ICGOO在线商城 > 集成电路(IC) > 时钟/计时 - 时钟发生器,PLL,频率合成器 > AD9522-0BCPZ

- 型号: AD9522-0BCPZ

- 制造商: Analog

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

AD9522-0BCPZ产品简介:

ICGOO电子元器件商城为您提供AD9522-0BCPZ由Analog设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 AD9522-0BCPZ价格参考¥144.92-¥144.92。AnalogAD9522-0BCPZ封装/规格:时钟/计时 - 时钟发生器,PLL,频率合成器, 。您可以下载AD9522-0BCPZ参考资料、Datasheet数据手册功能说明书,资料中有AD9522-0BCPZ 详细功能的应用电路图电压和使用方法及教程。

Analog Devices Inc.的AD9522-0BCPZ是一款高性能时钟发生器和锁相环(PLL)芯片,广泛应用于需要高精度和低抖动时钟信号的电子系统中。其主要应用场景包括: 1. 通信系统:用于无线基站、光纤通信设备和网络基础设施中,为高速数据转换器(如ADC/DAC)提供低相位噪声的参考时钟。 2. 测试与测量仪器:在示波器、频谱分析仪和信号发生器等设备中,提供稳定且精确的时钟源,确保测量精度。 3. 工业自动化与控制系统:为高精度传感器、数据采集系统和运动控制模块提供同步时钟信号。 4. 医疗成像设备:如MRI、CT扫描仪等,用于保证图像采集过程中各模块的精确同步。 5. 航空航天与国防:应用于雷达系统、导航设备和高频信号处理模块,满足对可靠性和性能的严苛要求。 该芯片支持多路输出时钟配置,具备灵活的频率合成能力,适合对时钟稳定性、抖动性能有高要求的场景。

| 参数 | 数值 |

| 产品目录 | 集成电路 (IC)半导体 |

| 描述 | IC CLOCK GEN 2.8GHZ VCO 64LFCSP时钟发生器及支持产品 12 LVDS/CMOS Output w/ Intg 2.8GHz VCO |

| DevelopmentKit | AD9522-0/PCBZ |

| 产品分类 | |

| 品牌 | Analog Devices |

| 产品手册 | |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 时钟和计时器IC,时钟发生器及支持产品,Analog Devices AD9522-0BCPZ- |

| 数据手册 | |

| 产品型号 | AD9522-0BCPZ |

| PLL | 是 |

| 产品目录页面 | |

| 产品种类 | 时钟发生器及支持产品 |

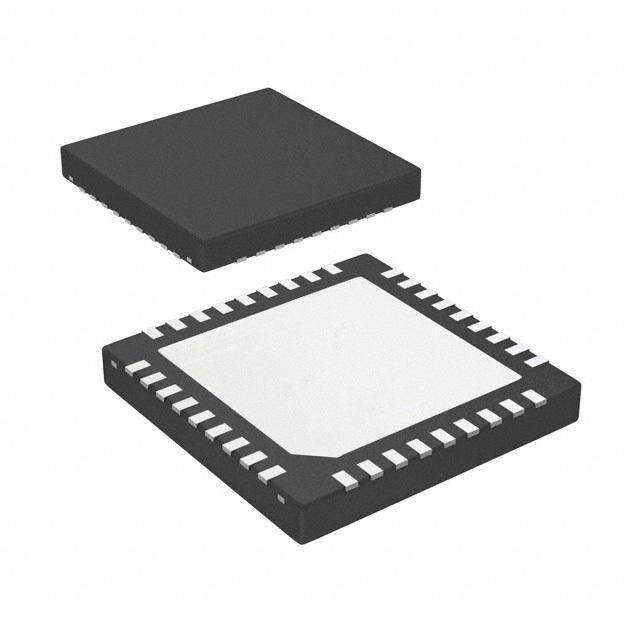

| 供应商器件封装 | 64-LFCSP-VQ(9x9) |

| 其它名称 | AD95220BCPZ |

| 分频器/倍频器 | 是/无 |

| 包装 | 托盘 |

| 商标 | Analog Devices |

| 安装类型 | 表面贴装 |

| 安装风格 | SMD/SMT |

| 封装 | Tray |

| 封装/外壳 | 64-VFQFN 裸露焊盘,CSP |

| 封装/箱体 | LFCSP-64 |

| 工作温度 | -40°C ~ 85°C |

| 工作电源电压 | 3.3 V |

| 工厂包装数量 | 260 |

| 差分-输入:输出 | 是/是 |

| 最大工作温度 | + 85 C |

| 最大输入频率 | 250 MHz |

| 最大输出频率 | 2950 MHz |

| 最小工作温度 | - 40 C |

| 标准包装 | 1 |

| 比率-输入:输出 | 2:12,2:24 |

| 电压-电源 | 3.135 V ~ 3.465 V |

| 电路数 | 1 |

| 类型 | Clock Generators |

| 系列 | AD9522-0 |

| 输入 | CMOS,LVDS,LVPECL |

| 输出 | CMOS,LVDS |

| 输出端数量 | 12 |

| 输出类型 | LVDS |

| 频率-最大值 | 2.95GHz |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

12 LVDS/24 CMOS Output Clock Generator with Integrated 2.8 GHz VCO Data Sheet AD9522-0 FEATURES FUNCTIONAL BLOCK DIAGRAM CP LF Low phase noise, phase-locked loop (PLL) On-chip voltage controlled oscillator (VCO) tunes from 2.53 GHz to 2.95 GHz OPTIONAL REF1 RR STATUS EO MONITOR 1Su dpifpfeorretsn teixatle orrn 2a ls 3in.3g lVe/-5e Vnd VeCdO r/eVfCeXreOn tcoe 2in.4p uGtHs z REFIN CHOVMONIT PLL VCO Accepts CMOS, LVPECL, or LVDS references to 250 MHz REFIN REF2 SWITAND Accepts 16.62 MHz to 33.3 MHz crystal for reference input ZERO DELAY Optional reference clock doubler DIVIDER CLK AND MUXES Reference monitoring capability LVDS/ Revertive automatic and manual reference switchover/ CMOS OUT0 holdover modes DIV/Φ OUT1 OUT2 Glitch-free switchover between references OUT3 Automatic recovery from holdover DIV/Φ OUT4 OUT5 Digital or analog lock detect, selectable OUT6 Optional zero delay operation DIV/Φ OUT7 OUT8 Twelve 800 MHz LVDS outputs divided into 4 groups OUT9 Each group of 3 has a 1-to-32 divider with phase delay DIV/Φ OUT10 OUT11 Additive output jitter as low as 242 fs rms Channel-to-channel skew grouped outputs < 60 ps SPI/I2C CONTROL Ea(cfho rL VfDS ≤ o 2u5tp0u Mt Hcazn) be configured as 2 CMOS outputs DIGPOITRATL ALNODGIC EEPROM AD9522 07219-001 OUT Figure 1. Automatic synchronization of all outputs on power-up Manual synchronization of outputs as needed The AD9522 serial interface supports both SPI and I²C® ports. SPI- and I²C-compatible serial control port An in-package EEPROM can be programmed through the 64-lead LFCSP serial interface and store user-defined register settings for Nonvolatile EEPROM stores configuration settings power-up and chip reset. APPLICATIONS The AD9522 features 12 LVDS outputs in four groups. Any of the 800 MHz LVDS outputs can be reconfigured as two Low jitter, low phase noise clock distribution 250 MHz CMOS outputs. Clock generation and translation for SONET, 10Ge, 10G FC, and other 10 Gbps protocols Each group of outputs has a divider that allows both the divide Forward error correction (G.710) ratio (from 1 to 32) and the phase (coarse delay) to be set. Clocking high speed ADCs, DACs, DDSs, DDCs, DUCs, MxFEs The AD9522 is available in a 64-lead LFCSP and can be operated High performance wireless transceivers from a single 3.3 V supply. The external VCO can have an ATE and high performance instrumentation operating voltage up to 5.5 V. Broadband infrastructures The AD9522 is specified for operation over the standard industrial GENERAL DESCRIPTION range of −40°C to +85°C. The AD9522-01 provides a multioutput clock distribution The AD9520-0 is an equivalent part to the AD9522-0 featuring function with subpicosecond jitter performance, along with an LVPECL/CMOS drivers instead of LVDS/CMOS drivers. on-chip PLL and VCO. The on-chip VCO tunes from 2.53 GHz to 2.95 GHz. An external 3.3 V/5 V VCO/VCXO of up to 2.4 GHz can also be used. 1 The AD9522 is used throughout this data sheet to refer to all the members of the AD9522 family. However, when AD9522-0 is used, it is referring to that specific member of the AD9522 family. Rev. A Document Feedback Information furnished by Analog Devices is believed to be accurate and reliable. However, no responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A. rights of third parties that may result from its use. Specifications subject to change without notice. No license is granted by implication or otherwise under any patent or patent rights of Analog Devices. Tel: 781.329.4700 ©2008–2015 Analog Devices, Inc. All rights reserved. Trademarks and registered trademarks are the property of their respective owners. Technical Support www.analog.com

