- 型号: HVR2500001004JR500

- 制造商: Vishay

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

HVR2500001004JR500产品简介:

ICGOO电子元器件商城为您提供HVR2500001004JR500由Vishay设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 HVR2500001004JR500价格参考¥0.29-¥0.29。VishayHVR2500001004JR500封装/规格:通孔电阻器, 1 MOhms ±5% 0.25W,1/4W 轴向 通孔电阻器 阻燃涂层,高电压,脉冲耐受,安全 金属薄膜。您可以下载HVR2500001004JR500参考资料、Datasheet数据手册功能说明书,资料中有HVR2500001004JR500 详细功能的应用电路图电压和使用方法及教程。

Vishay BC Components的HVR2500001004JR500是一款通孔高电压电阻器,属于HVR系列。该型号的应用场景主要集中在需要承受高电压、高稳定性和高可靠性的电路设计中。以下是其主要应用场景: 1. 电源管理 - 用于高压电源电路中的分压网络。 - 在开关电源(SMPS)和线性电源中作为启动电阻或限流电阻。 2. 浪涌保护 - 在电力电子设备中,用于吸收瞬时浪涌电流或电压。 - 配合TVS二极管或压敏电阻使用,提供额外的保护功能。 3. 高压测试设备 - 应用于高压测试仪器中,如绝缘测试仪、耐压测试仪等,用作分压或负载电阻。 - 提供精确的电压测量和监控功能。 4. 工业自动化 - 在工业控制设备中,用于电机驱动器、变频器或伺服控制器的启动和制动电路。 - 适用于需要高电压隔离的信号调理电路。 5. 医疗设备 - 在医疗成像设备(如X射线机、CT扫描仪)中,用于高压发生器电路。 - 确保设备在高电压环境下稳定运行。 6. 通信设备 - 在电信基站或光纤通信设备中,用于高压保护和信号调节。 - 适用于需要长期稳定工作的通信模块。 7. 汽车电子 - 在电动汽车(EV)或混合动力汽车(HEV)的高压系统中,用于电池管理系统(BMS)或逆变器电路。 - 提供可靠的高压监测和保护功能。 8. 照明系统 - 在高压气体放电灯(如HID灯)或LED驱动电路中,用于启动和限流。 特性优势: - 高耐压:额定电压高达2500V,适合高压环境。 - 高精度:阻值精度为±5%,满足精密应用需求。 - 高稳定性:温度系数低,能够在宽温范围内保持性能稳定。 - 耐用性强:采用通孔回流焊工艺,适合恶劣工作条件。 总之,HVR2500001004JR500凭借其高电压承受能力、高稳定性和可靠性,广泛应用于电力、工业、医疗、通信和汽车等领域,特别是在需要处理高压信号或提供保护功能的场合表现优异。

