- 型号: BFB0724H-T500

- 制造商: DELTA PRODUCTS CORPORATION

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

BFB0724H-T500产品简介:

ICGOO电子元器件商城为您提供BFB0724H-T500由DELTA PRODUCTS CORPORATION设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 BFB0724H-T500价格参考。DELTA PRODUCTS CORPORATIONBFB0724H-T500封装/规格:DC 风扇, 。您可以下载BFB0724H-T500参考资料、Datasheet数据手册功能说明书,资料中有BFB0724H-T500 详细功能的应用电路图电压和使用方法及教程。

Delta Electronics(台达电子)的DC风扇型号BFB0724H-T500是一款高效、耐用的直流无刷风扇,广泛应用于需要精确温控和高可靠性的场景。以下是其主要应用场景: 1. 通信设备 - 该风扇适用于通信基站、路由器、交换机等设备的散热系统。由于通信设备通常运行在高温或恶劣环境中,BFB0724H-T500的高可靠性与低噪音特性能够确保设备长时间稳定运行。 2. 工业控制 - 在工业自动化领域,如PLC控制器、变频器、伺服驱动器等,该风扇可为内部元件提供高效的散热解决方案,延长设备寿命并提高性能。 3. 电源供应器 - BFB0724H-T500常用于开关电源(SMPS)、不间断电源(UPS)等设备中,帮助快速排出热量,确保电源模块在高负载下正常工作。 4. 服务器与数据中心 - 数据中心内的服务器和存储设备对散热要求极高,这款风扇以其高风量和低功耗特点,成为服务器机箱或机柜散热的理想选择。 5. 医疗设备 - 医疗成像设备(如CT、MRI)、监护仪等精密仪器需要稳定的温度环境。该风扇具有良好的EMI屏蔽性能,适合在敏感的医疗环境中使用。 6. 消费电子产品 - 在高端投影仪、游戏主机或其他高性能消费电子产品中,BFB0724H-T500可用于冷却核心组件,保证设备安静且高效地运行。 7. 新能源领域 - 在太阳能逆变器、电动汽车充电桩等新能源相关设备中,该风扇可有效降低关键部件温度,提升整体效率和安全性。 特点总结: - 尺寸:紧凑设计,易于集成到各种设备中。 - 电压:支持直流供电,适配多种电源系统。 - 静音:运行时噪音低,适合对声学环境有要求的应用。 - 长寿命:采用无刷电机技术,使用寿命长,维护成本低。 总之,Delta Electronics的BFB0724H-T500凭借其卓越的性能和可靠性,成为众多行业设备散热方案的首选产品。

| 参数 | 数值 |

| 产品目录 | |

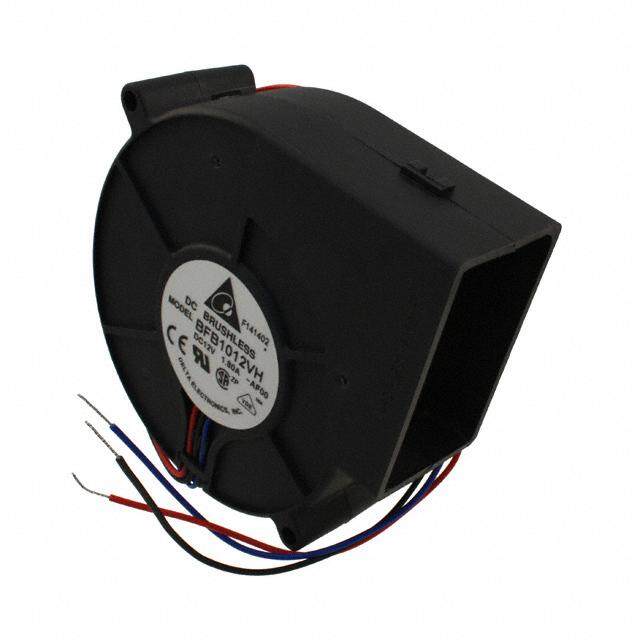

| 描述 | BLOWER 24VDC 75.7X75.7X30MM |

| 产品分类 | |

| 品牌 | Delta Electronics |

| 数据手册 | |

| 产品图片 | |

| 产品型号 | BFB0724H-T500 |

| rohs | 无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| RoHS指令信息 | |

| RPM | 2900 RPM |

| 产品系列 | BFB |

| 产品培训模块 | http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=23007http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=25946 |