AD9522-0 Data Sheet TABLE OF CONTENTS Features .............................................................................................. 1 Mode 1: Clock Distribution or External VCO < 1600 MHz Applications ....................................................................................... 1 .................................................................................................. 31 General Description ......................................................................... 1 Mode 2: High Frequency Clock Distribution—CLK or External VCO > 1600 MHz .................................................. 33 Functional Block Diagram .............................................................. 1 Phase-Locked Loop (PLL) .................................................... 35 Revision History ............................................................................... 4 Configuration of the PLL ...................................................... 35 Specifications ..................................................................................... 5 Phase Frequency Detector (PFD) ........................................ 35 Power Supply Requirements ....................................................... 5 Charge Pump (CP) ................................................................. 35 PLL Characteristics ...................................................................... 5 On-Chip VCO ........................................................................ 36 Clock Inputs .................................................................................. 8 PLL External Loop Filter ....................................................... 36 Clock Outputs ............................................................................... 8 PLL Reference Inputs ............................................................. 36 Timing Characteristics ................................................................ 9 Reference Switchover ............................................................. 37 Timing Diagrams ..................................................................... 9 Reference Divider R ............................................................... 37 Clock Output Additive Phase Noise (Distribution Only; VCO Divider Not Used) ...................................................................... 10 VCO/VCXO Feedback Divider N: P, A, B .......................... 37 Clock Output Absolute Phase Noise (Internal VCO Used) .. 11 Digital Lock Detect (DLD) ................................................... 39 Analog Lock Detect (ALD) ................................................... 39 Clock Output Absolute Time Jitter (Clock Generation Using Internal VCO) ............................................................................. 11 Current Source Digital Lock Detect (CSDLD) .................. 39 Clock Output Absolute Time Jitter (Clock Cleanup Using External VCXO/VCO Clock Input (CLK/CLK) ................ 40 Internal VCO) ............................................................................. 11 Holdover .................................................................................. 40 Clock Output Absolute Time Jitter (Clock Generation Using External/Manual Holdover Mode ........................................ 40 External VCXO) ......................................................................... 12 Automatic/Internal Holdover Mode .................................... 40 Clock Output Additive Time Jitter (VCO Divider Not Used) ....................................................................................................... 12 Frequency Status Monitors ................................................... 42 Clock Output Additive Time Jitter (VCO Divider Used) ..... 13 VCO Calibration .................................................................... 42 Serial Control Port—SPI Mode ................................................ 13 Zero Delay Operation ................................................................ 45 Serial Control Port—I²C Mode ................................................ 14 Internal Zero Delay Mode..................................................... 45 PD, SYNC, and RESET Pins ..................................................... 15 External Zero Delay Mode .................................................... 45 Serial Port Setup Pins: SP1, SP0 ............................................... 15 Clock Distribution ..................................................................... 46 LD, STATUS, and REFMON Pins ............................................ 15 Operation Modes ................................................................... 46 Power Dissipation ....................................................................... 16 Clock Frequency Division ..................................................... 47 Absolute Maximum Ratings .......................................................... 17 VCO Divider ........................................................................... 47 Thermal Resistance .................................................................... 17 Channel Dividers ................................................................... 47 ESD Caution ................................................................................ 17 Synchronizing the Outputs—SYNC Function ................... 49 Pin Configuration and Function Descriptions ........................... 18 LVDS Output Drivers ............................................................ 50 Typical Performance Characteristics ........................................... 21 CMOS Output Drivers .......................................................... 51 Test Circuits ..................................................................................... 26 Reset Modes ................................................................................ 51 Terminology .................................................................................... 27 Power-On Reset ...................................................................... 51 Detailed Block Diagram ................................................................ 28 Hardware Reset via the RESET Pin ..................................... 51 Theory of Operation ...................................................................... 29 Soft Reset via the Serial Port ................................................. 51 Operational Configurations ...................................................... 29 Soft Reset to Settings in EEPROM when EEPROM Pin = 0 via the Serial Port ......................................................................... 51 Mode 0: Internal VCO and Clock Distribution ................. 29 Rev. A | Page 2 of 84

Data Sheet AD9522-0 Power-Down Modes ................................................................... 51 SPI MSB/LSB First Transfers ..................................................... 57 Chip Power-Down via PD ..................................................... 51 EEPROM Operations ..................................................................... 60 PLL Power-Down .................................................................... 52 Writing to the EEPROM ............................................................ 60 Distribution Power-Down ..................................................... 52 Reading from the EEPROM ...................................................... 60 Individual Clock Output Power-Down................................ 52 Programming the EEPROM Buffer Segment.......................... 61 Individual Clock Channel Power-Down ............................. 52 Register Section Definition Group ....................................... 61 Serial Control Port .......................................................................... 53 IO_UPDATE (Operational Code 0x80) .............................. 61 SPI/I²C Port Selection ................................................................ 53 End-of-Data (Operational Code 0xFF) ............................... 61 I²C Serial Port Operation ........................................................... 53 Pseudo-End-of-Data (Operational Code 0xFE) ................. 61 I2C Bus Characteristics ........................................................... 53 Thermal Performance ..................................................................... 63 Data Transfer Process ............................................................. 54 Register Map .................................................................................... 64 Data Transfer Format ............................................................. 55 Register Map Descriptions ............................................................. 68 I²C Serial Port Timing ............................................................ 55 Applications Information ............................................................... 82 SPI Serial Port Operation ........................................................... 56 Frequency Planning Using the AD9522 .................................. 82 Pin Descriptions ...................................................................... 56 Using the AD9522 Outputs for ADC Clock Applications..... 82 SPI Mode Operation ............................................................... 56 LVDS Clock Distribution ........................................................... 82 Communication Cycle—Instruction Plus Data .................. 56 CMOS Clock Distribution ......................................................... 83 Write .........................................................................................5 6 Outline Dimensions ........................................................................ 84 Read ..........................................................................................5 6 Ordering Guide ........................................................................... 84 SPI Instruction Word (16 Bits) .................................................. 57 Rev. A | Page 3 of 84

AD9522-0 Data Sheet REVISION HISTORY 3/15—Rev. 0 to Rev. A Changes to External VCXO/VCO Clock Input (CLK/CLK) and Changes to Features Section............................................................ 1 Holdover Section ............................................................................ 40 Changes to Table 1 and Table 2 ....................................................... 5 Changes to Frequency Status Monitors Section and VCO Change to Input Frequency Parameter, Table 3 ........................... 8 Calibration Section ......................................................................... 42 Changes to Table 4 ............................................................................ 8 Changes to Figure 49 Caption ...................................................... 43 Changes to SDIO, SDO (Outputs) Parameter, Test Added Table 31; Renumbered Sequentially ................................ 44 Conditions/Comments Column, Table 13 .................................. 13 Changes to Zero Delay Operation Section and Internal Zero Changes to Table 17 ........................................................................ 15 Delay Mode Section ....................................................................... 45 Change to VCP Supply Parameter, Table 18 ............................... 16 Changes to Clock Distribution Section ....................................... 46 Change to Junction Temperature Parameter, Table 19 .............. 17 Added Channel Divider Maximum Frequency Section ............ 47 Changes to Pin 4 Description Column, Table 21 and Pin 22 Changes to Duty Cycle and Duty-Cycle Correction Section and Description Column, Table 21 ...................................................... 18 Table 37 ............................................................................................ 48 Deleted Figure 13; Renumbered Sequentially............................. 21 Changes to Synchronizing the Outputs—SYNC Function Added Test Circuits Section .......................................................... 26 Section .............................................................................................. 49 Moved Figure 33 and Figure 34 .................................................... 26 Changes to CMOS Output Drivers Section, Power-On Reset Changes to Figure 33 and Figure 34 ............................................. 26 Section, Hardware Reset via the RESET Pin Section, and Soft Changes to Mode 0: Internal VCO and Clock Distribution Reset via the Serial Port Section ................................................... 51 Section .............................................................................................. 29 Changes to Pin Descriptions Section and SPI Mode Operation Deleted Configuration and Register Settings Section ............... 29 Section .............................................................................................. 56 Changes to Figure 36 ...................................................................... 30 Changes to SPI Instruction Word (16 Bits) Section .................. 57 Changes to Figure 37 ...................................................................... 32 Changes to Figure 66, Figure 67 Caption, and Figure 68 .......... 58 Changes to Figure 38 ...................................................................... 34 Changes to EEPROM Operation Section .................................... 60 Changes to Configuration of the PLL Section and Charge Pump Changes to Table 49 ....................................................................... 64 (CP) Section .................................................................................... 35 Changes to Table 50 and Table 51 ................................................ 68 Changes to On-Chip VCO Section, Figure 40, and PLL Changes to Table 53 ....................................................................... 69 Reference Inputs Section ............................................................... 36 Changes to Table 55 ....................................................................... 77 Added Figure 42 and Figure 43; Renumbered Sequentially ..... 36 Changes to Table 58 ....................................................................... 81 Changes to Reference Switchover Section ................................... 37 Change to Frequency Planning Using the AD9522 Section ..... 82 Changes to Prescaler Section, A and B Counters Section, R and Updated Outline Dimensions ....................................................... 84 N Divider Delays, and Table 29 .................................................... 38 Changes to Current Source Digital Lock Detect (CSDLD) 10/08—Revision 0: Initial Version Section .............................................................................................. 39 Rev. A | Page 4 of 84

Data Sheet AD9522-0 SPECIFICATIONS Typical (typ) is given for VS = 3.3 V ± 5%; VS ≤ VCP ≤ 5.25 V; T = 25°C; RSET = 4.12 kΩ; CPRSET = 5.1 kΩ, unless otherwise noted. Minimum A (min) and maximum (max) values are given over full VS and T (−40°C to +85°C) variation. A POWER SUPPLY REQUIREMENTS Table 1. Parameter Min Typ Max Unit Test Conditions/Comments VS 3.135 3.3 3.465 V 3.3 V ± 5% VCP VS 5.25 V This supply is usually at the same voltage as VS; set VCP = 5.0 V ± 5% only if connecting a 5 V external VCO/VCXO RSET Pin Resistor 4.12 kΩ Sets internal biasing currents; connect to ground CPRSET Pin Resistor 5.1 kΩ Sets internal CP current range, nominally 4.8 mA (CP_lsb = 600 µA); actual current can be calculated by CP_lsb = 3.06/CPRSET; connect to ground BYPASS Pin Capacitor 220 nF Bypass for internal LDO regulator; necessary for LDO stability; connect to ground PLL CHARACTERISTICS Table 2. Parameter Min Typ Max Unit Test Conditions/Comments VCO (ON-CHIP) Frequency Range 2530 2950 MHz VCO Gain (K ) 52 MHz/V See Figure 8 VCO Tuning Voltage (V) 0.5 VCP − V VCP ≤ VS when using internal VCO T 0.5 Frequency Pushing (Open-Loop) 1 MHz/V Phase Noise at 1 kHz Offset −60 dBc/Hz LVDS output; f = 2750 MHz; f = 685MHz VCO OUT Phase Noise at 100 kHz Offset −118 dBc/Hz LVDS output; f = 2750 MHz; f = 685MHz VCO OUT Phase Noise at 1 MHz Offset −135 dBc/Hz LVDS output; f = 2750 MHz; f = 685MHz VCO OUT REFERENCE INPUTS Differential Mode (REFIN, REFIN) Differential mode (can accommodate single-ended input by ac grounding the unused complementary input) Input Frequency 0 250 MHz Frequencies below about 1 MHz must be dc-coupled; be careful to match V (self-bias voltage) CM Input Sensitivity 280 mV p-p PLL figure of merit (FOM) increases with increasing slew rate (see Figure 12); the input sensitivity is sufficient for ac-coupled LVDS and LVPECL signals Self-Bias Voltage, REFIN 1.35 1.60 1.75 V Self-bias voltage of REFIN1 Self-Bias Voltage, REFIN 1.30 1.50 1.60 V Self-bias voltage of REFIN1 Input Resistance, REFIN 4.0 4.8 5.9 kΩ Self-biased1 Input Resistance, REFIN 4.4 5.3 6.4 kΩ Self-biased1 Dual Single-Ended Mode (REF1, REF2) Two single-ended CMOS-compatible inputs Input Frequency (AC-Coupled) 10 250 MHz Slew rate must be > 50 V/µs with DC Offset Off) Input Frequency (AC-Coupled 250 MHz Slew rate must be > 50 V/µs, and input amplitude with DC Offset On) sensitivity specification must be met; see input sensitivity Input Frequency (DC-Coupled) 0 250 MHz Slew rate > 50 V/µs; CMOS levels Input Sensitivity (AC-Coupled 0.55 3.28 V p-p VIH must not exceed VS with DC Offset Off) Input Sensitivity (AC-Coupled 1.5 2.78 V p-p VIH must not exceed VS with DC Offset On) Input Logic High, DC Offset Off 2.0 V Input Logic Low, DC Offset Off 0.8 V Input Current −100 +100 µA Input Capacitance 2 pF Each pin, REFIN (REF1)/REFIN (REF2) Pulse Width High/Low 1.8 ns Amount of time a square wave is high/low determines the allowable input duty cycle Rev. A | Page 5 of 84