| 参数 | 数值 |

| 产品目录 | |

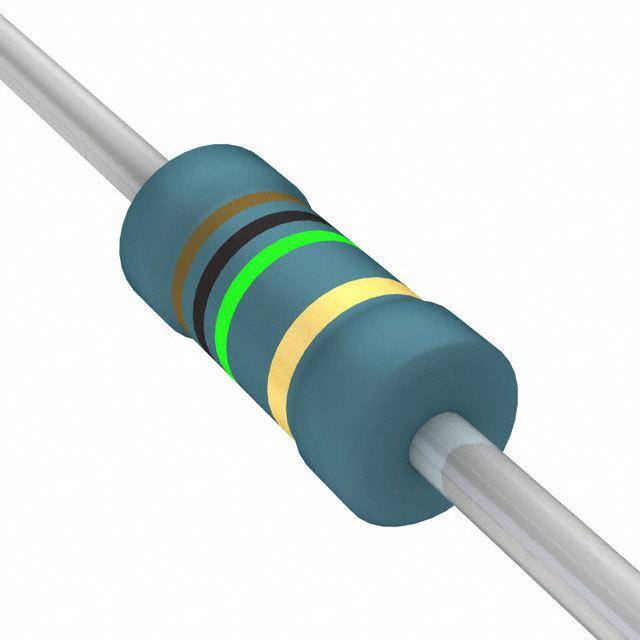

| 描述 | RES 1M OHM 1/4W 5% AXIAL |

| 产品分类 | |

| 品牌 | Vishay BC Components |

| 数据手册 | |

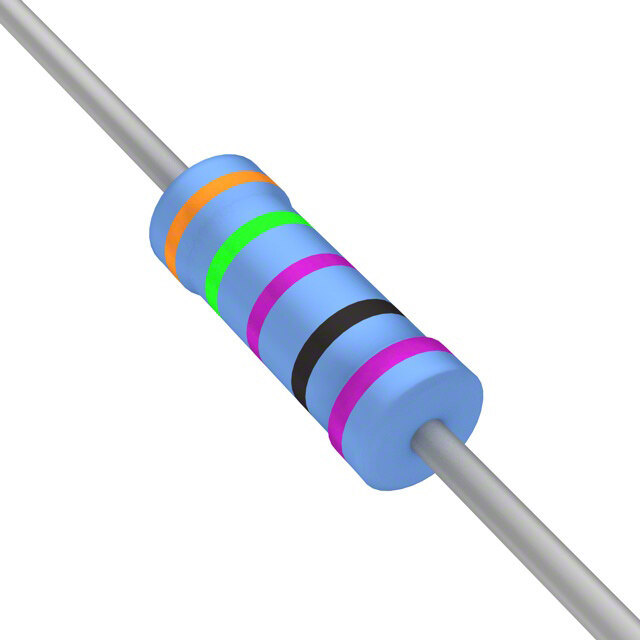

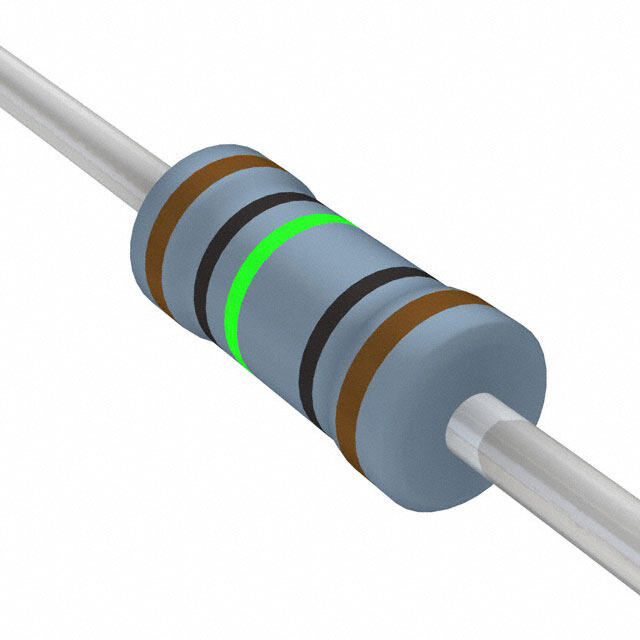

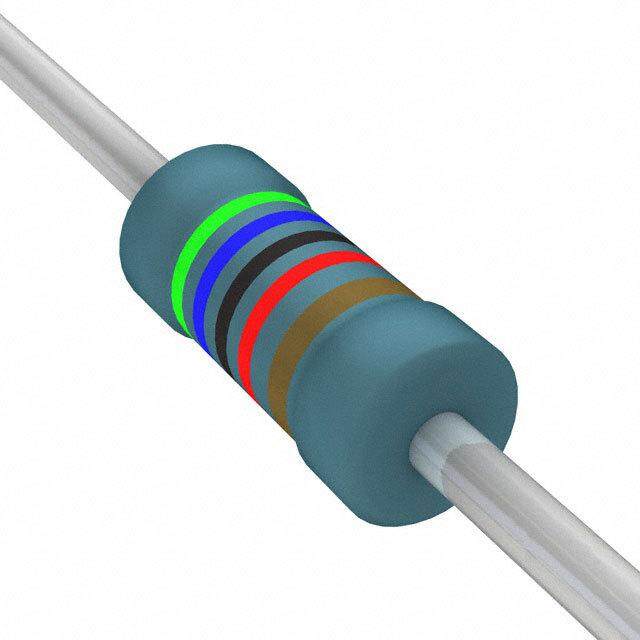

| 产品图片 |

|

| 产品型号 | HVR2500001004JR500 |

| rohs | 无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | HVR25 |

| 产品目录绘图 |

|

| 供应商器件封装 | 轴向 |

| 其它名称 | 2306 241 23105 |

| 功率(W) | 0.25W,1/4W |

| 包装 | 带卷 (TR) |

| 大小/尺寸 | 0.098" 直径 x 0.256" 长(2.50mm x 6.50mm) |

| 容差 | ±5% |

| 封装/外壳 | 轴向 |

| 成分 | 金属薄膜 |

| 标准包装 | 5,000 |

| 温度系数 | ±250ppm/°C |

| 特性 | 阻燃涂层,脉冲耐受 |

| 电阻(Ω) | 1M |

| 端子数 | 2 |

| 高度 | - |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

HVR25, HVR37 www.vishay.com Vishay BCcomponents High Ohmic (up to 10 M)/High Voltage (up to 3.5 kV) Metal Film Leaded Resistors FEATURES • Technology: metal film • High pulse loading (up to 10 kV) capability • Small size (0207/0411) • Compatible with lead (Pb)-free and lead containing soldering processes • Material categorization: for definitions of compliance please see www.vishay.com/doc?99912 APPLICATIONS • Power supplies • Electronic ballast DESIGN SUPPORT TOOLS click logo to get started • White goods • Television Models Available A homogenous film of metal alloy is deposited on a high grade ceramic body. After a helical groove has been cut in the resistive layer, tinned electrolytic copper wires are welded to the end-caps. The resistors are coated with a blue, non-flammable lacquer, which provides electrical, mechanical, and climatic protection. TECHNICAL SPECIFICATIONS DESCRIPTION HVR25 HVR37 Resistance range 100 k to 10 M 100 k to 10 M Resistance tolerance ± 5 % ± 1 % ± 5 % ± 1 % E-series E24 series E24/E96 series E24 series E24/E96 series Temperature coefficient 200 ppm/K Climatic category (LCT/UCT/days) 55/155/56 Rated dissipation, P 0.25 W 0.5 W 70 Maximum permissible voltage U max. DC 1600 V 3500 V RMS 1150 V 2500 V Basic specification IEC 60115-1 Stability after: Load (1000 h, P70) ± (5 % R + 0.1 ± (1.5 % R + 0.1 ± (5 % R + 0.1 ± (1.5 % R + 0.1 Long term damp heat test (56 days) ± (1.5 % R + 0.1 ± (1.5 % R + 0.1 ± (1.5 % R + 0.1 ± (1.5 % R + 0.1 Soldering (10 s, 260 °C) ± (1 % R + 0.1 ± (1 % R + 0.1 ± (1 % R + 0.1 ± (1 % R + 0.1 Revision: 11-Jul-2018 1 Document Number: 30260 For technical questions, contact: filmresistorsleaded@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

HVR25, HVR37 www.vishay.com Vishay BCcomponents PART NUMBER AND PRODUCT DESCRIPTION (1) Part Number: HVR2500001503JA100 H V R 2 5 0 0 0 0 1 5 0 3 J A 1 0 0 MODEL/SIZE VARIANT TCR/MATERIAL VALUE TOLERANCE PACKAGING (2) SPECIAL HVR2500 0 = neutral 0 = standard 3 digit value F = 1 % A1 Up to 2 digits HVR3700 1 digit multiplier J = 5 % A5 00 = standard MULTIPLIER R5 3 = *103 N4 4 = *104 5 = *105 Product Description: HVR25 5 % A1 150K HVR25 5 % A1 150K Model TOLERANCE PACKAGING (2) RESISTANCE VALUE HVR25 ± 1 % A1 150K = 150 k HVR37 ± 5 % A5 4M64 = 4.64 M R5 N4 Notes (1) The PART NUMBER is shown to facilitate the introduction of the unified part numbering system (2) Please refer to table PACKAGING, see next page PACKAGING AMMO PACK REEL MODEL TAPING PIECES CODE PIECES CODE 5000 A5 5000 R5 Axial, 52 mm HVR25 1000 A1 Radial 4000 N4 HVR37 Axial, 52 mm 1000 A1 5000 R5 DIMENSIONS L1 Ø D Ø d L2 A DIMENSIONS - Resistor types, mass and relevant physical dimensions L L D Ø d A MASS TYPE 1max. 2 max. max. (mm) (mm) (mm) (mm) (mm) (mg) HVR25 6.5 7.5 2.5 0.58 0.05 52.5 1.5 220 HVR37 10 12 4 0.70 0.03 52.5 1.5 500 Revision: 11-Jul-2018 2 Document Number: 30260 For technical questions, contact: filmresistorsleaded@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