| 侵入防护 | - |

| 其它名称 | 603-1476 |

| 其它有关文件 | http://www.delta.com.tw/product/cp/dcfans/download/pdf/general_info.pdf#page=6 |

| 功率(W) | 2.88W |

| 噪声 | 38 dB(A) |

| 大小/尺寸 | 方形 - 75.7mm 长 x 75.7mm 高 x 30mm 宽 |

| 工作温度 | 14 ~ 158°F (-10 ~ 70°C) |

| 材料–刀片 | 塑料 |

| 材料–框架 | 塑料 |

| 标准包装 | 84 |

| 气流 | 11.3 CFM (0.320m³/min) |

| 特性 | - |

| 电压-额定 | 24VDC |

| 电压范围 | 14 ~ 27.6VDC |

| 端接 | 2 引线 |

| 轴承类型 | 滚珠 |

| 重量 | 0.209 磅(94.8g) |

| 静压力 | 0.480 英寸水柱(119.6 Pa) |

| 预期寿命 | 40°C 时为 50000 小时 |

| 额定电流 | 0.120A |

| 风扇类型 | 鼓风机 |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

SPECIFICATION FOR APPROVAL =============================================== Customer Description DCFAN Part No. Rev. Delta Model No. BFB0724H-T500 Rev. 00 Sample Issue No. Sample Issue Date. 24-Nov-2006 PLEASE SEND ONE COPY OF THIS SPECIFICATION BACK AFTER YOU SIGNED APPROVAL FOR PRODUC- TION PRE-ARRANGEMENT. APPROVED BY : _____________________________ DATE : _____________________________ DELTA ELECTRONICS (THAILAND) PUBLIC COMPANY LIMITED. 111 MOO 9 WELLGROW INDUSTRIAL ESTATE BANGNA-TRAD ROAD, TAMBON BANGWUA, AMPHUR BANGPAKONG, CHACHOENGSAO 24180 THAILAND TEL. +66-(0)-38522455, FAX. +66-(0)-38522477 DEL-0776A4

None

None

None

None

None

None

Descriptions: 1. Delta will not guarantee the performance of the products if the application condition falls outside the parameters set forth in the specification. 2. A written request should be submitted to Delta prior to approval if deviation from this specification is required. 3. Please exercise caution when handling fans. Damage may be caused when pressure is applied to the impeller, if the fans are handled by the lead wires, or if the fans are hard-dropped to the production floor. 4. Except as pertains to some special designs, there is no guarantee that the products will be free from any such safety problems or failures as caused by the introduction of powder, droplets of water or encroachment of insect into the hub. 5. The above-mentioned conditions are representative of some unique examples and viewed as the first point of reference prior to all other information. 6. It is very important to establish the correct polarity before connecting the fan to the power source. Positive (+) and Negative (-). Damage may be caused to the fans if connection is with reverse polarity, as there is no foolproof method to protect against such error. 7. Delta fans are not suitable where any corrosive fluids are introduced to their environment. 8. Please ensure all fans are stored according to the storage temperature limits specified. Do not store fans in a high humidity environment. We highly recommend performance testing is conducted before shipping, if the fans have been stored over 6 months. 9. Not all fans are provided with the Lock Rotor Protection feature. If you impair the rotation of the impeller for the fans that do not have this function, the performance of those fans will lead to failure. 10. Please be cautious when mounting the fan. Incorrect mounting of fans may cause excess resonance, vibration and subsequent noise. 11. It is important to consider safety when testing the fans. A suitable fan guard should be fitted to the fan to guard against any potential for personal injury. 12. Except where specifically stated, all tests are carried out at relative (ambient) temperature and humidity conditions of 25oC, 65%. The test value is only for fan performance itself. 13. Be certain to connect an “over 4.7µF” capacitor to the fan externally when the application calls for using multiple fans in parallel, to avoid any unstable power.

Datasheet下载

Datasheet下载