AD9522-0 Data Sheet Parameter Min Typ Max Unit Test Conditions/Comments Crystal Oscillator Crystal Resonator Frequency Range 16.62 33.33 MHz Maximum Crystal Motional Resistance 30 Ω PHASE/FREQUENCY DETECTOR (PFD) PFD Input Frequency 100 MHz Antibacklash pulse width = 1.3 ns, 2.9 ns 45 MHz Antibacklash pulse width = 6.0 ns Reference Input Clock Doubler Frequency 0.004 50 MHz Antibacklash pulse width = 1.3 ns, 2.9 ns Antibacklash Pulse Width 1.3 ns Register 0x017[1:0] = 01b 2.9 ns Register 0x017[1:0] = 00b; Register 0x017[1:0] = 11b 6.0 ns Register 0x017[1:0] = 10b CHARGE PUMP (CP) I Sink/Source Programmable CP High Value 4.8 mA With CPRSET = 5.1 kΩ; higher I is possible by CP changing CPRSET Low Value 0.60 mA With CPRSET = 5.1 kΩ; lower I is possible by CP changing CPRSET Absolute Accuracy 2.5 % Charge pump voltage set to V /2 CP CPRSET Range 2.7 10 kΩ I High Impedance Mode Leakage 1 nA CP Sink-and-Source Current Matching 1 % 0.5 V < V < VCP − 0.5 V; V is the voltage on the CP (charge CP CP pump) pin; VCP is the voltage on the VCP power supply pin I vs. V 1.5 % 0.5 V < V < VCP − 0.5 V CP CP CP I vs. Temperature 2 % V = VCP/2 V CP CP PRESCALER (PART OF N DIVIDER) Prescaler Input Frequency P = 1 FD 300 MHz P = 2 FD 600 MHz P = 3 FD 900 MHz P = 2 DM (2/3) 200 MHz P = 4 DM (4/5) 1000 MHz P = 8 DM (8/9) 2400 MHz P = 16 DM (16/17) 3000 MHz P = 32 DM (32/33) 3000 MHz Prescaler Output Frequency 300 MHz A, B counter input frequency (prescaler input frequency divided by P) PLL N DIVIDER DELAY Register 0x019[2:0]; see Table 53 000 Off 001 385 ps 010 504 ps 011 623 ps 100 743 ps 101 866 ps 110 989 ps 111 1112 ps PLL R DIVIDER DELAY Register 0x019[5:3]; see Table 53 000 Off 001 365 ps 010 486 ps 011 608 ps 100 730 ps 101 852 ps 110 976 ps 111 1101 ps Rev. A | Page 6 of 84

Data Sheet AD9522-0 Parameter Min Typ Max Unit Test Conditions/Comments PHASE OFFSET IN ZERO DELAY REF refers to REFIN (REF1)/REFIN (REF2) Phase Offset (REF-to-LVDS Clock Output 1890 2348 3026 ps When N delay and R delay are bypassed Pins) in Internal Zero Delay Mode Phase Offset (REF-to-LVDS Clock Output 900 1217 1695 ps When N delay = Setting 111 and R delay is bypassed Pins) in Internal Zero Delay Mode Phase Offset (REF-to-CLK Input Pins) in 318 677 1085 ps When N delay and R delay are bypassed External Zero Delay Mode Phase Offset (REF-to-CLK Input Pins) in −329 +33 +360 ps When N delay = Setting 011 and R delay is bypassed External Zero Delay Mode NOISE CHARACTERISTICS In-Band Phase Noise of the Charge Pump/ The PLL in-band phase noise floor is estimated by Phase Frequency Detector (In-Band measuring the in-band phase noise at the output of Means Within the LBW of the PLL) the VCO and subtracting 20 log(N) (where N is the value of the N divider) At 500 kHz PFD Frequency −165 dBc/Hz At 1 MHz PFD Frequency −162 dBc/Hz At 10 MHz PFD Frequency −152 dBc/Hz At 50 MHz PFD Frequency −144 dBc/Hz PLL Figure of Merit (FOM) −222 dBc/Hz Reference slew rate > 0.5 V/ns; FOM + 10 log(f ) is an PFD approximation of the PFD/CP in-band phase noise (in the flat region) inside the PLL loop bandwidth; when running closed-loop, the phase noise, as observed at the VCO output, is increased by 20 log(N); PLL figure of merit decreases with decreasing slew rate; see Figure 12 PLL DIGITAL LOCK DETECT WINDOW2 Signal available at the LD, STATUS, and REFMON pins when selected by appropriate register settings; lock detect window settings can be varied by changing the CPRSET resistor Lock Threshold (Coincidence of Edges) Selected by Register 0x017[1:0] and Register 0x018[4] (this is the threshold to go from unlock to lock) Low Range (ABP 1.3 ns, 2.9 ns) 3.5 ns Register 0x017[1:0] = 00b, 01b, 11b; Register 0x018[4] = 1b High Range (ABP 1.3 ns, 2.9 ns) 7.5 ns Register 0x017[1:0] = 00b, 01b, 11b; Register 0x018[4] = 0b High Range (ABP 6.0 ns) 3.5 ns Register 0x017[1:0] = 10b; Register 0x018[4] = 0b Unlock Threshold (Hysteresis)2 Selected by Register 0x017[1:0] and Register 0x018[4] (this is the threshold to go from lock to unlock) Low Range (ABP 1.3 ns, 2.9 ns) 7 ns Register 0x017[1:0] = 00b, 01b, 11b; Register 0x018[4] = 1b High Range (ABP 1.3 ns, 2.9 ns) 15 ns Register 0x017[1:0] = 00b, 01b, 11b; Register 0x018[4] = 0b High Range (ABP 6.0 ns) 11 ns Register 0x017[1:0] = 10b; Register 0x018[4] = 0b 1 The REFIN and REFIN self-bias points are offset slightly to avoid chatter on an open input condition. 2 For reliable operation of the digital lock detect, the period of the PFD frequency must be greater than the unlock-after-lock time. Rev. A | Page 7 of 84

AD9522-0 Data Sheet CLOCK INPUTS Table 3. Parameter Min Typ Max Unit Test Conditions/Comments CLOCK INPUTS (CLK, CLK) Differential input Input Frequency 01 2.4 GHz High frequency distribution (VCO divider) 01 2 GHz Distribution only (VCO divider bypassed); this is the frequency range supported by the channel divider, see the Channel Divider Maximum Frequency section Input Sensitivity, Differential 150 mV p-p Measured at 2.4 GHz; jitter performance is improved with slew rates > 1 V/ns Input Level, Differential 2 V p-p Larger voltage swings can turn on the protection diodes and can degrade jitter performance Input Common-Mode Voltage, V 1.3 1.57 1.8 V Self-biased; enables ac coupling CM Input Common-Mode Range, V 1.3 1.8 V With 200 mV p-p signal applied; dc-coupled CMR Input Sensitivity, Single-Ended 150 mV p-p CLK ac-coupled; CLK ac-bypassed to RF ground Input Resistance 3.9 4.7 5.7 kΩ Self-biased Input Capacitance 2 pF 1 Below about 1 MHz, the input must be dc-coupled. Take care to match VCM. CLOCK OUTPUTS Table 4. Parameter Min Typ Max Unit Test Conditions/Comments LVDS CLOCK OUTPUTS Termination = 100 Ω across differential pair OUT0, OUT1, OUT2, OUT3, OUT4, OUT5, Differential (OUT, OUT) OUT6, OUT7, OUT8, OUT9, OUT10, OUT11 Output Frequency 800 MHz The AD9522 outputs toggle at higher frequencies, but the output amplitude may not meet the V OD specification Output Differential Voltage, V 247 360 454 mV V − V for each leg of a differential pair for default OD OH OL amplitude setting with the driver not toggling; the peak-to-peak amplitude measured using a differential probe across the differential pair with the driver toggling is roughly 2× these values (see Figure 20) Delta V 25 mV Absolute difference between voltage swing of OD normal pin and inverted pin, output driver static Output Offset Voltage, V 1.125 1.25 1.375 V (V + V )/2 across a differential pair OS OH OL Delta V 25 mV This is the absolute value of the difference between OS V when the normal output is high vs. when the OS complementary output is high Short-Circuit Current, I , I 14 24 mA Output shorted to GND SA SB Tristate Leakage Current per Output <1 nA Output in tristate with 100 Ω across differential pair CMOS CLOCK OUTPUTS OUT0A, OUT0B, OUT1A, OUT1B, OUT2A, Single-ended; termination = 10 pF OUT2B, OUT3A, OUT3B, OUT4A, OUT4B, OUT5A, OUT5B, OUT6A, OUT6B, OUT7A, OUT7B, OUT8A, OUT8B, OUT9A, OUT9B, OUT10A, OUT10B, OUT11A, OUT11B Output Frequency 250 MHz See Figure 21 Output Voltage High, V VS − 0.1 V At 1 mA load OH Output Voltage Low, V 0.1 V At 1 mA load OL Output Voltage High, V 2.7 V At 10 mA load OH Output Voltage Low, V 0.5 V At 10 mA load OL Rev. A | Page 8 of 84

Data Sheet AD9522-0 TIMING CHARACTERISTICS Table 5. Parameter Min Typ Max Unit Test Conditions/Comments LVDS OUTPUT RISE/FALL TIMES Termination = 100 Ω across differential pair Output Rise Time, t 150 350 ps 20% to 80%, measured differentially RP Output Fall Time, t 150 350 ps 80% to 20%, measured differentially FP PROPAGATION DELAY, t , CLK-TO-LVDS OUTPUT LVDS For All Divide Values 1866 2313 2812 ps High frequency clock distribution configuration 1808 2245 2740 ps Clock distribution configuration Variation with Temperature 1 ps/°C OUTPUT SKEW, LVDS OUTPUTS1 Termination = 100 Ω across differential pair LVDS Outputs That Share the Same Divider 7 60 ps LVDS Outputs on Different Dividers 19 162 ps All LVDS Outputs Across Multiple Parts 432 ps CMOS OUTPUT RISE/FALL TIMES Termination = open Output Rise Time, t 625 835 ps 20% to 80%; C = 10 pF RC LOAD Output Fall Time, t 625 800 ps 80% to 20%; C = 10 pF FC LOAD PROPAGATION DELAY, t , CLK-TO-CMOS OUTPUT Clock distribution configuration CMOS For All Divide Values 1913 2400 2950 ps Variation with Temperature 2 ps/°C OUTPUT SKEW, CMOS OUTPUTS1 CMOS Outputs That Share the Same Divider 10 55 ps All CMOS Outputs on Different Dividers 27 230 ps All CMOS Outputs Across Multiple Parts 500 ps OUTPUT SKEW, LVDS-TO-CMOS OUTPUT1 All settings identical; different logic type Outputs That Share the Same Divider −31 +152 +495 ps LVDS to CMOS on the same part Outputs That Are on Different Dividers −193 +160 +495 ps LVDS to CMOS on the same part 1 The output skew is the difference between any two similar delay paths while operating at the same voltage and temperature. Timing Diagrams tCLK CLK SINGLE-ENDED tLVDS 80% CMOS 10pF LOAD 20% tCMOS 07219-060 tRC tFC 07219-063 Figure 2. CLK/CLK to Clock Output Timing, DIV = 1 Figure 4. CMOS Timing, Single-Ended, 10 pF Load DIFFERENTIAL 80% LVDS 20% tRP tFP 07219-061 Figure 3. LVDS Timing, Differential Rev. A | Page 9 of 84