HVR25, HVR37 www.vishay.com Vishay BCcomponents PRODUCTS WITH RADIAL LEADS (HVR25) P2 P H 1 H H0 L L1 W 0 W F P0 P1 D0 DIMENSIONS - Radial taping SYMBOL PARAMETER VALUE TOLERANCE UNIT P Pitch of components 12.7 1.0 mm P0 Feed-hole pitch 12.7 0.2 mm P1 Feed-hole centre to lead at topside at the tape 3.85 0.5 mm P2 Feed-hole center to body center 6.35 1.0 mm F Lead-to-lead distance 4.8 0.7/-0 mm W Tape width 18.0 0.5 mm W Minimum hold down tape width 5.5 - mm 0 H1 Component height 29 Max. mm H Lead wire clinch height 16.5 0.5 mm 0 H Height of component from tape center 19.5 1 mm D0 Feed-hole diameter 4.0 0.2 mm L Maximum length of snipped lead 11.0 - mm L Minimum lead wire (tape portion) shortest lead 2.5 - mm 1 Note • Please refer document number 28721 “Packaging” for more detail MARKING The nominal resistance and tolerance are marked on the resistor using four or five colored bands in accordance with IEC 60062, marking codes for resistors and capacitors. Standard values of nominal resistance are taken from the E24 and E24/E96 series for resistors with a tolerance of 5 % or 1 % respectively. The values of the E24/E96 series are in accordance with IEC 60063. Yellow and grey are used instead of gold and silver because metal particles in the lacquer could affect high-voltage properties. Revision: 11-Jul-2018 3 Document Number: 30260 For technical questions, contact: filmresistorsleaded@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

HVR25, HVR37 www.vishay.com Vishay BCcomponents FUNCTIONAL PERFORMANCE P n o pati100 si s Di er w o P 0 - 55 0 70 155 Ambient temperature ϑ amb Derating - Standard Operation Maximum dissipation (P ) in percentage of rated power as a function of ambient temperature (T ) max. amb PULSE LOADING CAPABILITY Note • Maximum allowed peak pulse voltage in accordance with IEC 60065, 14.1.a; 50 discharges from a 1 nF capacitor charged to U ; max. 12 discharges/min 12 11 10 9 8 V) k (ax. 7 m Û 6 5 HVR25 R = (4.0 % R + 0.1 ) 4 10-2 10-1 100 101 102 R(MΩ) 12 11 10 9 8 V) k (ax. 7 m Û 6 HVR37 5 For 5 % tolerance R = (4.0 % R + 0.1 ) For 1 % tolerance R = (2.0 % R + 0.1 ) 4 10-2 10-1 100 101 102 R(MΩ) Revision: 11-Jul-2018 4 Document Number: 30260 For technical questions, contact: filmresistorsleaded@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

HVR25, HVR37 www.vishay.com Vishay BCcomponents TESTS AND REQUIREMENTS Essentially all tests are carried out in accordance with IEC 60115-1, category 55/155/56 (rated temperature range -55 °C to +155 °C; damp heat, long term, 56 days) and along the lines of IEC 60068-2-xx test method. The tests are carried out under standard atmospheric conditions according to IEC 60068-1, 5.3 unless otherwise specified. In some instances deviations from IEC recommendations were necessary for our method of specifying. PERFORMANCE IEC REQUIREMENTS IEC 60068-2-xx PERMISSIBLE CHANGE (R) 60115-1 TEST PROCEDURE TEST CLAUSE METHOD HVR25 HVR37 Temperature Between 4.8 - 200 ppm/K coefficient -55 °C and +155 °C 1000 h; loaded with P70 or Umax.; 1.5 h on; 0.5 h off 4.25.1 - Endurance at 70 °C for 5 % tolerance (5 % R + 0.1 ) for 1 % tolerance (1.5 % R + 0.1 ) 56 days; 40 °C; 90 % to 95 % RH Damp heat, loaded with 0.01 P 4.24 78 (Cab) 70 steady state for 5 % tolerance (5 % R + 0.1 ) for 1 % tolerance (1.5 % R + 0.1 ) 4.23 Climatic sequence 4.23.2 2 (Ba) Dry heat 16 h, 155 °C Damp heat, 24 h; 25 °C to 55 °C 4.23.3 30 (Db) cyclic 90 % to 100 % RH; 1 cycle (1.5 % R + 0.1 ) 4.23.4 1 (Aa) Cold 2 h, -55 °C Damp heat, 5 days; 25 °C to 55 °C 4.23.6 30 (Db) (accelerated) 90 to 100 % RH remaining cycles 30 min at LCT; 30 min at UCT; Rapid change of No visual damage 4.19 14 (Na) LCT = -55 °C; temperature (1 % R + 0.1 ) UCT = 155 °C; 5 cycles Room temperature; dissipation 6.25 x P 70 (voltage not more than 2 x limiting voltage, 4.13 - Short time overload 10 000 V ); max. 10 cycles 5 s on and 45 s off for 5 % tolerance (2 % R + 0.1 ) for 1 % tolerance (1 % R + 0.1 ) 4.12 - Noise IEC 60195 Max. 5 μV/V Max. 2.5 μV/V Robustness of 4.16 terminations: 4.16.2 21 (Ua1) Tensile all samples Load 10 N; 10 s No damage 4.16.3 21 (Ub) Bending half number Load 5 N; 4 x 90° (1 % R + 0.1 ) of samples Torsion other half of 4.16.4 21 (Uc) 3 x 360° in opposite direction samples Frequency 10 Hz to 500 Hz; displacement 4.22 6 (Fc) Vibration 1.5 mm or acceleration 10 g; (1.0 % R+ 0.1 ) 3 directions; total 6 h (3 x 2 h) Revision: 11-Jul-2018 5 Document Number: 30260 For technical questions, contact: filmresistorsleaded@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

