventwilloccur. 8.3.4.4.4 ClockSwitchEventwithHoldover Clock switch event with holdover enabled is recommended in this input clock switching mode. When an input clock switch event occurs, holdover mode is entered and the active clock is set to the clock input defined by the Status_CLKinX pins. When the new active clock meets the holdover exit conditions, holdover is exited and the active clock will continue to be used as a reference until another input clock switch event. PLL1 DLD must go highinbetweeninputclockswitchingevents." Table2.ActiveClockInput-AutoPinMode STATUS_CLKin1(1) STATUS_CLKin0 ACTIVECLOCK X 1 CLKin0 1 0 CLKin1 0 0 Reserved (1) ThepolarityofStatus_CLKin1andStatus_CLKin0inputpinscanbeinvertedwiththeCLKin_SEL_INVbit. 8.3.5 HoldoverMode Holdover mode causes PLL2 to stay locked on frequency with minimal frequency drift when an input clock reference to PLL1 becomes invalid. While in holdover mode, the PLL1 charge pump is TRI-STATED and a fixed tuningvoltageissetonCPout1tooperatePLL1inopenloop. 8.3.5.1 EnableHoldover Program HOLDOVER_MODE to enable holdover mode. Holdover mode can be manually enabled by programmingtheFORCE_HOLDOVERbit. Theholdovermodecanbesettooperatein2differentsub-modes. • FixedCPout1(EN_TRACK=0or1,EN_MAN_DAC=1). • TrackedCPout1(EN_TRACK=1,EN_MAN_DAC=0). – NotvalidwhenEN_VTUNE_RAIL_DET=1. Updates to the DAC value for the Tracked CPout1 sub-mode occurs at the rate of the PLL1 phase detector frequencydividedbyDAC_CLK_DIV.TheseupdatesoccuranytimeEN_TRACK=1. TheDACupdaterateshouldbeprogrammedfor<=100kHztoensureDACholdoveraccuracy. WhentrackingisenabledthecurrentvoltageofDACcanbereadback,seeDAC_CNT. 26 SubmitDocumentationFeedback Copyright©2011–2014,TexasInstrumentsIncorporated ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808

LMK04803,LMK04805,LMK04806,LMK04808 www.ti.com SNAS489K–MARCH2011–REVISEDDECEMBER2014 8.3.5.2 EnteringHoldover TheholdovermodeisenteredasdescribedinInputClockSwitching.Typicallythisisbecause: • FORCE_HOLDOVERbitisset. • PLL1loseslockaccordingtoPLL1_DLD,and – HOLDOVER_MODE=2 – DISABLE_DLD1_DET=0 • CPout1voltagecrossesDAChighorlowthreshold,and – HOLDOVER_MODE=2 – EN_VTUNE_RAIL_DET=1 – EN_TRACK=1 – DAC_HIGH_TRIP=UserValue – DAC_LOW_TRIP=UserValue – EN_MAN_DAC=1 – MAN_DAC=UserValue 8.3.5.3 DuringHoldover PLL1isruninopenloopmode. • PLL1chargepumpissettoTRI-STATE. • PLL1DLDwillbeunasserted. • TheHOLDOVERstatusisasserted • DuringholdoverIfPLL2waslockedpriortoentryofholdovermode,PLL2DLDwillcontinuetobeasserted. • CPout1voltagewillbesetto: – avoltagesetintheMAN_DACregister(fixedCPout1). – avoltagedeterminedtobethelastvalidCPout1voltage(trackedCPout1). • PLL1DLDwillattempttolockwiththeactiveclockinput. The HOLDOVER status signal can be monitored on the Status_HOLDOVER or Status_LD pin by programming theHOLDOVER_MUXorLD_MUXregisterto"HoldoverStatus." 8.3.5.4 ExitingHoldover Holdovermodecanbeexitedinoneoftwoways. • Manually,byprogrammingthedevicefromthehost. • Automatically, By a clock operating within a specified ppm of the current PLL1 frequency on the active clock input.SeeInputClockSwitchingformoredetailonwhichclockinputisactive. To exit holdover by programming, set HOLDOVER_MODE = Disabled. HOLDOVER_MODE can then be re- enabled by programming HOLDOVER_MODE = Enabled. Care should be taken to ensure that the active clock upon exiting holdover is as expected, otherwise the CLKin_SELECT_MODE register may need to be re- programmed. Copyright©2011–2014,TexasInstrumentsIncorporated SubmitDocumentationFeedback 27 ProductFolderLinks:LMK04803 LMK04805 LMK04806 LMK04808