AD9522-0 Data Sheet CLOCK OUTPUT ADDITIVE PHASE NOISE (DISTRIBUTION ONLY; VCO DIVIDER NOT USED) Table 6. Parameter Min Typ Max Unit Test Conditions/Comments CLK-TO-LVDS ADDITIVE PHASE NOISE Distribution section only; does not include PLL and VCO CLK = 1.6 GHz, Output = 800 MHz Input slew rate > 1 V/ns Divider = 2 At 10 Hz Offset −100 dBc/Hz At 100 Hz Offset −110 dBc/Hz At 1 kHz Offset −117 dBc/Hz At 10 kHz Offset −126 dBc/Hz At 100 kHz Offset −134 dBc/Hz At 1 MHz Offset −137 dBc/Hz At 10 MHz Offset −147 dBc/Hz At 100 MHz Offset −148 dBc/Hz CLK = 1 GHz, Output = 200 MHz Input slew rate > 1 V/ns Divider = 5 At 10 Hz Offset −111 dBc/Hz At 100 Hz Offset −123 dBc/Hz At 1 kHz Offset −132 dBc/Hz At 10 kHz Offset −141 dBc/Hz At 100 kHz Offset −146 dBc/Hz At 1 MHz Offset −150 dBc/Hz >10 MHz Offset −156 dBc/Hz CLK-TO-CMOS ADDITIVE PHASE NOISE Distribution section only; does not include PLL and VCO CLK = 1 GHz, Output = 500 MHz Input slew rate > 1 V/ns Divider = 2 At 10 Hz Offset −102 dBc/Hz At 100 Hz Offset −114 dBc/Hz At 1 kHz Offset −122 dBc/Hz At 10 kHz Offset −129 dBc/Hz At 100 kHz Offset −135 dBc/Hz At 1 MHz Offset −140 dBc/Hz >10 MHz Offset −150 dBc/Hz CLK = 1 GHz, Output = 50 MHz Input slew rate > 1 V/ns Divider = 20 At 10 Hz Offset −125 dBc/Hz At 100 Hz Offset −136 dBc/Hz At 1 kHz Offset −144 dBc/Hz At 10 kHz Offset −152 dBc/Hz At 100 kHz Offset −157 dBc/Hz At 1 MHz Offset −160 dBc/Hz >10 MHz Offset −164 dBc/Hz Rev. A | Page 10 of 84

Data Sheet AD9522-0 CLOCK OUTPUT ABSOLUTE PHASE NOISE (INTERNAL VCO USED) Table 7. Parameter Min Typ Max Unit Test Conditions/Comments LVDS ABSOLUTE PHASE NOISE Internal VCO; VCO divider = 4; LVDS output and for loop bandwidths < 1 kHz VCO = 2950 MHz; Output = 737.5 MHz At 1 kHz Offset −59 dBc/Hz At 10 kHz Offset −90 dBc/Hz At 100 kHz Offset −115 dBc/Hz At 1 MHz Offset −133 dBc/Hz At 10 MHz Offset −146 dBc/Hz At 40 MHz Offset −149 dBc/Hz VCO = 2750 MHz; Output = 685 MHz At 1 kHz Offset −60 dBc/Hz At 10 kHz Offset −92 dBc/Hz At 100 kHz Offset −118 dBc/Hz At 1 MHz Offset −135 dBc/Hz At 10 MHz Offset −148 dBc/Hz At 40 MHz Offset −151 dBc/Hz VCO = 2550 MHz; Output = 632.5 MHz At 1 kHz Offset −64 dBc/Hz At 10 kHz Offset −95 dBc/Hz At 100 kHz Offset −120 dBc/Hz At 1 MHz Offset −137 dBc/Hz At 10 MHz Offset −148 dBc/Hz At 40 MHz Offset −151 dBc/Hz CLOCK OUTPUT ABSOLUTE TIME JITTER (CLOCK GENERATION USING INTERNAL VCO) Table 8. Parameter Min Typ Max Unit Test Conditions/Comments LVDS OUTPUT ABSOLUTE TIME JITTER Application example based on a typical setup where the reference source is clean, so a wider PLL loop bandwidth is used; reference = 15.36 MHz; R DIV = 1 VCO = 2949 MHz; LVDS = 245.76 MHz; PLL LBW = 55 kHz 187 fs rms Integration bandwidth = 200 kHz to 10 MHz 352 fs rms Integration bandwidth = 12 kHz to 20 MHz VCO = 2580 MHz; LVDS = 122.88 MHz; PLL LBW = 55 kHz 166 fs rms Integration bandwidth = 200 kHz to 10 MHz 321 fs rms Integration bandwidth = 12 kHz to 20 MHz VCO = 2580 MHz; LVDS = 61.44 MHz; PLL LBW = 55 kHz 218 fs rms Integration bandwidth = 200 kHz to 10 MHz 378 fs rms Integration bandwidth = 12 kHz to 20 MHz CLOCK OUTPUT ABSOLUTE TIME JITTER (CLOCK CLEANUP USING INTERNAL VCO) Table 9. Parameter Min Typ Max Unit Test Conditions/Comments LVDS OUTPUT ABSOLUTE TIME JITTER Application example based on a typical setup where the reference source is jittery, so a narrower PLL loop bandwidth is used; reference = 19.44 MHz; R DIV = 162 VCO = 2799 MHz; LVDS = 155.52 MHz; PLL LBW = 1.8 kHz 617 fs rms Integration bandwidth = 12 kHz to 20 MHz VCO = 2580 MHz; LVDS = 122.88 MHz; PLL LBW = 1.8 kHz 514 fs rms Integration bandwidth = 12 kHz to 20 MHz Rev. A | Page 11 of 84

AD9522-0 Data Sheet CLOCK OUTPUT ABSOLUTE TIME JITTER (CLOCK GENERATION USING EXTERNAL VCXO) Table 10. Parameter Min Typ Max Unit Test Conditions/Comments LVDS OUTPUT ABSOLUTE TIME JITTER Application example based on a typical setup using an external 245.76 MHz VCXO (Toyocom TCO-2112); reference = 15.36 MHz; R DIV = 1 LVDS = 245.76 MHz; PLL LBW = 125 Hz 87 fs rms Integration bandwidth = 200 kHz to 5 MHz 108 fs rms Integration bandwidth = 200 kHz to 10 MHz 146 fs rms Integration bandwidth = 12 kHz to 20 MHz LVDS = 122.88 MHz; PLL LBW = 125 Hz 120 fs rms Integration bandwidth = 200 kHz to 5 MHz 151 fs rms Integration bandwidth = 200 kHz to 10 MHz 207 fs rms Integration bandwidth = 12 kHz to 20 MHz LVDS = 61.44 MHz; PLL LBW = 125 Hz 157 fs rms Integration bandwidth = 200 kHz to 5 MHz 210 fs rms Integration bandwidth = 200 kHz to 10 MHz 295 fs rms Integration bandwidth = 12 kHz to 20 MHz CLOCK OUTPUT ADDITIVE TIME JITTER (VCO DIVIDER NOT USED) Table 11. Parameter Min Typ Max Unit Test Conditions/Comments LVDS OUTPUT ADDITIVE TIME JITTER Distribution section only; does not include PLL and VCO; measured at rising edge of clock signal CLK = 622.08 MHz 69 fs rms Integration bandwidth = 12 kHz to 20 MHz Any LVDS Output = 622.08 MHz Divide Ratio = 1 CLK = 622.08 MHz 116 fs rms Integration bandwidth = 12 kHz to 20 MHz Any LVDS Output = 155.52 MHz Divide Ratio = 4 CLK = 100 MHz 263 fs rms Calculated from SNR of ADC method Any LVDS Output = 100 MHz Broadband jitter Divide Ratio = 1 CLK = 500 MHz 242 fs rms Calculated from SNR of ADC method Any LVDS Output = 100 MHz Broadband jitter Divide Ratio = 5 CMOS OUTPUT ADDITIVE TIME JITTER Distribution section only; does not include PLL and VCO CLK = 200 MHz 289 fs rms Calculated from SNR of ADC method Any CMOS Output Pair = 100 MHz Broadband jitter Divide Ratio = 2 Rev. A | Page 12 of 84

Data Sheet AD9522-0 CLOCK OUTPUT ADDITIVE TIME JITTER (VCO DIVIDER USED) Table 12. Parameter Min Typ Max Unit Test Conditions/Comments LVDS OUTPUT ADDITIVE TIME JITTER Distribution section only; does not include PLL and VCO; uses rising edge of clock signal CLK = 500 MHz; VCO DIV = 5; LVDS = 100 MHz; 248 fs rms Calculated from SNR of ADC method Bypass Channel Divider; Duty-Cycle Correction = On (broadband jitter) CMOS OUTPUT ADDITIVE TIME JITTER Distribution section only; does not include PLL and VCO; uses rising edge of clock signal CLK = 200 MHz; VCO DIV = 2; CMOS = 100 MHz; 290 fs rms Calculated from SNR of ADC method Bypass Channel Divider; Duty-Cycle Correction = Off (broadband jitter) CLK = 200 MHz; VCO DIV = 1; CMOS = 100 MHz; 288 fs rms Calculated from SNR of ADC method Bypass Channel Divider; Duty-Cycle Correction = Off (broadband jitter) SERIAL CONTROL PORT—SPI MODE Table 13. Parameter Min Typ Max Unit Test Conditions/Comments CS (INPUT) CS has an internal 30 kΩ pull-up resistor Input Logic 1 Voltage 2.0 V Input Logic 0 Voltage 0.8 V Input Logic 1 Current 3 µA Input Logic 0 Current −110 µA The minus sign indicates that current is flowing out of the AD9522, which is due to the internal pull-up resistor Input Capacitance 2 pF SCLK (INPUT) IN SPI MODE SCLK has an internal 30 kΩ pull-down resistor in SPI mode, but not in I2C mode Input Logic 1 Voltage 2.0 V Input Logic 0 Voltage 0.8 V Input Logic 1 Current 110 µA Input Logic 0 Current 1 µA Input Capacitance 2 pF SDIO (WHEN AN INPUT IN BIDIRECTIONAL MODE) Input Logic 1 Voltage 2.0 V Input Logic 0 Voltage 0.8 V Input Logic 1 Current 1 µA Input Logic 0 Current 1 µA Input Capacitance 2 pF SDIO, SDO (OUTPUTS) Output Logic 1 Voltage 2.7 V At 1 mA current; maximum recommended current: 5 mA Output Logic 0 Voltage 0.4 V At 1 mA current TIMING Clock Rate (SCLK, 1/t ) 25 MHz SCLK Pulse Width High, t 16 ns HIGH Pulse Width Low, t 16 ns LOW SDIO to SCLK Setup, t 4 ns DS SCLK to SDIO Hold, t 0 ns DH SCLK to Valid SDIO and SDO, t 11 ns DV CS to SCLK Setup and Hold, tS, tC 2 ns CS Minimum Pulse Width High, tPWH 3 ns Rev. A | Page 13 of 84