HVR25, HVR37 www.vishay.com Vishay BCcomponents PERFORMANCE IEC REQUIREMENTS IEC 60068-2-xx PERMISSIBLE CHANGE (R) 60115-1 TEST PROCEDURE TEST CLAUSE METHOD HVR25 HVR37 2 s; 235 °C: Solder bath method; Good tinning Solderability SnPb40 4.17 20 (Ta) ( 95 % covered); (after aging) 3 s; 245 °C: Solder bath method; no visible damage SnAg3Cu0.5 Resistance to Thermal shock: 10 s; 260 °C; 4.18 20 (Tb) (1 % R + 0.1 ) soldering heat 3 mm from body Component solvent 4.29 45 (XA) Isopropyl alcohol No visible damage resistance U = 500 V DC 4.6.11 - Insulation resistance during 1 min, Rins min. 104 M V-block method U = 700 V Voltage proof on RMS 4.7 - during 1 min, No flashover or breakdown insulation V-block method 12NC INFORMATION FOR HISTORICAL CODING REFERENCE ONLY • The resistors have a 12 digit ordering code starting with Last Digit of 12NC Indicating Resistance Decade 2306 • The next 4 or 5 digits indicate the resistor type and RESISTANCE RESISTANCE LAST DIGIT DECADE (5 %) DECADE (1 %) packaging • For 5 % tolerance the last 3 digits indicate the resistance 100 k to 910 k 100 k to 976 k 4 value: 1 M to 9.1 M 1 M to 9.76 M 5 - The first 2 digits indicate the resistance value - The last digit indicates the resistance decade in = 10 M = 10 M 6 accordance with table 12NC Example • For 1 % tolerance the last 4 digits indicate the resistance HVR25, 150 k, 5 %, ammopack 1000 pieces is value: 2306 241 13154 - The first 3 digits indicate the resistance value - The last digit indicates the resistance decade in accordance with table 12NC - resistor type and packaging 2306 ... ..... DESCRIPTION BANDOLIER BANDOLIER IN AMMOPACK ON REEL RADIAL TAPED TYPE TAPE WIDTH TOLERANCE 1000 UNITS 5000 UNITS 5000 UNITS 4000 UNITS 5 % 241 36... 241 13... 241 53... 241 23.... HVR25 52.5 1 % 241 0.... 241 8.... 241 7.... 241 6.... 5 % - 242 13... - 242 23... HVR37 52.5 1 % - 242 8.... - 242 6.... Revision: 11-Jul-2018 6 Document Number: 30260 For technical questions, contact: filmresistorsleaded@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Legal Disclaimer Notice www.vishay.com Vishay Disclaimer ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE. Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively, “Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other disclosure relating to any product. Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special, consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular purpose, non-infringement and merchantability. Statements regarding the suitability of products for certain types of applications are based on Vishay’s knowledge of typical requirements that are often placed on Vishay products in generic applications. Such statements are not binding statements about the suitability of products for a particular application. It is the customer’s responsibility to validate that a particular product with the properties described in the product specification is suitable for use in a particular application. Parameters provided in datasheets and / or specifications may vary in different applications and performance may vary over time. All operating parameters, including typical parameters, must be validated for each customer application by the customer’s technical experts. Product specifications do not expand or otherwise modify Vishay’s terms and conditions of purchase, including but not limited to the warranty expressed therein. Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining applications or for any other application in which the failure of the Vishay product could result in personal injury or death. Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk. Please contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for such applications. No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document or by any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners. © 2017 VISHAY INTERTECHNOLOGY, INC. ALL RIGHTS RESERVED Revision: 08-Feb-17 1 Document Number: 91000

Datasheet下载

Datasheet下载