AD9522-0 Data Sheet SERIAL CONTROL PORT—I²C MODE Table 14. Parameter Min Typ Max Unit Test Conditions/Comments SDA, SCL (WHEN INPUTTING DATA) Input Logic 1 Voltage 0.7 × VS V Input Logic 0 Voltage 0.3 × VS V Input Current with an Input Voltage Between −10 +10 µA 0.1 × VS and 0.9 × VS Hysteresis of Schmitt Trigger Inputs 0.015 × VS V Pulse Width of Spikes That Must Be Suppressed by 50 ns the Input Filter, t SPIKE SDA (WHEN OUTPUTTING DATA) Output Logic 0 Voltage at 3 mA Sink Current 0.4 V Output Fall Time from VIH to VIL with a Bus 20 + 0.1 C 250 ns C = capacitance of one bus line in pF MIN MAX b b Capacitance from 10 pF to 400 pF TIMING Note that all I2C timing values refer to VIH (0.3 × VS) and MIN VIL levels (0.7 × VS) MAX Clock Rate (SCL, f ) 400 kHz I2C Bus Free Time Between a Stop and Start Condition, t 1.3 µs IDLE Setup Time for a Repeated Start Condition, t 0.6 µs SET; STR Hold Time (Repeated) Start Condition (After This Period, 0.6 µs the First Clock Pulse Is Generated), t HLD; STR Setup Time for Stop Condition, t 0.6 µs SET; STP Low Period of the SCL Clock, t 1.3 µs LOW High Period of the SCL Clock, t 0.6 µs HIGH SCL, SDA Rise Time, t 20 + 0.1 C 300 ns C = capacitance of one bus line in pF RISE b b SCL, SDA Fall Time, t 20 + 0.1 C 300 ns C = capacitance of one bus line in pF FALL b b Data Setup Time, t 120 ns This is a minor deviation from the SET; DAT original I²C specification of 100 ns minimum Data Hold Time, t 140 880 ns This is a minor deviation from the HLD; DAT original I²C specification of 0 ns minimum1 Capacitive Load for Each Bus Line, C 400 pF b 1 According to the original I2C specification, an I2C master must also provide a minimum hold time of 300 ns for the SDA signal to bridge the undefined region of the SCL falling edge. Rev. A | Page 14 of 84

Data Sheet AD9522-0 PD, SYNC, AND RESET PINS Table 15. Parameter Min Typ Max Unit Test Conditions/Comments INPUT CHARACTERISTICS Each of these pins has an 30 kΩ internal pull-up resistor Logic 1 Voltage 2.0 V Logic 0 Voltage 0.8 V Logic 1 Current 1 µA Logic 0 Current −110 µA The minus sign indicates that current is flowing out of the AD9522, which is due to the internal pull-up resistor Capacitance 2 pF RESET TIMING Pulse Width Low 50 ns RESET Inactive to Start of Register Programming 100 ns SYNC TIMING Pulse Width Low 1.3 ns High speed clock is CLK input signal SERIAL PORT SETUP PINS: SP1, SP0 Table 16. Parameter Min Typ Max Unit Test Conditions/Comments SP1, SP0 These pins do not have internal pull-up/pull-down resistors Logic Level 0 0.25 × VS V VS is the voltage on the VS pin Logic Level ½ 0.4 × VS 0.65 × VS V User can float these pins to obtain Logic Level ½; if floating this pin, connect a capacitor to ground Logic Level 1 0.8 × VS V LD, STATUS, AND REFMON PINS Table 17. Parameter Min Typ Max Unit Test Conditions/Comments OUTPUT CHARACTERISTICS When selected as a digital output (CMOS); there are other modes in which these pins are not CMOS digital outputs; see Table 53, Register 0x017, Register 0x01A, and Register 0x01B Output Voltage High, V 2.7 V At 1 mA current; maximum recommended current: 5 mA OH Output Voltage Low, V 0.4 V At 1 mA current OL MAXIMUM TOGGLE RATE 100 MHz Applies when mux is set to any divider or counter output, or PFD up/down pulse; also applies in analog lock detect mode; usually debug mode only; note that spurs can couple to output when any of these pins are toggling ANALOG LOCK DETECT Capacitance 3 pF On-chip capacitance; used to calculate RC time constant for analog lock detect read back; use a pull-up resistor REF1, REF2, AND VCO FREQUENCY STATUS MONITOR Normal Range 1.02 MHz Frequency above which the monitor indicates the presence of the reference Extended Range 8 kHz Frequency above which the monitor indicates the presence of the reference LD PIN COMPARATOR Trip Point 1.6 V Hysteresis 260 mV Rev. A | Page 15 of 84

AD9522-0 Data Sheet POWER DISSIPATION Table 18. Parameter Min Typ Max Unit Test Conditions/Comments POWER DISSIPATION, CHIP Does not include power dissipated in external resistors; all LVDS outputs terminated with 100 Ω across differential pair; all CMOS outputs have 10 pF capacitive loading Power-On Default 0.88 1.0 W No clock; no programming; default register values PLL Locked; One LVDS Output Enabled 0.54 0.63 W f = 25 MHz; f = 250 MHz; VCO = 2750 MHz; VCO divider = 2; REF OUT one LVDS output and output divider enabled; zero delay off; I = 4.8 mA CP PLL Locked; One CMOS Output Enabled 0.55 0.66 W f = 25 MHz; f = 62.5 MHz; VCO = 2750 MHz; VCO divider = 2; REF OUT one CMOS output and output divider enabled; zero delay off; I = 4.8 mA CP Distribution Only Mode; VCO Divider On; 0.36 0.43 W f = 2.4 GHz; f = 200 MHz; VCO divider = 2; one LVDS output CLK OUT One LVDS Output Enabled and output divider enabled; zero delay off Distribution Only Mode; VCO Divider Off; 0.33 0.4 W f = 2.4 GHz; f = 200 MHz; VCO divider bypassed; one LVDS CLK OUT One LVDS Output Enabled output and output divider enabled; zero delay off Maximum Power, Full Operation 1.1 1.3 W PLL on; internal VCO = 2750 MHz; VCO divider = 2; all channel dividers on; 12 LVDS outputs at 125 MHz; zero delay on PD Power-Down 35 50 mW PD pin pulled low; does not include power dissipated in termination resistors PD Power-Down, Maximum Sleep 27 43 mW PD pin pulled low; PLL power-down, Register 0x010[1:0] = 01b; power-down SYNC, Register 0x230[2] = 1b; power-down distribution reference, Register 0x230[1] = 1b VCP Supply 2.3 8 mW PLL operating; typical closed-loop configuration POWER DELTAS, INDIVIDUAL FUNCTIONS Power delta when a function is enabled/disabled VCO Divider On/Off 33 43 mW VCO divider not used REFIN (Differential) Off 25 31 mW Delta between reference input off and differential reference input mode REF1, REF2 (Single-Ended) On/Off 16 22 mW Delta between reference inputs off and one single-ended reference enabled; double this number if both REF1 and REF2 are powered up VCO On/Off 60 95 mW Internal VCO disabled; CLK input selected PLL Dividers and Phase Detector On/Off 54 67 mW PLL off to PLL on, normal operation; no reference enabled LVDS Channel 118 146 mW No LVDS output on to one LVDS output on; channel divider set to 1 LVDS Driver 11 15 mW Second LVDS output turned on, same channel CMOS Channel 120 154 mW No CMOS output on to one CMOS output on; channel divider set to 1; f = 62.5 MHz and 10 pF of capacitive loading OUT CMOS Driver On/Off 16 30 mW Additional CMOS outputs within the same channel turned on Channel Divider Enabled 33 40 mW Delta between divider bypassed (divide-by-1) and divide-by-2 to divide-by-32 Zero Delay Block On/Off 30 35 mW Rev. A | Page 16 of 84

Data Sheet AD9522-0 ABSOLUTE MAXIMUM RATINGS Table 19. Stresses at or above those listed under Absolute Maximum With Ratings may cause permanent damage to the product. This is a Parameter or Pin Respect to Rating stress rating only; functional operation of the product at these VS GND −0.3 V to +3.6 V or any other conditions above those indicated in the operational VCP, CP GND −0.3 V to +5.8 V section of this specification is not implied. Operation beyond REFIN, REFIN GND −0.3 V to VS + 0.3 V the maximum operating conditions for extended periods may RSET, LF, BYPASS GND −0.3 V to VS + 0.3 V affect product reliability. CPRSET GND −0.3 V to VS + 0.3 V THERMAL RESISTANCE CLK, CLK GND −0.3 V to VS + 0.3 V Thermal impedance measurements were taken on a JEDEC CLK CLK −1.2 V to +1.2 V JESD51-5 2S2P test board in still air in accordance with JEDEC SCLK/SCL, SDIO/SDA, SDO, CS GND −0.3 V to VS + 0.3 V JESD51-2. See the Thermal Performance section for more details. OUT0, OUT0, OUT1, OUT1, GND −0.3 V to VS + 0.3 V OUT2, OUT2, OUT3, OUT3, Table 20. OUT4, OUT4, OUT5, OUT5, Package Type θ Unit JA OUT6, OUT6, OUT7, OUT7, 64-Lead LFCSP (CP-64-4) 22 °C/W OUT8, OUT8, OUT9, OUT9, OUT10, OUT10, OUT11, OUT11 SYNC, RESET, PD GND −0.3 V to VS + 0.3 V ESD CAUTION REFMON, STATUS, LD GND −0.3 V to VS + 0.3 V SP0, SP1, EEPROM GND −0.3 V to VS + 0.3 V Junction Temperature1 125°C Storage Temperature Range −65°C to +150°C Lead Temperature (10 sec) 300°C 1 See the Specifications section for operating temperature range (TA). Rev. A | Page 17 of 84

AD9522-0 Data Sheet PIN CONFIGURATION AND FUNCTION DESCRIPTIONS EFIN (REF1)EFIN (REF2)PRSETSSNDSETSUT0 (OUT0A)UT0 (OUT0B)SUT1 (OUT1A)UT1 (OUT1B)UT2 (OUT2A)UT2 (OUT2B)S RRCVVGRVOOVOOOOV 4321098765432109 6666655555555554 VS 1 PIN 1 48OUT3 (OUT3A) REFMON 2 INDICATOR 47OUT3 (OUT3B) LD 3 46VS VCP 4 45OUT4 (OUT4A) CP 5 44OUT4 (OUT4B) STATUS 6 43OUT5 (OUT5A) REF_SEL 7 AD9522 42OUT5 (OUT5B) SYNC 8 41VS TOP VIEW LF 9 (Not to Scale) 40VS BYPASS10 39OUT8 (OUT8B) VS11 38OUT8 (OUT8A) VS12 37OUT7 (OUT7B) CLK13 36OUT7 (OUT7A) CLK14 35VS CS15 34OUT6 (OUT6B) SCLK/SCL16 33OUT6 (OUT6A) 7890123456789012 1112222222222333 SDIO/SDASDOGNDSP1SP0EEPROMRESETPDT9 (OUT9A)T9 (OUT9B)VS0 (OUT10A)0 (OUT10B)1 (OUT11A)1 (OUT11B)VS UU 1111 OO UTUTUTUT N1.O ETXEPSOSED DIE PAD MUST BE CONNECTED TO OGNOD.OO 07219-003 Figure 5. Pin Configuration Table 21. Pin Function Descriptions Input/ Pin Pin No. Output Type Mnemonic Description 1, 11, 12, 27, I Power VS 3.3 V Power Pins. 32, 35, 40, 41, 46, 49, 54, 57, 60, 61 2 O 3.3 V CMOS REFMON Reference Monitor (Output). This pin has multiple selectable outputs. 3 O 3.3 V CMOS LD Lock Detect (Output). This pin has multiple selectable outputs. 4 I Power VCP Power Supply for Charge Pump (CP); VS ≤ VCP ≤ 5.25 V. VCP must still be connected to 3.3 V if the PLL is not used. 5 O Loop filter CP Charge Pump (Output). This pin connects to an external loop filter. This pin can be left unconnected if the PLL is not used. 6 O 3.3 V CMOS STATUS Programmable Status Output. 7 I 3.3 V CMOS REF_SEL Reference Select. It selects REF1 (low) or REF2 (high). This pin has an internal 30 kΩ pull-down resistor. 8 I 3.3 V CMOS SYNC Manual Synchronizations and Manual Holdover. This pin initiates a manual synchronization and is used for manual holdover. Active low. This pin has an internal 30 kΩ pull-up resistor. 9 I Loop filter LF Loop Filter (Input). It connects internally to the VCO control voltage node. 10 O Loop filter BYPASS This pin is for bypassing the LDO to ground with a 220 nF capacitor. This pin can be left unconnected if the PLL is not used. 13 I Differential CLK Along with CLK, this pin is the differential input for the clock distribution section. clock input 14 I Differential CLK Along with CLK, this pin is the differential input for the clock distribution section. If a clock input single-ended input is connected to the CLK pin, connect a 0.1 µF bypass capacitor from this pin to ground. Rev. A | Page 18 of 84

Data Sheet AD9522-0 Input/ Pin Pin No. Output Type Mnemonic Description 15 I 3.3 V CMOS CS Serial Control Port Chip Select; Active Low. This pin has an internal 30 kΩ pull-up resistor. 16 I 3.3 V CMOS SCLK/SCL Serial Control Port Clock Signal. This pin has an internal 30 kΩ pull-down resistor in SPI mode but is high impedance in I²C mode. 17 I/O 3.3 V CMOS SDIO/SDA Serial Control Port Bidirectional Serial Data In/Out. 18 O 3.3 V CMOS SDO Serial Control Port Unidirectional Serial Data Out. 19, 59 I GND GND Ground Pins. 20 I Three-level SP1 Select SPI or I²C as the serial interface port and select the I²C slave address in I²C logic mode. Three-level logic. This pin is internally biased for the open logic level. 21 I Three-level SP0 Select SPI or I²C as the serial interface port and select the I²C slave address in I²C logic mode. Three-level logic. This pin is internally biased for the open logic level. 22 I 3.3 V CMOS EEPROM Setting this pin high selects the register values stored in the internal EEPROM to be loaded at reset and/or power-up. Setting this pin low causes the AD9522 to load the hard-coded default register values at power-up/reset. This pin has an internal 30 kΩ pull-down resistor. Note that to guarantee the proper loading of EEPROM during startup, a high-low-high pulse on the RESET pin occurs after the power supply stabilizes. 23 I 3.3 V CMOS RESET Chip Reset, Active Low. This pin has an internal 30 kΩ pull-up resistor. 24 I 3.3 V CMOS PD Chip Power-Down, Active Low. This pin has an internal 30 kΩ pull-up resistor. 25 O LVDS or OUT9 (OUT9A) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 26 O LVDS or OUT9 (OUT9B) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 28 O LVDS or OUT10 (OUT10A) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 29 O LVDS or OUT10 (OUT10B) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 30 O LVDS or OUT11 (OUT11A) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 31 O LVDS or OUT11 (OUT11B) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 33 O LVDS or OUT6 (OUT6A) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 34 O LVDS or OUT6 (OUT6B) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 36 O LVDS or OUT7 (OUT7A) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 37 O LVDS or OUT7 (OUT7B) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 38 O LVDS or OUT8 (OUT8A) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 39 O LVDS or OUT8 (OUT8B) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 42 O LVDS or OUT5 (OUT5B) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 43 O LVDS or OUT5 (OUT5A) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 44 O LVDS or OUT4 (OUT4B) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 45 O LVDS or OUT4 (OUT4A) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. Rev. A | Page 19 of 84

AD9522-0 Data Sheet Input/ Pin Pin No. Output Type Mnemonic Description 47 O LVDS or OUT3 (OUT3B) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 48 O LVDS or OUT3 (OUT3A) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 50 O LVDS or OUT2 (OUT2B) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 51 O LVDS or OUT2 (OUT2A) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 52 O LVDS or OUT1 (OUT1B) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 53 O LVDS or OUT1 (OUT1A) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 55 O LVDS or OUT0 (OUT0B) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 56 O LVDS or OUT0 (OUT0A) Clock Output. This pin can be configured as one side of a differential LVDS output CMOS or as a single-ended CMOS output. 58 O Current set RSET Clock Distribution Current Set Resistor. Connect a 4.12 kΩ resistor from this pin resistor to GND. 62 O Current set CPRSET Charge Pump Current Set Resistor. Connect a 5.1 kΩ resistor from this pin to GND. resistor This resistor can be omitted if the PLL is not used. 63 I Reference REFIN (REF2) Along with REFIN, this is the differential input for the PLL reference. Alternatively, input this pin is a single-ended input for REF2. 64 I Reference REFIN (REF1) Along with REFIN, this is the differential input for the PLL reference. Alternatively, input this pin is a single-ended input for REF1. EPAD GND GND The exposed die pad must be connected to GND. Rev. A | Page 20 of 84

Data Sheet AD9522-0 TYPICAL PERFORMANCE CHARACTERISTICS 275 5 3 CHANNELS—6 LVDS 250 225 mA) 4 3 CHANNELS—3 LVDS N ( PUMP DOWN PUMP UP mA) 200 P PI 3 RENT ( 175 ROM C CUR 150 2 CHANNELS—2 LVDS NT F 2 E R R 125 U C 1 100 1 CHANNEL—1 LVDS 75 0 0 200 FR4E00QUENCY (6M0H0z) 800 1000 07219-108 0 0.5 1.0VOLTA1G.5E ON C2P.0 PIN (V)2.5 3.0 3.5 07219-111 Figure 6. Total Current vs. Frequency, CLK-to-Output (PLL Off), Channel and Figure 9. Charge Pump Characteristics at VCP = 3.3 V VCO Divider Bypassed, LVDS Outputs Terminated 100 Ω Across Differential Pair 240 5 2 CHANNELS—8 CMOS 220 200 mA) 4 N ( PUMP DOWN PUMP UP mA) 180 P PI 3 RENT ( 160 2 CHANNELS—2 CMOS ROM C CUR 140 NT F 2 E R 120 1 CHANNEL—2 CMOS UR C 1 100 1 CHANNEL—1 CMOS 80 0 0 50 FR1E00QUENCY (1M5H0z) 200 250 07219-109 0 0.5 1.0 1.V5OLT2A.0GE O2.N5 CP3 P.0IN (V3).5 4.0 4.5 5.0 07219-112 Figure 7. Total Current vs. Frequency, CLK-to-Output (PLL Off), Channel and Figure 10. Charge Pump Characteristics at VCP = 5.0 V VCO Divider Bypassed, CMOS Outputs with 10 pF Load 65 –140 T U P N 60 FD I –145 P O D T –150 K (MHz/V)VCO 5505 SE REFERRE(dBc/Hz)–155 OI –160 N E S 45 PHA –165 D F P 402.55 2.65 VCO FREQ2U.7E5NCY (GHz) 2.85 2.95 07219-010 –1700.1 P1FD FREQUENCY (MH10z) 100 07219-013 Figure 8. KVCO vs. VCO Frequency Figure 11. PFD Phase Noise Referred to PFD Input vs. PFD Frequency Rev. A | Page 21 of 84

AD9522-0 Data Sheet –208 3.5 VS_DRV = 3.3V –210 3.0 Hz) VS_DRV = 3.135V c/ –212 B 2.5 VS_DRV = 2.5V d RIT ( –214 VS_DRV = 2.35V ME V) 2.0 F –216 (H O O E V 1.5 UR –218 G DIFFERENTIAL INPUT L FI –220 1.0 L P –222 0.5 SINGLE-ENDED INPUT –2240 0.2 0.4INPUT 0S.L6EW RA0T.8E (V/ns1).0 1.2 1.4 07219-114 010k RESISTIV1Ek LOAD (Ω) 100 07219-118 Figure 12. PLL Figure of Merit (FOM) vs. Slew Rate at REFIN/REFIN Figure 15. CMOS Output VOH (Static) vs. RLOAD (to Ground) 0 0.4 –10 0.3 –20 V) 0.2 –30 T ( U m) –40 TP 0.1 B U WER (d ––5600 TIAL O 0 PO –70 REN –0.1 E F –80 F DI –0.2 –90 –0.3 –100 –110 –0.4 100 105 110 115FREQ12U0ENC1Y2 5(MHz1)30 135 140 145 07219-116 0 1 2 3 4 5 6TIM7E (8ns)9 10 11 12 13 14 15 07219-014 Figure 13. PFD/CP Spurs; 122.88 MHz; PFD = 15.36 MHz; Figure 16. LVDS Output (Differential) at 100 MHz LBW = 127 kHz; ICP = 3.0 mA; fVCO = 2580 MHz Output Terminated 100 Ω Across Differential Pair 0 0.4 –10 0.3 –20 p) p- 0.2 –30 V dBm) –40 WING ( 0.1 POWER ( ––5600 ENTIAL S –0.10 R –70 E F F –0.2 –80 DI –0.3 –90 –100 –0.4 122.38 122.58 F12R2E.7Q8UENCY1 (2M2.H9z8) 123.18 123.38 07219-117 0 0.5 1.0 TIM1E.5 (ns) 2.0 2.5 3.0 07219-015 Figure 14. Output Spectrum, LVDS; 122.88 MHz; PFD = 15.36 MHz; Figure 17. LVDS Differential Voltage Swing at 800 MHz LBW = 127 kHz; ICP = 3.0 mA; fVCO = 2580 MHz Output Terminated 100 Ω Across Differential Pair Rev. A | Page 22 of 84

Data Sheet AD9522-0 4.0 3.2 3.5 2.8 2.4 3.0 DE (V) 2.0 E (V) 2.5 2pF U D PLIT 1.6 LITU 2.0 M P 10pF A 1.2 M 1.5 A 0.8 1.0 20pF 0.4 0.5 0 0 10 20 30 40TIM5E0 (ns)60 70 80 90 100 07219-018 00 100 200 FRE3Q00UENCY4 0(M0Hz) 500 600 700 07219-124 Figure 18. CMOS Output with 10 pF Load at 25 MHz Figure 21. CMOS Output Swing vs. Frequency and Capacitive Load –50 3.2 2pF LOAD –60 2.8 –70 2.4 L1O0pAFD Hz) –80 PLITUDE (V) 21..06 NOISE (dBc/ ––11–109000 M E A 1.2 S –120 A H P –130 0.8 –140 0.4 –150 0 –160 0 1 2 3 4 TIME5 (ns)6 7 8 9 10 07219-019 1k 10k F10R0EkQUENCY 1(HMz) 10M 100M 07219-023 Figure 19. CMOS Output with 2 pF and 10 pF Load at 250 MHz Figure 22. Internal VCO Phase Noise (Absolute), LVDS Output at 633 MHz 1600 –50 –60 1400 p) 7mA SETTING –70 mV p- 1200 Hz) –80 G ( 1000 Bc/ –90 N d WI E ( –100 S 800 S AL DEFAULT 3.5mA SETTING NOI –110 NTI 600 SE –120 E A R H E P –130 F 400 F DI –140 200 –150 0 –160 0 200 FR40E0QUENCY (6G0H0z) 800 1000 07219-123 1k 10k F10R0EkQUENCY 1(HMz) 10M 100M 07219-024 Figure 20. LVDS Differential Voltage Swing vs. Frequency Figure 23. Internal VCO Phase Noise (Absolute), LVDS Output at 685 MHz Output Terminated 100 Ω Across Differential Pair Rev. A | Page 23 of 84

AD9522-0 Data Sheet –50 –100 –60 –70 –110 Hz) –80 Hz) dBc/ –90 dBc/ –120 E ( –100 E ( S S NOI –110 NOI E E –130 S –120 S A A H H P –130 P –140 –140 –150 –160 –150 1k 10k F10R0EkQUENCY 1(HMz) 10M 100M 07219-025 10 100 1k FR1E0QkUENC1Y0 0(kHz) 1M 10M 100M 07219-130 Figure 24. Internal VCO Phase Noise (Absolute), LVDS Output at 737 MHz Figure 27. Additive (Residual) Phase Noise, CLK-to-LVDS at 800 MHz, Divide-by-1 –100 –110 –110 –120 c/Hz) –120 c/Hz) –130 B B d d E ( E ( OIS –130 OIS –140 N N E E S S A –140 A –150 H H P P –150 –160 –160 –170 10 100 1k FR1E0QkUENC1Y0 0(kHz) 1M 10M 100M 07219-128 10 100 1k FR1E0QkUENC1Y0 0(kHz) 1M 10M 100M 07219-131 Figure 25. Additive (Residual) Phase Noise, Figure 28. Additive (Residual) Phase Noise, CLK-to-LVDS at 245.76 MHz, Divide-by-1 CLK-to-CMOS at 50 MHz, Divide-by-20 –100 –100 –110 –110 Bc/Hz) –120 Bc/Hz) –120 d d E ( E ( OIS –130 OIS –130 N N E E S S A –140 A –140 H H P P –150 –150 –16010 100 1k FR1E0QkUENC1Y0 0(kHz) 1M 10M 100M 07219-129 –16010 100 1k FR1E0QkUENC1Y0 0(kHz) 1M 10M 100M 07219-132 Figure 26. Additive (Residual) Phase Noise, Figure 29. Additive (Residual) Phase Noise, CLK-to-LVDS at 200 MHz, Divide-by-5 CLK-to-CMOS at 250 MHz, Divide-by-4 Rev. A | Page 24 of 84

Data Sheet AD9522-0 –100 –80 INTEGRATED RMS JITTER (12kHz TO 20MHz): 146fs –90 –110 –100 Bc/Hz) –120 Bc/Hz) –110 d d E ( E ( OIS –130 OIS –120 N N SE SE –130 A –140 A H H P P –140 –150 –150 –160 –160 1k 10k F10R0EkQUENCY 1(HMz) 10M 100M 07219-033 1k 10k F10R0EkQUENCY 1(HMz) 10M 100M 07219-135 Figure 30. Phase Noise (Absolute) Clock Generation; Internal VCO at Figure 32. Phase Noise (Absolute), External VCXO (Toyocom TCO-2112) 2580 MHz; PFD = 15.36 MHz; LBW = 40 kHz; LVDS Output = 122.88 MHz at 245.76 MHz; PFD = 15.36 MHz; LBW = 250 Hz; LVDS Output = 245.76 MHz –80 INTEGRATED RMS JITTER (12kHz TO 20MHz): 617fs INTEGRATED RMS JITTER (20kHz TO 80MHz): 450fs (EXTRAPOLATED) –90 –100 Hz) Bc/ –110 d E ( OIS –120 N SE –130 A H P –140 –150 –160 1k 10k F10R0EkQUENCY 1(HMz) 10M 100M 07219-034 Figure 31. Phase Noise (Absolute) Clock Cleanup; Internal VCO at 2799 MHz; PFD = 120 kHz; LBW = 1.92 kHz; LVDS Output = 155.52 MHz Rev. A | Page 25 of 84

AD9522-0 Data Sheet TEST CIRCUITS R2 R2 390Ω 3kΩ CP LF CP LF C2 C2 C1 240nF C3 C1 4.7µF C3 62pF R1 33pF 1.5nF R1 2.2nF 820Ω 2.1kΩ BYPASS BYPASS CAPFBOAYCRPI TLAODSORS C22102nF 07219-234 CAPFBOAYCRPI TLAODSORS C22102nF 07219-235 Figure 33. PLL Loop Filter Used for Clock Generation Plot (See Figure 30) Figure 34. PLL Loop Filter Used for Clock Cleanup Plot (See Figure 31) Rev. A | Page 26 of 84

Data Sheet AD9522-0 TERMINOLOGY Time Jitter Phase Jitter and Phase Noise Phase noise is a frequency domain phenomenon. In the time An ideal sine wave can be thought of as having a continuous domain, the same effect is exhibited as time jitter. When observing and even progression of phase with time from 0° to 360° for a sine wave, the time of successive zero crossings varies. In a square each cycle. Actual signals, however, display a certain amount wave, the time jitter is a displacement of the edges from their of variation from ideal phase progression over time. This ideal (regular) times of occurrence. In both cases, the variations in phenomenon is called phase jitter. Although many causes can timing from the ideal are the time jitter. Because these variations contribute to phase jitter, one major cause is random noise, are random in nature, the time jitter is specified in seconds root which is characterized statistically as Gaussian (normal) in mean square (rms) or 1 sigma of the Gaussian distribution. distribution. Time jitter that occurs on a sampling clock for a DAC or an This phase jitter leads to a spreading out of the energy of the ADC decreases the signal-to-noise ratio (SNR) and dynamic sine wave in the frequency domain, producing a continuous range of the converter. A sampling clock with the lowest possible power spectrum. This power spectrum is usually reported as a jitter provides the highest performance from a given converter. series of values whose units are dBc/Hz at a given offset in frequency from the sine wave (carrier). The value is a ratio Additive Phase Noise (expressed in decibels) of the power contained within a 1 Hz Additive phase noise is the amount of phase noise that is bandwidth with respect to the power at the carrier frequency. attributable to the device or subsystem being measured. For each measurement, the offset from the carrier frequency is The phase noise of any external oscillators or clock sources is also given. subtracted. This makes it possible to predict the degree to which the device impacts the total system phase noise when used in It is meaningful to integrate the total power contained within conjunction with the various oscillators and clock sources, each some interval of offset frequencies (for example, 10 kHz to of which contributes its own phase noise to the total. In many 10 MHz). This is called the integrated phase noise over that cases, the phase noise of one element dominates the system frequency offset interval and can be readily related to the time phase noise. When there are multiple contributors to phase jitter due to the phase noise within that offset frequency interval. noise, the total is the square root of the sum of squares of the Phase noise has a detrimental effect on the performance of ADCs, individual contributors. DACs, and RF mixers. It lowers the achievable dynamic range of Additive Time Jitter the converters and mixers, although they are affected in somewhat Additive time jitter is the amount of time jitter that is attributable to different ways. the device or subsystem being measured. The time jitter of any external oscillators or clock sources is subtracted. This makes it possible to predict the degree to which the device impacts the total system time jitter when used in conjunction with the various oscillators and clock sources, each of which contributes its own time jitter to the total. In many cases, the time jitter of the external oscillators and clock sources dominates the system time jitter. Rev. A | Page 27 of 84

AD9522-0 Data Sheet DETAILED BLOCK DIAGRAM REF_SEL VS GND RSET REFMON CPRSET VCP DISTRIBUTION REFERENCE REFERENCE SWITCHOVER LD REF1 E LOCK BL DETECT OPTIONALREFIN REF2 BUFSTATUSSTATUS CLOCKDOUBLER RDIVIDER PROGRAMMA R DELAY PLLREFERENCE HOLD REFIN AMP STATUS BYPASS LOW DROPOUT REGULATOR (LDO) PHASE PRPE,S PC A+ L1ER COUAN/TBERS PRO GNR DAEMLMAAYBLE FDREETQEUCETNOCRY CHPUAMRGPE CP N DIVIDER LF ZERO DELAY BLOCK STATUS DIVIDE BY 1, 2, 3, 4, 5, OR 6 CLK CLK OUT0 OUT0 1 0 DIVIDE BY OUT1 PD 1 TO 32 OUT1 DIGITAL EEPROM SYNC LOGIC RESET OUT2 OUT2 EEPROM OUT3 SP1 SERIAL OUT3 PORT SP0 DECODE DIVIDE BY OUT4 1 TO 32 OUT4 SPI I2C UT INTERFACE INTERFACE P OUT5 T U SCLK/SCL OUT5 O S SDIO/SDA O M SDO C CS OUT6 LV OUT6 S/ D V L DIVIDE BY OUT7 1 TO 32 OUT7 OUT8 OUT8 OUT9 OUT9 DIVIDE BY OUT10 1 TO 32 OUT10 AD9522 OUT11 OUT11 07219-028 Figure 35. Rev. A | Page 28 of 84

Data Sheet AD9522-0 THEORY OF OPERATION OPERATIONAL CONFIGURATIONS Table 22. Settings When Using Internal VCO The AD9522 can be configured in several ways. These Register Description configurations must be set up by loading the control registers 0x010[1:0] = 00b PLL normal operation (PLL on) (see Table 49 to Table 60). Each section or function must be 0x010 to 0x01E PLL settings; select and enable a reference individually programmed by setting the appropriate bits in the input; set R, N (P, A, B), PFD polarity, and ICP according to the intended loop configuration corresponding control register or registers. After the desired 0x1E1[1] = 1b VCO selected as the source configuration is programmed, the user can store these values in 0x01C[2:0] Enable reference inputs the on-board EEPROM to allow the part to power up in the 0x1E0[2:0] Set VCO divider desired configuration without user intervention. 0x1E1[0] = 0b Use the VCO divider as the source for Mode 0: Internal VCO and Clock Distribution the distribution section When using the internal VCO and PLL, the VCO divider must 0x018[0] = 0b Reset VCO calibration and issue IO_UPDATE be employed to ensure in most cases that the input frequency to the 0x232[0] = 1b (not necessary for the first time after power-up, but must be done subsequently) channel dividers does not exceed its specified maximum frequency 0x018[0] = 1b Initiate VCO calibration, issue IO_UPDATE (see Table 3). The exceptions to this are VCO direct mode and 0x232[0] = 1b cases where the VCO frequency is ≤2000 MHz. The channel divider maximum input frequency is 2000 MHz provided that the user does not choose a divide-by-17 or a divide-by-3. If divide-by-3 or divide-by-17 is desired, the maximum channel divider input frequency is 1600 MHz. The internal PLL uses an external loop filter to set the loop bandwidth. The external loop filter is also crucial to the loop stability. The internal PLL uses an external loop filter to set the loop bandwidth. The external loop filter is also crucial to the loop stability. When using the internal VCO, it is necessary to calibrate the VCO (Register 0x018[0] = 1b) to ensure optimal performance. For internal VCO and clock distribution applications, use the register settings shown in Table 22. Rev. A | Page 29 of 84

AD9522-0 Data Sheet REF_SEL VS GND RSET REFMON CPRSET VCP DISTRIBUTION REFERENCE REFERENCE SWITCHOVER LD REF1 E LOCK BL DETECT OPTIONALREFIN REF2 BUFSTATUSSTATUS CLOCKDOUBLER RDIVIDER PROGRAMMA R DELAY PLLREFERENCE HOLD REFIN AMP STATUS BYPASS LOW DROPOUT REGULATOR (LDO) PHASE PRPE,S PC A+ L1ER COUAN/TBERS PRO GNR DAEMLMAAYBLE FDREETQEUCETNOCRY CHPUAMRGPE CP N DIVIDER LF ZERO DELAY BLOCK STATUS DIVIDE BY 1, 2, 3, 4, 5, OR 6 CLK CLK OUT0 OUT0 1 0 DIVIDE BY OUT1 PD 1 TO 32 OUT1 DIGITAL EEPROM SYNC LOGIC RESET OUT2 OUT2 EEPROM OUT3 SP1 SERIAL OUT3 PORT SP0 DECODE DIVIDE BY OUT4 1 TO 32 OUT4 SPI I2C T INTERFACE INTERFACE U OUT5 P T SCLK/SCL OUT5 OU SDIO/SDA S O SDO M CS OUT6 S/C OUT6 D V L DIVIDE BY OUT7 1 TO 32 OUT7 OUT8 OUT8 OUT9 OUT9 DIVIDE BY OUT10 1 TO 32 OUT10 AD9522 OUT11 OUT11 07219-030 Figure 36. Internal VCO and Clock Distribution (Mode 0) Rev. A | Page 30 of 84

Data Sheet AD9522-0 Mode 1: Clock Distribution or External VCO < 1600 MHz Table 24. Settings for Using Internal PLL with External VCO < 1600 MHz When the external clock source to be distributed or the external Register Description VCO/VCXO is <1600 MHz, a configuration that bypasses the VCO divider can be used. This is the only difference from Mode 2. 0x1E1[0] = 1b Bypass the VCO divider as the source for the distribution section Bypassing the VCO divider limits the frequency of the clock 0x010[1:0] = 00b PLL normal operation (PLL on) along source to <1600 MHz (due to the maximum input frequency with other appropriate PLL settings in allowed at the channel dividers). Register 0x010 to Register 0x01E For clock distribution applications where the external clock is <1600 MHz, use the register settings shown in Table 23. An external VCO/VCXO requires an external loop filter that must be connected between CP and the tuning pin of the VCO/ Table 23. Settings for Clock Distribution < 1600 MHz VCXO. This loop filter determines the loop bandwidth and stability Register Description of the PLL. Make sure to select the proper PFD polarity for the 0x010[1:0] = 01b PLL asynchronous power-down (PLL off) VCO/VCXO being used. 0x1E1[0] = 1b Bypass the VCO divider as the source for the distribution section Table 25. Setting the PFD Polarity 0x1E1[1] = 0b CLK selected as the source Register Description 0x010[7] = 0b PFD polarity positive (higher control voltage When using the internal PLL with an external VCO < 1600 MHz, produces higher frequency) the PLL must be turned on. 0x010[7] = 1b PFD polarity negative (higher control voltage produces lower frequency) Rev. A | Page 31 of 84

AD9522-0 Data Sheet REF_SEL VS GND RSET REFMON CPRSET VCP DISTRIBUTION REFERENCE REFERENCE SWITCHOVER LD REF1 E LOCK BL DETECT OPTIONALREFIN REF2 BUFSTATUSSTATUS CLOCKDOUBLER RDIVIDER PROGRAMMA R DELAY PLLREFERENCE HOLD REFIN AMP STATUS BYPASS LOW DROPOUT REGULATOR (LDO) PHASE PRPE,S PC A+ L1ER COUAN/TBERS PRO GNR DAEMLMAAYBLE FDREETQEUCETNOCRY CHPUAMRGPE CP N DIVIDER LF ZERO DELAY BLOCK STATUS DIVIDE BY 1, 2, 3, 4, 5, OR 6 CLK CLK OUT0 OUT0 1 0 DIVIDE BY OUT1 PD 1 TO 32 OUT1 DIGITAL EEPROM SYNC LOGIC RESET OUT2 OUT2 EEPROM OUT3 SP1 SERIAL OUT3 PORT SP0 DECODE DIVIDE BY OUT4 1 TO 32 OUT4 SPI I2C S INTERFACE INTERFACE OUT5 PUT SCLK/SCL OUT5 UT O SDIO/SDA S SDO MO CS OUT6 C OUT6 DS/ V L DIVIDE BY OUT7 1 TO 32 OUT7 OUT8 OUT8 OUT9 OUT9 DIVIDE BY OUT10 1 TO 32 OUT10 AD9522 OUT11 OUT11 07219-031 Figure 37. Clock Distribution or External VCO < 1600 MHz (Mode 1) Rev. A | Page 32 of 84

Data Sheet AD9522-0 Mode 2: High Frequency Clock Distribution—CLK or Table 26. Default Register Settings for Clock Distribution Mode External VCO > 1600 MHz Register Description The AD9522 power-up default configuration has the PLL 0x010[1:0] = 01b PLL asynchronous power-down (PLL off) powered off and the routing of the input set so that the CLK/ 0x1E0[2:0] = 000b Set VCO divider = 2 CLK input is connected to the distribution section through the 0x1E1[0] = 0b Use the VCO divider VCO divider (divide-by-1/divide-by-2/divide-by-3/divide-by-4/ 0x1E1[1] = 0b CLK selected as the source divide-by-5/divide-by-6). This is a distribution-only mode that allows for an external input up to 2400 MHz (see Table 3). The When using the internal PLL with an external VCO, the PLL maximum frequency that can be applied to the channel dividers must be turned on. is 1600 MHz; therefore, higher input frequencies must be divided down before reaching the channel dividers. Table 27. Settings When Using an External VCO Register Description When the PLL is enabled, this routing also allows the use of the 0x010[1:0] = 00b PLL normal operation (PLL on) PLL with an external VCO or VCXO with a frequency <2400 MHz. 0x010 to 0x01E PLL settings; select and enable a In this configuration, the internal VCO is not used and is powered reference input; set R, N (P, A, B), PFD off. The external VCO/VCXO feeds directly into the prescaler. polarity, and I according to the intended CP The register settings shown in Table 26 are the default values of loop configuration these registers at power-up or after a reset operation. 0x1E1[1] = 0b CLK selected as the source An external VCO requires an external loop filter that must be connected between CP and the tuning pin of the VCO. This loop filter determines the loop bandwidth and stability of the PLL. Make sure to select the proper PFD polarity for the VCO being used. Table 28. Setting the PFD Polarity Register Description 0x010[7] = 0b PFD polarity positive (higher control voltage produces higher frequency) 0x010[7] = 1b PFD polarity negative (higher control voltage produces lower frequency) Rev. A | Page 33 of 84

AD9522-0 Data Sheet REF_SEL VS GND RSET REFMON CPRSET VCP DISTRIBUTION REFERENCE REFERENCE SWITCHOVER LD REF1 E LOCK BL DETECT OPTIONALREFIN REF2 BUFSTATUSSTATUS CLOCKDOUBLER RDIVIDER PROGRAMMA R DELAY PLLREFERENCE HOLD REFIN AMP STATUS BYPASS LOW DROPOUT REGULATOR (LDO) PHASE PRPE,SPC +A L1ER COUAN/TBERS PRO GNR DAEMLMAYABLE FDREETQEUCETNOCRY CHPUAMRGPE CP N DIVIDER LF ZERO DELAY BLOCK STATUS DIVIDE BY 1, 2, 3, 4, 5, OR 6 CLK CLK OUT0 OUT0 1 0 DIVIDE BY OUT1 PD 1TO 32 OUT1 DIGITAL EEPROM SYNC LOGIC RESET OUT2 OUT2 EEPROM OUT3 SP1 SERIAL OUT3 PORT SP0 DECODE DIVIDE BY OUT4 1TO 32 OUT4 SPI I2C S INTERFACE INTERFACE OUT5 PUT SCLK/SCL OUT5 UT O SDIO/SDA S SDO O M CS OUT6 C OUT6 DS/ V L DIVIDE BY OUT7 1TO 32 OUT7 OUT8 OUT8 OUT9 OUT9 DIVIDE BY OUT10 1TO 32 OUT10 AD9522 OUT11 OUT11 07219-029 Figure 38. High Frequency Clock Distribution or External VCO > 1600 MHz (Mode 2) Rev. A | Page 34 of 84